Water pipe reinforcing rib type cooling wall

A technology of reinforcing ribs and staves, applied in the field of metallurgical casting, can solve problems such as water pipe cracks, stave water leakage, and stave cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

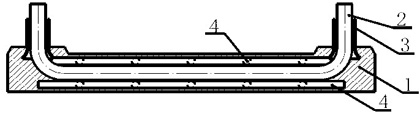

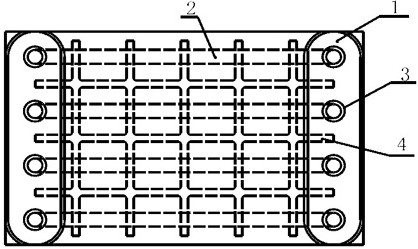

[0019] see figure 1 and figure 2 , The present invention provides a water pipe stiffener type stave, the stave is composed of a stave body 1, a cooling water pipe 2, a protection pipe 3 and a mesh rib 4.

[0020] A cooling water pipe 2 is arranged on the stave body 1, a protective pipe 3 is installed at the inlet and outlet of the cooling water pipe 2, and mesh reinforcement ribs 4 are fixedly laid above and below the cooling water pipe 2, which are the upper mesh reinforcement ribs and the lower layer respectively. Mesh reinforcement. The upper layer of mesh reinforcement and the lower layer of mesh reinforcement are laid to fix the water pipe and prevent the water pipe from floating up and down when it is washed by high-temperature molten metal.

[0021] The mesh reinforcing rib 4 is composed of several vertically arranged ribs and several horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com