Repairing device for shaft end of large gear shaft

A technology for gear shafts and shaft ends, which is applied in the field of repairing large-scale shaft parts. It can solve the problems of long disassembly time, difficult quality control, troublesome repairs, etc., so as to reduce repair cycle and cost, improve quality consistency, and ensure repair quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

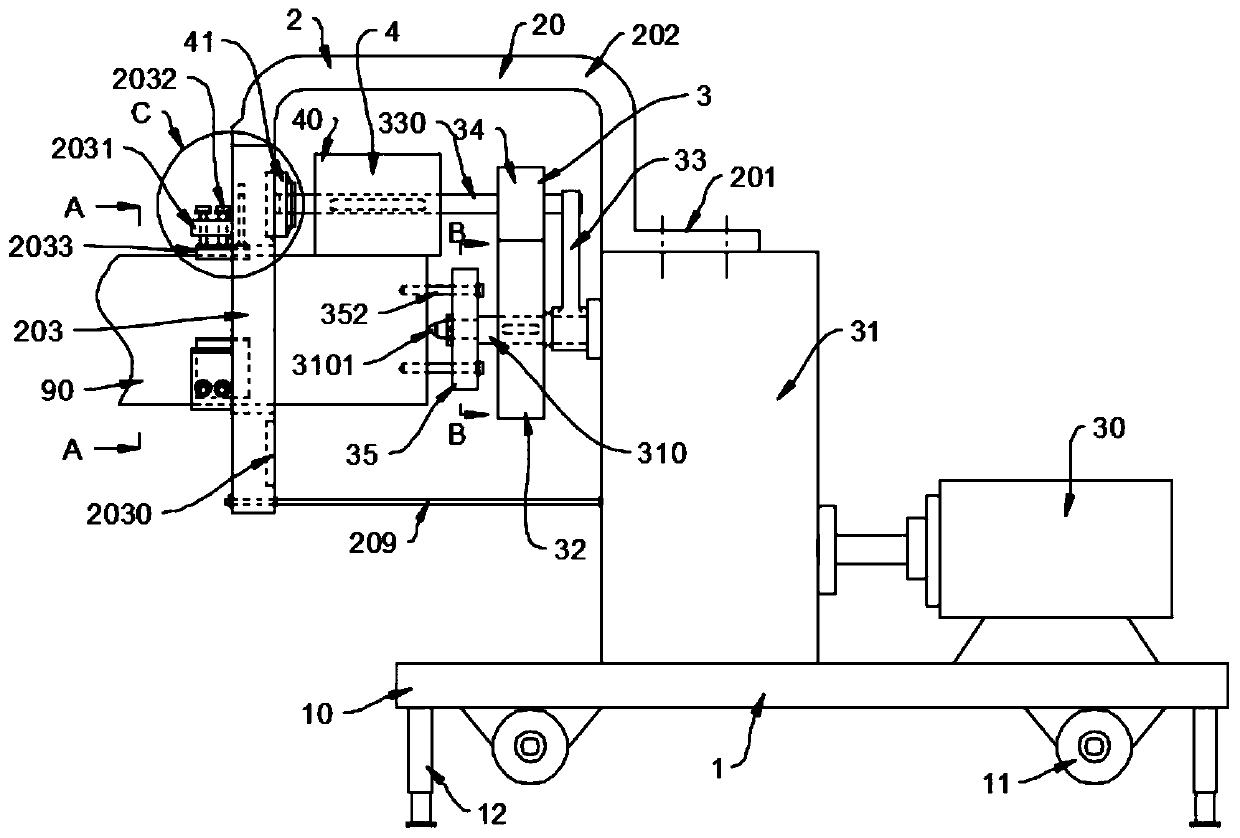

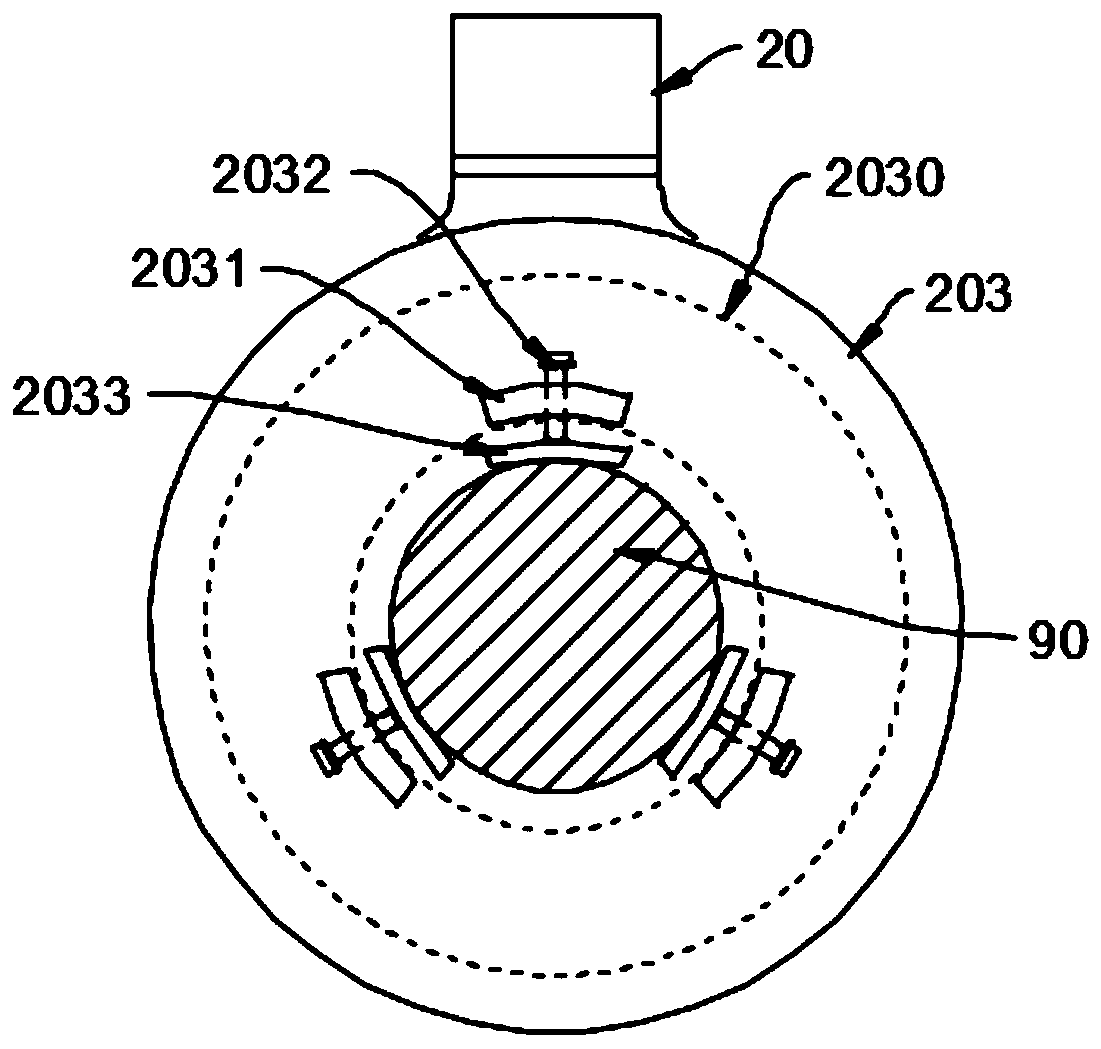

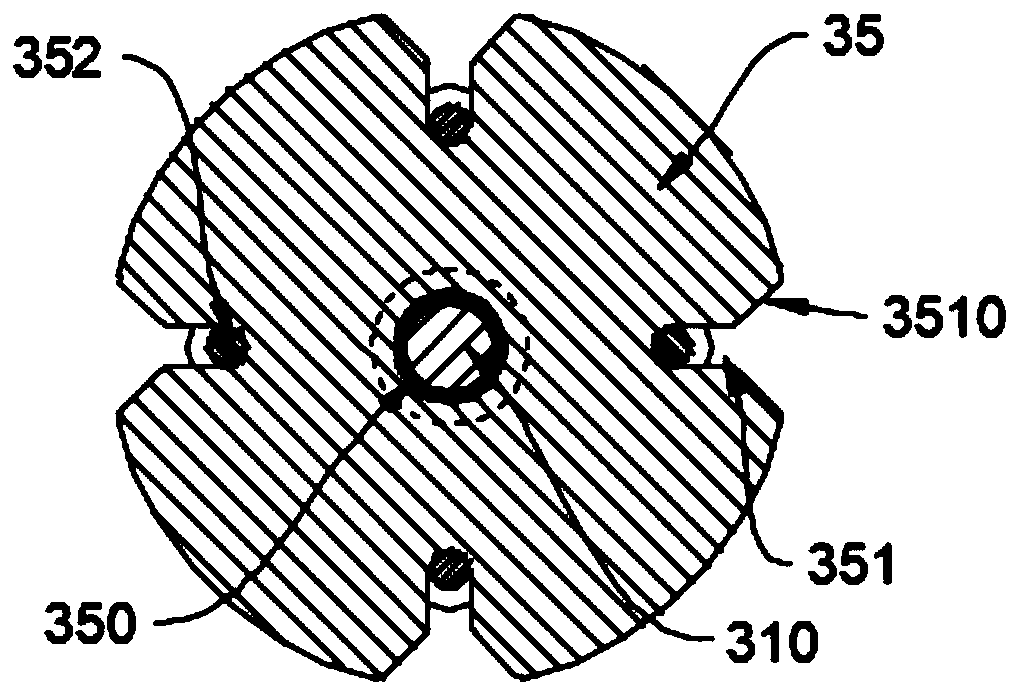

[0057] This embodiment includes a common platform for the complete set of large gear shaft shaft end repairing equipment consisting of a bearing platform, a locking device and a transmission device, as well as special equipment based on the shared platform such as a shaft end processing device, a welding repairing device, and a repairing rolling device.

[0058] In this embodiment, the explosive welding method is mainly used to repair the shaft end of the large gear shaft on site. First, the shaft end processing device is installed on the shared platform to grind the shaft end to obtain the shaft end with a size that meets the process requirements; then the shaft end is installed and welded on the shared platform. The repair device performs explosive welding on the shaft end to repair the missing size of the shaft end; then installs the shaft end processing device on the shared platform to grind the shaft end according to the needs, and obtains the shaft end that meets the size ...

Embodiment 2

[0116] This embodiment includes a large-scale gear shaft shaft end repair device complete set of equipment shared platform consisting of a bearing platform, a locking device and a transmission device, as well as a shaft end processing device, a cladding presetting device, a cladding repair device, a stress relief device, and a repairing device. Rolling device and other special equipment based on shared platform.

[0117] In this embodiment, the laser cladding method is mainly used to repair the shaft ends of large gear shafts on site. First, the shaft end processing device is installed on the shared platform to grind the shaft ends to obtain the shaft ends that meet the technological requirements; then, based on the shared platform, the Install the cladding presetting device, cladding repair device, and stress relief device to perform cladding presetting, cladding repair and stress relief treatment on the shaft end to obtain a shaft end that meets the final process requirements...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com