Method for processing trepanning of crankshaft crank red trepanning hole for large-scale ship and special trepanning drill

A technology of nesting drill and crank throw, which is applied in the field of nesting processing and special nesting drill of large-scale marine crankshaft crank red bushing hole, which can solve the difficult processing of the next finishing process, consume a lot of energy, and the next finishing process Process difficulties and other problems, to achieve the effect of improving production and operating efficiency, ensuring product quality, and controlling production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

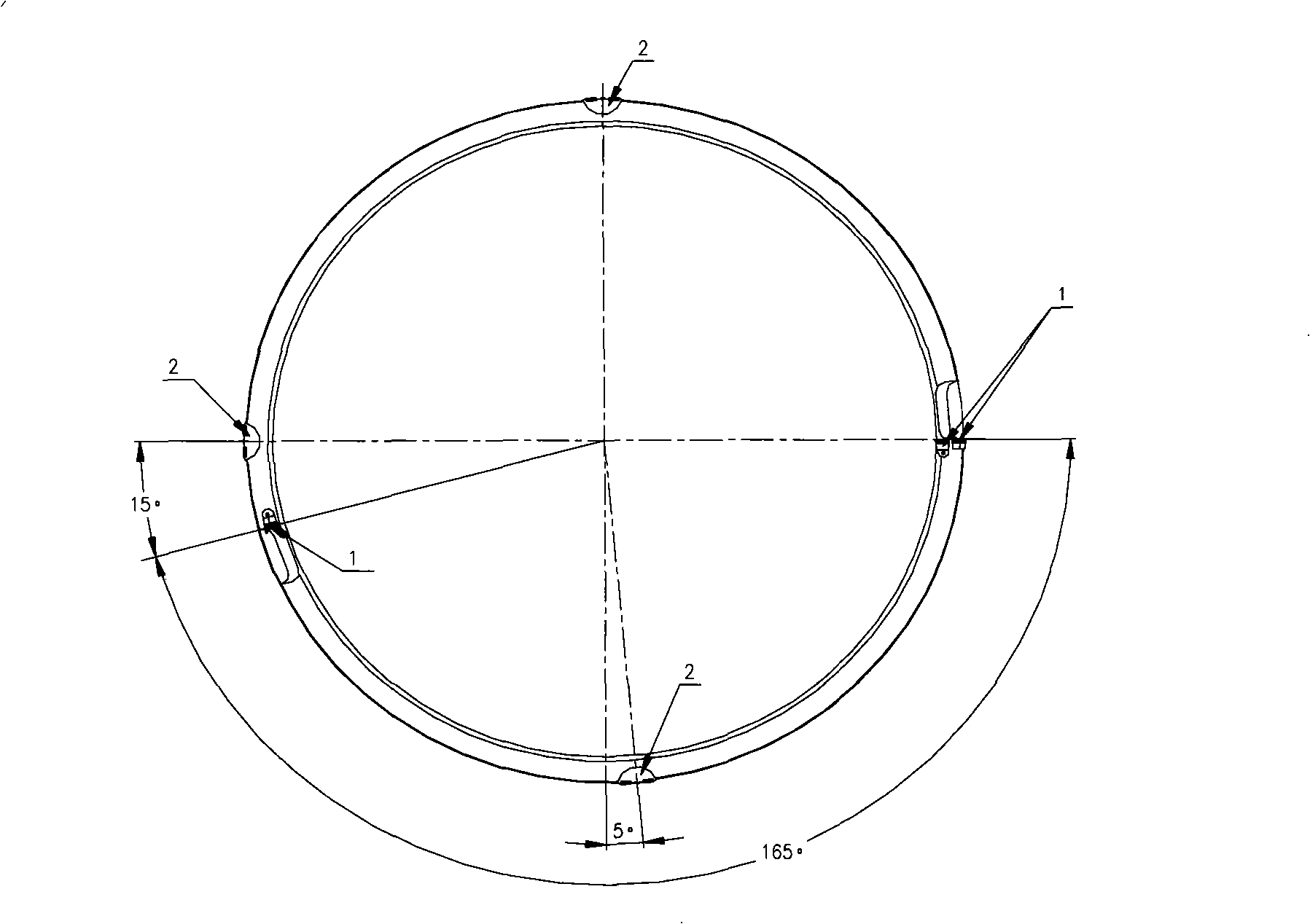

[0024] The large-scale marine crankshaft mentioned in the present invention refers to the marine crankshaft adopted by ships with more than 10,000 tons. The nesting processing of the large-diameter inner hole of the crank throw refers to the processing of the inner hole of Φ708mm or larger (Φindicates the diameter in the field of mechanical processing). For general boring processing, machining the Φ708mm inner hole does not belong to the large diameter inner hole processing, but it is quite large for the nesting processing of the Φ708mm inner hole, so it is called the crank throw "large diameter Inner hole" nesting processing.

