Method for measuring degree of turn-to-turn short-circuit fault of rotor and accurately positioning same

An inter-turn short-circuit fault, precise positioning technology, applied in the direction of measuring electricity, measuring devices, electrical winding testing, etc., can solve the problems of inability to locate, large measurement deviation, only qualitative judgment, etc., to achieve convenient operation, simple methods, and repairs. The effect of cost and cycle reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] A method for measuring and accurately locating a rotor turn-to-turn short-circuit fault degree, specifically comprising the following steps:

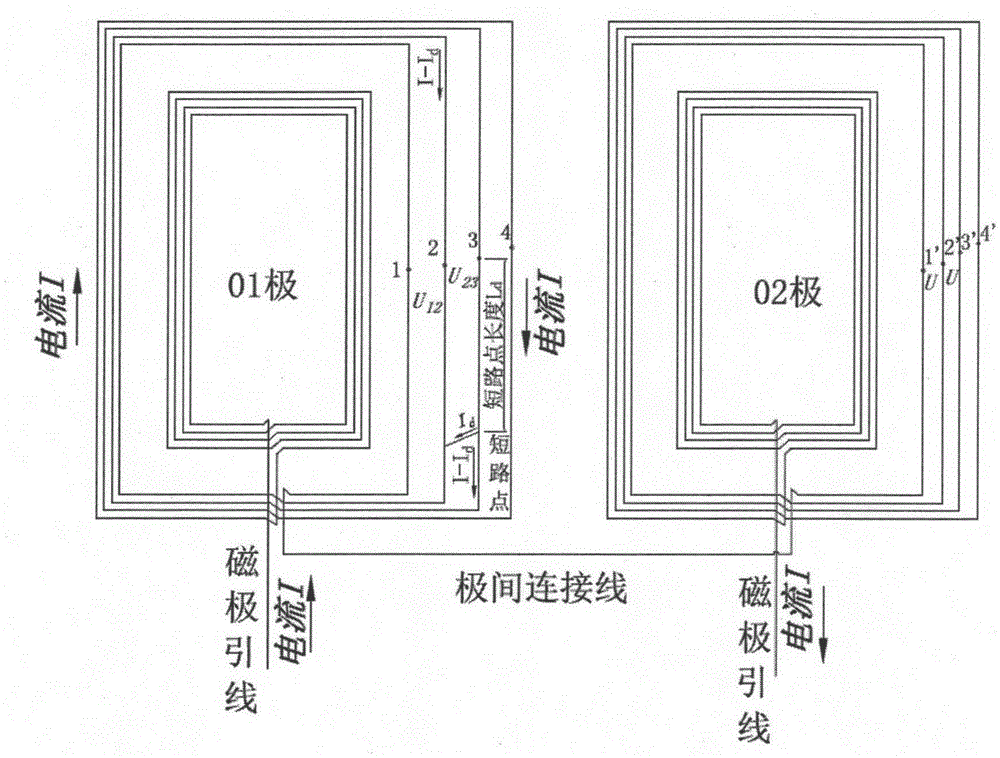

[0035] The first step: if figure 1 As shown, input 100V to 200V constant-voltage alternating current at the lead wire of the rotor, measure the voltage distribution of each group of coils, and compare the voltage difference between the two poles with the same number of coils to preliminarily determine the group number of the coil where the inter-turn short circuit fault point is located;

[0036] Step 2: Input 10A to 20A constant current direct current at the lead wire of the rotor, measure the voltage value between each turn of the group number coil where the fault point is located and the voltage value between each turn of the coil of the same group at another pole, and record the current direction at the same time ;

[0037] Step 3: Calculate the specific location of the fault point, that is, the short circuit location betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com