A method and device for electro-spark bronze plating on the surface of aircraft metal parts

A technology of bronze plating and electric spark, which is applied in the coating process and coating of metal materials, can solve the problems that the coating surface cannot be satisfied, the hardness has dropped significantly, and the bonding strength requirements of the pattern design cannot be met.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The original coating on the matching surface of the piston rod and the inner ring on the landing gear of the Su-27 aircraft overhauled is taken as an example to illustrate the specific realization of the present invention.

[0017] The essence of the present invention is to etch excess metal based on the electric erosion phenomenon during the pulsed spark discharge between the electrode material and the workpiece (positive and negative electrodes), so as to meet the predetermined requirements for the size, shape and surface quality of the workpiece. The equipment adopts the principle of capacitive discharge, and uses the pulsating current to instantly form a discharge spark on the surface of the metal workpiece to melt and vaporize the electrode material, so that it forms an alloy coating with the base material (workpiece).

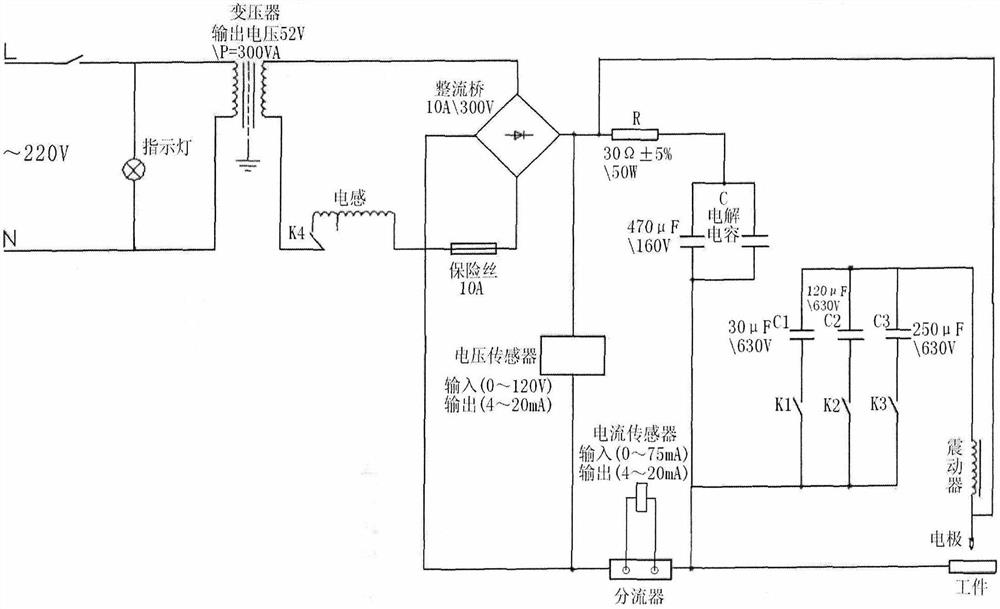

[0018] The circuit that produces the spark coating device includes a transformer, a rectifier bridge, a capacitor bank C, a capacitor bank (C1, C2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com