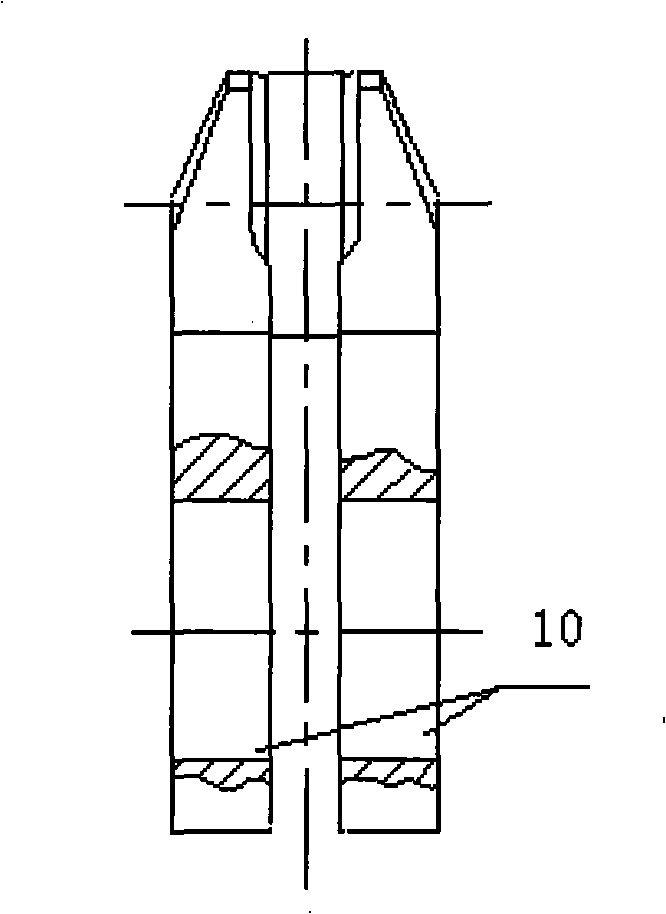

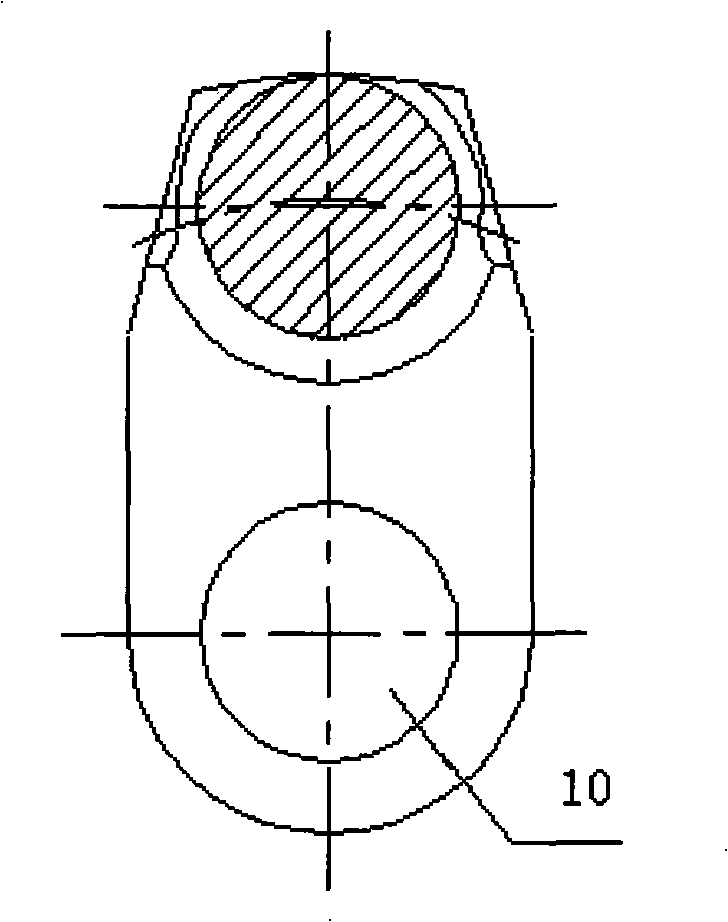

[0025] Said nesting processing refers to adopting the nesting drilling operation method, processing with a hollow drill bit (called a nesting drill, or ring drill), and a mandrel remains in the center of the workpiece after processing. Compared with direct drilling, the advantage of nesting processing is that the dimensional accuracy required by the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com