Patents

Literature

78results about How to "Shorten the repair cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Repairing method of master cylinder plunger piston of radial forging machine

The invention discloses a repairing method of a master cylinder plunger piston of a radial forging machine; in the invention, two false shafts are manufactured and are connected to two ends of the master cylinder plunger piston as the standard for processing the master cylinder plunger piston and a thin-wall steel sleeve; the thin-wall steel sleeve adopts a 38CrMoAl forging piece, and heat treatment tempering and multichannel heat treatment stress elimination are carried out to the thin-wall steel sleeve, and nitriding treatment is carried out to the surface of the thin-wall steel sleeve to improve the hardness, after cylinder type fixing glue is coated on the surface of the master cylinder plunger piston, the thin-wall steel sleeve is embedded and sheathed on the master cylinder plunger piston after heat treatment is carried out, and the thin-wall steel sleeve is grounded into design size; by adopting the method, the damaged master cylinder plunger piston can be repaired, and repairing can be carried out repeatedly, the effectiveness of the master cylinder plunger piston is restored, the maintaining cost and repairing period can be greatly reduced and the normal operation of the production equipment can be ensured.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

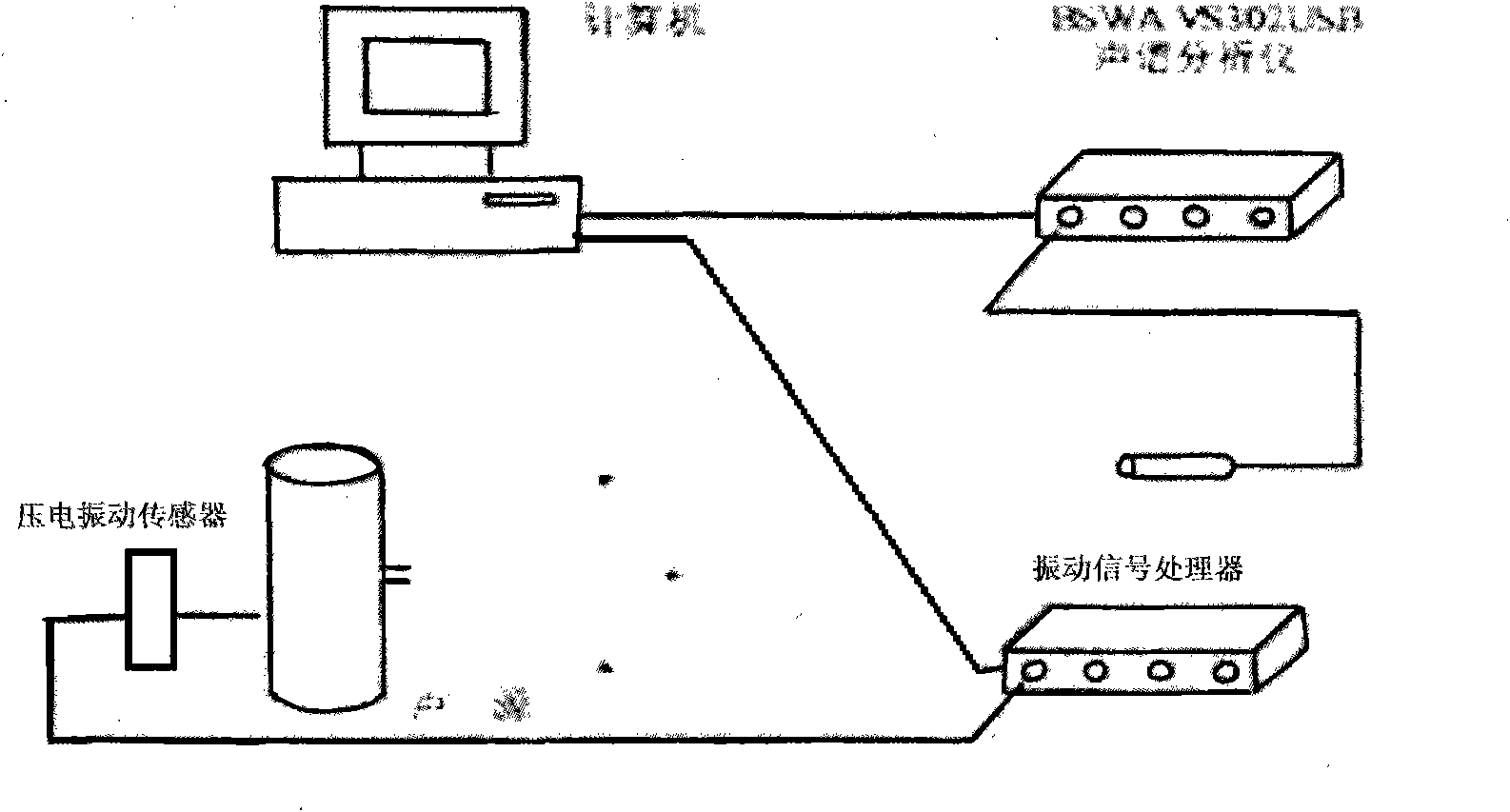

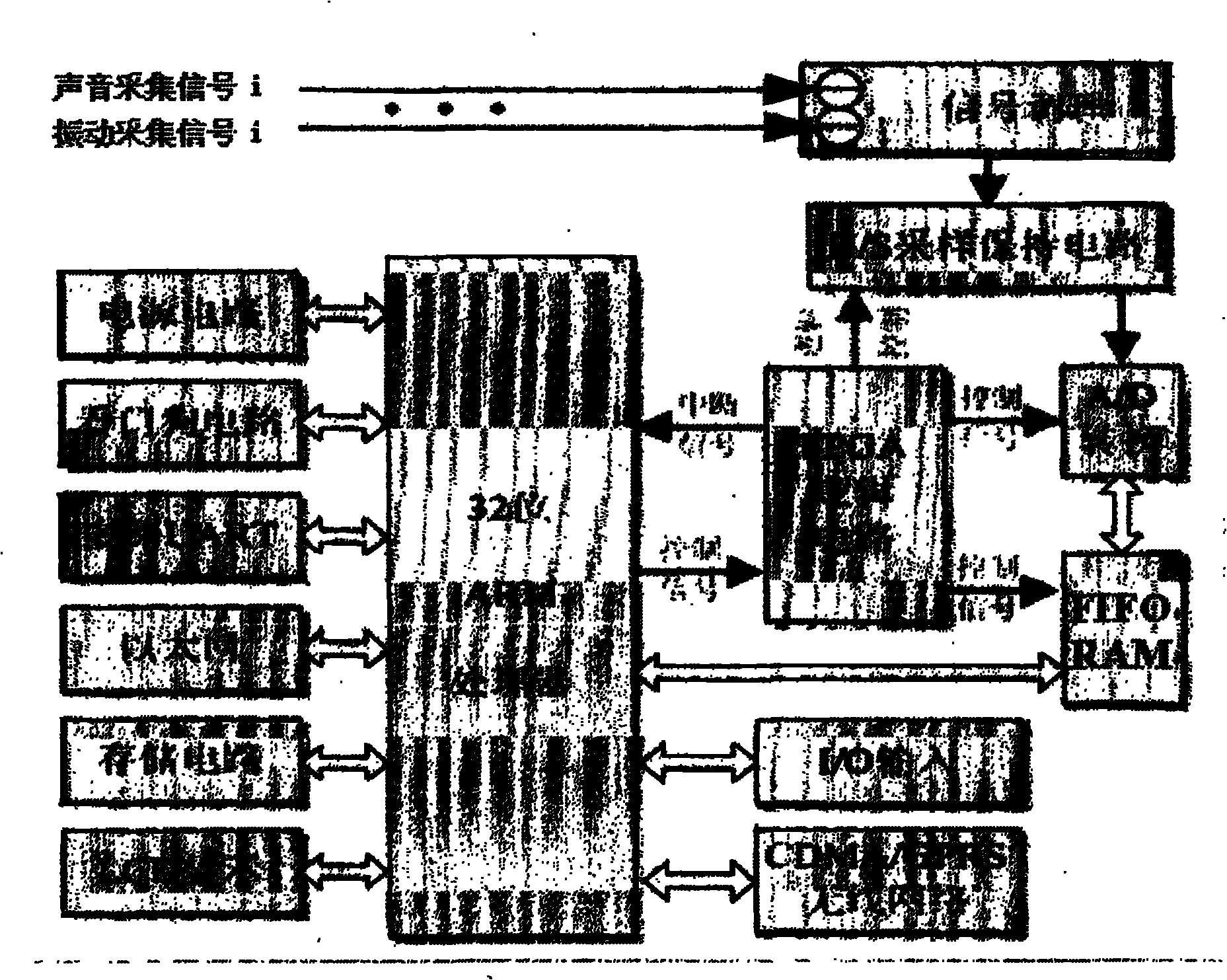

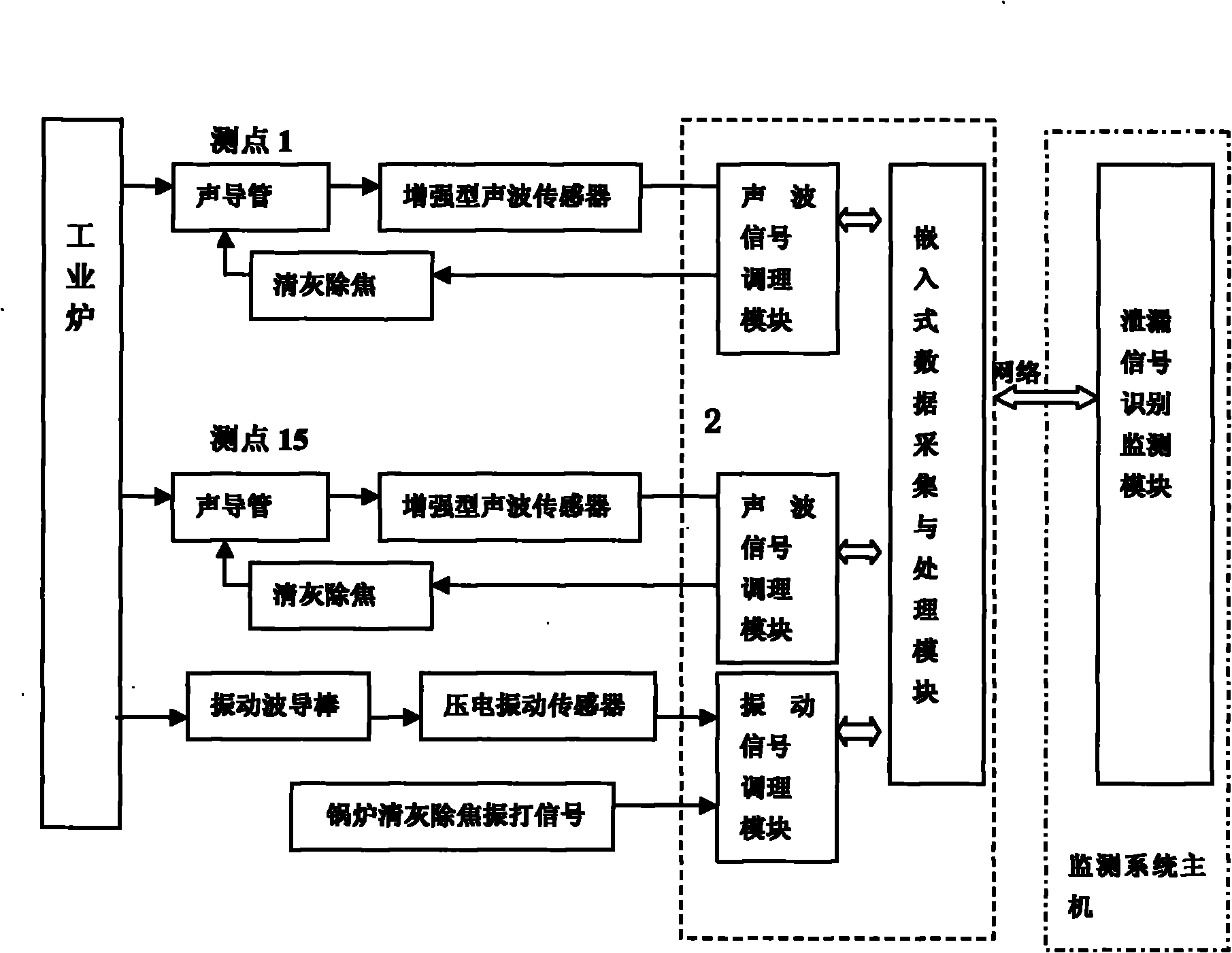

Safety detecting method for flue gas waste heat recovery power system of industrial furnace

ActiveCN101871733AReal-time detectabilityReal-time early warningFurnace componentsSubsonic/sonic/ultrasonic wave measurementData acquisitionEngineering

The invention discloses a safety detecting method for a flue gas waste heat recovery power system of an industrial furnace. Furnace pipe leakage is detected by adopting information fusion and double parameters of furnace inside sound and furnace wall vibration; two measuring signals are mutually supplemented and mutually tested; and after two kinds of information are fused by a BP (Back Propagation) neural network, a leakage alarm is given. In the method, a fin between furnace pipes of all heated surfaces of the industrial furnace are perforate; sound wave guide pipes are communicated with the inner side of the furnace after penetrating through the opening on the fin and fixed between the furnace pipes and at a header; a reinforcing type sound wave sensor is installed at the other end of the sound wave guide pipe for receiving a noise signal transmitted into the furnace by the sound wave guide pipe; the sensor is used for acquiring and receiving all field sound data in the furnace, transmitting a current signal to an embedded type data acquiring and processing system at a long distance and transmitting the processed data to a host machine of a monitoring system by a network; and the wall of the industrial furnace is provided with a piezoelectric crystal vibrating sensor for detecting a vibrating signal of the furnace wall and giving a leakage alarm after fusing the two kinds of information.

Owner:KUNMING UNIV OF SCI & TECH

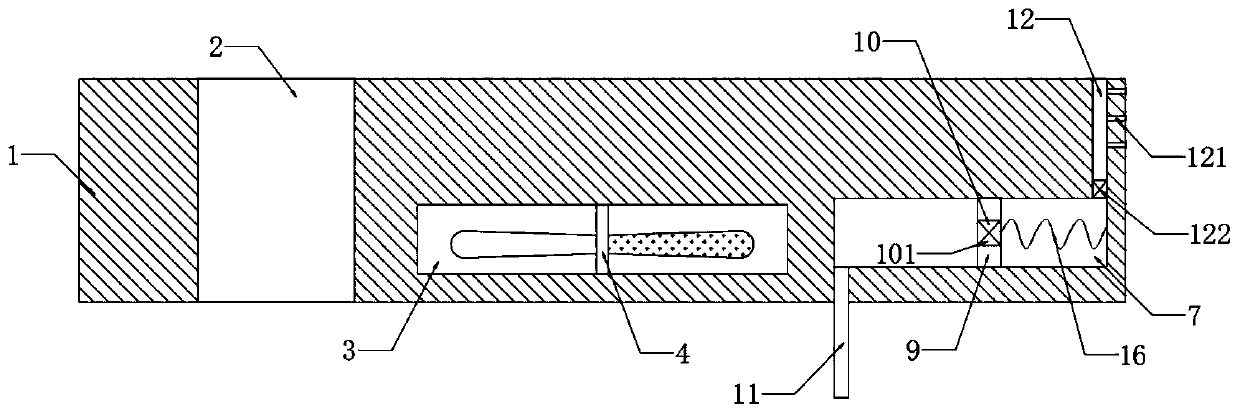

Insulation damage rapid recovery method of variable-frequency high-voltage motor winding

ActiveCN109586519AShorten the repair cycleReduce repair costsManufacturing dynamo-electric machinesCushionMica

The invention discloses an insulation damage rapid recovery method of a variable-frequency high-voltage motor winding. The method comprises the steps of firstly, finding an insulation damage positionof a copper wire of the motor winding, removing a slot wedge and a cushion strip above the damage position, and exposing the motor winding; stripping an anti-corona layer and insulation layers right above a fault point, and reserving the main insulation layers at two sides of the fault point as much as possible; sequentially cutting off the copper wire and upwards turning up the copper wire from an end part of the winding at the fault point from top to bottom, exposing the insulation damage point position, and removing the damage point insulation layer and carbide impurity; employing insulation paper to bind turns of the motor winding, welding the cutoff copper wire, pouring epoxy resin and mica powder in a proportion being 6:1, scraping residual epoxy resin, and waiting for curing; assembling the motor winding after the epoxy resin is cured, and completing rapid recovery of insulation damage. By the method, the winding is not needed to be replaced, insulation replacement is only performed on the insulation damage position, the recovery period and the recovery cost are effectively reduced, and the demand of urgent need for production recovery in a site is satisfied.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Non-distortion repairing method for micro-damage of casting alloy part

InactiveCN101444869ALow heat inputInstant high temperatureArc welding apparatusCrazingElectric discharge

The invention discloses a non-distortion repairing method for micro-damage of casting alloy part. In the method, a revolving solid anode bar made from CoCrW alloy is clamped on a rotary collet of an electric discharge machine, and spare parts to be repaired are connected with the cathode of the electric discharge machine; the power of the electric discharge machine is adjusted between 1000W and 1800W, and the frequency is adjusted into low frequency; shield argon is adjusted between 8L / min and 35L / min, and argon in an argon bottle is guided to a coating part by a copper pipe; a dipped finish of the copper pipe aims damage parts of the spare parts; after the power is turned on, the rotary cathode bar and the damage surfaces of the spare parts are contacted with degrees between 55 degrees and 75 degrees, and reciprocating coating is carried out at repairing parts. The method uses the characters of high transient temperature and short endurance time of electric spark micro-arc aggradation to reduce heat input in the repairing of spare parts, thereby avoiding the defects of great heat input amount of argon-arc welding, long acting time, much deformation of spare parts and easy generation of cracks in the prior art. The method overcomes the problems of border effect of plasma spraying, great investment cost of devices, low bonding strength of coating, easy plunger separation and chip off-falling for hot spraying in the prior art.

