Repairing method of master cylinder plunger piston of radial forging machine

A technology of radial forging and repairing method is applied in the repairing field of the main cylinder plunger of radial forging machine, which can solve the problems of increasing production cost, long production cycle, wear and the like, so as to reduce the repairing cycle, reduce the maintenance cost, and ensure the normal operation. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

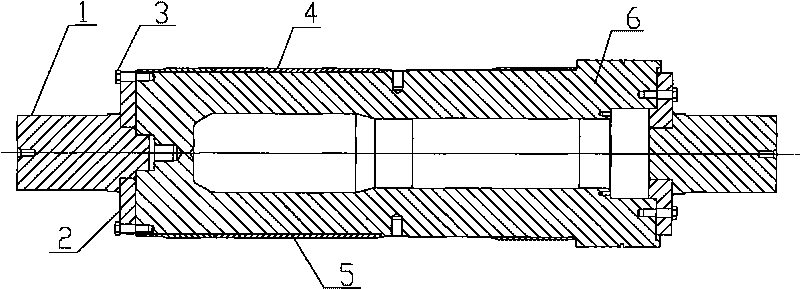

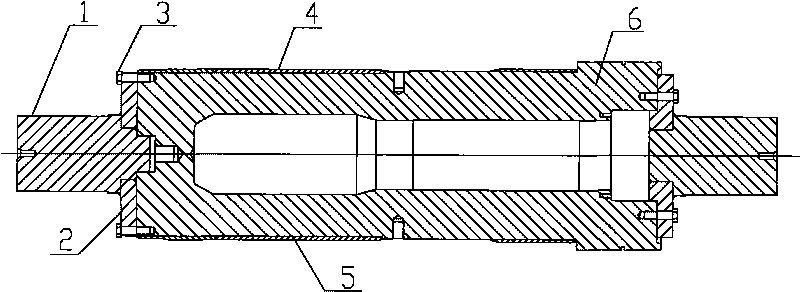

[0018] like figure 1 As shown, the repair method of the radial forging machine master cylinder plunger of the present invention comprises the following steps:

[0019] Step 1. Make two dummy shafts 1 according to the outer diameter of the plunger 6 of the master cylinder. One end of the dummy shaft 1 is a disc 2 with several through holes in the circumferential direction. The two dummy shafts 1 pass through the through holes of the disc 2 to Bolts 3 are concentrically connected to both ends of the master cylinder plunger 6;

[0020] Step 2: Making three sections of thin-walled steel sleeve 4, the thin-walled steel sleeve 4 is made of 38CrMoAl forging, after rough turning, the forging is subjected to ultrasonic flaw detection, Class II inspection, heat treatment, quenching and tempering and three stabilization treatments,

[0021] The first stabilization treatment process is: heating up to 80°C per hour, raising the temperature to 300°C, holding for 1 hour, then raising the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com