External field aircraft canopy organic glass broken hole damage repairing method

A plexiglass and aircraft cockpit technology, applied in the field of aviation plexiglass repair, can solve the problems of low aircraft operation rate, long repair time, high replacement cost, etc., and achieve the effect of simple process, easy operation and saving repair cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical means, creative features, achieved goals and effects of the present invention easy to understand and understand, the present invention is further described below with reference to the accompanying drawings and embodiments.

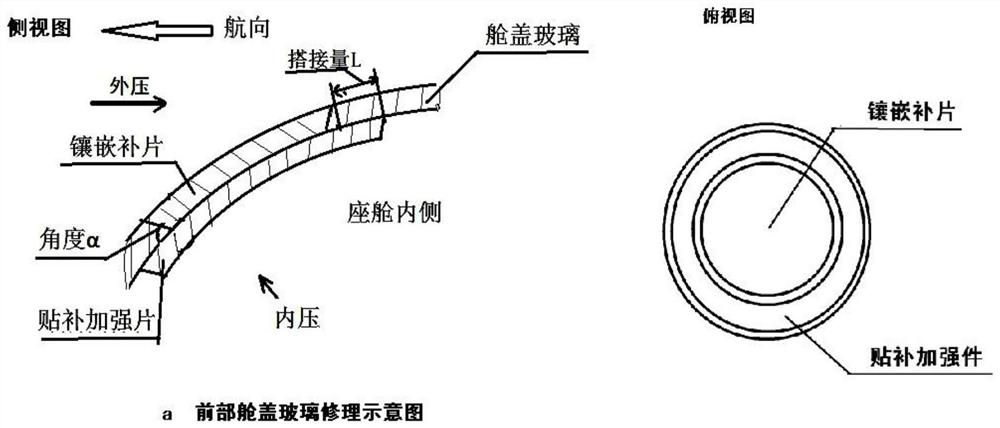

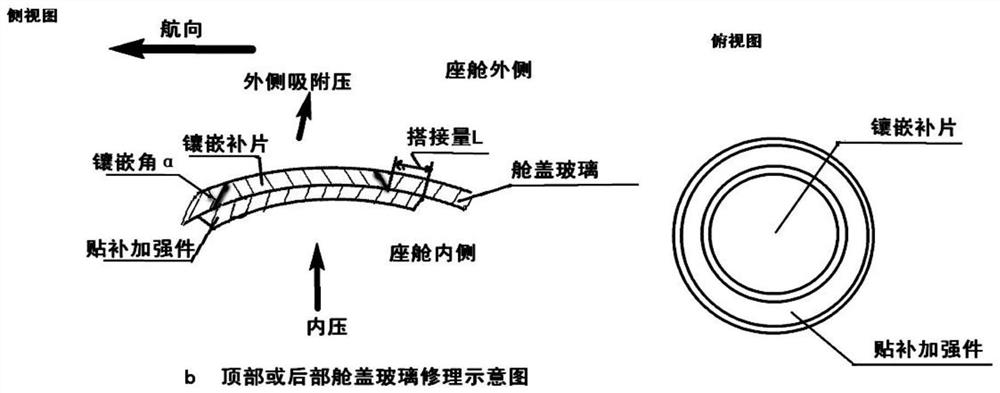

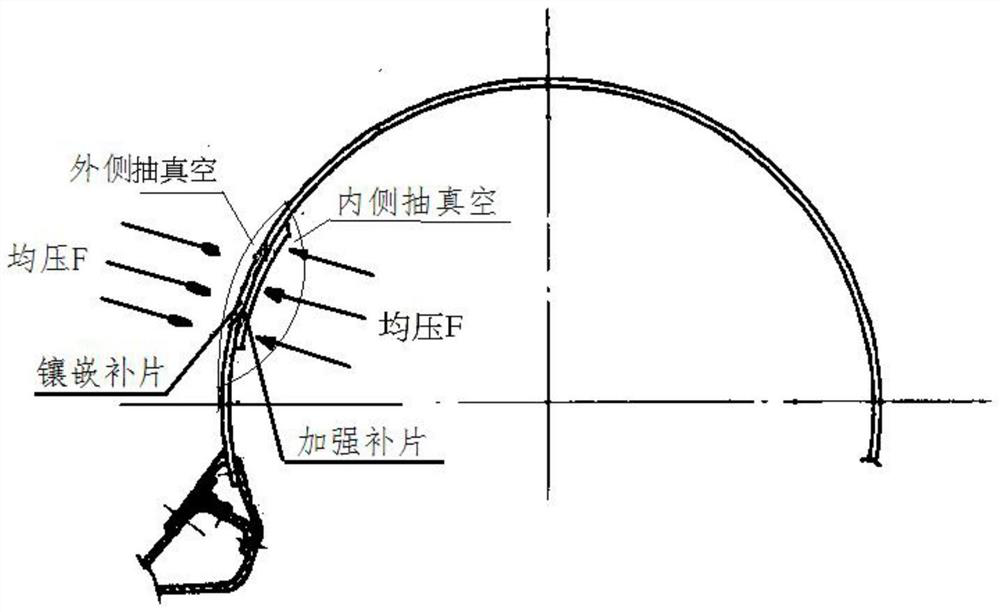

[0042] like Figure 1 to Figure 3 As shown, a method for repairing damage to plexiglass holes in an outfield aircraft cockpit cover includes the following steps:

[0043] (1) Determine the damage area of the hole by visual inspection and a silver streak detector, mark the damaged repair area with a marker pen, draw the position of each reference line on the cockpit cover glass, and mark the inlaid patch inlay position and the reinforcement patch. Subsidized location.

[0044] (2) Using the step-by-step grinding method, grind the damaged hole to the specified circular hole, and then grind it to the specified wedge cone size. The ratio of the thickness of the round hole on the inclined surface of the original canopy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com