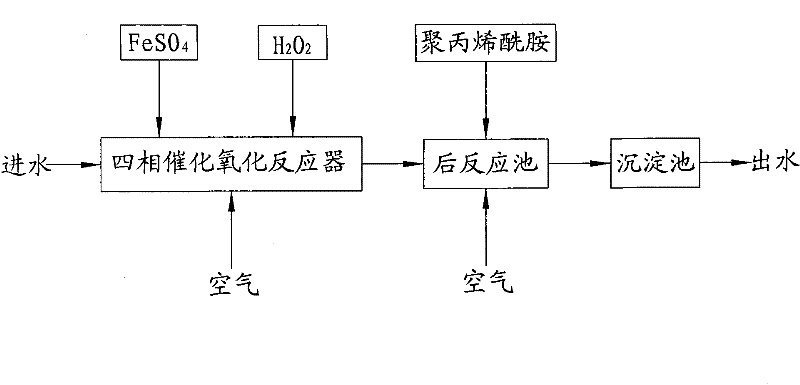

Method for advanced treatment of waste water by four-phase catalytic oxidation

A four-phase catalytic oxidation and advanced treatment technology, which is applied in chemical instruments and methods, chemical/physical processes, water/sewage multi-stage treatment, etc., can solve the problems of high operating cost and large dosage of chemicals, and achieve high operating cost , Reduce the water output index, the effect of purifying water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

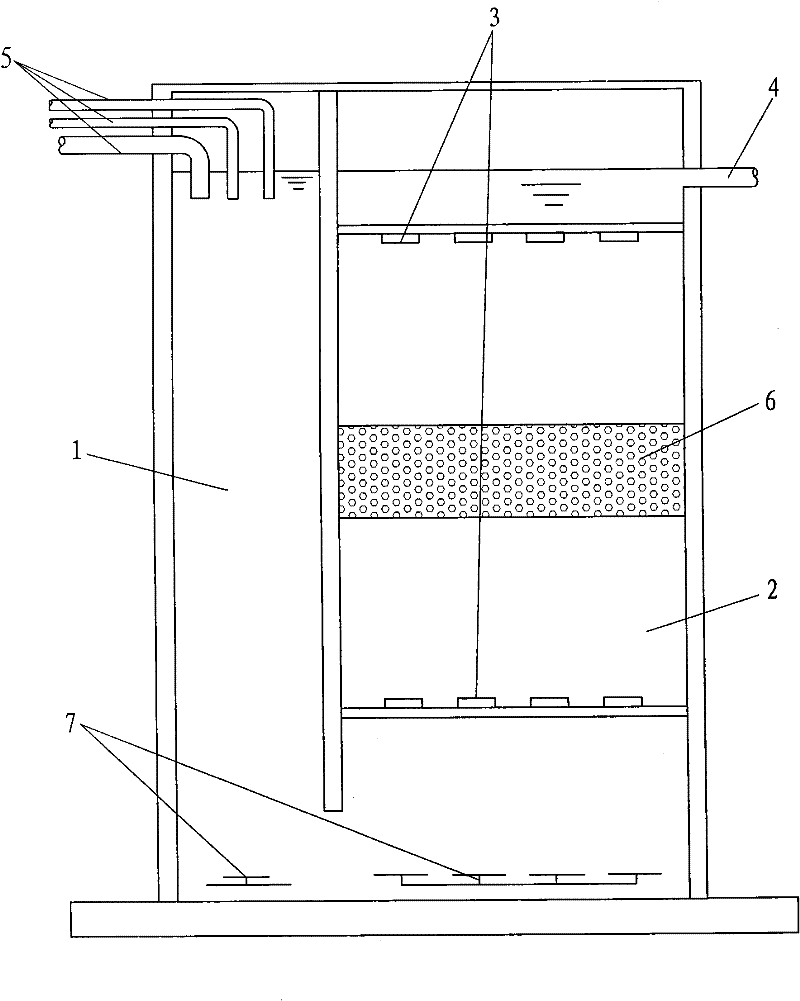

[0043] The test wastewater in this example is leather wastewater. After physical, chemical and biochemical treatment, the wastewater directly enters the NdFeB magnet and Cu-Ti-Fe / Al 2 o 3 The reaction in the four-phase catalytic oxidation reactor of the honeycomb ceramic catalyst bed, and the water quality indicators when entering the treatment system are as follows:

[0044] COD cr : 200mg / l;

[0045] Chroma: 300 times;

[0046] Project water volume is 4000m 3 / d, the process conditions for reactor operation are as follows:

[0047] Dwell time: 30 minutes;

[0048] Temperature: 20-35°C;

[0049] Aeration gas water ratio: 10:1;

[0050] Cu-Ti-Fe / Al described in 2 o 3 The preparation method of the honeycomb ceramic catalyst in the honeycomb ceramic catalyst is as follows: adopt the sol-gel method to prepare an alumina coating on the honeycomb ceramic carrier, and in the pseudo-boehmite dry rubber powder (Shandong Aluminum Company, brand P-DF-07-LSi ) with a certain co...

Embodiment 2

[0061] The test wastewater in this example is the penicillin fermentation wastewater. After the wastewater is treated by physical, chemical and biochemical treatment, it directly enters the magnet with NdFeB magnet and Cu-Ti-Fe / Al 2 o 3 The reaction in the four-phase catalytic oxidation reactor of the honeycomb ceramic catalyst bed, and the water quality indicators when entering the treatment system are as follows:

[0062] COD cr : 300mg / l;

[0063] Chroma: 200 times;

[0064] Project water volume is 2000m 3 / d, the process conditions for reactor operation are as follows:

[0065] Dwell time: 20 minutes;

[0066] Temperature: 30-40°C;

[0067] Aeration gas water ratio: 10:1;

[0068] The Cu-Ti-Fe / Al 2 o 3 The preparation method of the honeycomb ceramic catalyst in the honeycomb ceramic catalyst is as follows: adopt the sol-gel method to prepare an alumina coating on the honeycomb ceramic carrier, and in the pseudo-boehmite dry rubber powder (Shandong Aluminum Company...

Embodiment 3

[0079] The test wastewater in this example is coking wastewater. After physical, chemical and biochemical treatment, the wastewater directly enters the magnet with NdFeB magnet and Cu-Ti-Fe / Al 2 o 3 The reaction in the four-phase catalytic oxidation reactor of the honeycomb ceramic catalyst bed, and the water quality indicators when entering the treatment system are as follows:

[0080] COD cr : 400mg / 1;

[0081] Chroma: 500 times;

[0082] Project water volume is 1500m 3 / d, the process conditions for reactor operation are as follows:

[0083] Duration of stay: 15 minutes;

[0084] Temperature: 30-45°C;

[0085] Aeration gas water ratio: 10:1;

[0086] The Cu-Ti-Fe / Al 2 o 3 The preparation method of the honeycomb ceramic catalyst in the honeycomb ceramic catalyst is as follows: adopt the sol-gel method to prepare an alumina coating on the honeycomb ceramic carrier, and in the pseudo-boehmite dry rubber powder (Shandong Aluminum Company, brand P-DF-07-LSi ) with a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com