Owner:PLA NO 5719 FACTORY

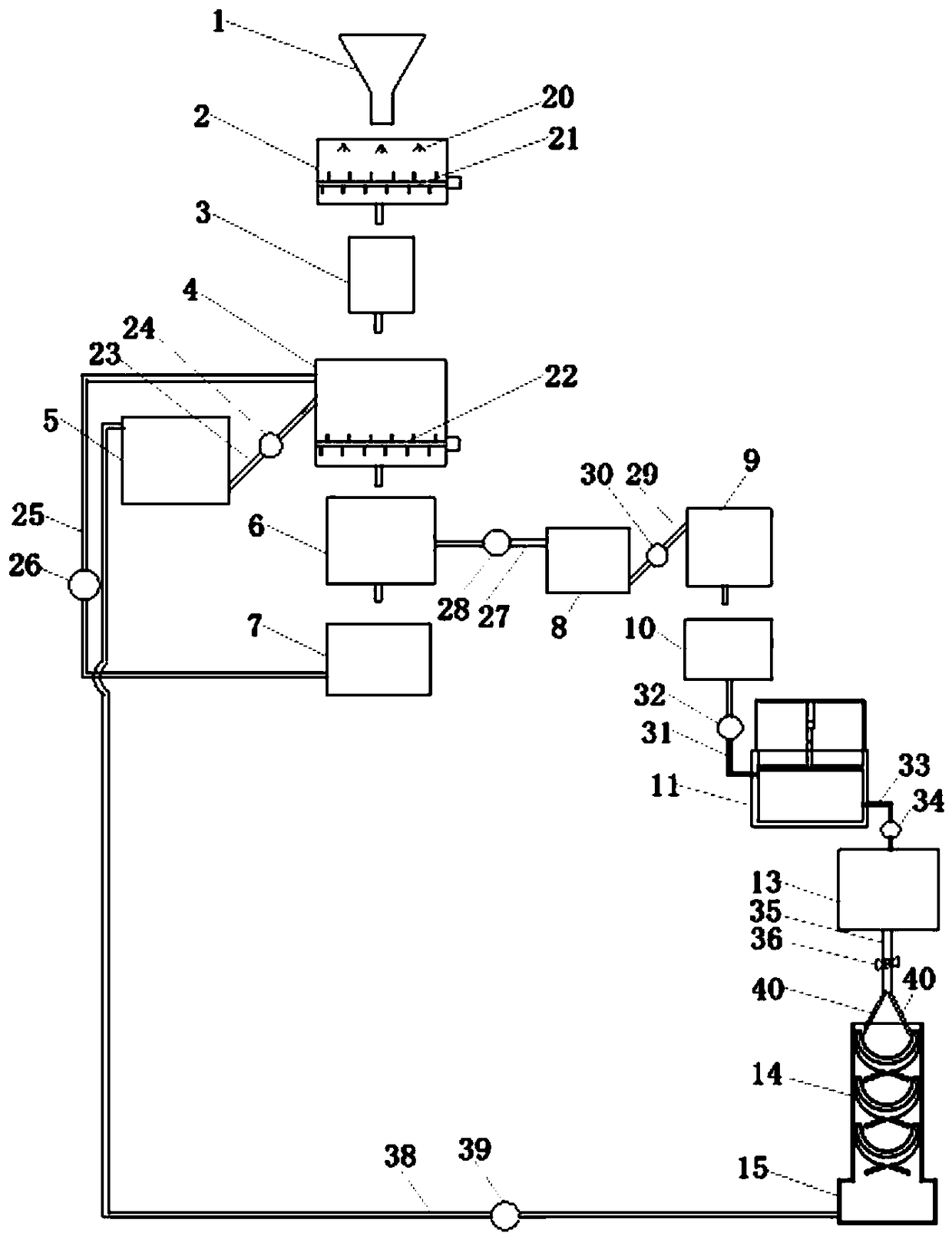

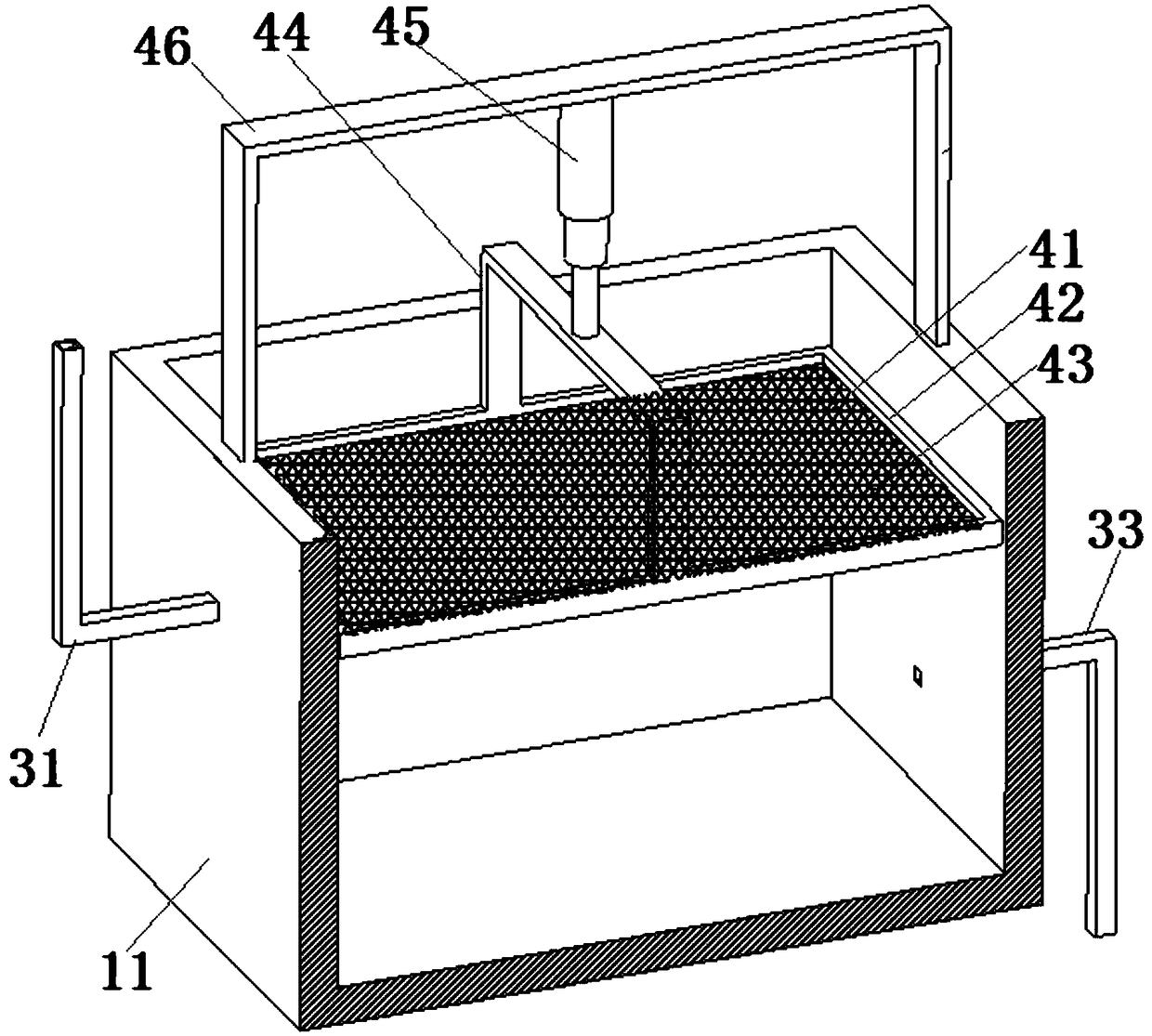

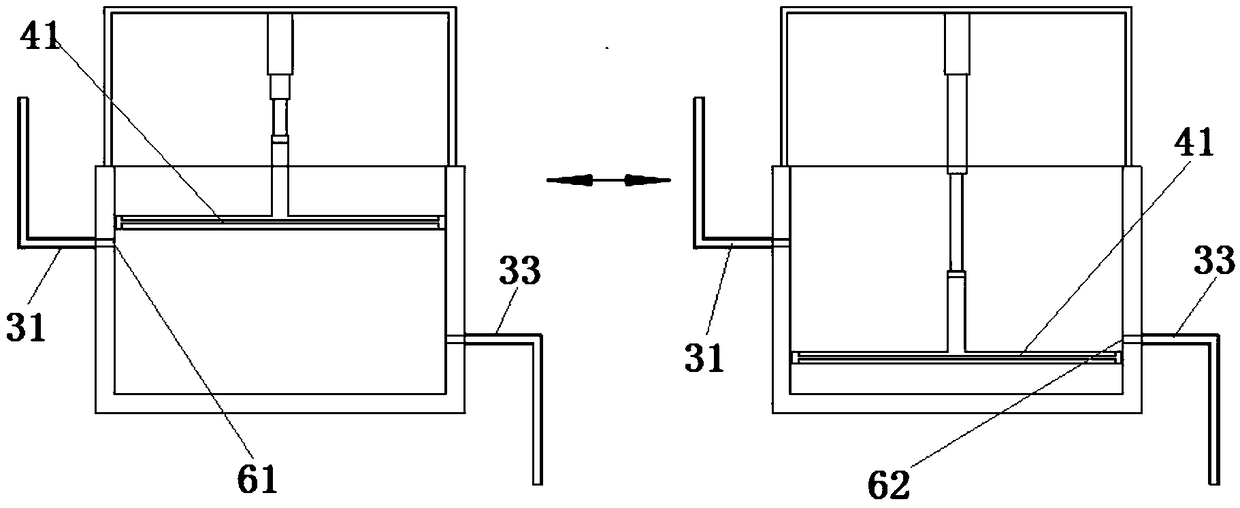

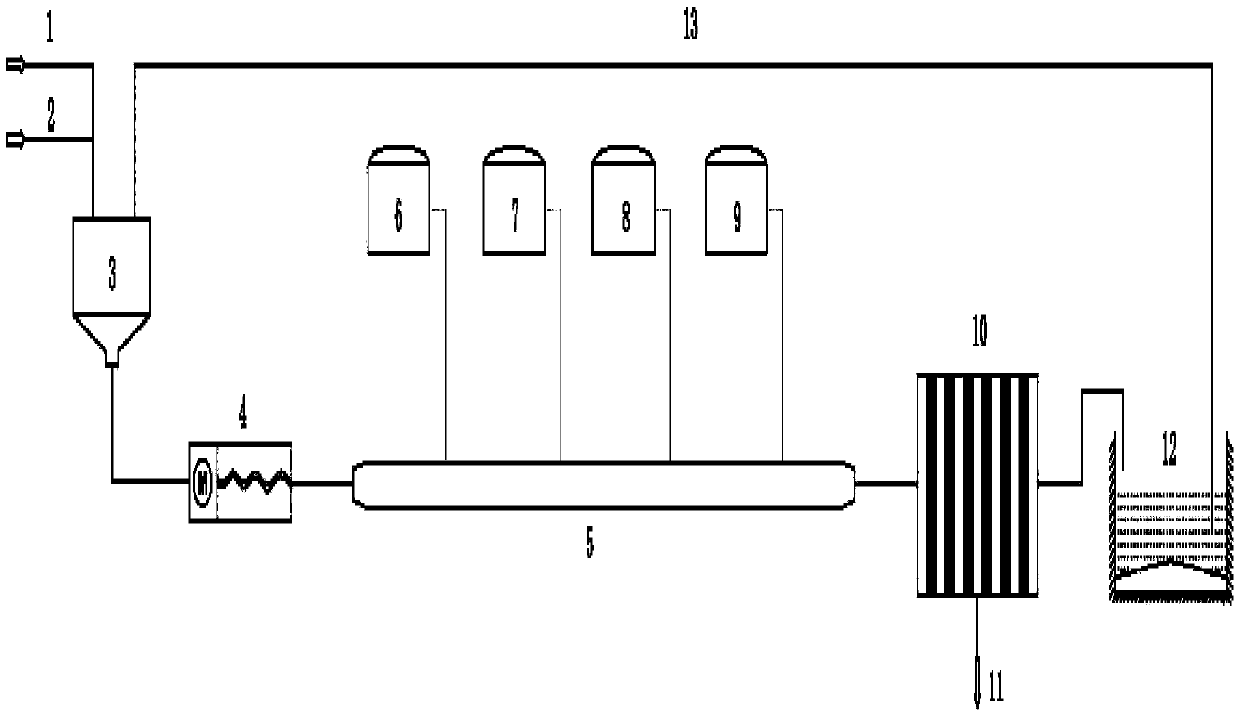

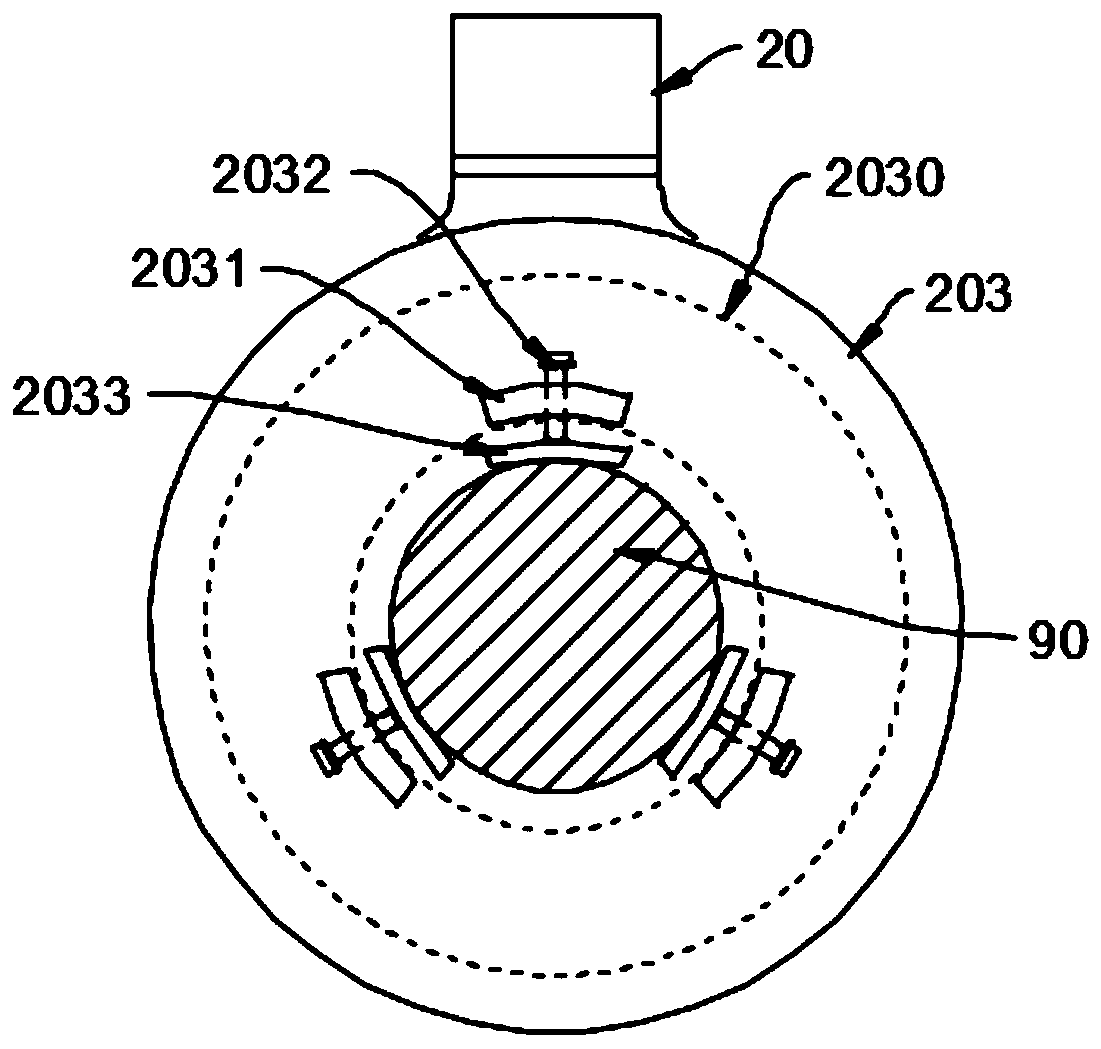

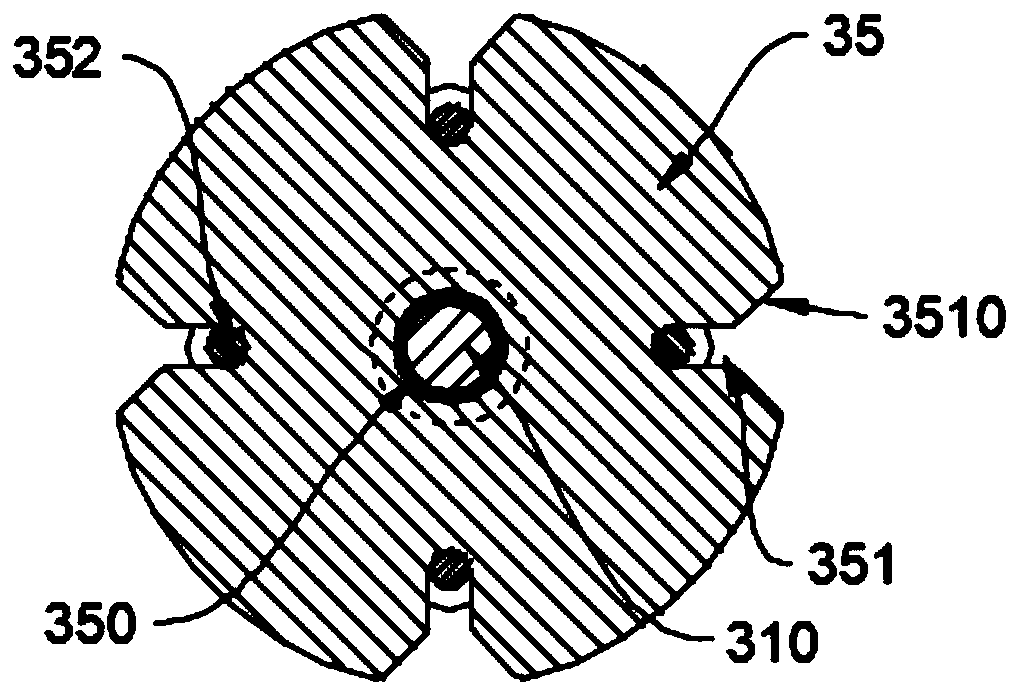

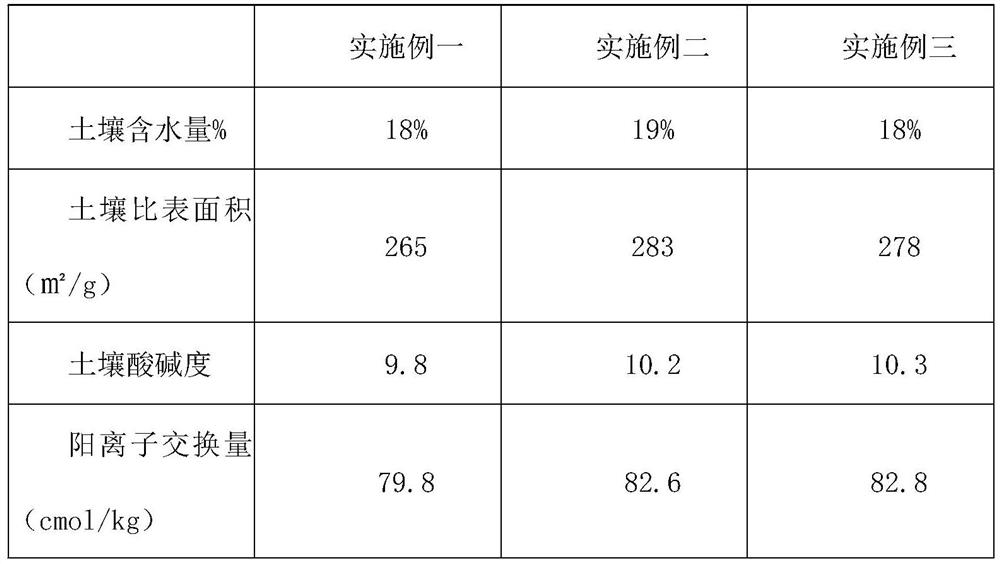

Soil restoration system and restoration method

ActiveCN109111021AShorten the repair cycleImprove repair effectContaminated soil reclamationTreatment involving filtrationRestoration methodEngineering

The invention discloses a soil restoration system and restoration method. The soil restoration system comprises a soil breaker, a soil wetting stirring box, a soil heating container, a soil dissolvingand diluting stirring box and a muddy water collection pond which are successively arranged, and also comprises a first water collection pond, a water heating container, a water cooling container, astanding precipitation pond, a second water collection pond and a water filtering and adsorption box which are successively arranged, a movable coverage net structure is arranged in the standing precipitation pond, a plurality of filtering and adsorption units are arranged in the water filtering and adsorption box, and the plurality of filtering adsorption units can successively filter and adsorbthe water in the water filtering and adsorption box. By adopting the soil restoration system and restoration method provided by the invention, the soil can be effectively restored, the restoration method is reasonable, and the popularization is facilitated.

Owner:广州中宜生态环境科技有限公司

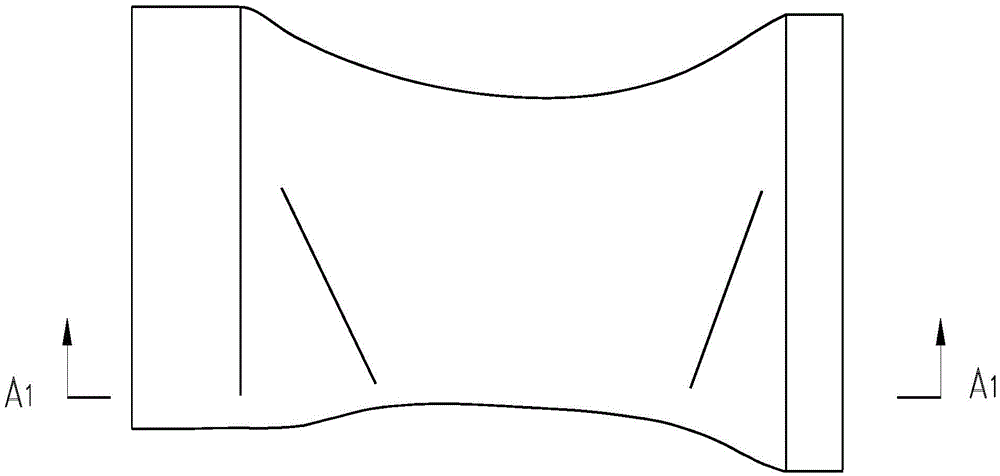

Method for repairing molding surface of blade rolling mold

InactiveCN103264462AImprove product qualityShorten the repair cycleMaterials scienceRepair processes

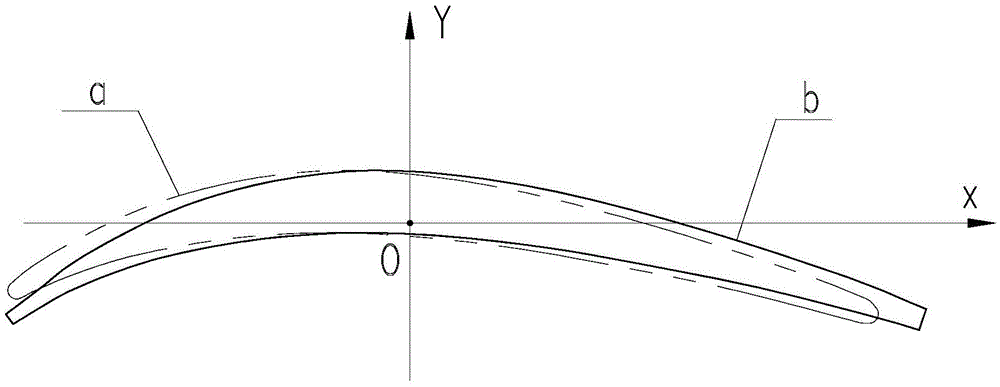

The invention relates to a method for repairing a molding surface of a blade rolling mold. The method comprises the following steps of: checking the allowance of the molding surface of the blade rolling mold, drawing grid lines, rolling a blade of which the molding surface can meet the repairing requirement, repairing the side parts of the rolling mold; measuring the blade molding surface and finding the molding surface position of the rolling mold corresponding to a blade out-of-tolerance part, setting the repairing amount of the rolling mold and sequencing the parts of the rolling mold, processing problems generated during the repairing process, and ensuring the surface quality of the rolling mold; and checking the allowance of the molding surface of a new rolling mold, drawing grid lines on the molding surface of the new rolling mold, rolling the blade, measuring the molding surface of the blade, finding out the part of the blade, exceeding an acceptance tolerance, and determining the repaired part through grids on the rolling blade and corresponding the determined parts to the rolling mold. The method has the advantages that about one third of the repairing period is shortened; about 30 mold repairing test pieces in every set of molds are reduced; particularly, the repairing of the rolling mold for rolling the complicated blades with curved surfaces can be realized by using the method; and the product quality of the blades is greatly improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

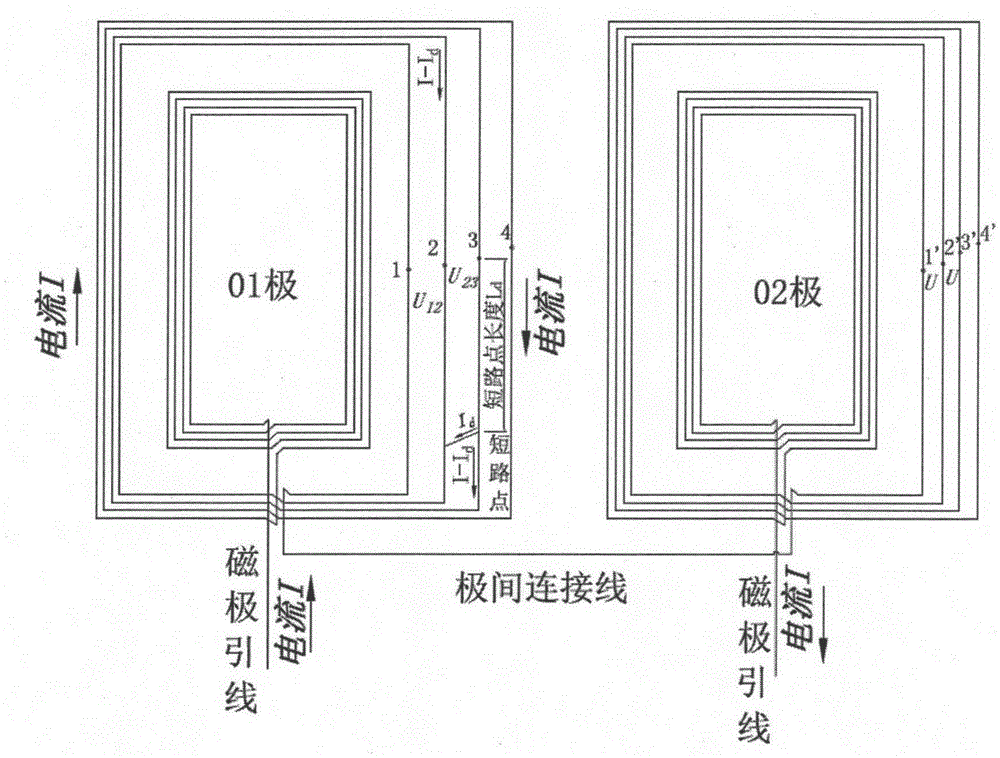

Method for measuring degree of turn-to-turn short-circuit fault of rotor and accurately positioning same

