A numerical control machining method for improving the fillet quality of overflow brick weir crest

A processing method and overflow brick technology, applied in the direction of digital control, program control, comprehensive factory control, etc., can solve problems such as delayed production cycle, overflow brick scrapping, and poor quality of the entire overflow block, so as to ensure the production cycle , Eliminate uncontrollable phenomena, and ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

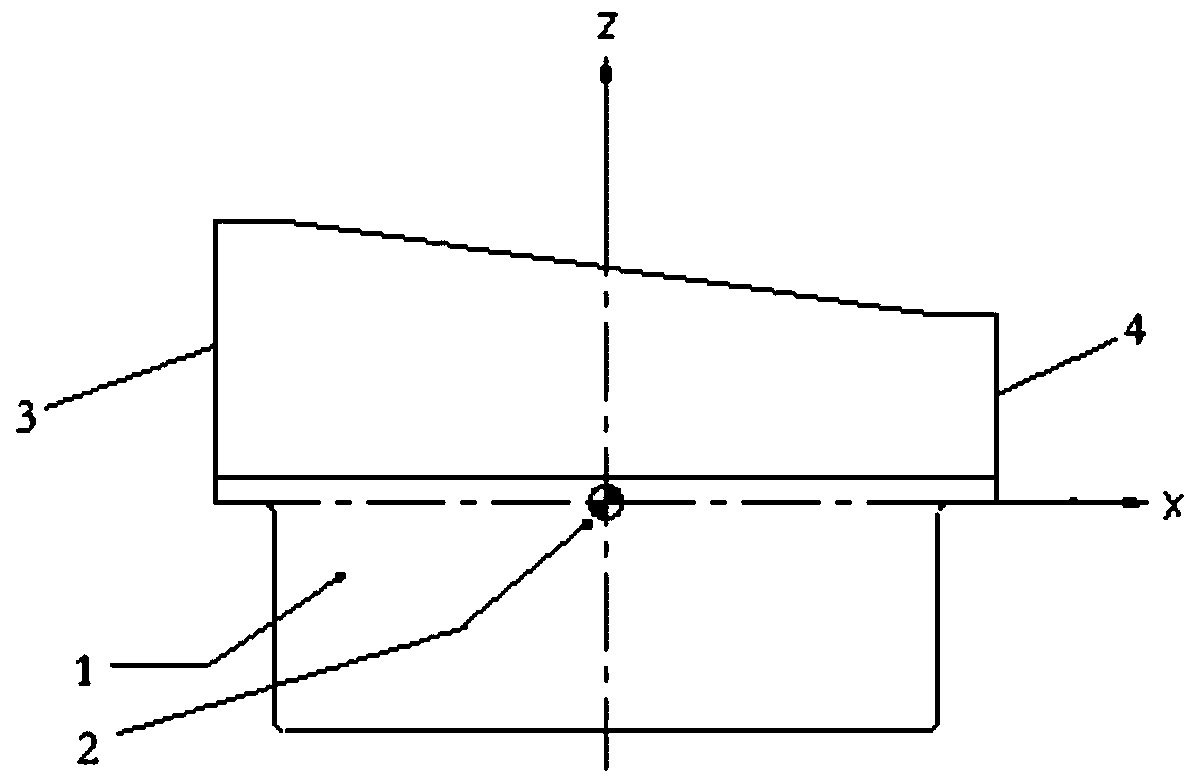

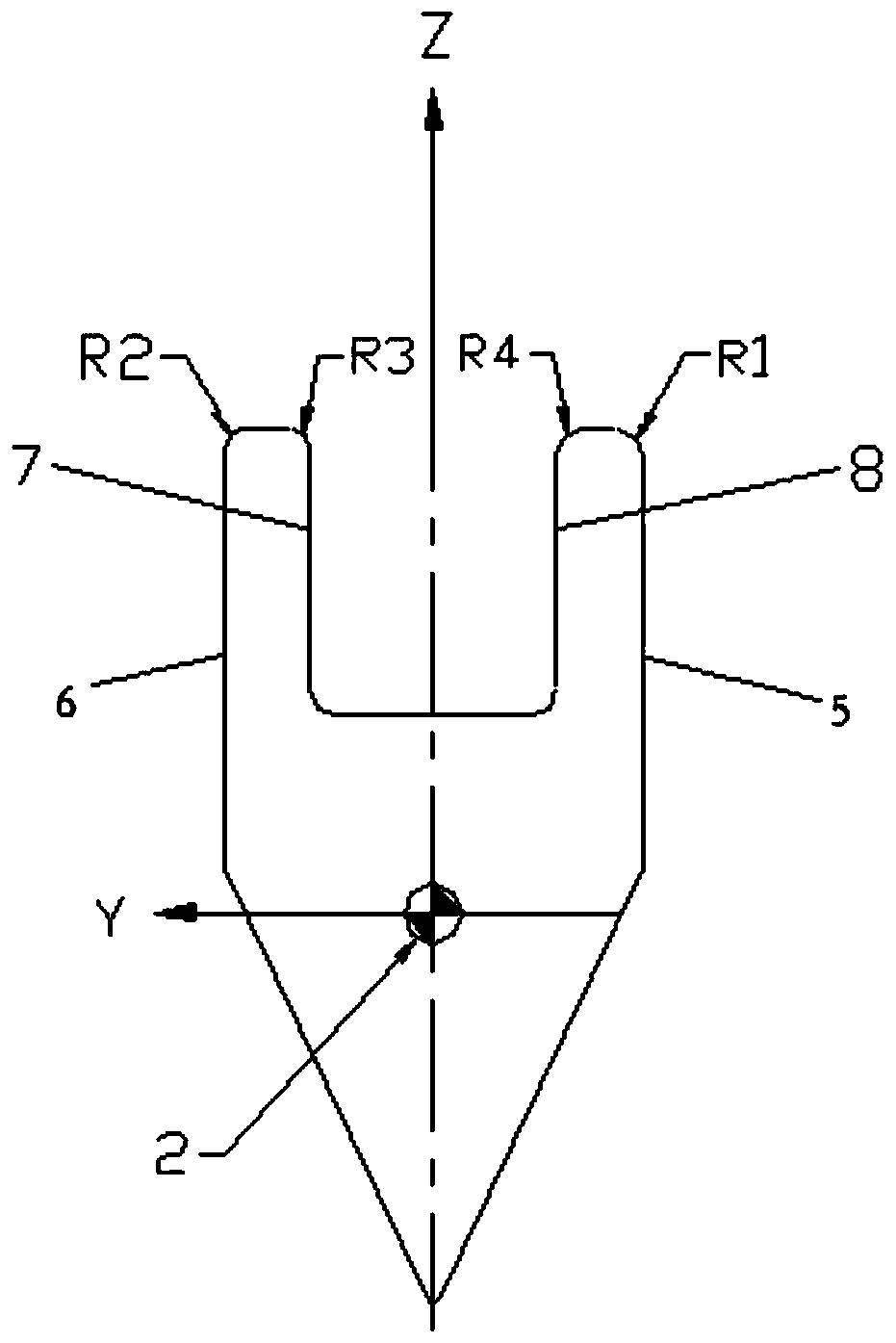

[0022] See figure 1 and figure 2 , the glass liquid overflows from the overflow groove of the overflow brick in the middle of the formed overflow brick 1, climbs over the fillet of the weir top of the overflow brick, flows along the straight overflow surface on both sides of the overflow brick to the inclined overflow surface, and The tips of the flow bricks merge into the substrate glass; the steps at both ends of the size are the reference plane and the support surface in the height direction when the overflow bricks are assembled in the forming furnace. as a height reference.

[0023] see figure 1 , 2, processing method of the present invention comprises the following steps:

[0024] Step 1: Set the length direction of the overflow brick as the X axis, the width direction as the Y axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com