A Design Method for Thermal Load Release of Bolted Connections

A design method and thermal load technology, applied in aircraft component testing, aircraft assembly, etc., can solve the problems of small size, large bolt load, and small number of connection points, so as to reduce design and production costs, increase bearing capacity, and reduce design. and processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below in conjunction with embodiment.

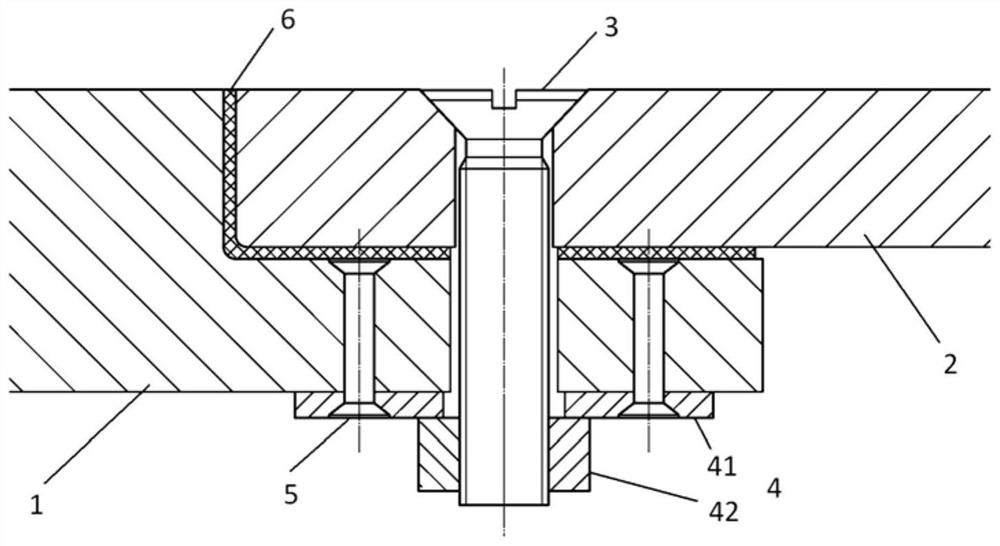

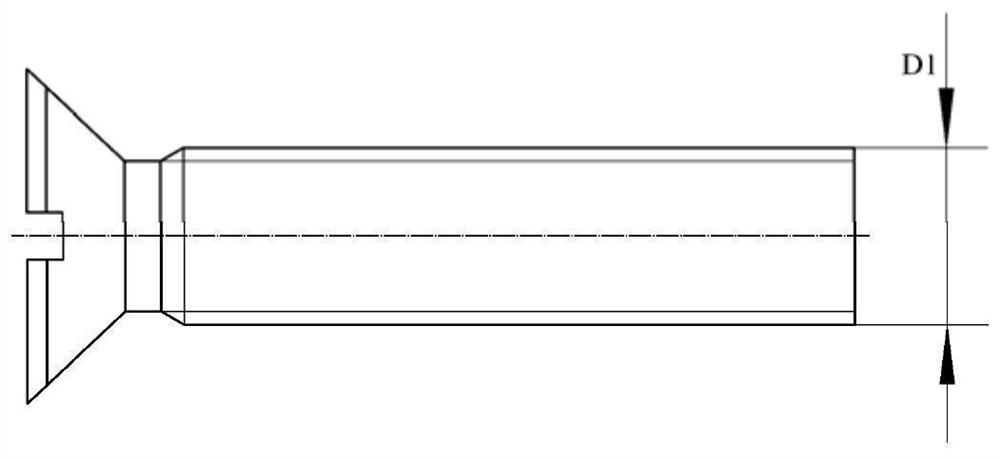

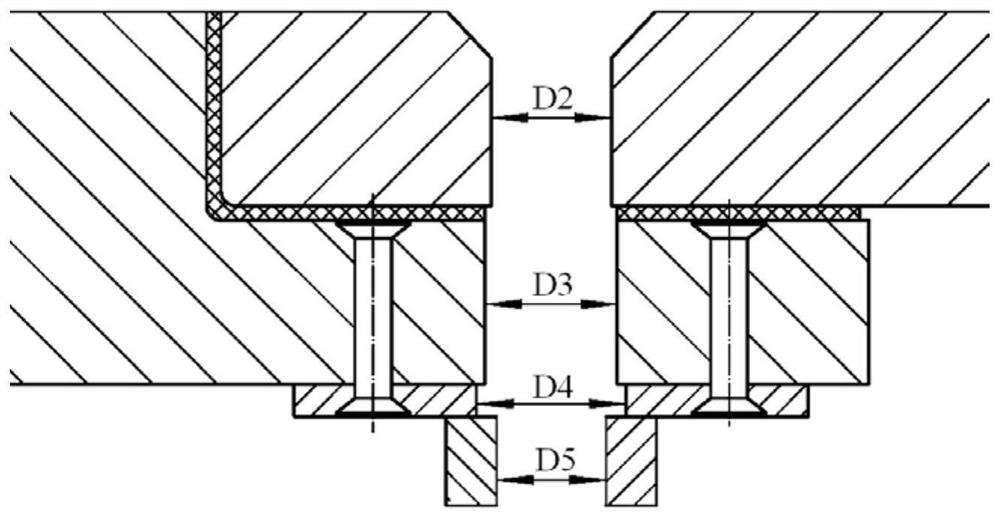

[0033] The aircraft hatch cover and the fuselage are connected by lap joints. The overlapping edges 1 and 2 are reserved at the corresponding positions of the fuselage and the hatch cover, and the hatch cover and the fuselage are fixed with the countersunk head screw 3 and the self-locking nut 4 of the two-ear movable support plate. The self-locking nut 4 of the two-ear movable supporting plate comprises two parts of a supporting plate 41 and a nut 42, and the supporting plate is fixed on the overlapping edge of the fuselage using a rivet 5. The rivets are countersunk head rivets, and the rivet heads need to be repaired to ensure that there are no protrusions on the surface of the overlapping edges of the fuselage. The screw is a countersunk screw 3, which is processed by high-quality structural steel or superalloy. The nut 42 is a self-locking nut with anti-loosening capability. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com