The invention discloses a method for measuring degree of a turn-to-turn short-circuit fault of a rotor and accurately positioning the same. The method is characterized in that a safe current-constant DC voltage is acted on a static slip ring or axial lead, the voltages of different coils are measured, the voltage or voltage different of different corresponding portions of a two-pole winding of a rotor without turn-to-turn short-circuit fault is equivalent, the number of the coil in which short circuit occurs can be determined preliminarily, the voltage between every two turns is then measured, and the position of the short circuit point and the short circuit degree are calculated according to the voltage value between the short-circuit turns. According to the method of the invention, the Kirchhoff's current law is used to search the turn-to-turn short-circuit fault point of the rotor, the concrete position of the fault point can be determined before the rotor is dismounted for repair, subsequent work scheme is then made in a scientific, reasonable and targeted manner according to the position of the fault point, the maintenance cost and period are greatly reduced, labor, material and financial cost is greatly reduced, and huge economic loss is avoided.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

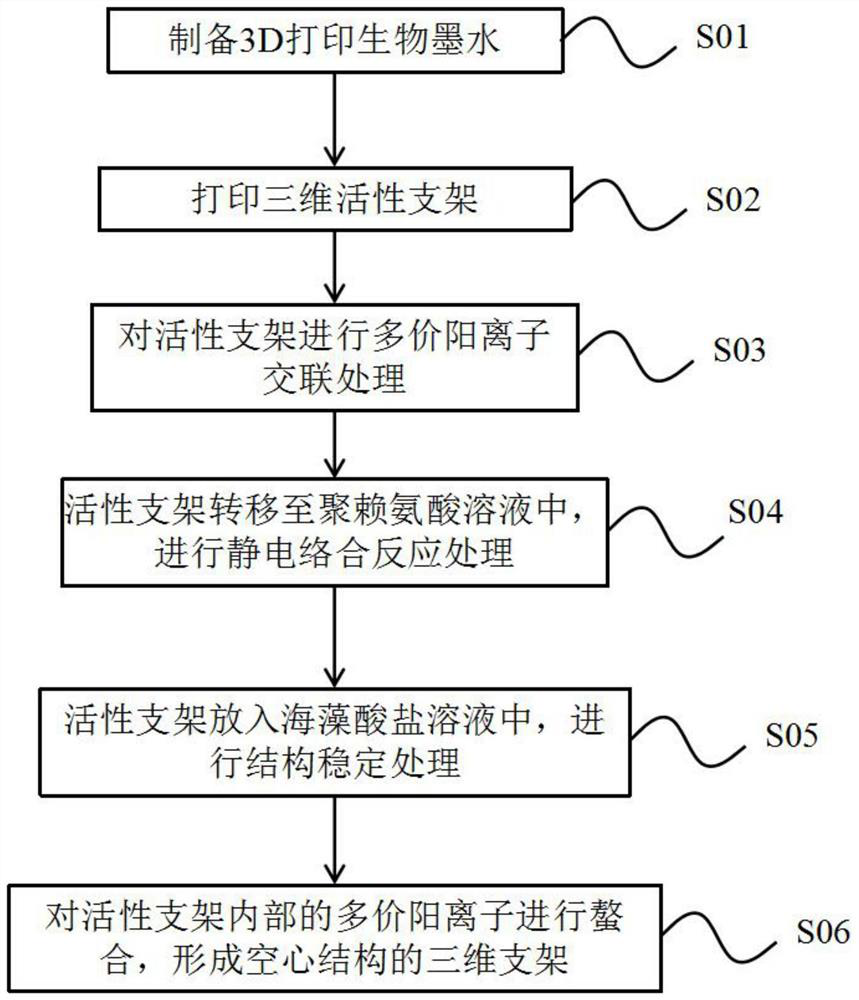

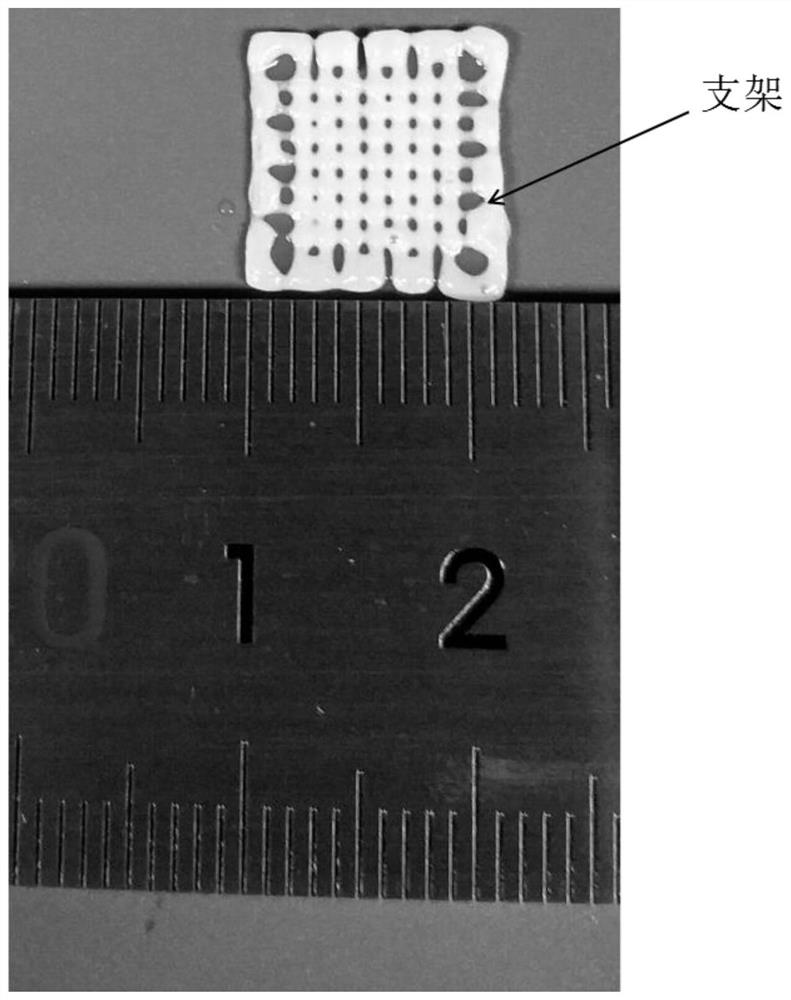

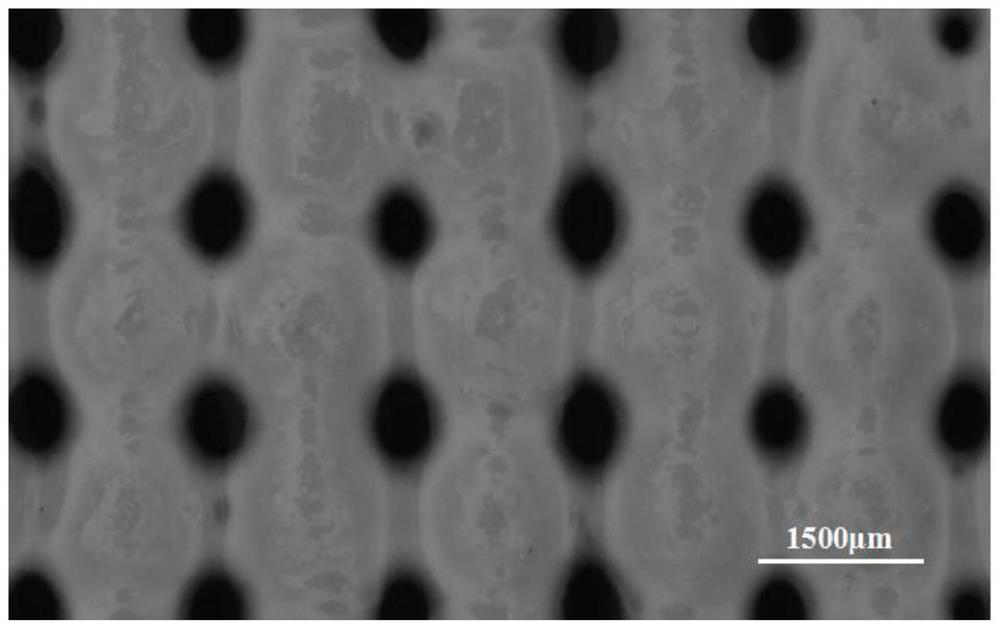

Three-dimensional stent with communicating hollow structure and preparation method of three-dimensional stent

ActiveCN112618792AImprove structural stabilityShorten the repair cycleAdditive manufacturing apparatusProsthesisChemistryTissue engineering

The invention discloses a three-dimensional stent and a preparation method thereof. The preparation method comprises the steps of compounding cells and alginate hydrogel, and preparing 3D printing biological ink; constructing an active stent with a three-dimensional structure through 3D printing; performing multivalent cation cross-linking treatment on the active stent; transferring the active stent subjected to multivalent cation cross-linking treatment into a polylysine solution, and performing electrostatic complexing reaction treatment to obtain a stable structure; and chelating multivalent cations in the active stent after the electrostatic complexing reaction treatment, so that alginate in the active stent dissolves out. The three-dimensional stent has the communicating hollow structure, is high in operability, can carry various cells, medicines and bioactive factors through the communicating hollow structure besides meeting the physical characteristics of stability, a specific three-dimensional structure and the like required by a biological printing stent material, is beneficial to nutrient transportation and exchange, is beneficial to acceleration of tissue engineering repair, and is good in structural stability and excellent in pore controllability.

Owner:SHENZHEN INST OF ADVANCED TECH

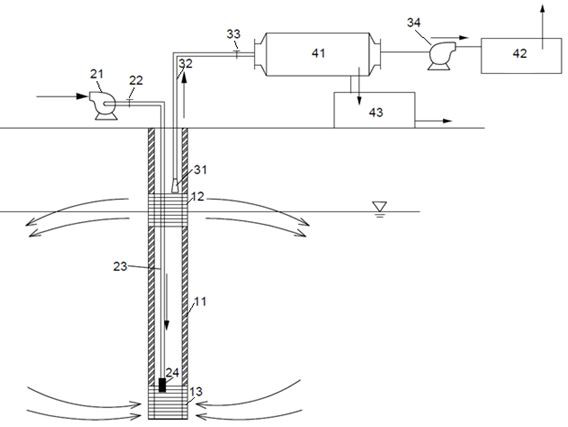

In-situ circulation well repair system and method for perfluorinated and polyfluoroalkyl compounds in underground water

InactiveCN114604983AHigh recovery rateImprove efficiencyWater contaminantsWater aerationVapor–liquid separatorAeration system

Owner:BEIJING GEOENVIRON ENG & TECH

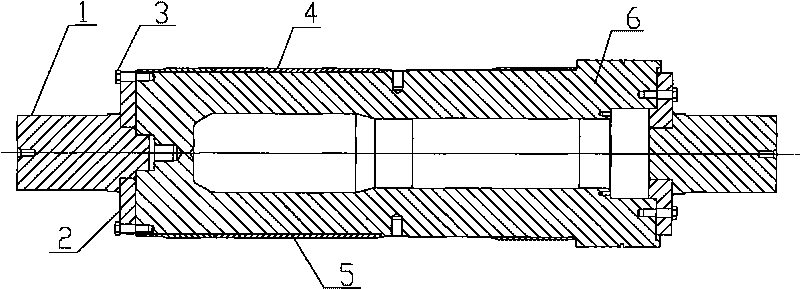

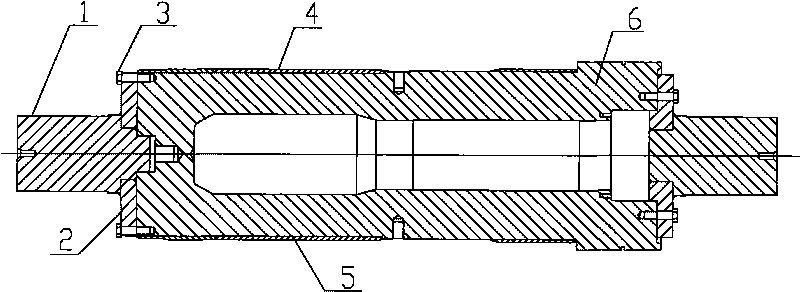

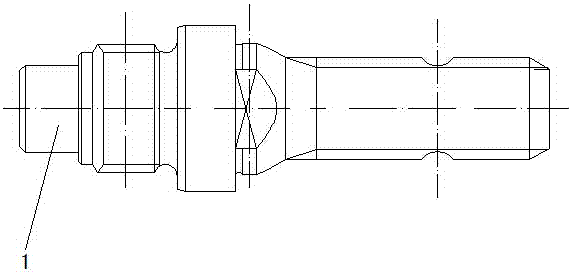

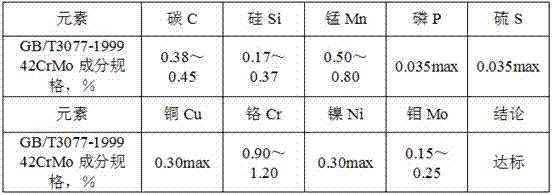

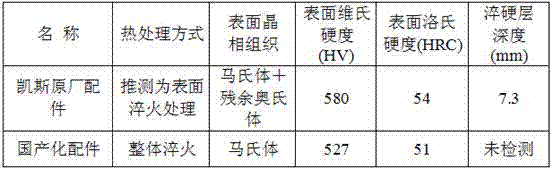

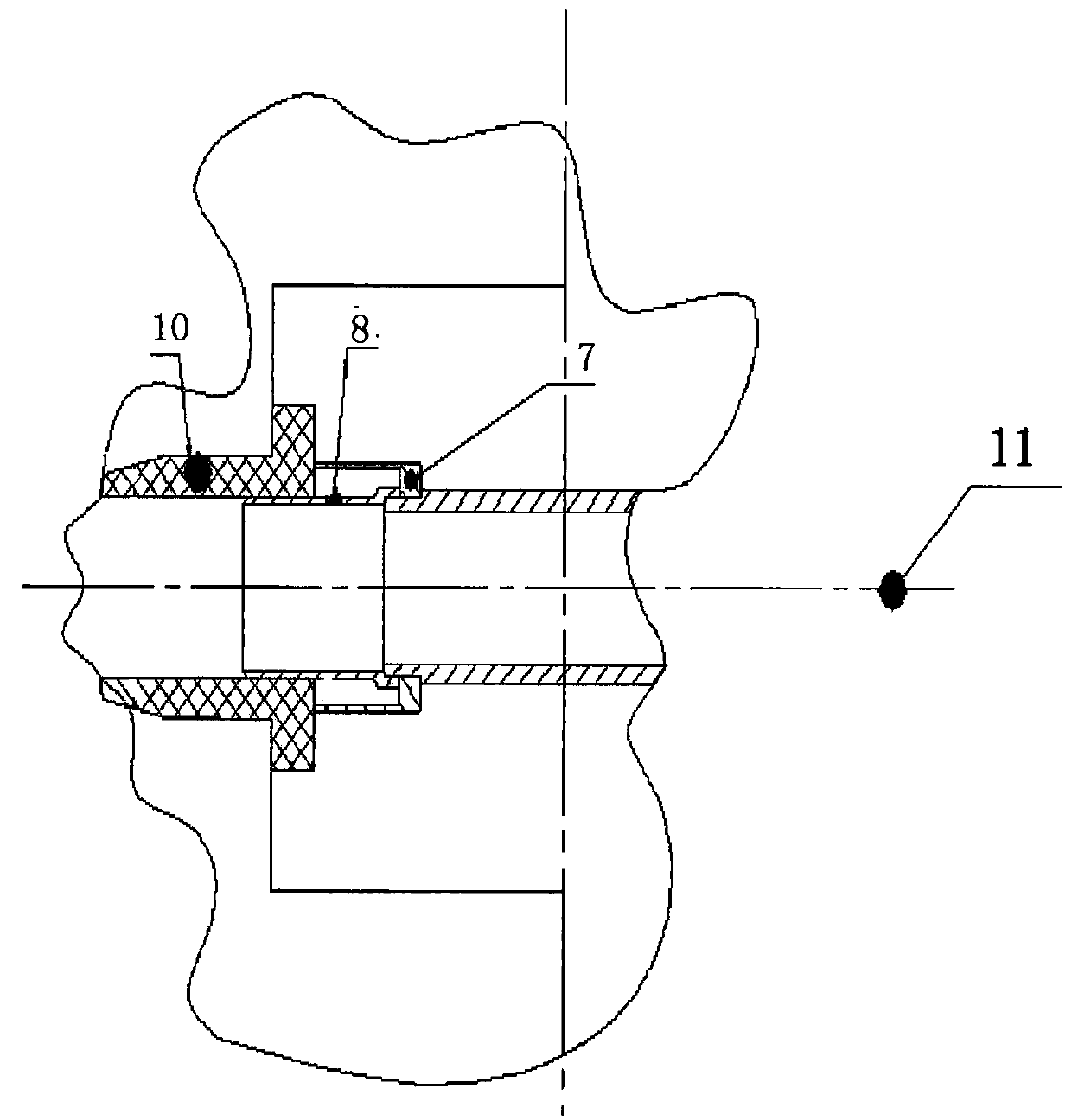

Power output shaft of tractor and machining method of shaft

PendingCN106870547ALow costShorten the repair cycleAuxillary drivesShaftsMechanical devicesEngineering

The invention provides a power output shaft of a tractor and a machining method of the shaft, and belongs to the technical field of mechanical devices. The invention provides a low-cost power output shaft of the tractor and the machining method of the shaft. The power output shaft comprises a shaft body. The shaft body is made of 42CrMo structural alloy steel. The machining method of the power output shaft of the tractor includes the following steps that overall quenching and tempering are conducted on the roughly-turned shaft body 1, the quenching heating time ranges from 1 h to 2 h, the quenching temperature ranges from 800 DEG C to 900 DEG C, then, oil cooling is conducted till the temperature ranges from 220 DEG C to 240 DEG C, then, high-temperature tempering is conducted, the high-temperature tempering temperature ranges from 500 DEG C to 600 DEG C, the high-temperature tempering time ranges from 2.5 h to 3 h, normal-temperature oil cooling is conducted after high-temperature tempering till the temperature is lowered to the room temperature, and the surface hardness of the shaft body 1 can reach HBS270 to HBS280; and fourthly, 80 kw local annealing treatment is adopted for a dense-tooth spline part on the head portion of the shaft body, the processing frequency is 10000 Hz, the heating time ranges from 9 min to 11 min, the heating temperature ranges from 600 DEG C to 800 DEG C, the annealing time ranges from 600 DEG C to 800 DEG C, the annealing time ranges from 9 min to 11 min, and then extrusion forming is conducted through a formed mold. The power output shaft and the machining method are low in cost.

Owner:HEILONGJIANG AGRI MACHINERY REPAIR INST

Reassembly method of high precision porous component

ActiveCN103111823AGuaranteed production cycleMeet assembly requirementsWorking environmentDislocation

The invention discloses a reassembly method of a high precision porous component. The high precision porous component is provided with a plurality of high-lock bolt holes, each high-lock bolt hole and an assemble place substrate are operated in an accurate counterpoint mode when the high precision porous component is assembled. The high precision porous component is characterized in that the method includes the following steps: a, dislocation processing of prefabricated holes; b, locating fastening of a novel high precision porous component; c, precision reaming of the prefabricated holes; and d, installation of high-lock bolts. According to the reassembly method of the high precision porous component, the prefabricated holes are required to be only renovated and processed on line, original hole manufacturing work which needs to be done in a narrow space and is difficult to operate is mostly transferred to a working environment which is spacious and easy for operation, the repair cycle is greatly shortened under the premise that assembly requirements are met, and assembly operation difficulty is reduced.

