Preparation method and application of biochar for soil remediation

A soil remediation and biochar technology, which is applied in the field of biochar preparation for soil remediation, can solve the problems of long remediation period, low remediation performance, and large dosage, and achieve the advantages of short reaction time, improved remediation performance, and reduced dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

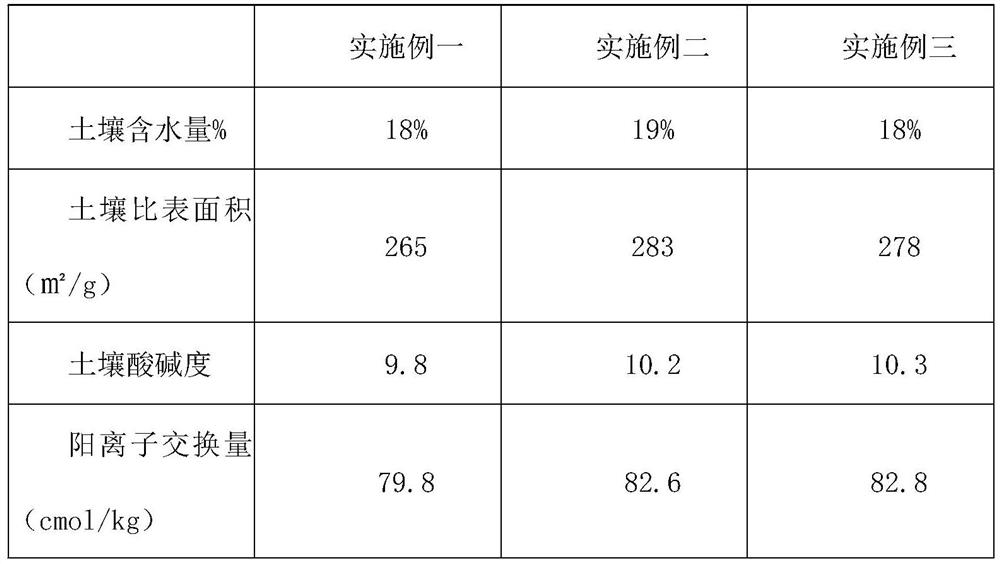

Embodiment 1

[0023] The invention provides a technical solution: a method for preparing biochar for soil remediation, the preparation method comprising the following steps:

[0024] Step 1: After cleaning the biomass raw material, put it into a vacuum drying oven at 40°C for drying. The drying time is 30 minutes. Take out the dried biomass raw material and put it into a pulverizer for crushing and filtering to obtain biomass powder. ;

[0025] Step 2: Put the biomass powder obtained in step 1 into the carbonization furnace, pass protective gas into the carbonization furnace, heat the carbonization furnace with an external heating method, and control the temperature rise of the carbonization furnace at 7 / s The speed is raised to 400°C. When the temperature of the carbonization furnace reaches 400°C, the biomass powder in the carbonization furnace is heated by internal heating, and the heating temperature is controlled at 500°C. The reaction time is 5 hours. After the reaction is completed, ...

Embodiment 2

[0037] A method for preparing biochar for soil restoration, the preparation method comprising the following steps:

[0038] Step 1: After cleaning the biomass raw material, put it into a vacuum drying oven at 40°C for drying. The drying time is 60 minutes. Take out the dried biomass raw material and put it into a pulverizer for pulverization and filtration to obtain biomass powder ;

[0039] Step 2: Put the biomass powder obtained in step 1 into the carbonization furnace, pass protective gas into the carbonization furnace, heat the carbonization furnace with an external heating method, and control the temperature rise of the carbonization furnace at 5 / s The speed is raised to 400°C. When the temperature of the carbonization furnace reaches 400°C, the biomass powder in the carbonization furnace is heated by internal heating, and the heating temperature is controlled at 800°C. The reaction time is 3 hours. After the reaction is completed, cool to Obtain biochar material at room...

Embodiment 3

[0051] A method for preparing biochar for soil restoration, the preparation method comprising the following steps:

[0052] Step 1: After cleaning the biomass raw material, put it into a vacuum drying oven at 40°C for drying. The drying time is 60 minutes. Take out the dried biomass raw material and put it into a pulverizer for pulverization and filtration to obtain biomass powder ;

[0053] Step 2: Put the biomass powder obtained in step 1 into the carbonization furnace, pass protective gas into the carbonization furnace, heat the carbonization furnace with an external heating method, and control the temperature rise of the carbonization furnace at 5 / s The speed is raised to 400°C. When the temperature of the carbonization furnace reaches 400°C, the biomass powder in the carbonization furnace is heated by internal heating, and the heating temperature is controlled at 1000°C. The reaction time is 3 hours. After the reaction is completed, cool to Obtain biochar material at roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com