Reassembly method of high precision porous component

An assembly method and high-precision technology, applied in the field of reassembly of high-precision porous components, can solve problems such as high locking bolt hole position, poor concentricity dimensional accuracy and stability, inability to meet aircraft repair requirements, and bushing fit clearances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

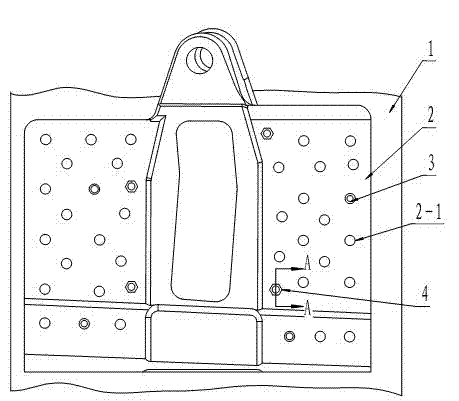

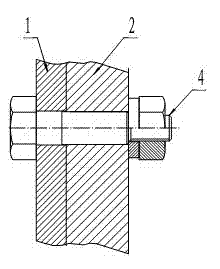

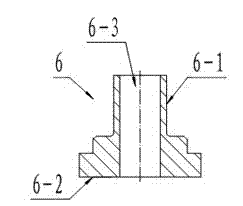

[0023] The high-precision porous member mentioned in the method of the present invention has multiple high-precision bolt holes with high precision requirements, and the reassembly refers to the assembly process of replacing the old high-precision porous member with a new high-precision porous member. The method of the present invention abandons the on-line processing method of all high-lock bolt holes on the new high-precision porous components of the original process, and firstly performs off-position processing of prefabricated holes on the new high-precision porous components, and then fixes the components through positioning, setting the knife with a set, and hole-to-hole precision Reaming and other steps, the prefabricated holes are processed into high-lock bolt holes that can accurately match the original high-lock bolt holes on the assembly base, and then high-lock bolts are driven into each high-lock bolt hole of the high-precision porous component and tightened.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com