Owner:FACTORY 5721 OF PLA

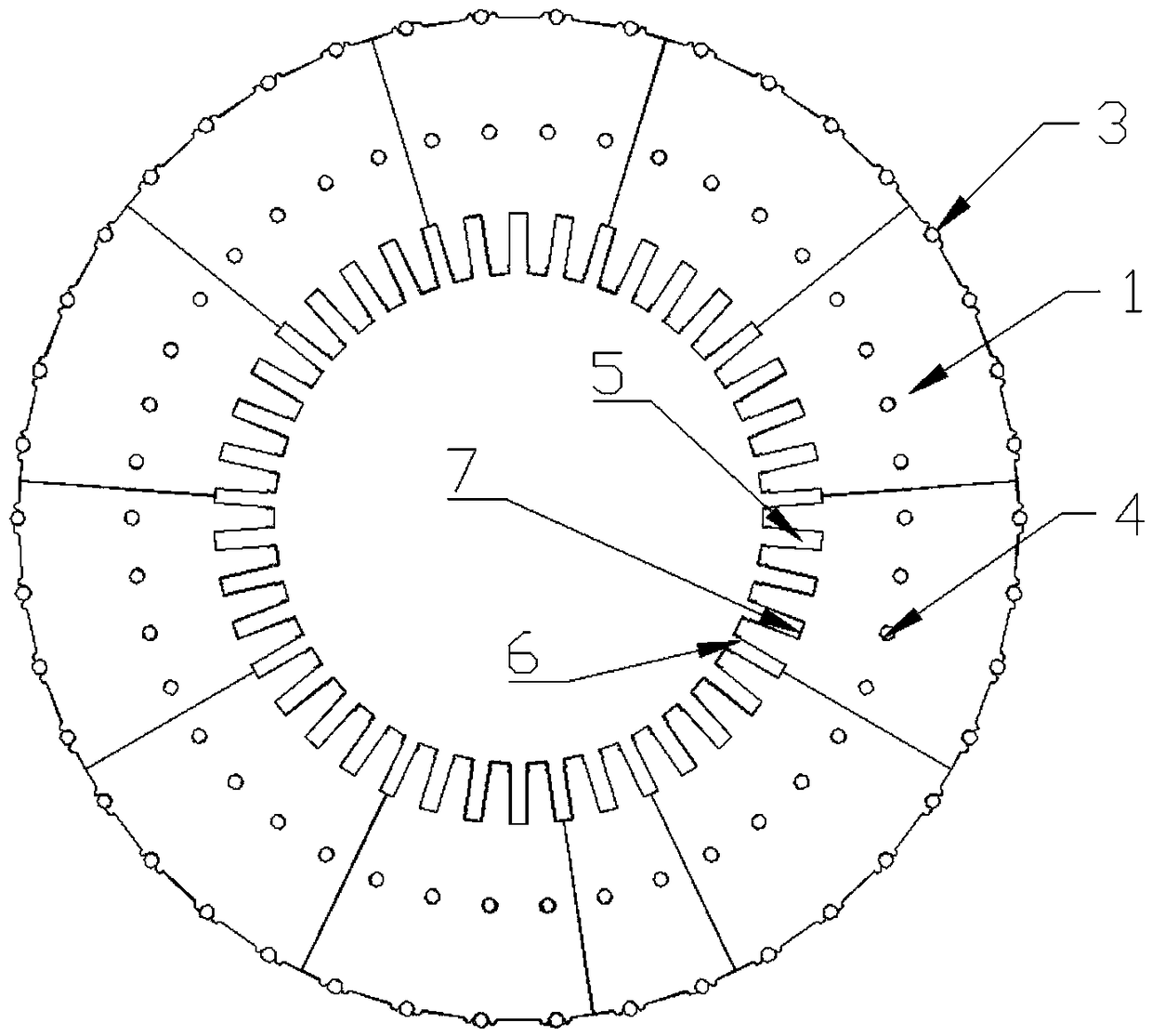

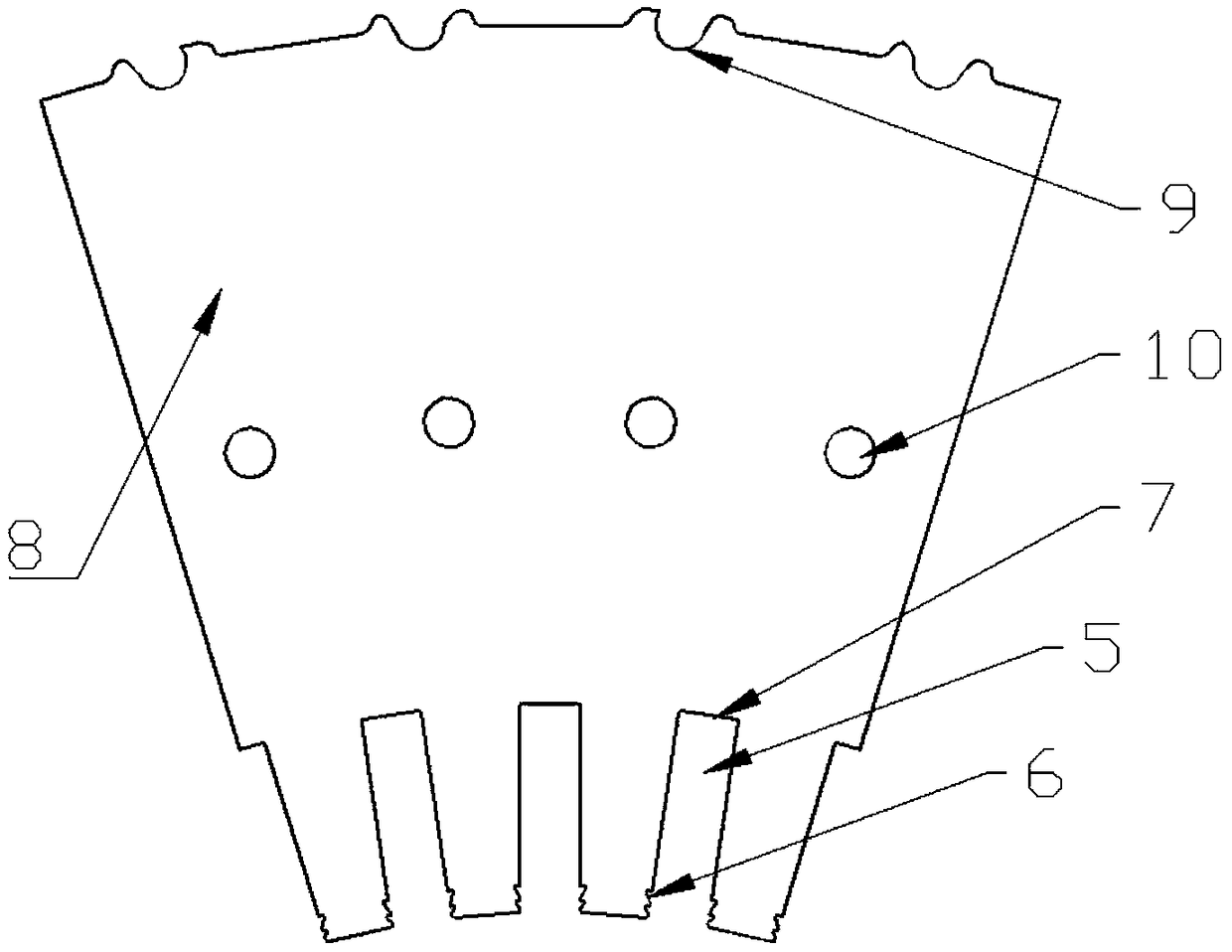

Site horizontal lamination edge segment iron core process of turbo generator

ActiveCN108880137AMeet assembly requirementsMeet operational requirementsManufacturing stator/rotor bodiesEdge segmentPunching

The invention relates to a site horizontal lamination edge segment iron core process of a turbo generator. In order to overcome influence of a punching sheet and press finger assembly gravity on the size and the linearity of a groove during the horizontal lamination process, a lower slot is positioned by a positioning screw rod, a groove-type rod, a slot groove and a positioning rod, shaping is performed on a center-penetrating screw rod hole by a tool center-penetrating screw rod, and the press finger assembly quality is ensured by the positioning screw rod, the groove-type rod, the slot groove, the positioning rod and a press finger fixing tool after lamination.

Owner:HARBIN ELECTRIC MASCH CO LTD

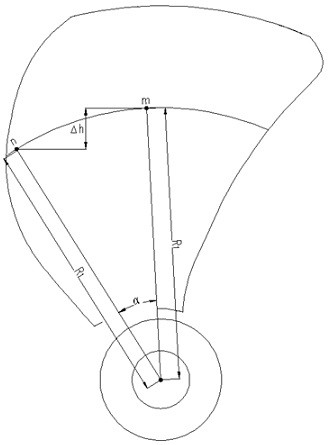

Judging and regulating method for blade rolling process

The invention discloses a judging and regulating method for a blade rolling process, belonging to the technical field of aviation engine blade rolling. The method is rapid, accurate and capable of greatly shortening the regulating time, shortening the repair period of a rolling die, reducing the consumption of die repairing test blocks and manpower and ensuring that a blade meets the requirement of a design drawing to the maximum extent. The judging and regulating method comprises the following steps of firstly, judging and regulating a seaming position; secondly, judging profile offsetting and twisting; thirdly, judging and regulating die profile air inlet and exhaust side direction translation; fourthly, judging and regulating blade rotation around the vertical direction; fifthly, judging and regulating a blade along the vertical direction; sixthly, judging and regulating blade rotation around a horizontal shaft; and seventhly, judging and regulating blade rotation around a central line of a blade body.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

