Method for recovering organosilicon micro-molecules and organosilicon cyclic compounds through cracking silicone rubber serial substances

A silicone rubber and organosilicon technology, applied in the field of comprehensive utilization of chemical products, can solve the problems of limited processing capacity, secondary pollution, and large acid consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

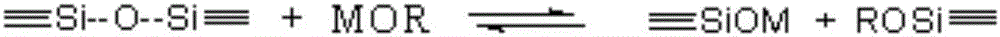

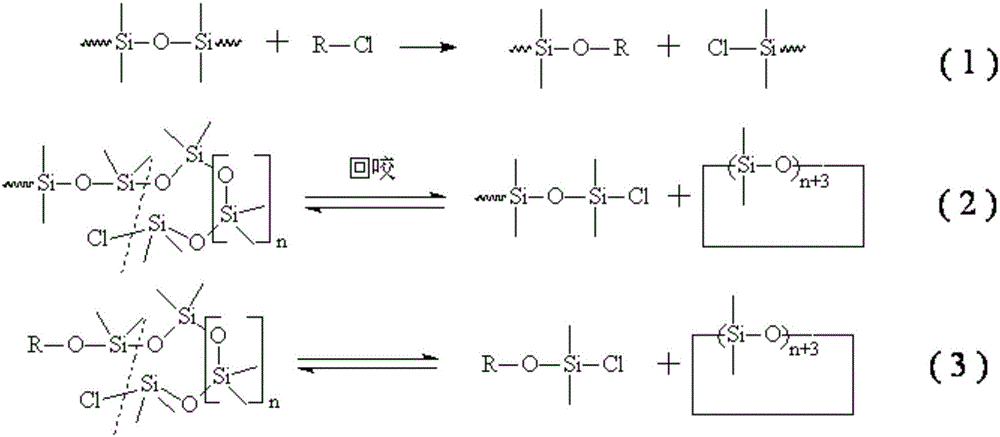

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039] The present invention will be further described below through specific examples, but not limited thereto.

[0040] The raw materials used in the examples are conventional commercially available raw materials or synthesized according to reference methods.

[0041] The molecular weights described in the examples are number average molecular weights. The parts described in the examples are all parts by weight.

Embodiment 1

[0043] Put 500 grams of raw silicone rubber with a molecular weight of 600,000 into a 1-liter reactor, then slowly add 5 grams of methyltrichlorosilane, start stirring and raise the temperature of the device to reflux (66°C), and keep the reflux reaction After 4 hours, the reflux reaction was stopped. Add 10 mL of ethanol to terminate the reaction. The product was washed successively with saturated sodium bicarbonate solution and saturated sodium chloride solution. The product was dried over anhydrous magnesium sulfate overnight. The magnesium sulfate solid was filtered off to obtain a cracked product (infrared and nuclear magnetic analysis showed that the product was a mixture of small organic silicon molecules and cyclic bodies). The viscosity of the cracked product was tested using a rotational viscometer, and the test result was 20.5. This data shows that there is no macromolecule, and the cracking efficiency of raw silicone rubber is 100%.

Embodiment 2

[0045] As described in Example 1, except that toluene was added as a solvent, and the reaction time was 3 hours. Then ethanol was added to terminate the reaction, and the product was washed with saturated sodium bicarbonate solution and saturated sodium chloride solution successively. After drying over anhydrous magnesium sulfate and filtering, toluene was removed from the cleavage product by distillation. The viscosity of the cracked product after removing toluene was tested by a rotational viscometer, and the test result was 18.5, indicating that no macromolecule existed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com