Fluid transportation and reaction integrated repairing method for organic-inorganic composite contaminated soil, and system thereof

A technology of polluted soil and inorganic composite, applied in the restoration of polluted soil, etc., can solve problems such as ineffective repair, and achieve the effect of reducing equipment investment, shortening repair cycle, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

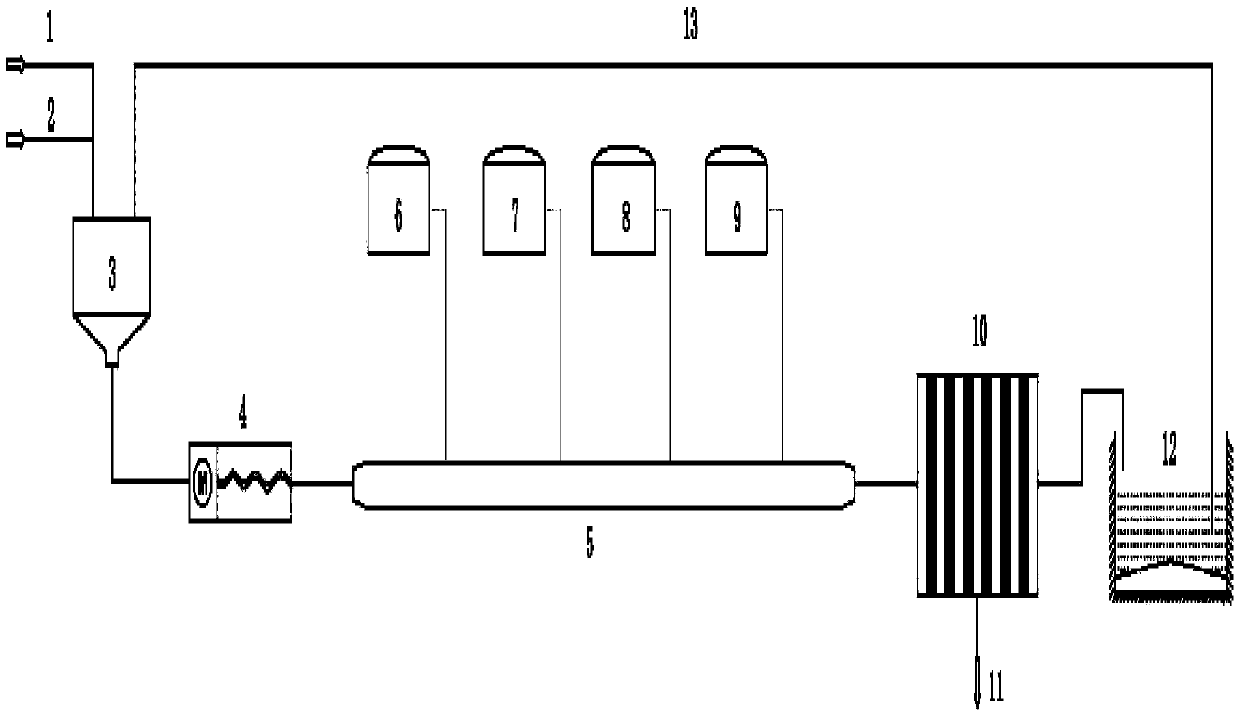

[0028] The polluted soil of a coking plant is cohesive soil, and the main pollutants are heavy metal chromium (CrⅥ) and benzene series (benzene, toluene, ethylbenzene). The organic-inorganic composite contaminated soil remediation method is used for treatment.

[0029] In the batching system, contaminated soil and water are mixed to prepare soil slurry, and the liquid-solid volume ratio is 5:1. Among them, the water flow is 60m 3 / h. The mixed slurry enters the pipeline reaction system under the action of the screw pump.

[0030] In the pipeline reaction system, the flow velocity of the soil slurry in the reaction pipeline is 0.05-0.08m / s. The total length of the reaction pipeline is 70m, and 4 (1#, 2#, 3#, 4#) feeding bypasses are set on the pipeline, and the interval between each bypass feeding point is 15m. Among them, 1# and 2# feed bypass to add heavy metal stabilizer (the main component is FeSO 4 ·7H 2 O), 3# and 4# feeding bypass add oxidizing agent (main component...

Embodiment 2

[0033] An explosion occurred in a hazardous chemical storage and transportation warehouse, resulting in the leakage of hazardous chemicals and causing soil pollution. After analysis, the soil type is sandy soil, and the main pollutants are sodium cyanide and methyl tert-butyl ether. The method for remediation of organic-inorganic composite polluted soil is adopted for treatment.

[0034] In the batching system, contaminated soil and water are mixed to make a slurry with a liquid-solid volume ratio of 2:1. Among them, the water flow is 90m 3 / h. The mixed slurry enters the pipeline reaction system under the action of the screw pump.

[0035] In the pipeline reaction system, the flow velocity of the soil slurry in the reaction pipeline is 0.3-0.5m / s. The total length of the reaction pipeline is 50m, and 3 (1#, 2#, 3#) feeding bypasses are set on the pipeline, and the interval between each bypass feeding point is 10m. Among them, hydrogen peroxide is added to the 1# feeding b...

Embodiment 3

[0038] A large amount of drilling cuttings solid waste was produced during the exploitation of an oilfield. After analysis, the soil type is cohesive soil, and the main pollutants are heavy metal chromium (CrVI) and crude oil, and the above-mentioned organic-inorganic composite polluted soil remediation method is used for treatment.

[0039]In the batching system, contaminated soil and a reversible solvent (N,N dimethylcyclohexylamine) were mixed to prepare a slurry with a liquid-solid volume ratio of 4:1. Among them, the reversible solvent flow rate is 150m 3 / h. The mixed slurry enters the pipeline reaction system under the action of the screw pump.

[0040] In the pipeline reaction system, the flow velocity of the soil slurry in the reaction pipeline is 0.08-0.1m / s. The total length of the reaction pipeline is 120m, and 3 (1#, 2#, 3#) feeding bypasses are set on the pipeline, and the interval between each bypass feeding point is 10m. 1#, 2# and 3# feed bypass to add hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com