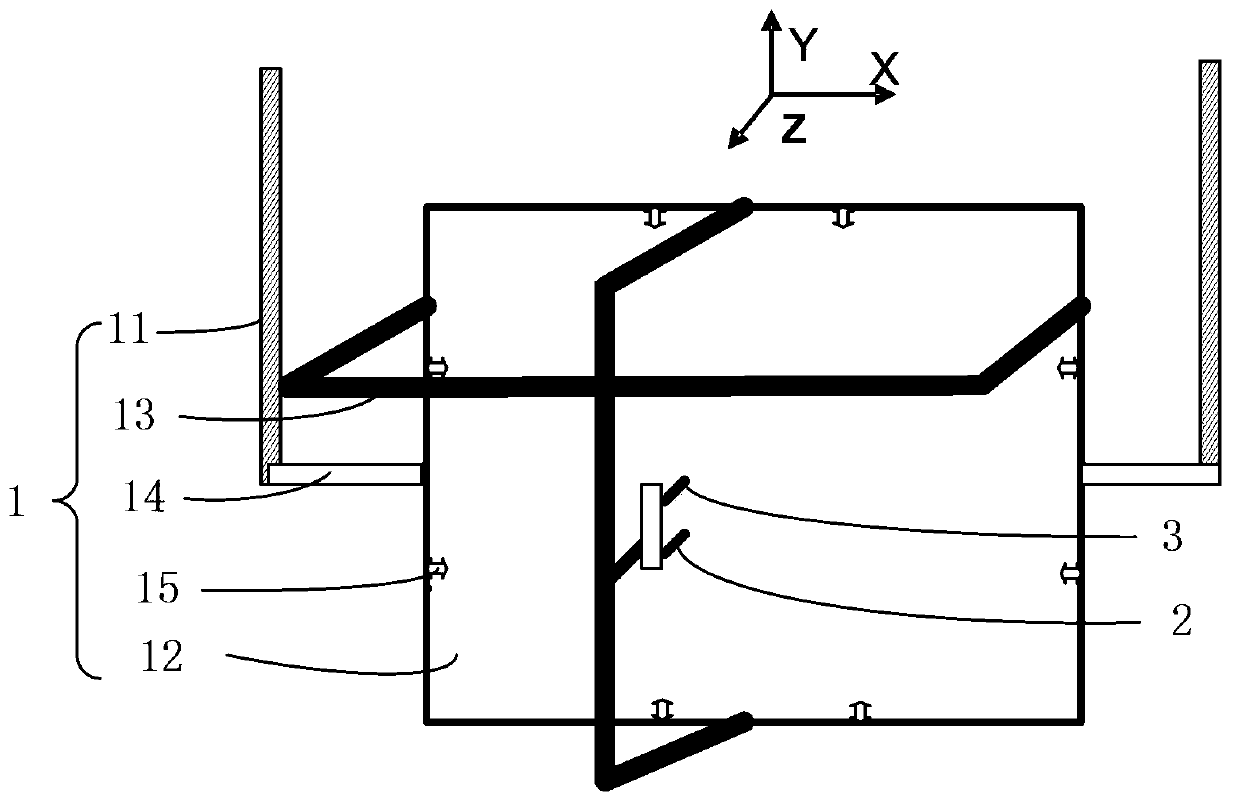

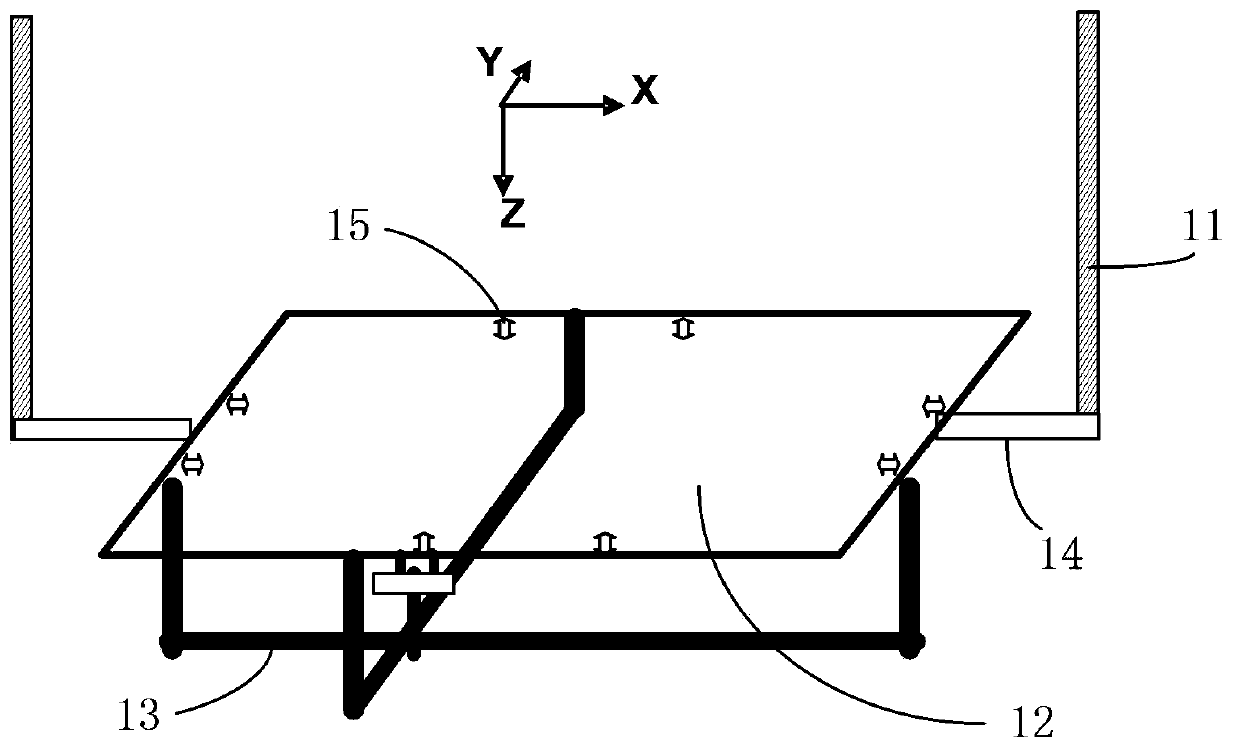

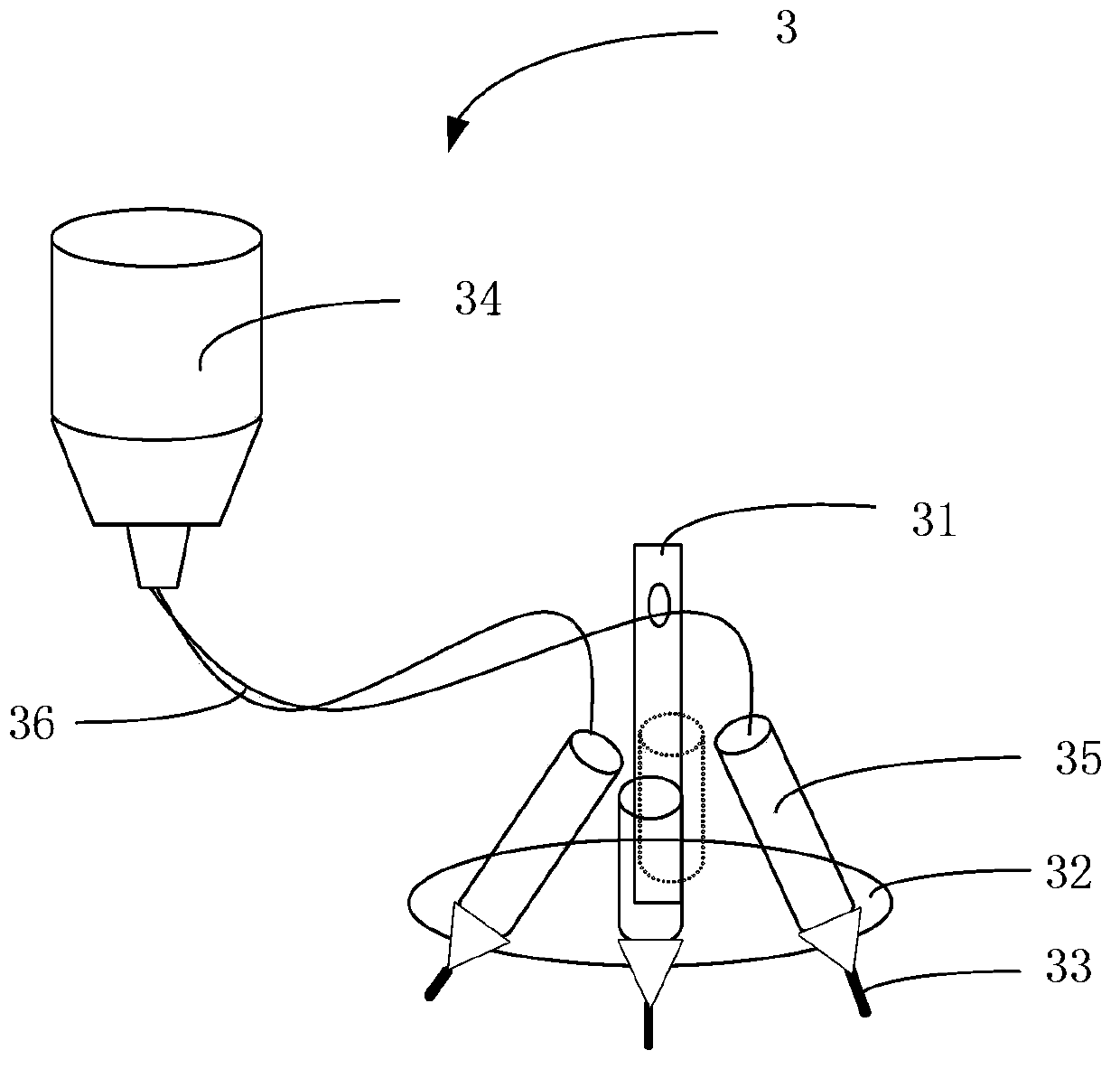

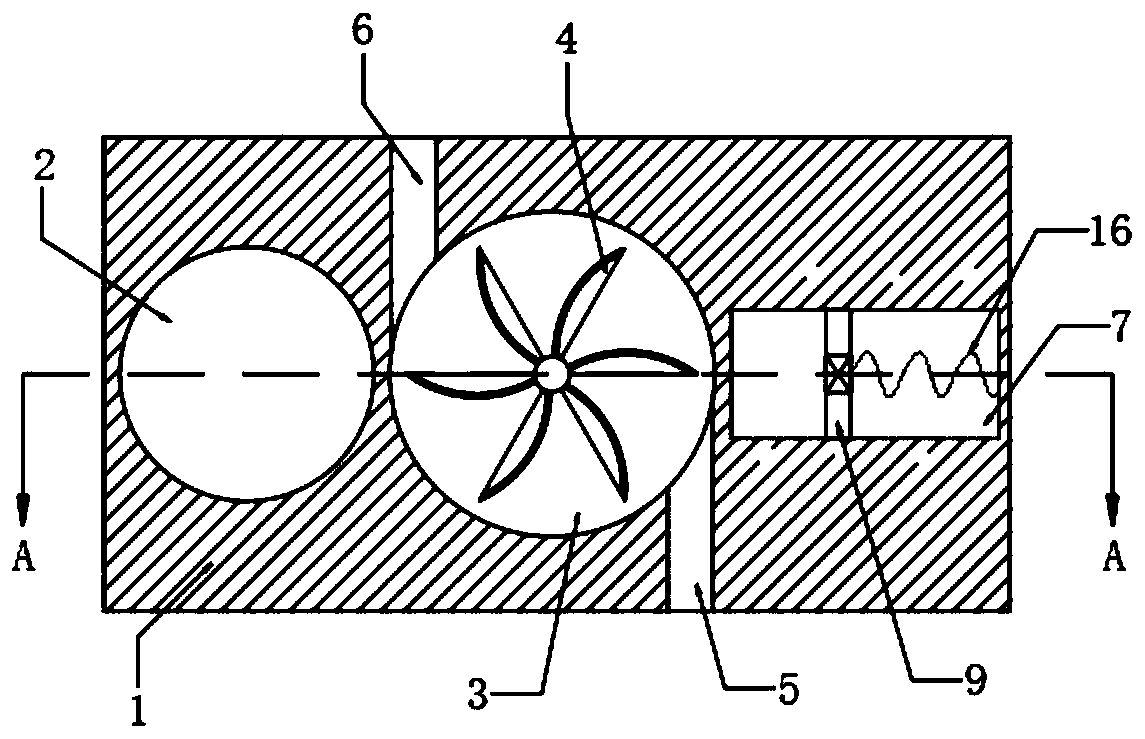

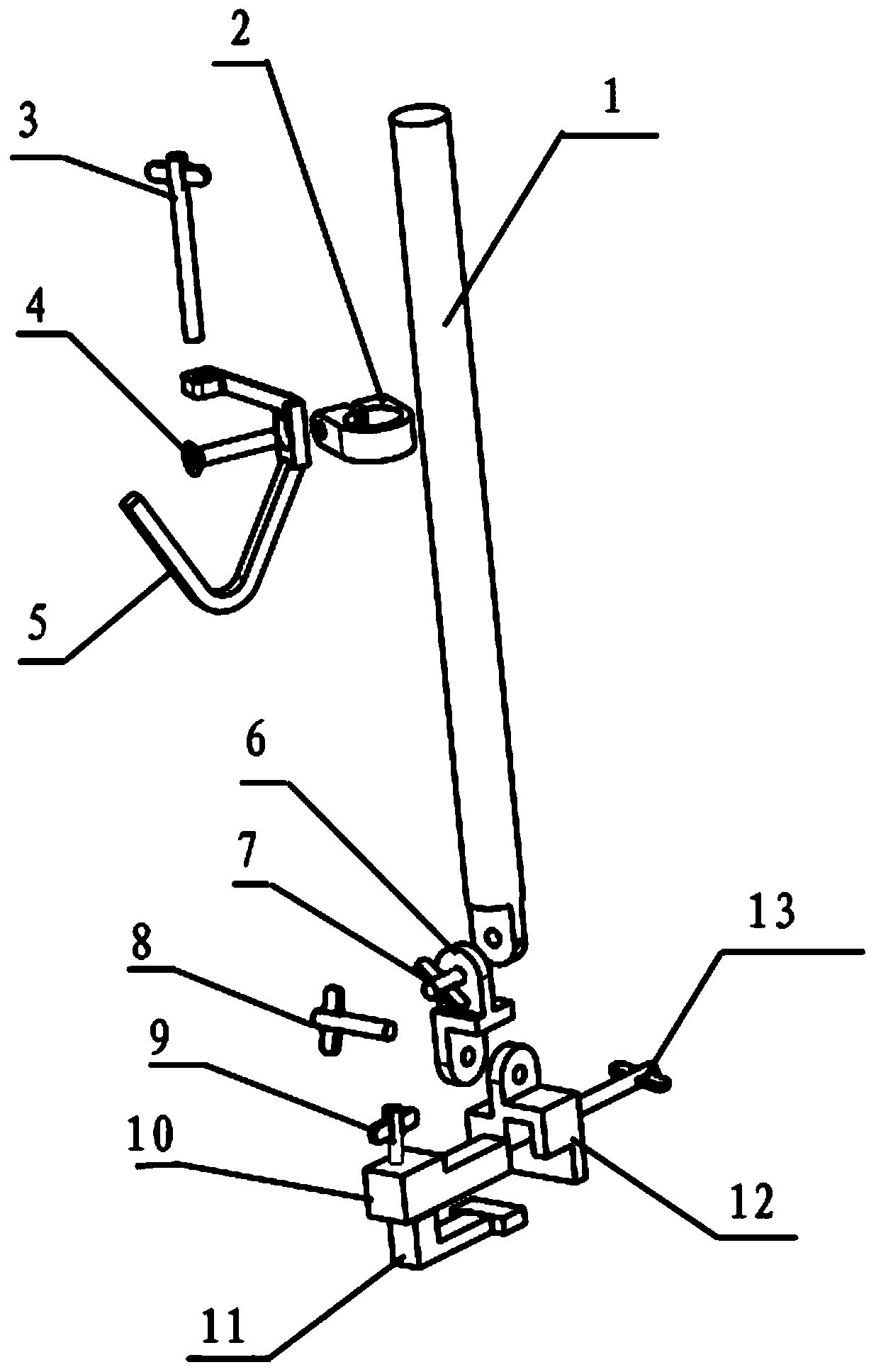

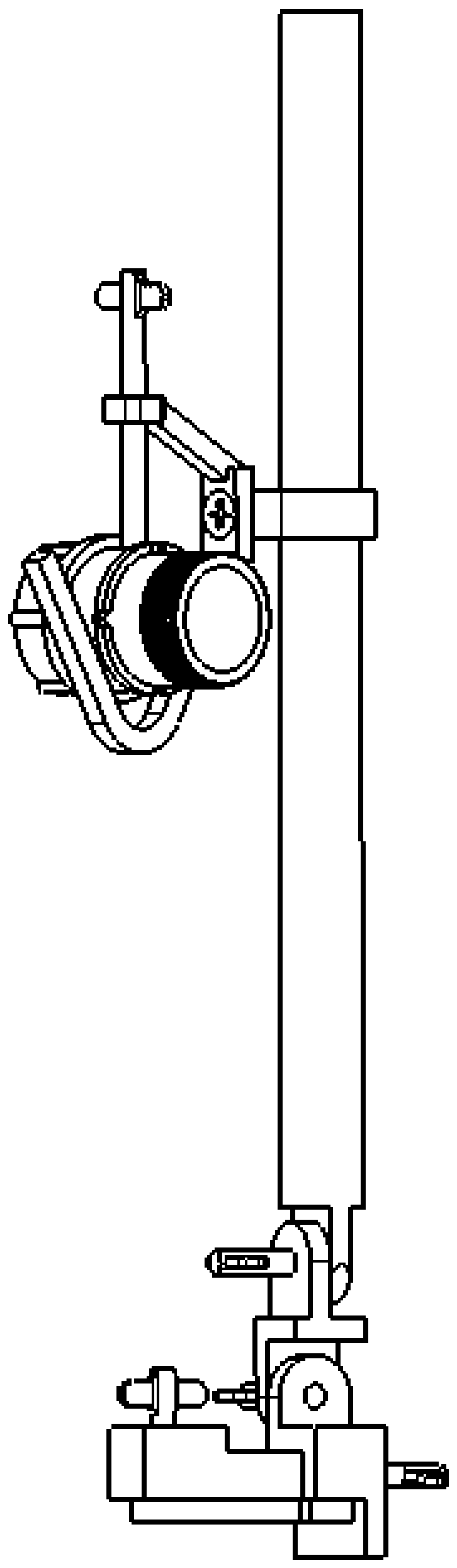

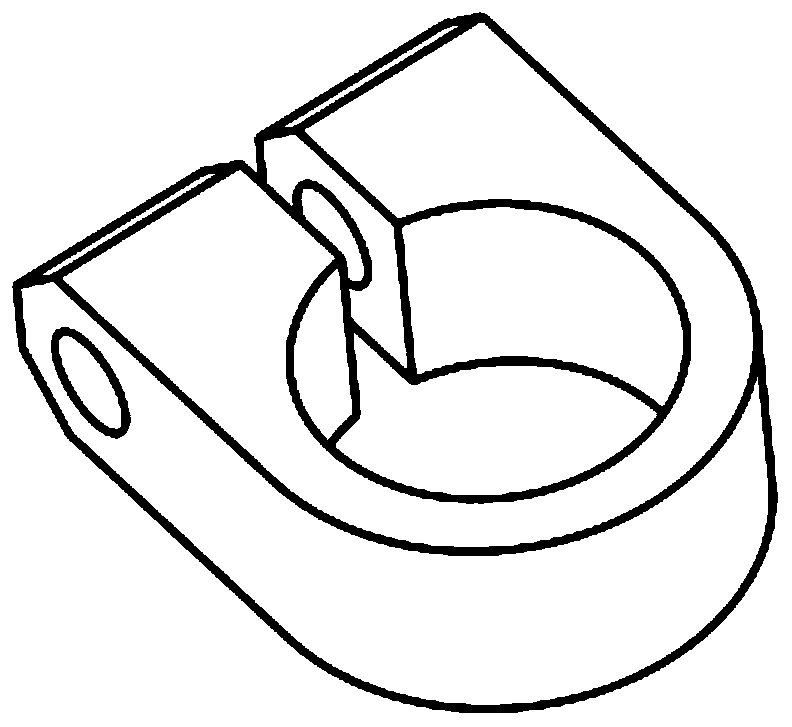

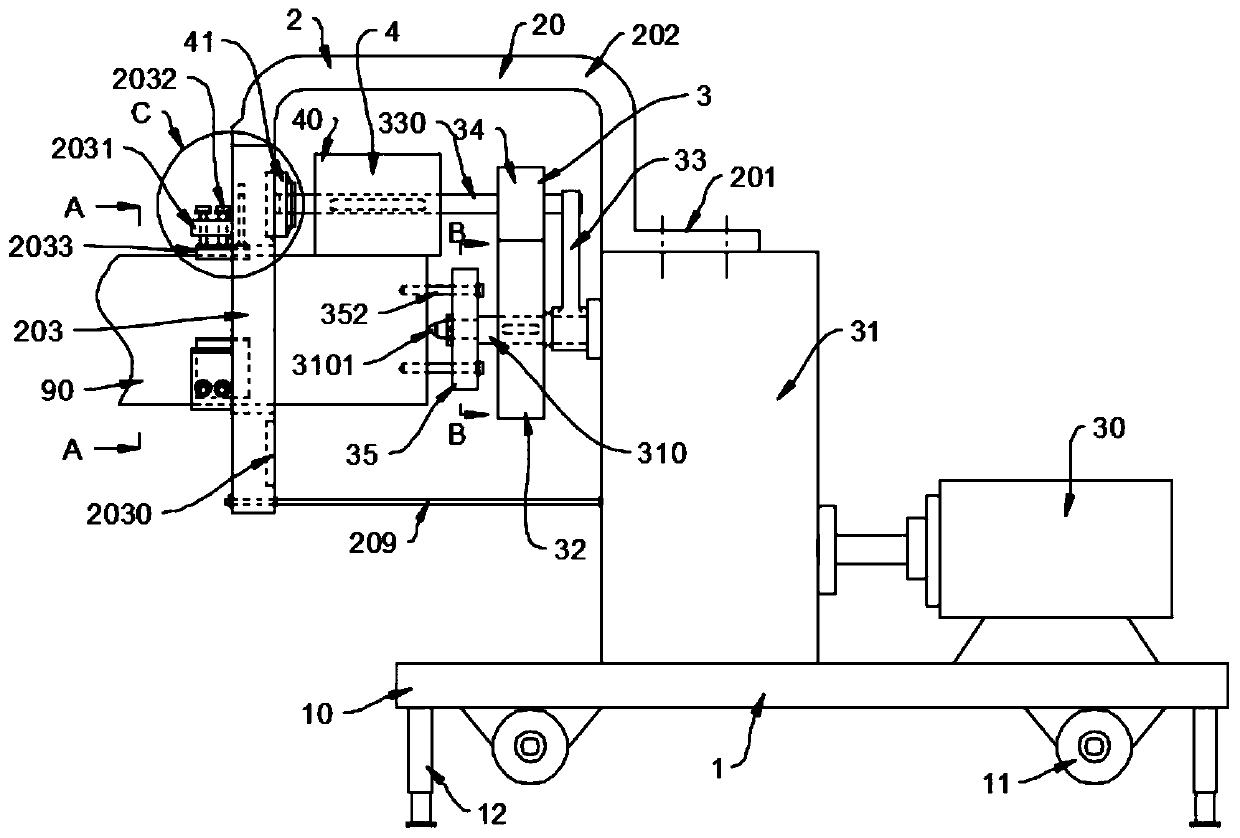

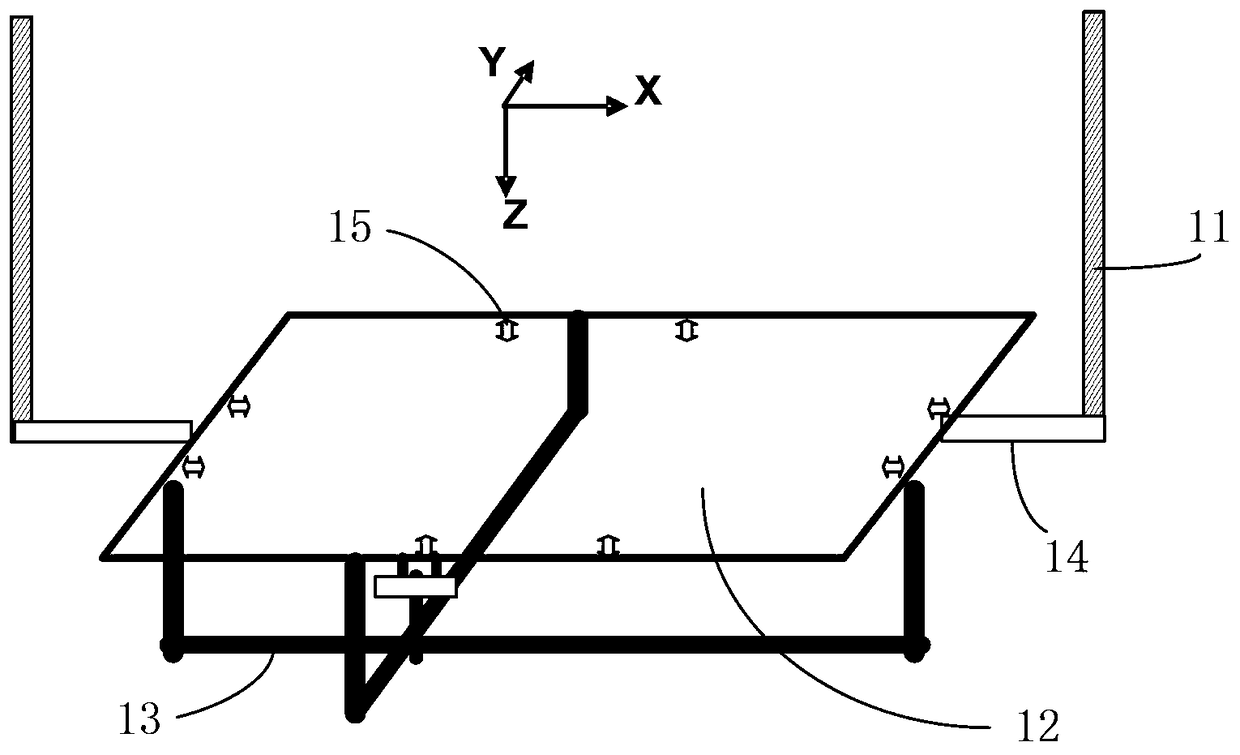

Scratched mask repair apparatus and method

ActiveCN103969945ATimely and fast repairDoes not affect production capacityPhotomechanical exposure apparatusMicrolithography exposure apparatusSoftware engineeringMechanical engineering

The present invention discloses a scratched mask repair apparatus and a method. The apparatus comprises a bracket device, a defect detection device and a repair module, wherein the bracket device is arranged in a photolithography machine chamber, the defect detection device and the repair module are arranged on the bracket device, and the repair module comprises a plurality of repair refills with different sizes. According to the present invention, the bracket device of the scratched mask repair apparatus is directly arranged in the photolithography machine chamber, and can timely and rapidly perform repair in the photolithography machine during mask scratching without influence on productivity of the photolithography machine, such that the function of the photolithography machine is complete, the automation degree of the photolithography machine is high, the mask repair can be directly completed in the photolithography machine, and the internal space of the photolithography machine is completely utilized so as to substantially shorten the repair period and provide characteristics of simpleness, rapidness, low cost, and no influence on productivity.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

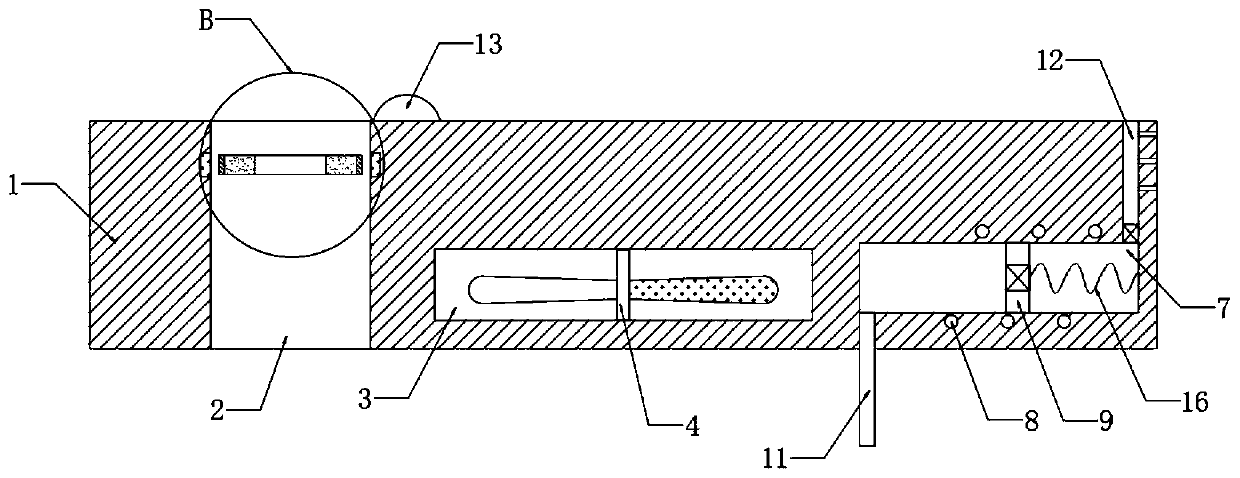

Bioremediation device for treating river pollution

InactiveCN111517576AIncrease oxygen contentPromote life activitiesWater treatment parameter controlWater cleaningBioremediationRiver pollution

The invention discloses a bioremediation device for treating river pollution, which comprises a floating plate, an aquatic plant placement groove is formed in the upper end of the floating plate; a circular groove is formed in the side wall of the floating plate; a water wheel is rotatably connected to the inner bottom of the circular groove; one blade of the water wheel is made of iron; a water inlet and a water outlet which are communicated with the circular groove are respectively formed in two opposite side walls of the floating plate; a strip-shaped groove is formed in the side wall of the floating plate, a sliding plug made of magnetic materials is connected into the strip-shaped groove in a sealed and sliding mode, the sliding plug is elastically connected to the inner wall of the strip-shaped groove through a spring, and an air inlet pipe and an air outlet pipe which are communicated with the strip-shaped groove are fixedly connected to the floating plate. Air on the river surface is pumped into river water through kinetic energy of the river, the oxygen content in the river water is greatly increased, life activities of various aerobic microorganisms and other organisms inthe river water are promoted, then the decomposition speed of pollutants in the river is increased, and the bioremediation period is shortened.

Owner:曹钰坤

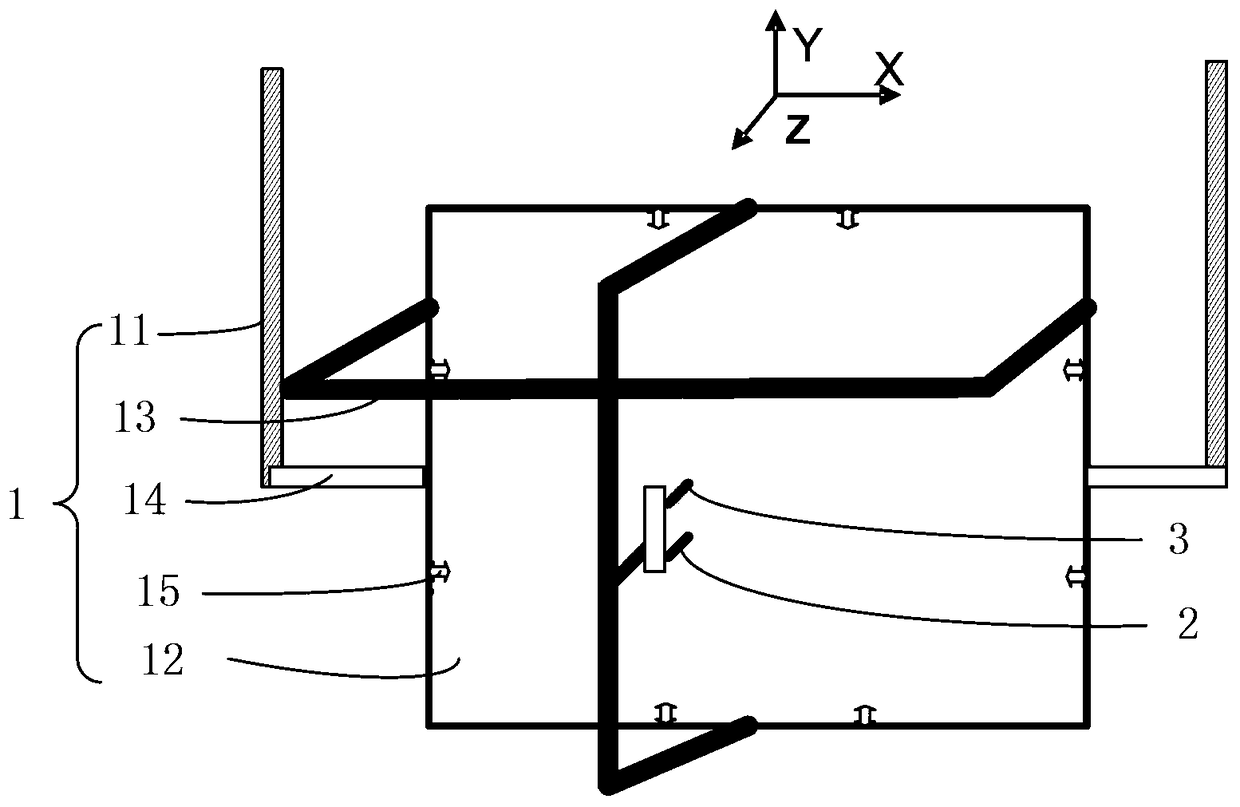

Fluid transportation and reaction integrated repairing method for organic-inorganic composite contaminated soil, and system thereof

PendingCN108672483AShorten the repair cycleLess investmentContaminated soil reclamationPollution soilInorganic compound

The invention relates to a fluid transportation and reaction integrated repairing method for organic-inorganic composite contaminated soil. The method comprises the following steps: processing the organic-inorganic composite contaminated soil in a batching system to obtain a slurry, and inputting the obtained soil slurry into a pipeline reaction system by a screw pump; arranging a plurality of bypasses at different positions of a main pipeline in the pipeline reaction system; injecting reagents into the main pipeline through the dosing bypasses in the flowing process of the soil slurry, and allowing the reagents to be mixed with the soil slurry flowing in the pipeline and be reacted with compound contaminants in the soil slurry in order to degrade or solidify the contaminants and achieve the purpose of repairing soil; and allowing the slurry discharged from the pipeline to enter a solid-liquid separation system, and carrying out solid-liquid separation by using a solid-liquid separation device, wherein the separated soil is air-dried, and then is backfilled or granulated, and the separated liquid is treated and then is recycled to the batching system for reuse. The method has the advantages of simplicity in operation, low cost, high efficiency and energy saving.

Owner:TIANJIN UNIV

Device for manufacturing mechanical shaft in operation

InactiveCN1660539ASimple structureEasy to transport with the carOther manufacturing equipments/toolsDevices fixationEngineering

A follow-up machining apparatus for greater mechanical axle (workpiece) is composed of a locating mechanism using said great mechanical axle as reference, a ring-type tool carriage assemblage fixed to said locating mechanism and revolving around said axle, and a driver unit. After said follow-up machining apparatus is fixed to said great axle, the axis is machined by the cutting tool moving around it.

