Judging and regulating method for blade rolling process

An adjustment method and blade technology, applied in metal rolling and other directions, can solve the problems of many types of differences, it is difficult to accurately determine the adjustment method, etc., to reduce consumption, shorten repair cycle, and save adjustment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0067] A method for judging and adjusting during blade rolling, comprising the following steps:

[0068] Step 1: Judgment and adjustment of bite position,

[0069] Step A: Use a caliper to measure the size of the bite position, and judge whether it meets the size set on the process drawing. If not, adjust it to meet the process requirements;

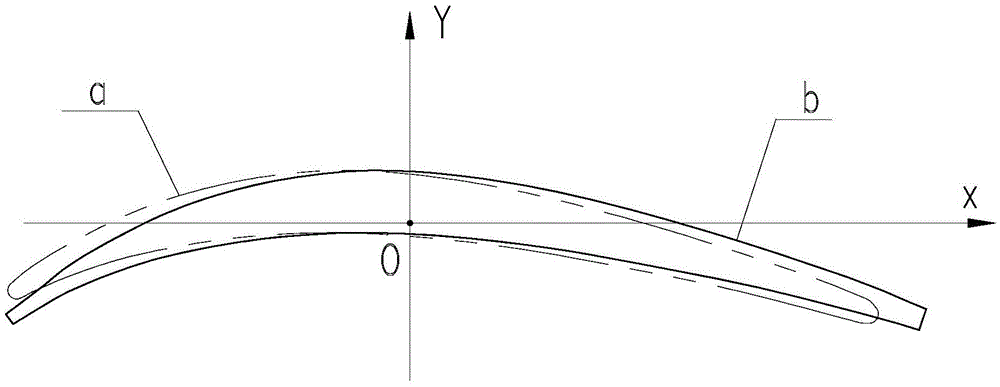

[0070] Step B: Measure the profile of the blade with a large twist angle blade, and compare the profile measurement result with the theoretical profile;

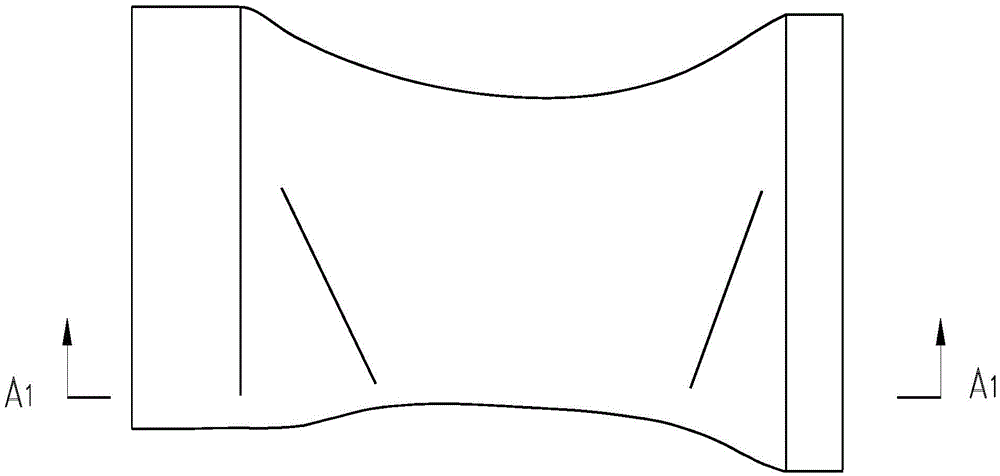

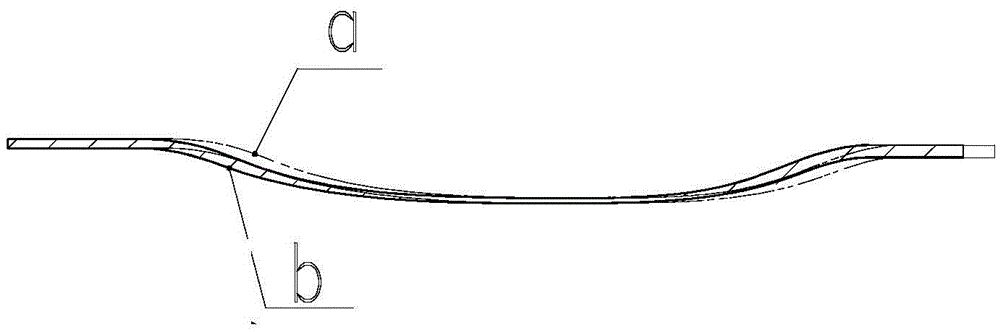

[0071] Step C: If there is a difference in the position of the exhaust edge of the blade along the bending angle of the longitudinal section of the airfoil, such as figure 1 , figure 2 As shown, it needs to be adjusted by changing the bite position;

[0072] Step D: Comparing and analyzing the measurement data to obtain the adjustment amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com