Site horizontal lamination edge segment iron core process of turbo generator

A technology of turbogenerator and iron core, which is applied in the manufacture of stator/rotor body, etc., which can solve the problems of long cycle, high cost and difficulty in repair process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

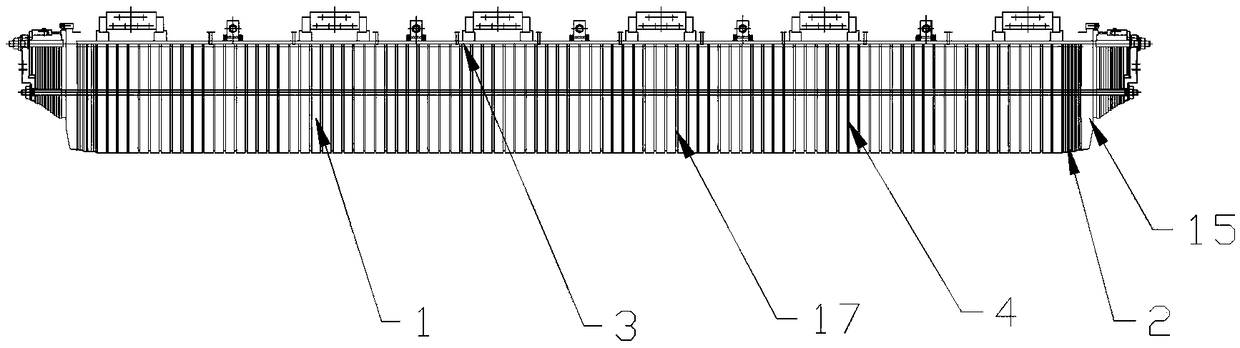

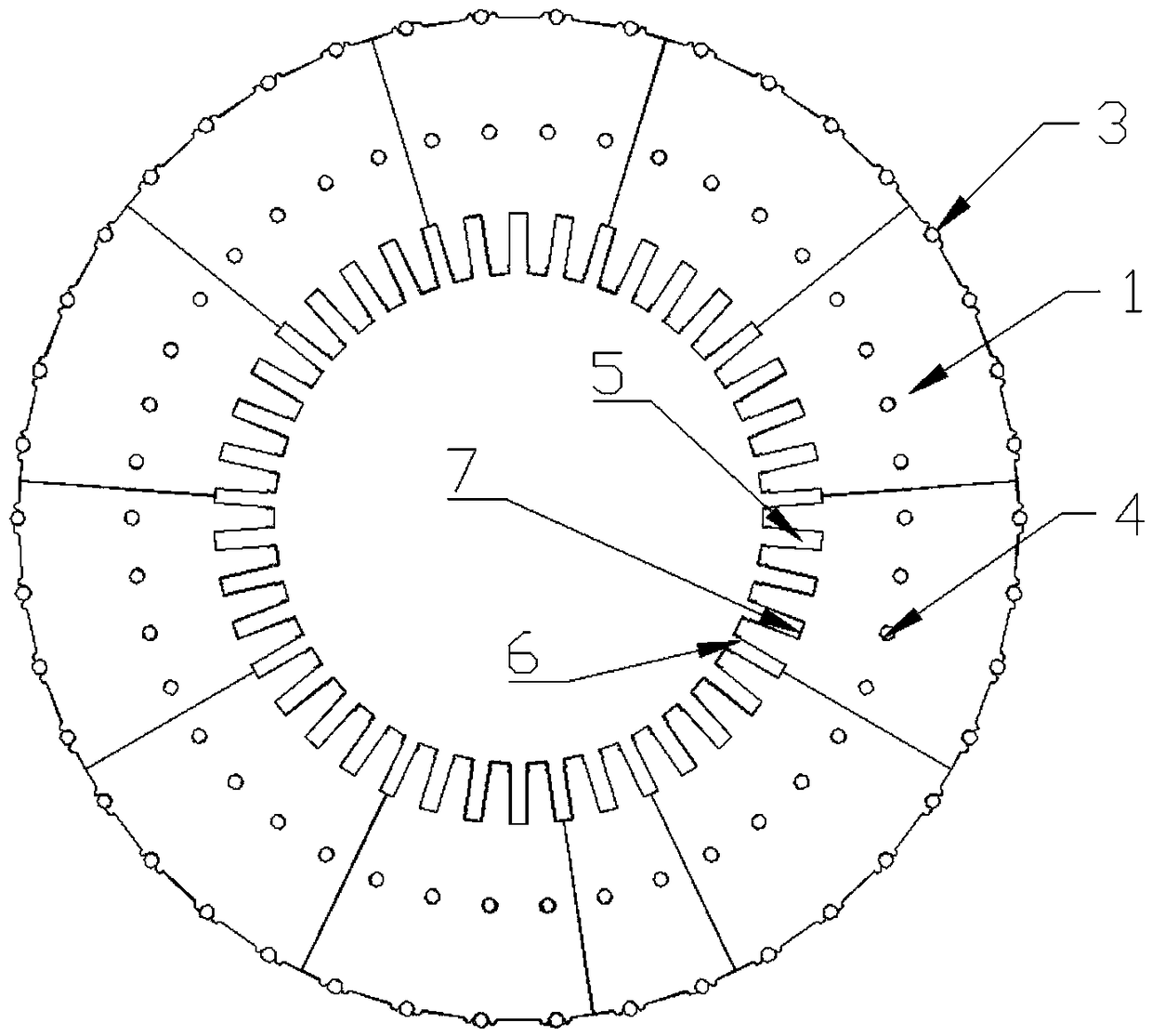

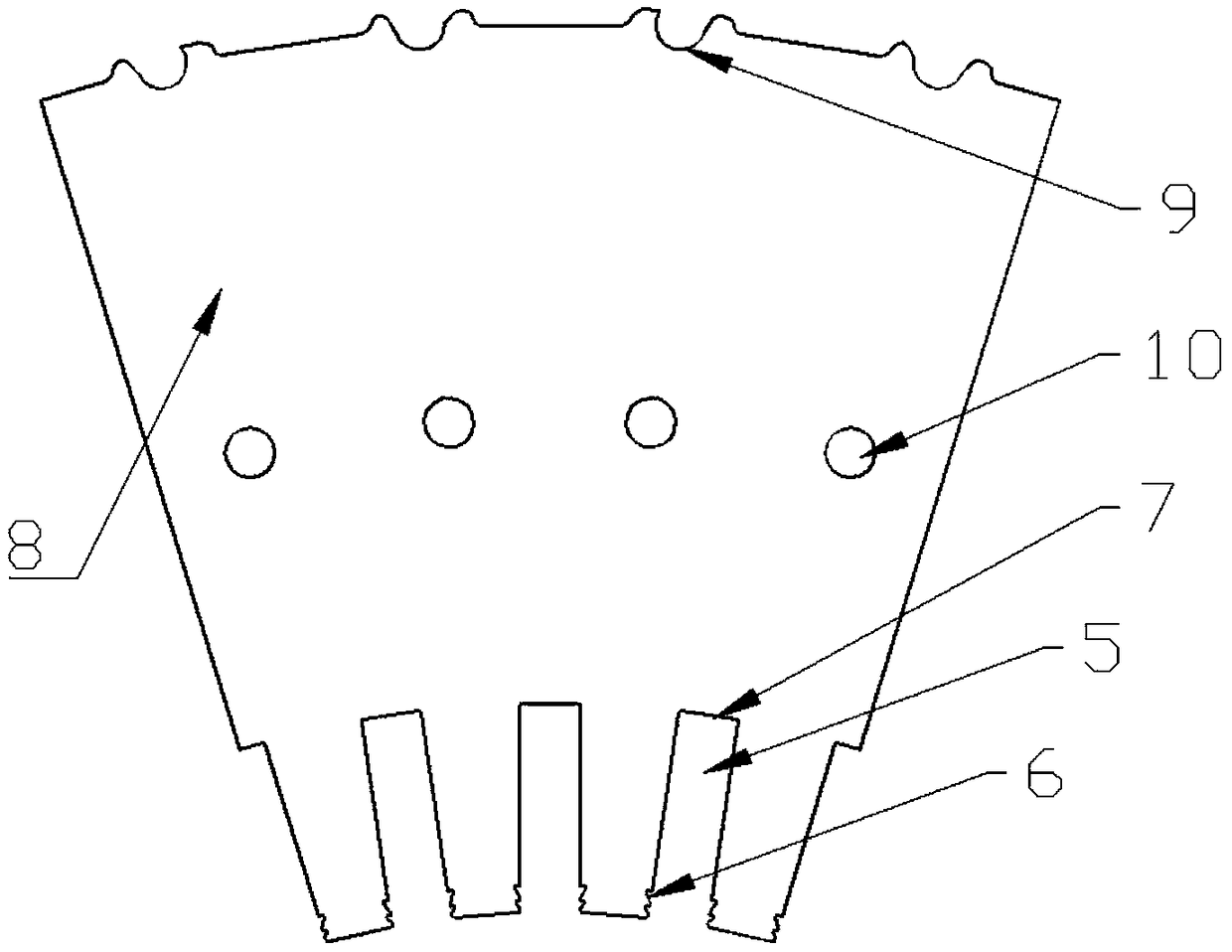

[0025] On-site horizontal stacking side section iron core technology for turbogenerator stator. Its technological implementation process is as follows:

[0026] 1) Before stacking the side section core 2, install all the positioning tools in place first, position the positioning slot 9 on the back of the stator core 1 with the positioning screw 3, and position the slot wedge slot 6 of the lower wire slot 5 with the slot wedge slot positioning rod 12 and extend it. Out of a length greater than the thickness of the side core 2, the slot bottom 7 of the lower wire slot 5 is positioned with a slot-like rod 11 and stretched out to a length greater than the thickness of the side segment iron core 2, the slot-like rod 11 is pushed against the slot bottom 7 by the top wire 13, The groove wedge groove positioning rod 12 and the groove sample rod 11 can coordinate the tangential and radial two-way positioning of the lower wire groove 5, and a set of groove wedge groove positioning rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com