Movable automatic lifting flexible docking block unit for ship

An automatic lifting and flexible technology, applied in dry docks, slipways, ships, etc., can solve the problems of inaccurate precision, waste of resources, and deformation of the hull.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above-mentioned purpose, features and advantages of the patent of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

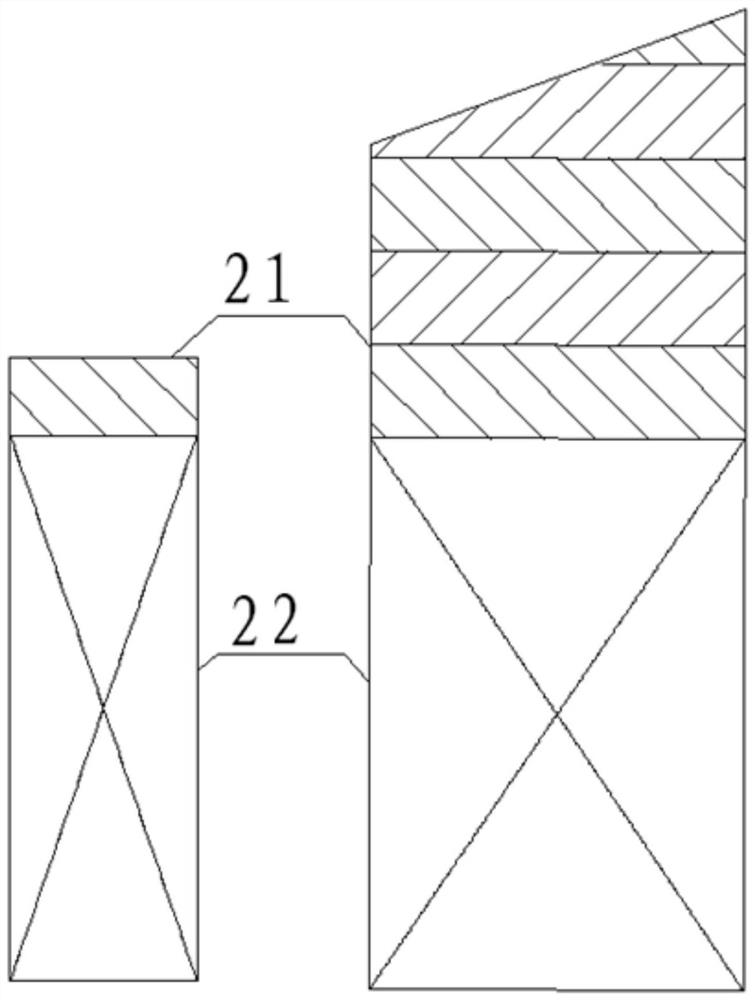

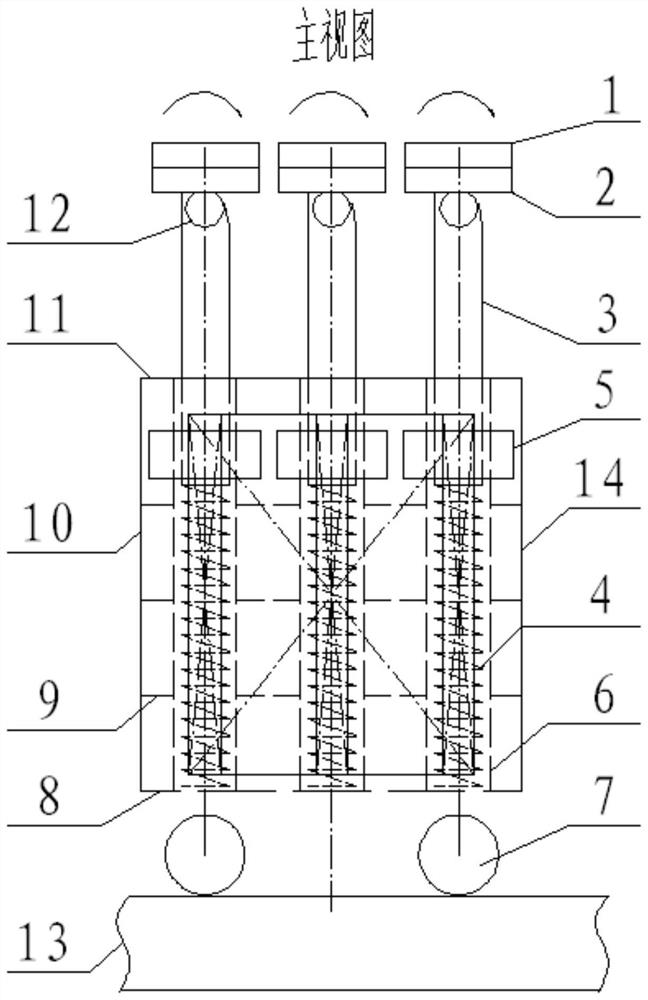

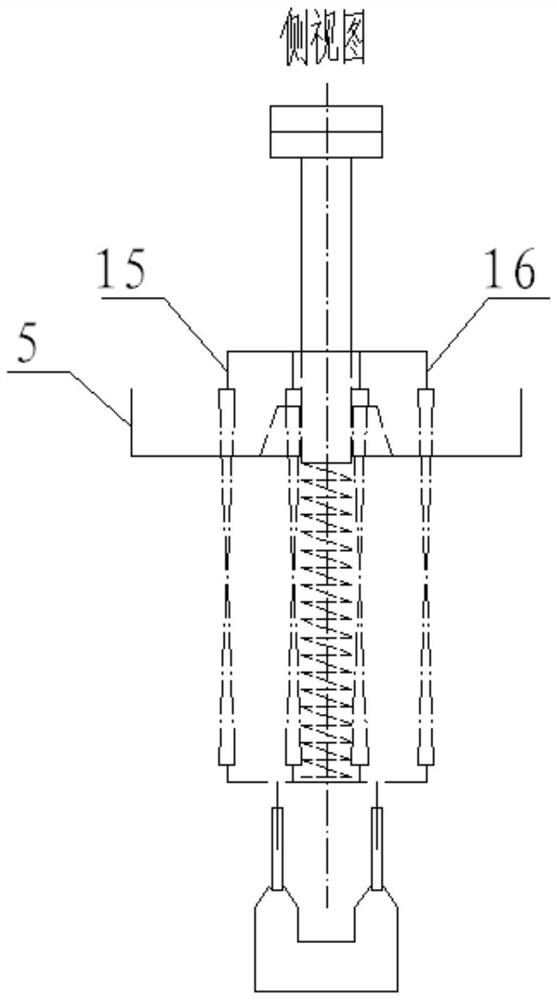

[0019] like figure 2 , image 3 and Figure 4 (The number of rows and columns of docking pier units can be adjusted according to the actual size of the dock) Shown is a structural schematic diagram and a schematic layout schematic diagram of a marine movable automatic lifting flexible docking pier unit according to an embodiment of the present invention. In the figure, 1 is a rubber backing plate, 2 is a movable supporting plate, 3 is a transition iron column, 4 is a strong spring, 5 is a pressure iron bracket, 6 is a steel pipe sleeve, 7 is a sliding mechanism, 8 is a bottom plate, 9 For stiffener, 10 is left wallboard, 11 is top plate, 12 is movable iron bolt, 13 is horizontal rail, 14 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com