Owner:SHENYANG DALU LASER TECH

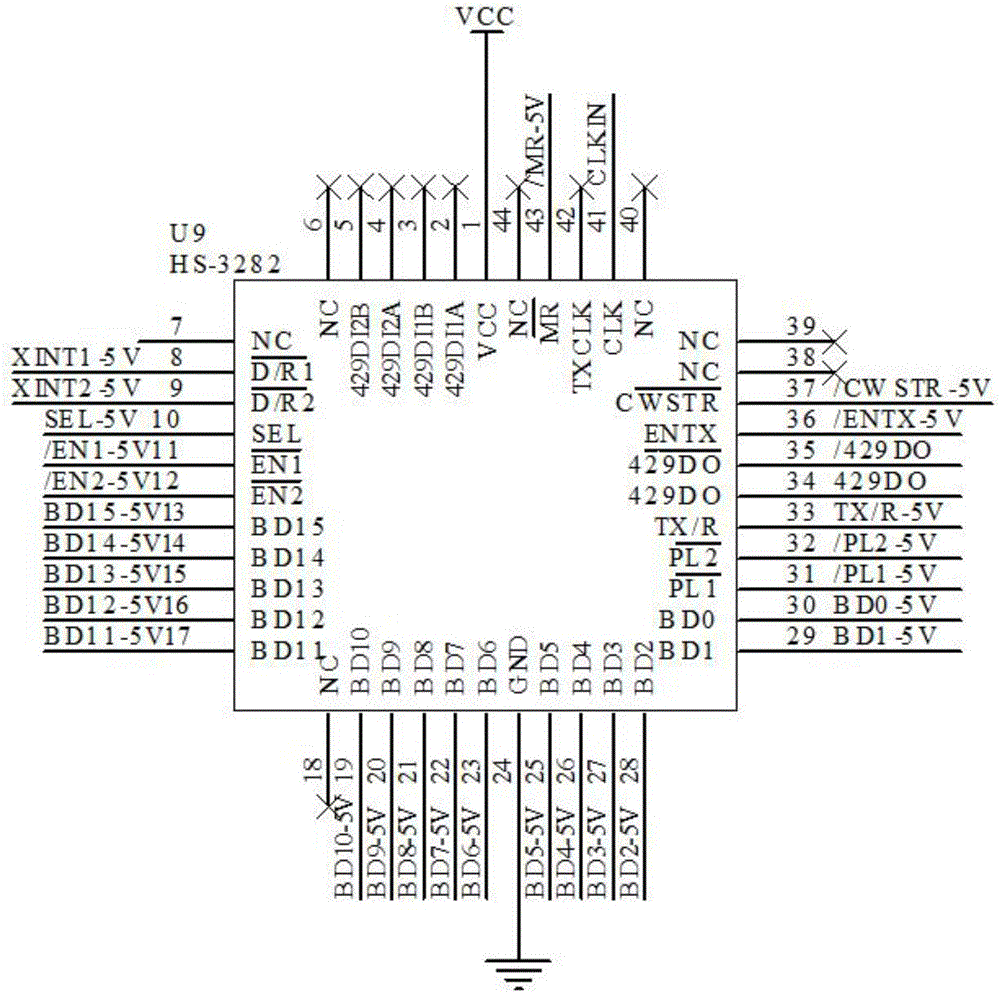

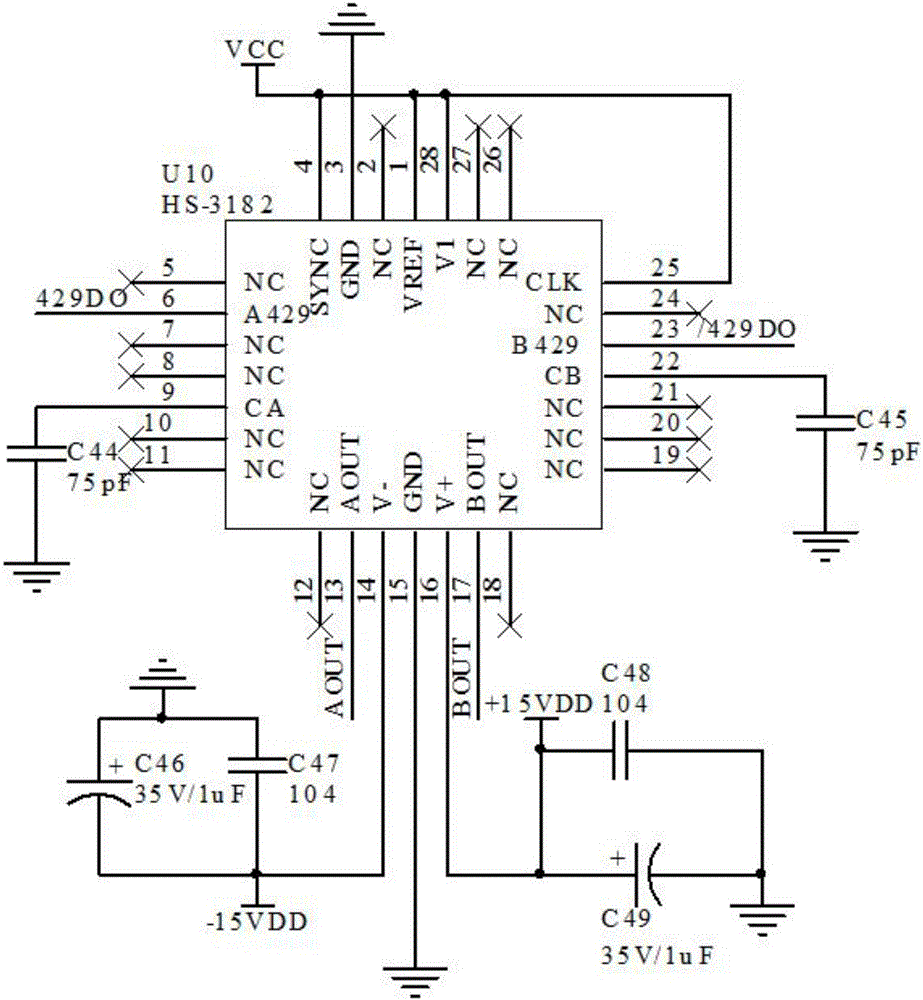

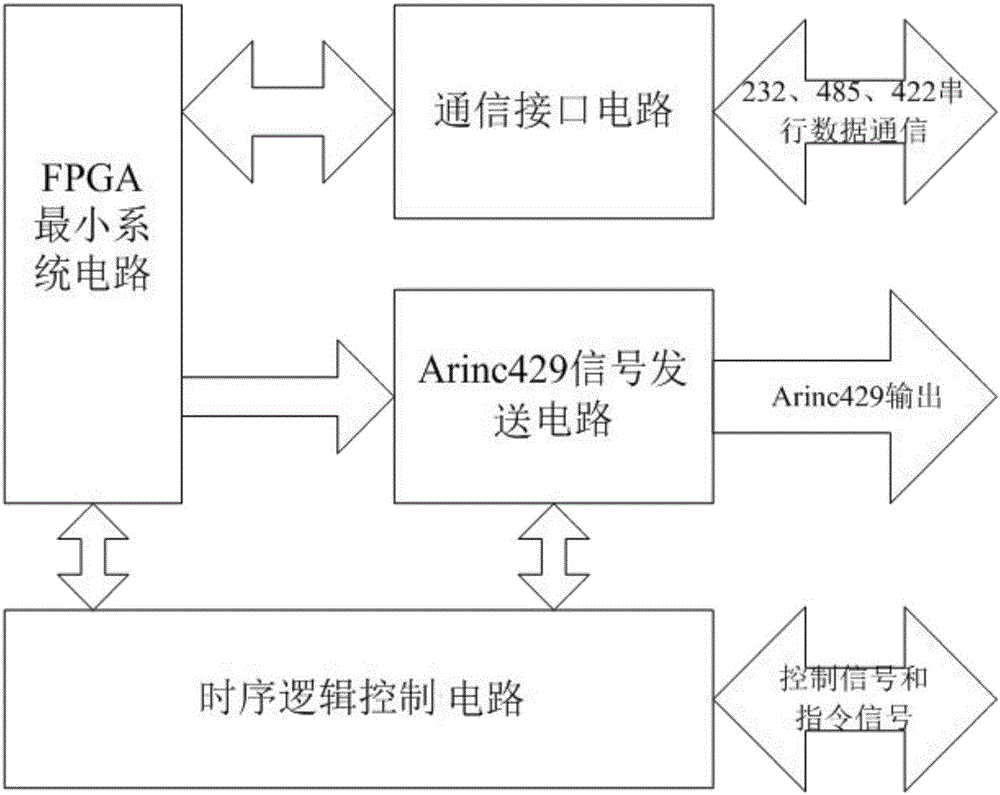

Testing system for aiming at 80C186 architecture interface board

InactiveCN106094795ARealize fault locationShorten the repair cycleProgramme controlElectric testing/monitoringCommunication interfacePhase locked loop circuit

The invention relates to a testing system for aiming at an 80C186 architecture interface board. The testing system comprises an FPGA least system circuit, a communication interface circuit, an Arinc429 signal transmitting circuit and a sequential logic control circuit. The FPGA least system is mainly composed of seven small parts, namely a clock input circuit, a resetting input circuit, a JTAG interface circuit, a program configuring circuit, a voltage supply circuit, a phase-locked loop circuit and an indicating lamp circuit. In the communication interface circuit, because a hardware language in which a serial-port communication protocol can be built is utilized on the FPGA, a corresponding adapter interface chip is utilized for RS232, RS422 and RS485 interface communication in the communication interface circuit. The testing system can supply a testing facility and a testing method for interface board testing of the 80C186 processor architecture board, thereby realizing quick product fault positioning, shortening mending period and ensuring high product quality.

Owner:国营芜湖机械厂

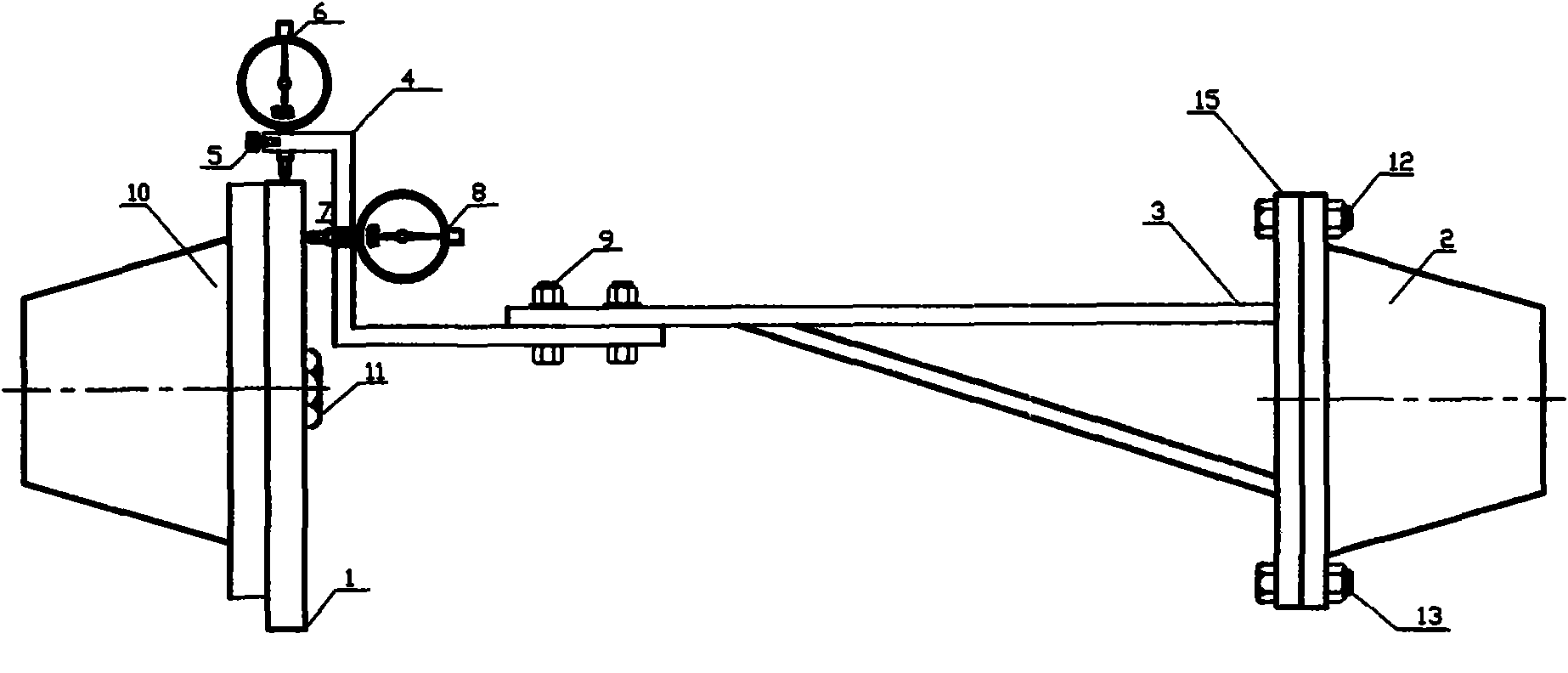

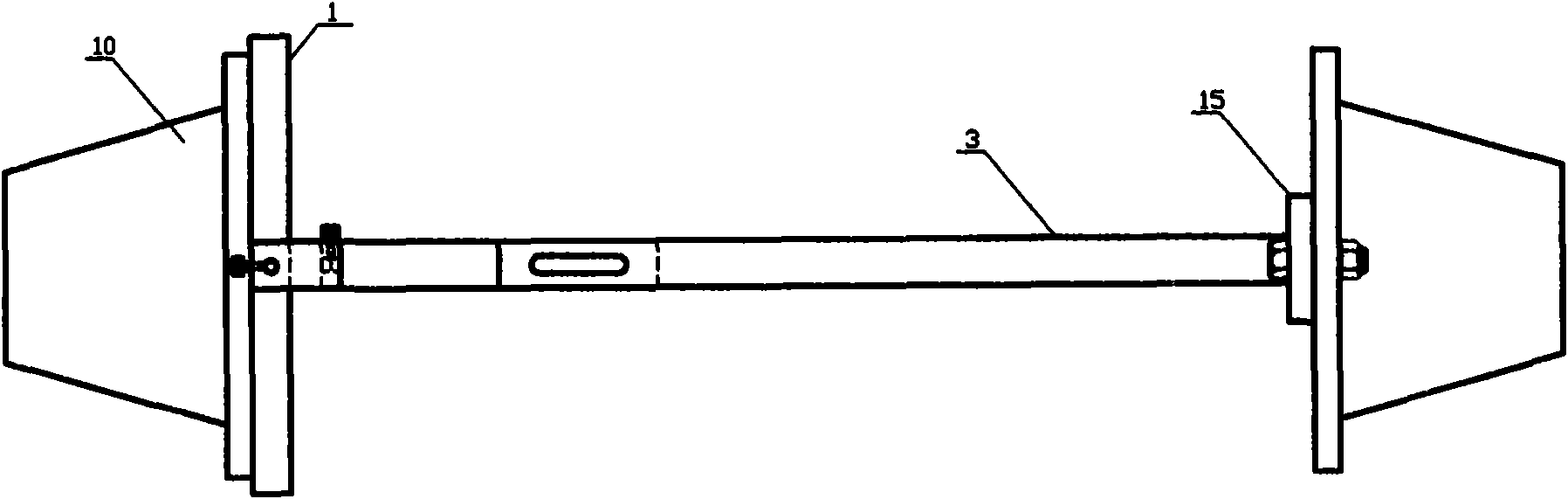

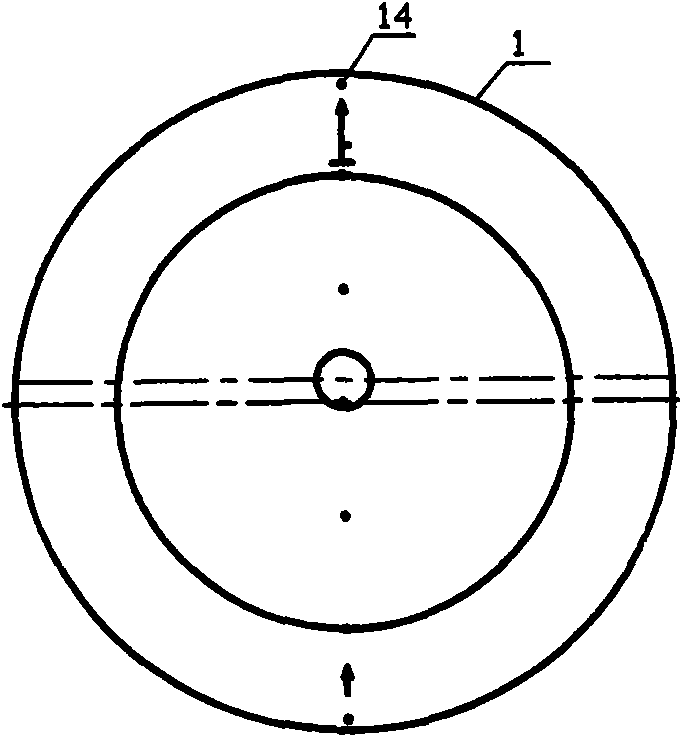

Diesel locomotive starting gear box antiregulation device

InactiveCN101863267AShorten the repair cycleHigh measurement accuracyVehicle servicing/repairingPositional TechniqueDiesel locomotive

The invention discloses a diesel locomotive starting gear box antiregulation device, belonging to the technical field of starting gear box location in the process of repairing locomotives, which mainly solves the time-consuming and laboursome problems existing in the original method. The antiregulation device is mainly characterized by comprising an eccentric technical flange connected with an output flange of a diesel locomotive diesel engine, an antiregualtion device seat connected with a B-type diesel locomotive starting gear box flange, an antiregulation device bracket, a dialgage frame, a radial dialgage and an axial dialgage, wherein, one end of the antiregulation device bracket is fixed on the antiregulation device seat, and the other end is fixedly connected with the dialgage frame through a connection groove, a fixed regulation screw and the connection groove on the dialgage frame; the dialgage frame is in an orthogonal Z shape; and the radial dialgage and the axial dialgage are fixed on the dialgage frame in a right angle. The antiregualtion device has the characteristics of reducing staff labor intensity, improving work efficiency, shorting repairing cycle of locomotives and having high measuring precision, and is mainly used for starting gear box location when the locomotive is repaired.

Owner:南车襄樊机车有限公司

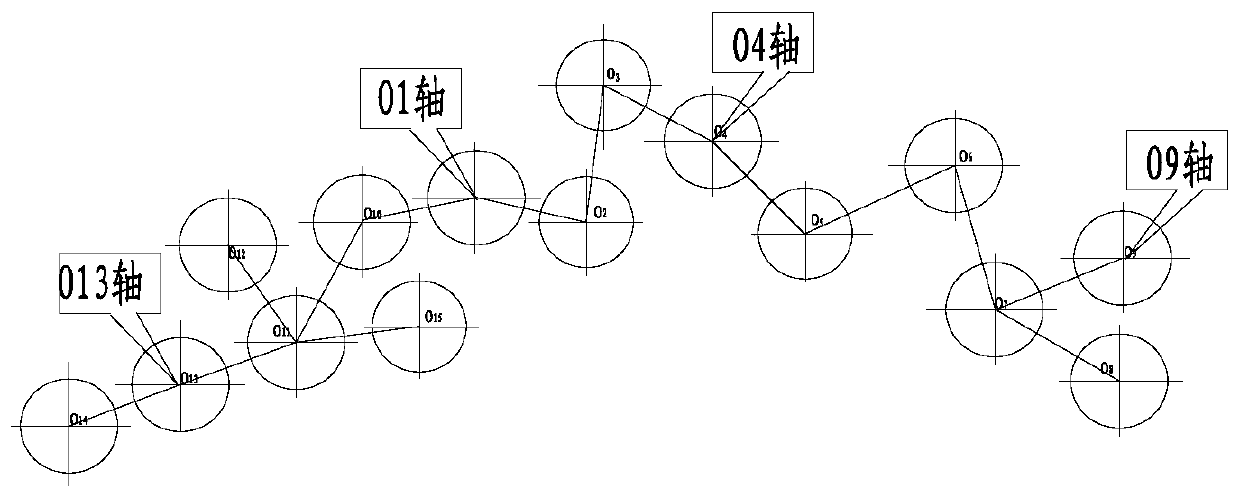

Method for repairing aviation weak-rigidity casing

The invention belongs to a casing repairing method, and particularly relates to a method for repairing an aviation slender thin-wall weak-rigidity casing. The method comprises the following steps thatfirstly, each hole system of the casing is measured by using three coordinates, a shaft system with an external spigot is used as a reference, the holes of other shaft systems on a main shell body ofthe casing is aligned through the coordinates, after the main shell body of the casing is repaired, the main shell body of the casing is taken as a reference, and the holes in a matched shell body ofthe casing is aligned to be repaired. According to the method, the alignment accuracy is effectively improved by means of position alignment, and the specific operation is cured, so that the repairing period of the shell body is shortened and fixed, the production rhythm arrangement is facilitated, and the waste of the time cost is reduced.

