Recycled concrete, recycled concrete prefabricated part and preparation method thereof

A technology of recycled concrete and prefabricated components, applied in the field of concrete, can solve the problems of reduced fluidity and workability of concrete, increased water absorption of recycled aggregates, and large loss of concrete slump, so as to improve the loss of large slump and reduce Water absorption and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0041] This preparation example prepared a modified recycled aggregate, the specific method is as follows:

[0042] Pre-treatment: Clean the recycled aggregate, and then dry it naturally until the surface is dry.

[0043] Soaking: Soak the dried recycled aggregate in a sodium carbonate solution with a temperature of 25°C and a concentration of 35wt% for 24 hours.

[0044] Drying: Take the soaked recycled aggregate out of the sodium carbonate solution and dry it under natural conditions to obtain modified recycled aggregate.

preparation example 2-7

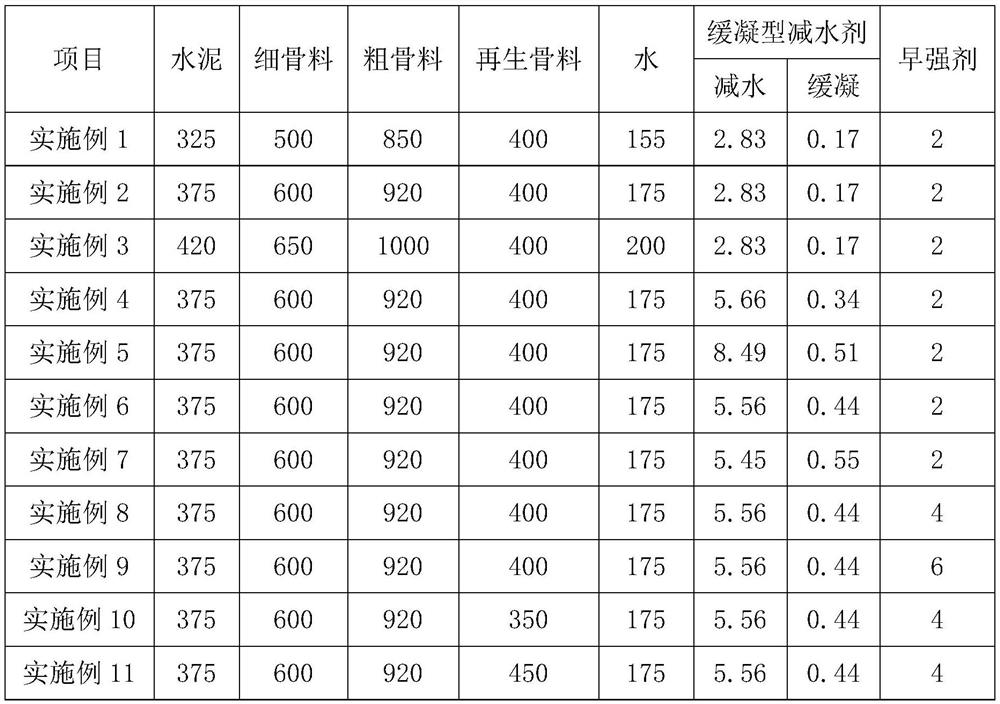

[0046] As shown in Table 1, Preparation Examples 2-7 are basically the same as Preparation Example 1, the main difference is that in the soaking step, the concentration of the sodium carbonate solution used and the soaking time of the recycled aggregate in the sodium carbonate solution are different.

[0047] The control parameter of soaking step in table 1 preparation example 1-7

[0048] project Sodium carbonate concentration / wt% Soaking time / h Preparation Example 1 35 24 Preparation example 2 25 24 Preparation example 3 15 24 Preparation Example 4 5 24 Preparation Example 5 15 36 Preparation Example 6 15 48 Example 7 15 60

preparation example 8

[0050] This preparation example is basically the same as preparation example 6, the main difference is: in the soaking step, the recycled aggregate is soaked in potassium carbonate solution.

[0051] Specifically:

[0052] Pre-treatment: Clean the recycled aggregate, and then dry it naturally until the surface is dry.

[0053]Soaking: Soak the dried recycled aggregate in a potassium carbonate solution with a temperature of 25°C and a concentration of 15wt% for 48 hours.

[0054] Drying: Take the soaked recycled aggregate out of the potassium carbonate solution and dry it under natural conditions to obtain modified recycled aggregate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com