Device for manufacturing mechanical shaft in operation

A technology of processing equipment and machinery, applied in the field of accompanying mechanical processing equipment, can solve problems such as time-consuming and labor-intensive, and achieve the effect of simple structure, shortening repair cycle and cost, and convenient transportation with vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

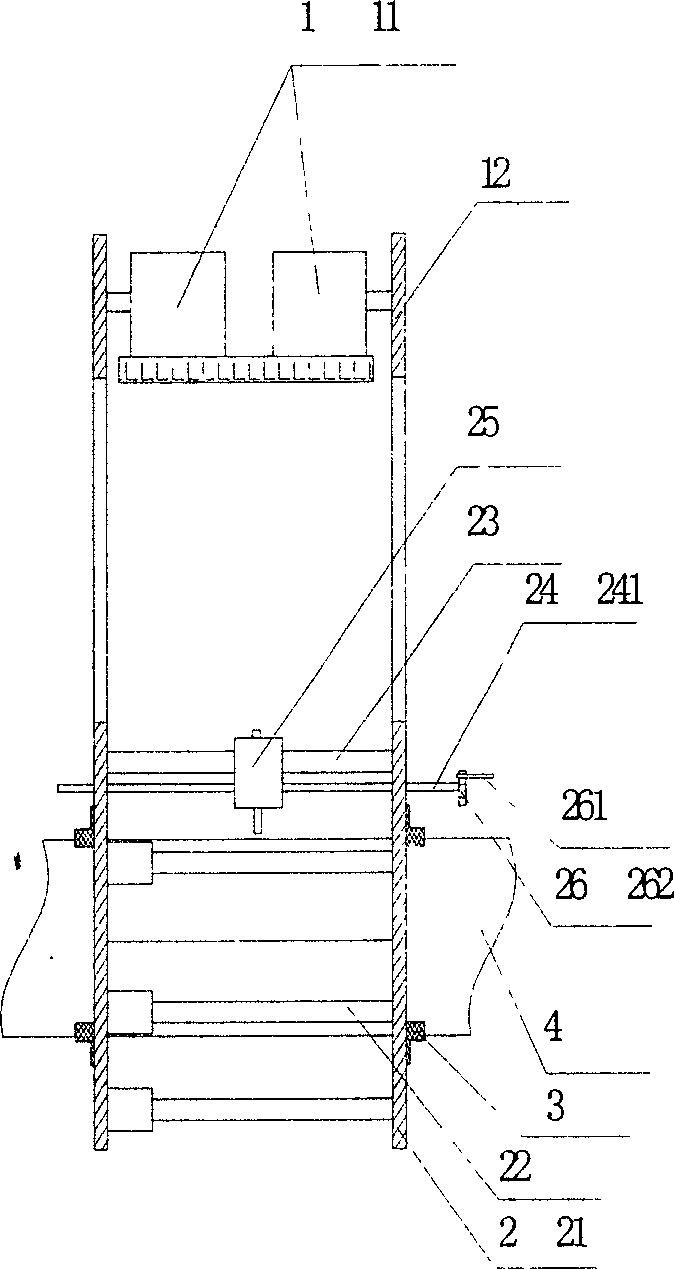

[0024] Example traveling mill

[0025] The traveling mill is composed of a driving mechanism (1), a rim tool rest assembly (2), a chuck (3) and a cutting tool.

[0026] The driving mechanism (1) is composed of a frequency-variable speed-regulating motor (11) and a transmission mechanism (12), and the molded product is selected according to the calculated motor power and corresponding rotating speed. For making transmission stable, adopt two shaft extension reducers, drive sprocket is installed on its two ends shaft head, and passive sprocket is exactly the rim (21) of rim knife rest assembly (2). The transmission mode of drive mechanism (11) and wheel rim knife rest assembly (2) selects chain drive, and purpose makes adjusting flexibly, is applicable to the condition and the environment of on-the-spot changeable.

[0027] Wheel rim knife rest assembly (2) is made up of wheel rim (21), adjustable connecting rod (22), guide rail, (23), knife rest (25). Wheel rim (21) is the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com