Owner:HARBIN DONGAN ENGINE GRP

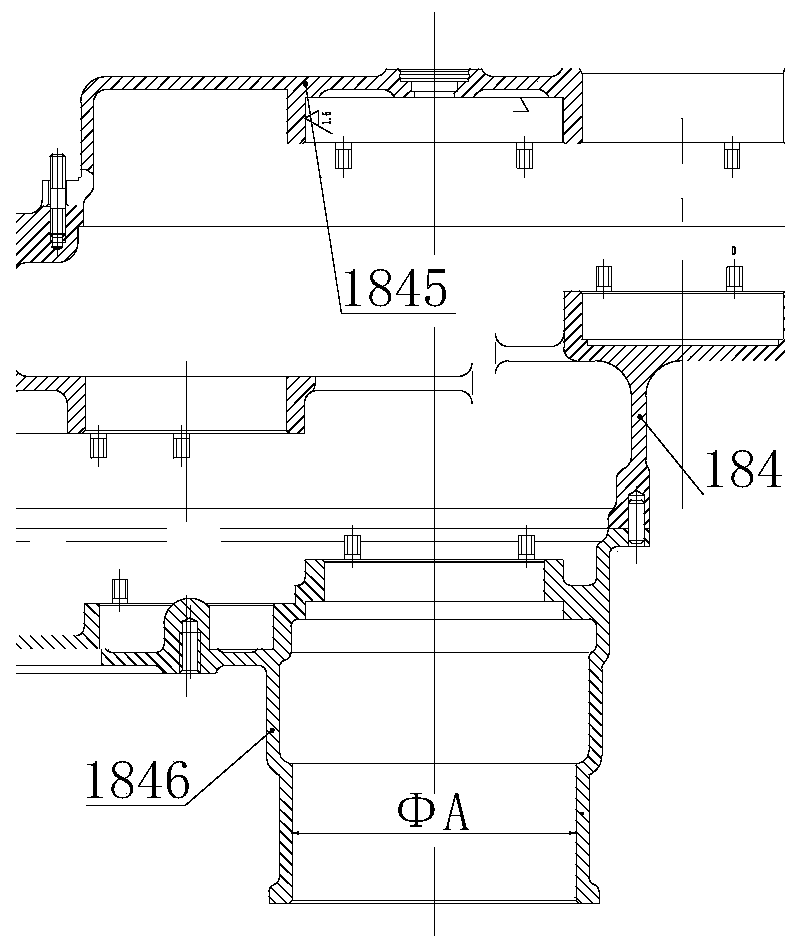

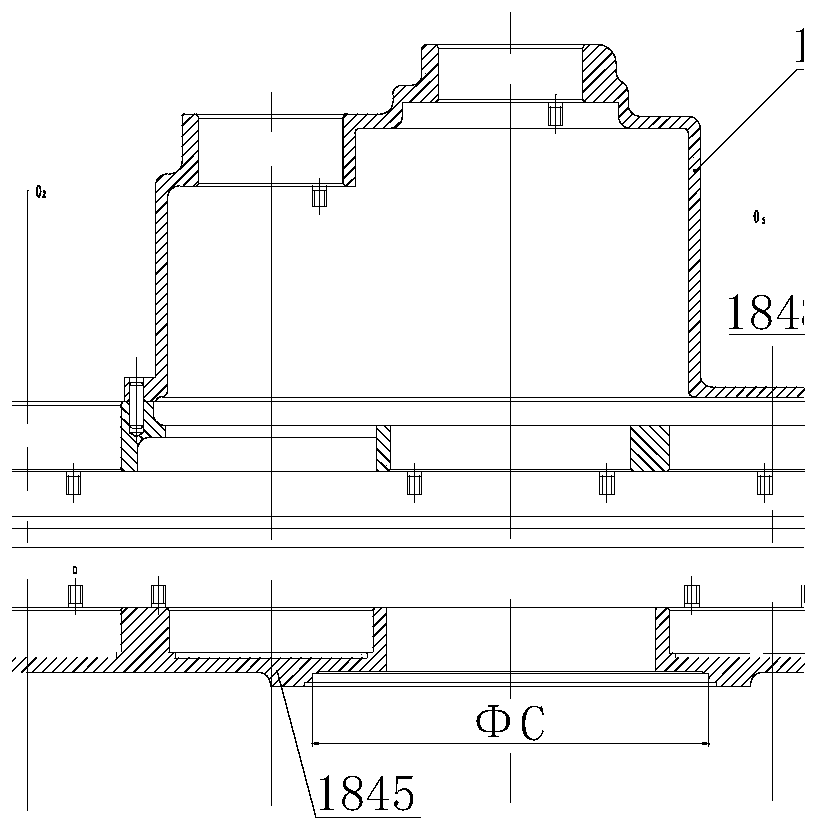

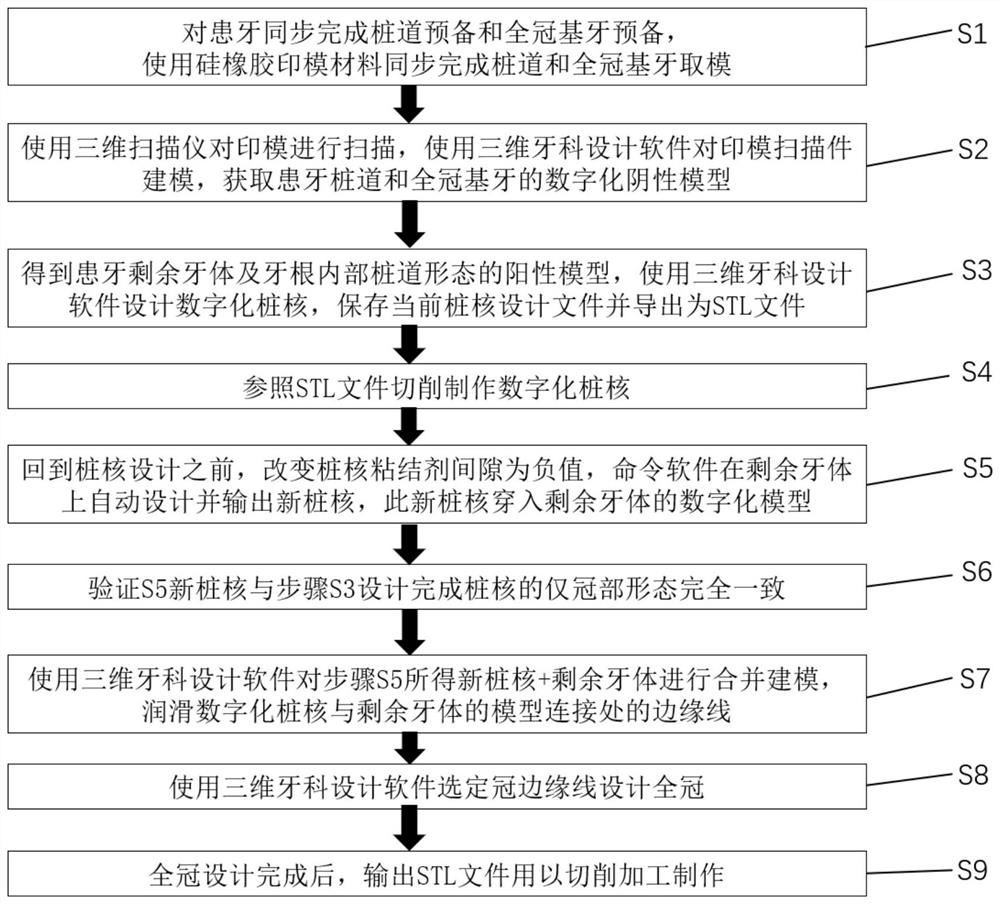

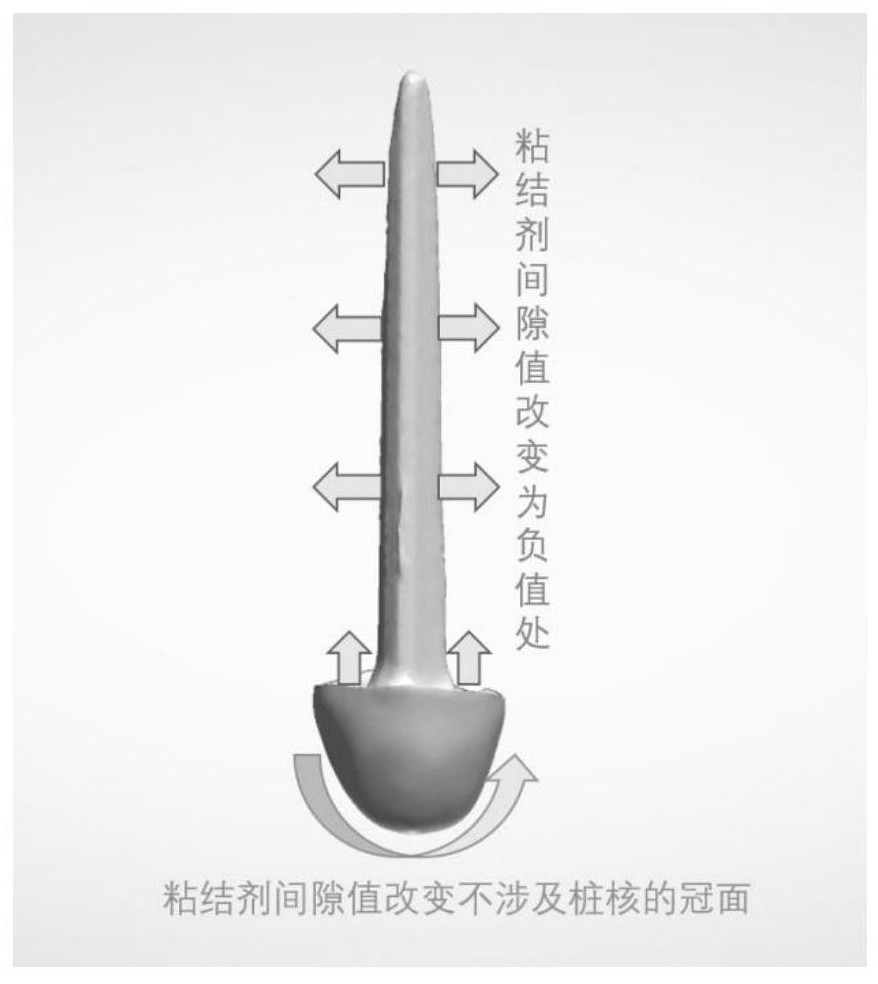

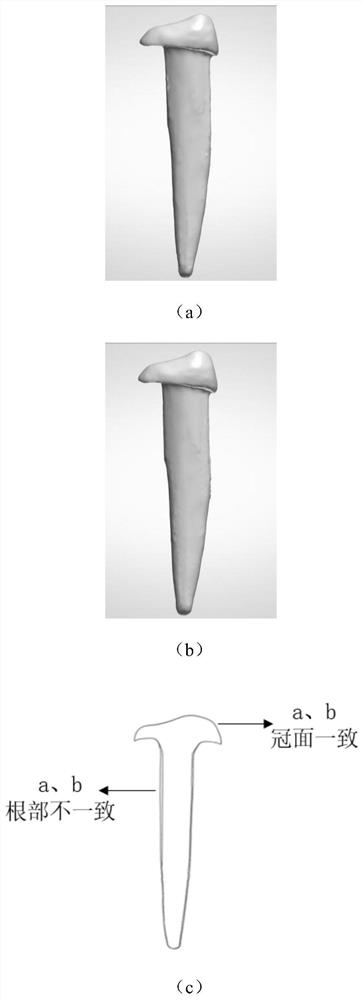

Full-digital design method for synchronously designing tooth pile core and crown by computer

ActiveCN113813057ASimultaneous Design ImplementationOvercoming a Synchronous Design Post-CoreTooth crownsTeeth cappingSoftware engineeringStructural engineering

The invention provides a full-digital design method for synchronously designing a tooth pile core and a crown by a computer. The method comprises the following steps of: synchronously completing pile path preparation and full-crown abutment tooth preparation for an affected tooth to obtain a silicone rubber impression including the pile path of the affected tooth and the full-crown abutment tooth form; modeling an impression scanning piece; designing a personalized pile core, and cutting and manufacturing a digital pile core by referring to an STL file; changing the gap of the pile core binder to a negative value at the beginning of the pile core design, so that the designed and output new pile core can smoothly penetrate into the digital model of the remaining tooth body, thereby fitting the new pile core and the remaining tooth body into a whole; and designing a full crown to achieve full-digital synchronous design of tooth pile cores and crowns. According to the method, the full crown can be immediately designed on the basis of the digital pile core after the digital pile core is designed by the computer, the pile core, the tooth body and the full crown are tightly combined at the computer level, the defects of an existing digital pile core technology are overcome, and the purposes of optimizing design steps, shortening the pile core and crown repair period of a patient and simplifying the manufacturing process of a technician are achieved.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

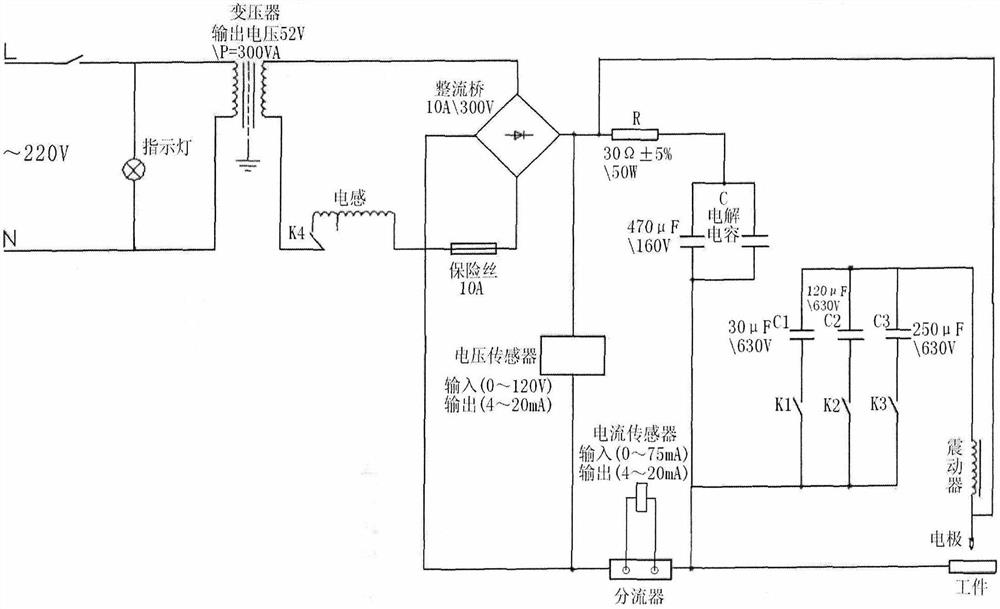

A method and device for electro-spark bronze plating on the surface of aircraft metal parts

ActiveCN113068437BImprove surface propertiesExtend your lifeMetallic material coating processesEvaporationEngineering

The invention discloses a method and a device for electro-spark bronze plating on the surface of aircraft metal parts. The electrodes of the device vibrate by means of a vibrator to periodically connect and disconnect the circuit, and instantaneously form sparks of instantaneous thermal pulse discharge on the surface of the metal workpiece. , so that the contact part of the electrode material is melted, boiled and evaporated. This method uses different power, vibration frequency, and amplitude for electro-spark bronze plating. The end surface of the electrode material contacts the workpiece surface and swings to both sides to make a uniform movement back and forth, so that the surface layer of the workpiece alloying. The invention solves the problem that the traditional electric spark strengthening has a large thermal impact on the workpiece substrate and the hardness drops significantly, and at the same time it cannot meet the use requirements that there should be gaps on the coating surface, improves the wear resistance and scratch resistance of the surface, and breaks through the constraints The technical bottleneck of surface alloying repair of aircraft overhaul metal parts.

Owner:国营芜湖机械厂

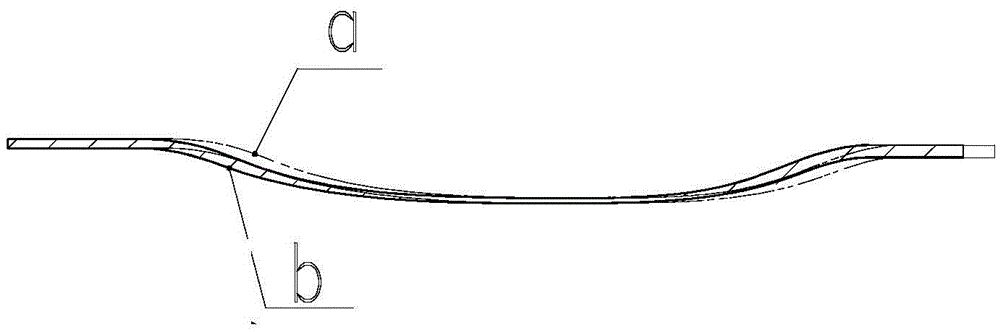

Method for preventing paint cracking on surface of transition region between composite material paddle and metal part

The invention belongs to the field of manufacturing of composite material blades, in particular to a method for preventing paint cracking on the surface of a transition area between a composite material paddle and a metal part. The surface of the composite material paddle needs to be provided with different metal parts in a glued mode, the deformation amount of the metal part is different from that of the composite material in the flying process, so that the appearance and the quality of the blade of the composite material are influenced due to the fact that cracks are easily generated on thepaint surface of the transition area. According to the method for preventing paint cracking on the surface of the transition region between the composite material paddle and the metal part, the surface treatment is carried out on the transition area before paint spraying, the rough grinding is carried out on the part of the transition area, and the cleaning and airing are carried out; the bottom glue is sprayed and aired; the glass cloth is cut and is glued and soaked, the glass cloth is laid in the transition area, and a vacuum bag is manufactured for vacuumizing and pressing; the surface ofthe vacuum bag is cleaned after solidified; and the method for preventing paint cracking on the surface of the transition region between the composite material paddle and the metal part is safe and reliable in quality, simple and convenient to operate and capable of reducing the maintenance cost, so that the repairing period of the surface cracks of the blade metal part is shortened.

Owner:JIANGXI CHANGHE AVIATION IND

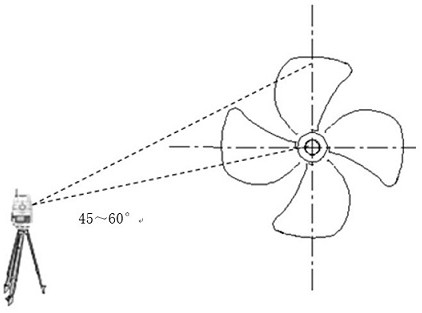

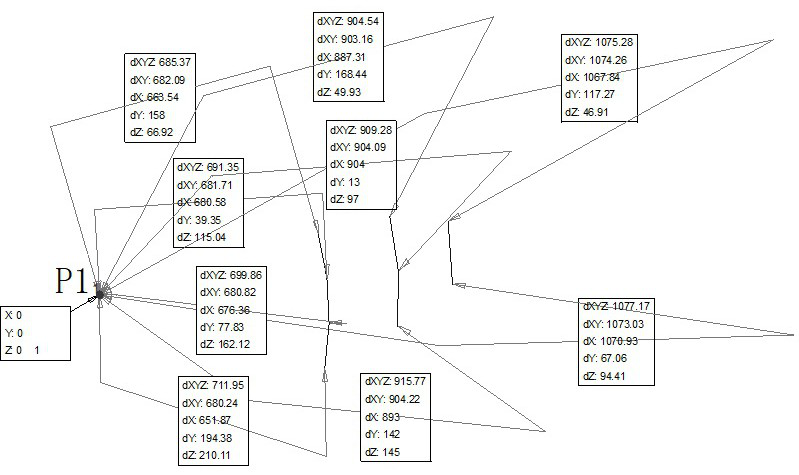

Propeller pitch three-dimensional measurement process method

ActiveCN112504151AAchieve high-precision pitch measurementReduce measurement outsourcing costsUsing optical meansThree dimensional measurementStructural engineering

The invention discloses a propeller pitch three-dimensional measurement process method. The method comprises the following steps of A, surveying and marking a straight line on a platform, B, vertically placing a propeller in the center area of the straight line, C, marking out radiation included angles at different radiuses of each blade by utilizing pitch gauge survey and marking the radiation included angles, D, erecting a total station, collecting head and tail end points of a surveyed straight line, and establishing a space coordinate system, E, measuring the circle center space position of the upper end surface of the propeller hub as a pitch measurement reference, F, pasting a reflector plate at the position of the measuring point, and sequentially measuring the three-coordinate dataof the radiation included angle at different radiuses of each blade, which is firstly surveyed and marked by a pitch gauge, G, correcting the identification survey and marking precision, H, measuringthe spatial position of the radiation included angle identification at different radiuses of each blade, and I, calculating the local pitch and the section pitch of the propeller. High-precision pitch measurement of the fixed pitch propeller, the variable pitch propeller and the adjustable pitch propeller can be realized, the outsourcing cost of shipyard propeller pitch measurement is reduced, the ship repair period is shortened, and the working efficiency is remarkably improved.

Owner:大连辽南船厂

Welding-fixing device for circular connectors

PendingCN111069833ASatisfy the needs of welding fixation and stabilitySimple structureWelding/cutting auxillary devicesAuxillary welding devicesScrew threadElectric cables

The invention discloses a welding-fixing device for circular connectors. The welding-fixing device for the circular connectors comprises a fixed rod, a rotary sleeve, an installation support, an adapting support, a right-angled sectional material fixing block A, a right-angled sectional material fixing block B and a right-angled sectional material fixing block C, wherein the rotary sleeve is installed on the outer circumferential surface of the fixed rod in a sleeved manner, and capable of moving up and down along the axis of the fixed rod and rotating around the axis of the fixed rod; the endA of the installation support is installed on the rotary sleeve through a bolt, and one circular connector to be welded is placed in a V-shaped structure of the installation support; a locking screwA penetrates through the end B of the installation support and is matched with a thread hole C in the end B, and then the tail end of the locking screw A abuts against the outer circumferential surface of the circular connector; and the welding-fixing device for the circular connectors needs to be fixed to a right-angled sectional material on an aircraft. The welding-fixing device for the circularconnectors is capable of carrying out multi-angle and multi-dimensional fixing on the circular connectors with different diameters, and then welding with cables with different lengths in an equipmentcabin.

Owner:大连长丰实业总公司

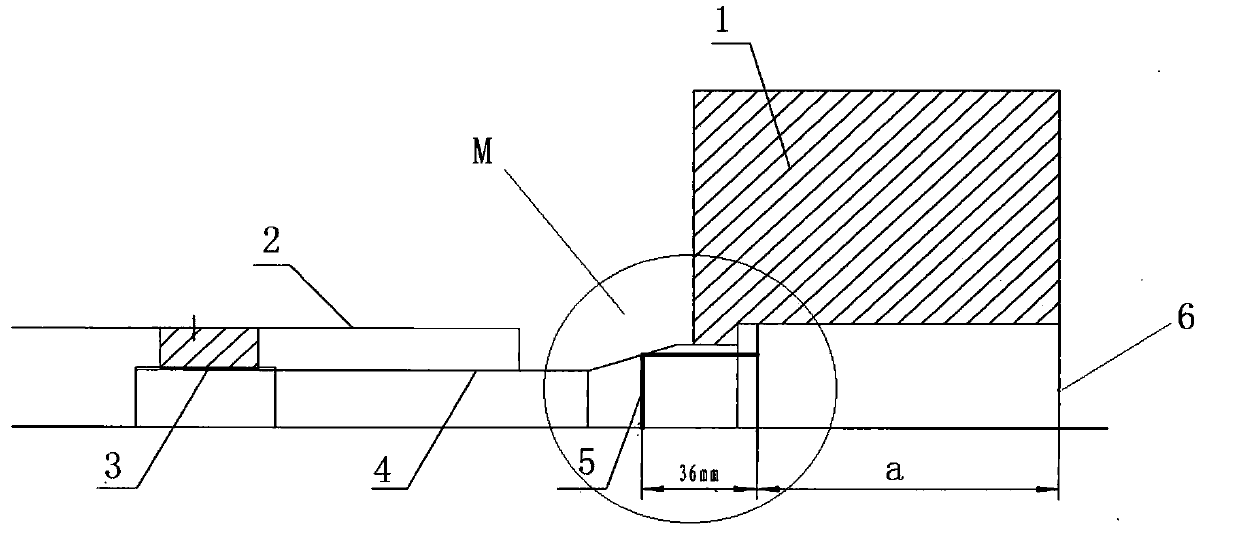

Movable automatic lifting flexible docking block unit for ship

ActiveCN112606972AMeet the needs of useRealize switchingDry-dockingSlipwaysMarine engineeringSteel tube

The invention discloses a movable automatic lifting flexible docking block unit for ship. The unit is characterized in that a sleeve is arranged in a box body, a strong spring is installed in a steel pipe sleeve, the top end of the strong spring is connected with a transition iron column, and a movable iron bolt is welded with a supporting plate into a whole and connected with the top of the transition iron column to form a movable supporting tray; a rubber pad is arranged on the upper surface of the movable supporting tray; iron weight trays are symmetrically arranged on the transition iron column; a sliding mechanism is arranged outside the bottom of the box body and a pulley is in contact with the rail; and transverse rails are erected on the longitudinal rails, and the longitudinal rails are directly installed and fixed to the dock ground. Ship docking and switching of different docking schemes are achieved by adjusting the positions of the transverse rails and the flexible docking block units, automatic stretching of the strong springs, automatic rotation of the movable supporting plate and adding of heavy objects to the weight iron bracket, adjustment such as manual adding of wooden base plates is not needed, and therefore the working efficiency is improved, shipyard expenditure is saved, and resource waste is reduced.

Owner:CHINA SHIP DEV & DESIGN CENT

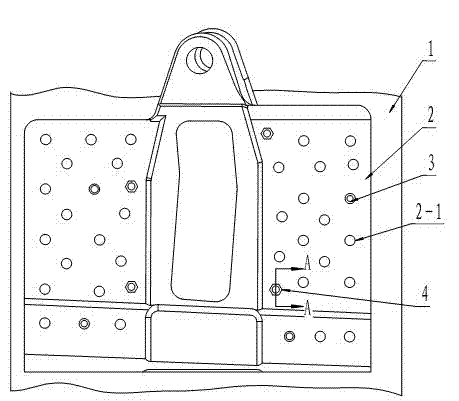

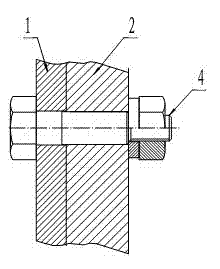

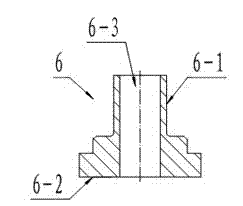

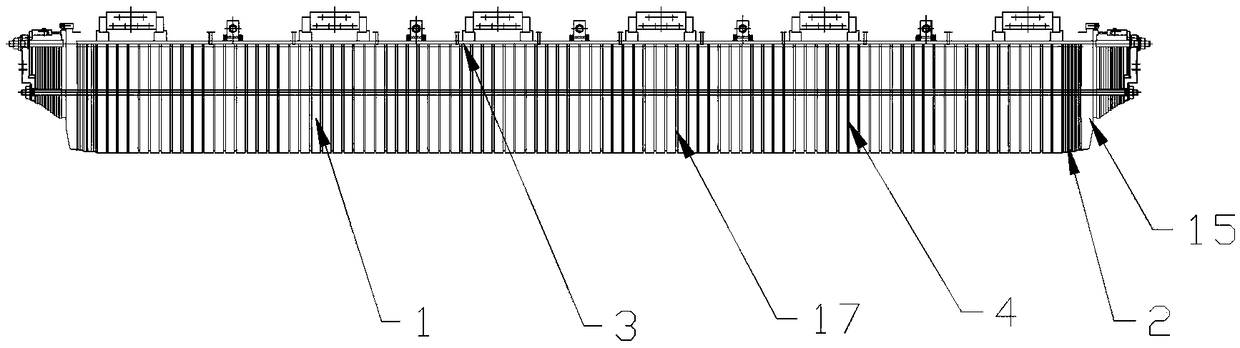

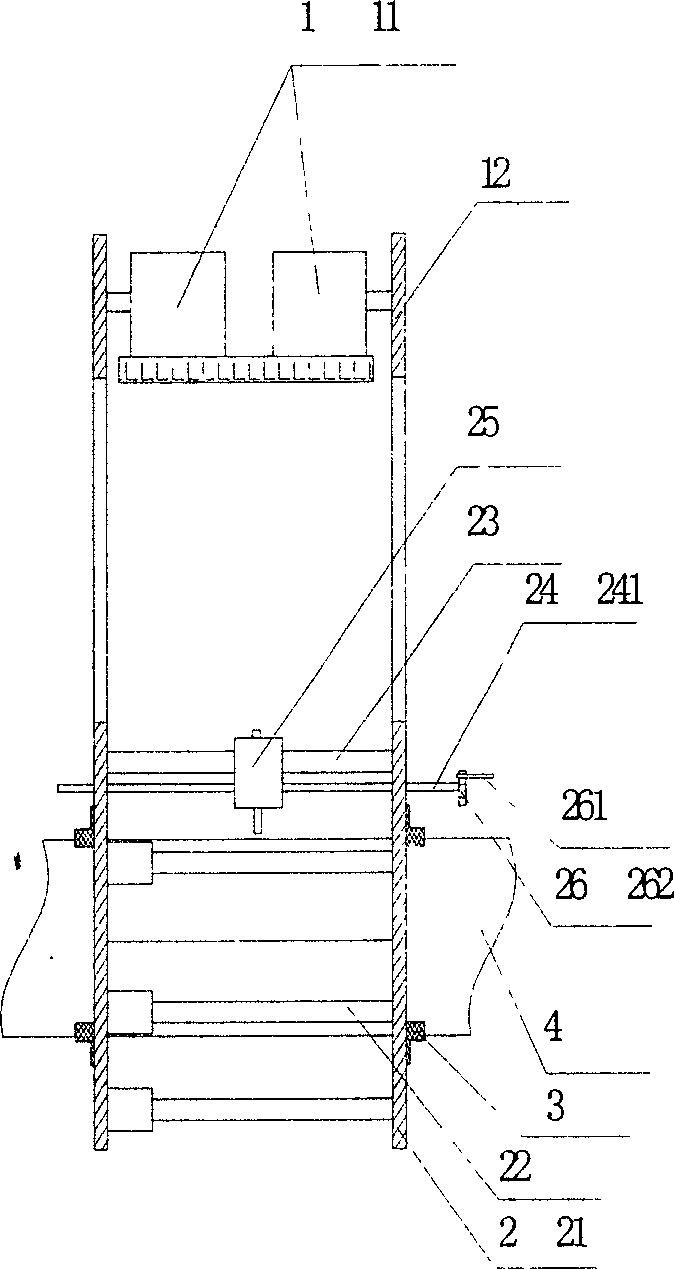

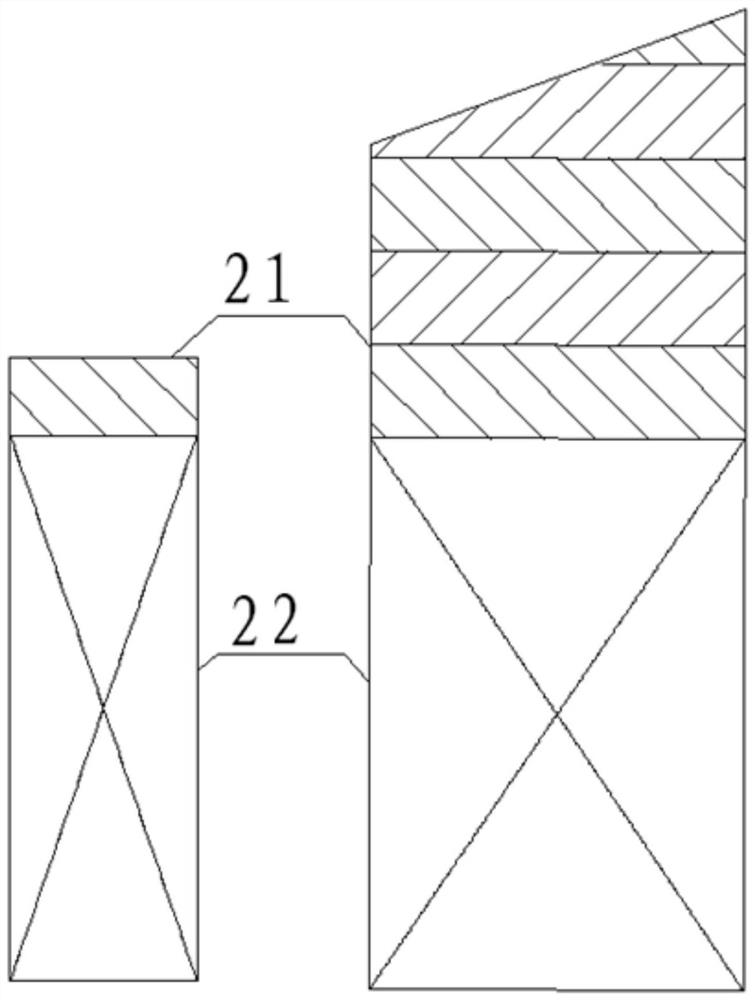

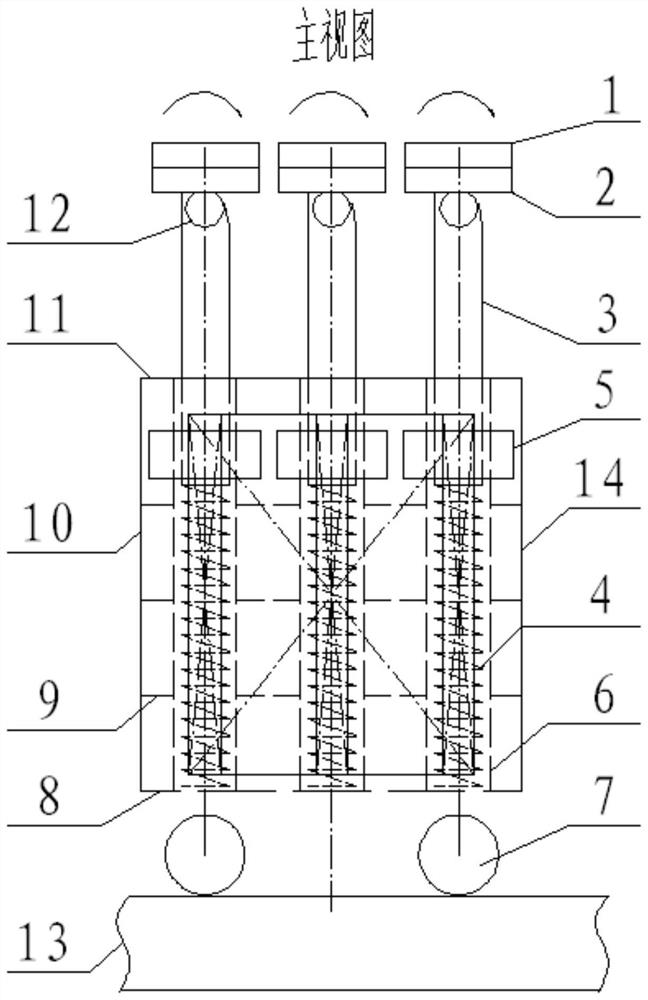

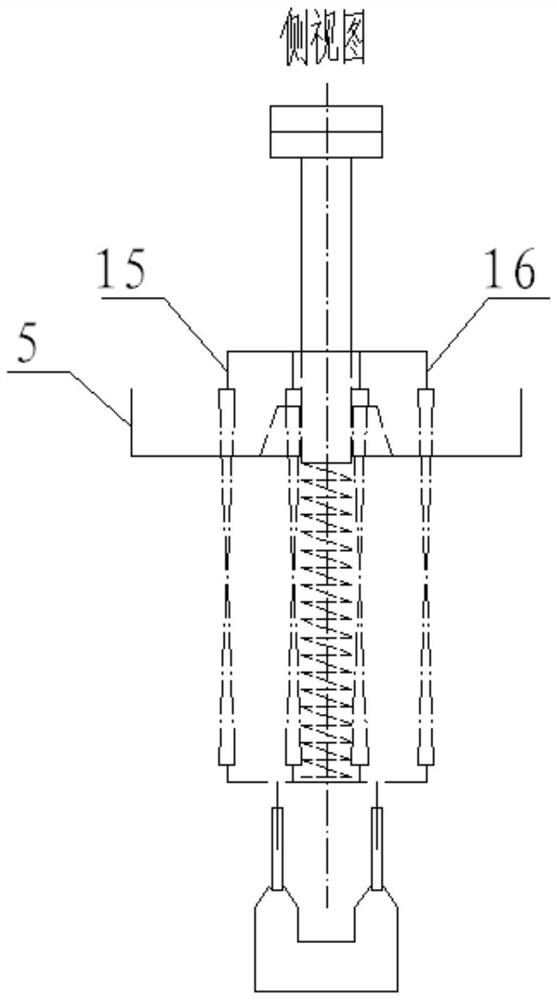

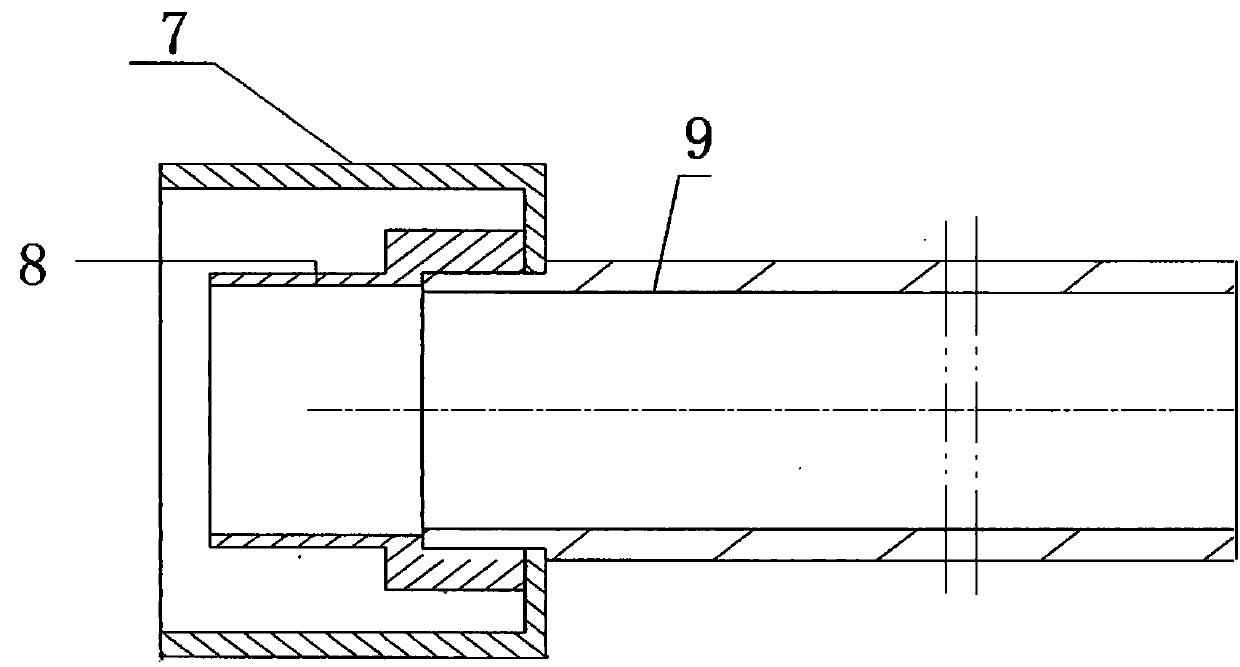

Repairing device for shaft end of large gear shaft

The invention discloses a repairing device for a shaft end of a large gear shaft; the repairing device comprises a bearing platform, a locking device and a transmission device, wherein the bearing platform comprises a chassis as well as wheels and hydraulic support legs, and the wheels and the hydraulic support legs are arranged below the chassis; the transmission device is arranged on the upper surface of the chassis; the locking device comprises a top frame, one end of the top frame is detachably and fixedly arranged on the bearing platform or detachably and fixedly arranged at the top of atransmission gear box of a transmission arranged on the chassis, and the other end of the top frame is detachably fixed on an action object; and the transmission device comprises a motor and a changespeed gear box which are arranged on the bearing platform as well as a processing element rotating shaft driven by the motor and the change speed gear box, and the processing element rotating shaft isprovided with a shaft end processing device. Without returning to the factory and transshipment, the repairing efficiency is improved, the repairing cycle is shortened and cost is reduced; and compared with manual repair, improvement of the repairing quality and quality consistency can be guaranteed to a certain extent.

Owner:常州市醇通机械科技有限公司

Preparation method and application of biochar for soil remediation

InactiveCN112707759AShorten heating timeShort reaction timeCarbon preparation/purificationFertilizer mixturesBiomassEnvironmental chemistry

The invention belongs to the technical field of biochar preparation and application, and particularly relates to a preparation method and application of biochar for soil remediation. Biomass powder is heated twice. The biomass powder can be preheated through primary heating, the yield of biochar can be increased through a slow heating mode, and meanwhile, the yield of gas is reduced. A microwave thermal cracking method is adopted for secondary heating, it can be guaranteed that the biomass powder is heated in an internal and external balanced mode in the reaction process, the heating time is shortened, materials are not limited, secondary heating reaction can be carried out on components in the biomass powder after primary heating is completed, and the yield of the biochar after primary heating is improved again. The reaction time is short, the reaction temperature is divided into two stages, namely slow heating and rapid constant-temperature heating, the yield of the biochar is increased, and the processing cost is reduced. Animal waste and an oxidizing agent are added on the basis of the biochar material, so that the efficacy of the biochar agent is improved.

Owner:昂骏环境科技(上海)有限公司

Scratch mask repairing device and method

ActiveCN103969945BTimely and fast repairDoes not affect production capacityPhotomechanical exposure apparatusMicrolithography exposure apparatusMechanical engineeringPhotolithography

The present invention discloses a scratched mask repair apparatus and a method. The apparatus comprises a bracket device, a defect detection device and a repair module, wherein the bracket device is arranged in a photolithography machine chamber, the defect detection device and the repair module are arranged on the bracket device, and the repair module comprises a plurality of repair refills with different sizes. According to the present invention, the bracket device of the scratched mask repair apparatus is directly arranged in the photolithography machine chamber, and can timely and rapidly perform repair in the photolithography machine during mask scratching without influence on productivity of the photolithography machine, such that the function of the photolithography machine is complete, the automation degree of the photolithography machine is high, the mask repair can be directly completed in the photolithography machine, and the internal space of the photolithography machine is completely utilized so as to substantially shorten the repair period and provide characteristics of simpleness, rapidness, low cost, and no influence on productivity.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

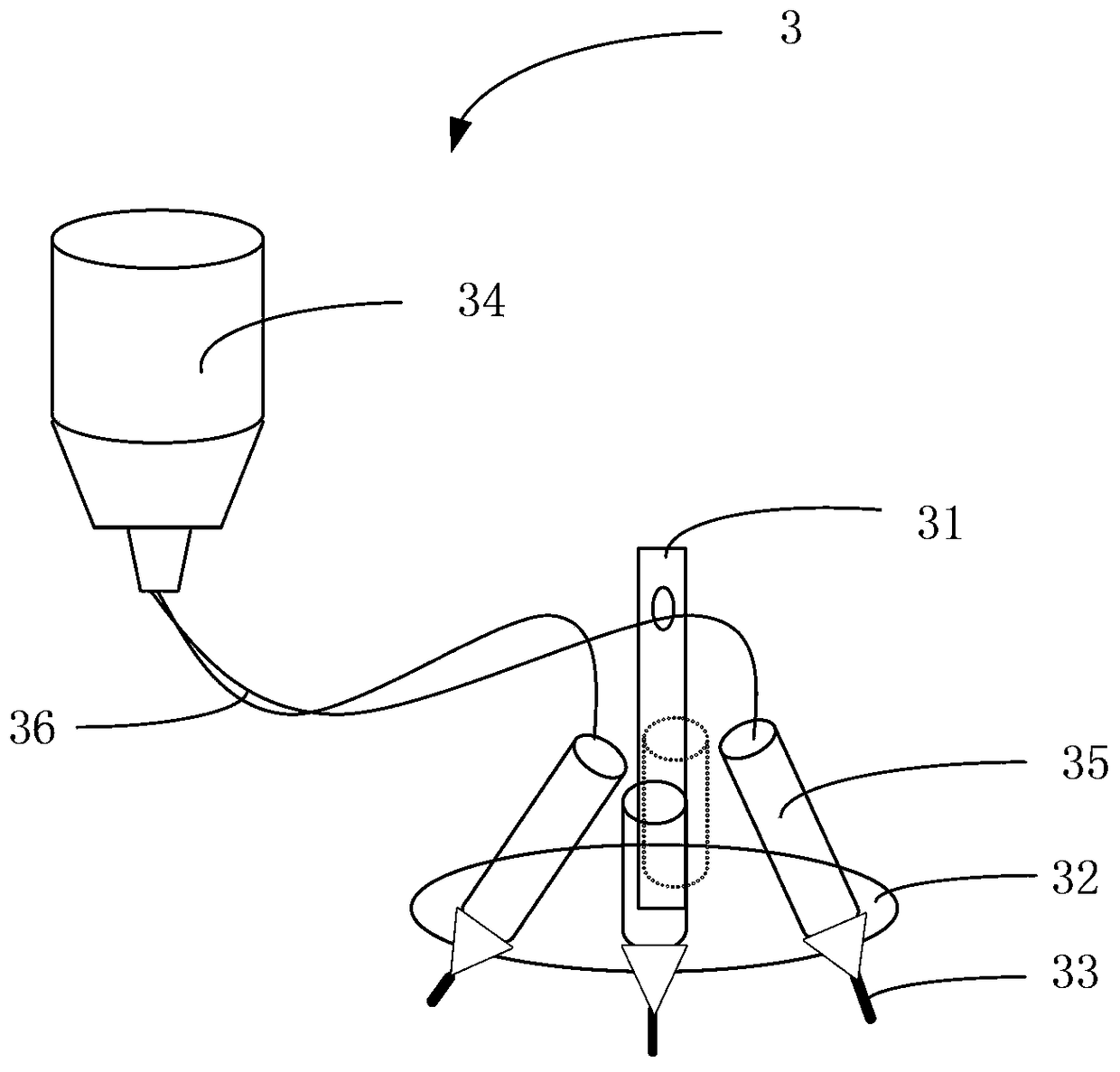

A method for splitting the deep hole in the slender inner cavity of an aero-engine

ActiveCN105458648BDecomposition failure is inevitableShorten the repair cycleMetal working apparatusAviationDecomposition

The invention belongs to the technical field of aircraft engine repairing, and relates to a long and thin inner cavity deep hole splitting method for an aircraft engine. The method comprises the steps that firstly, the axial distance a between a tensioning pipe and the opening end of the air inlet side of an engine low-pressure rotor is measured to serve as the reference size for cutting off the tensioning pipe; the feeding amount is measured through a splitting device, and the splitting depth is calculated; the tool end of the splitting device enters from the engine air inlet side, the feeding amount b of the splitting device is measured, and when the difference between a and b is smaller than or equal to 0.1 mm, contact between a guiding core shaft end of the splitting device and the end face of the tensioning pipe is determined; then, high-temperature alloy deep hole cutting is carried out, the tensioning pipe starts to be split from a boss through the splitting device, and when the outer diameter of the tensioning pipe is equal to the outer diameter of a tool of the splitting device through cutting, in other words, the axial depth is the sum of a and 36 mm, the tensioning pipe is cut off; and a low-pressure unit body and the vortex rotor are split into two main assemblies from the front end and the rear end of a main machine. According to the long and thin inner cavity deep hole splitting method, the repairing cycle is shortened to the maximum degree, the cost is greatly saved, and meanwhile the function of assisting decomposition of the engine is achieved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com