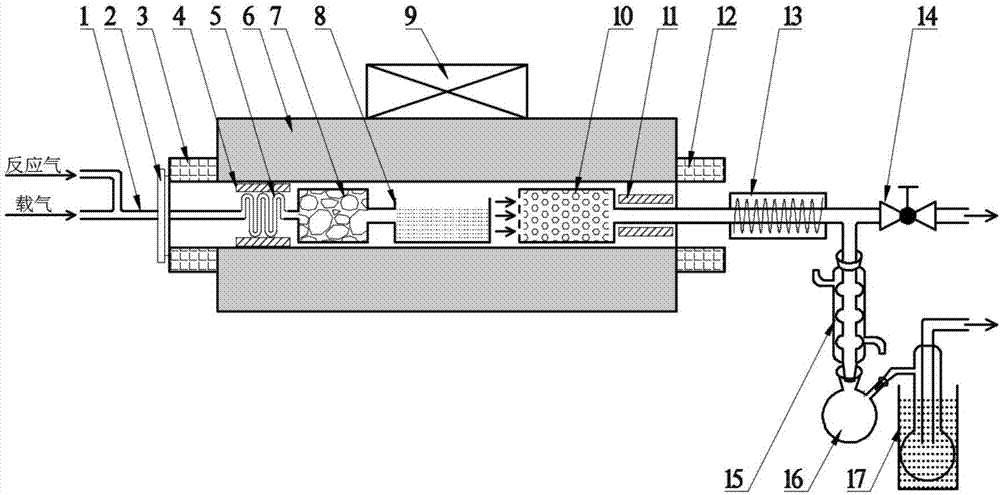

Device and method for coproducing bio-oil and biochar from solid waste through efficient microwave depolymerization

A technology for solid waste and bio-oil, applied in the field of waste resource utilization, can solve the problems of lack of microwave thermal cracking device, lack of two-stage catalytic device, etc., to reduce oxygen content, improve quality, realize clean and cyclic production and utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

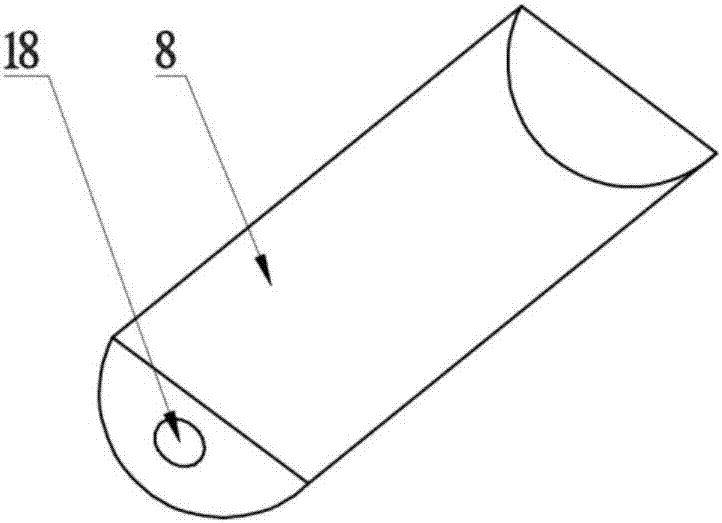

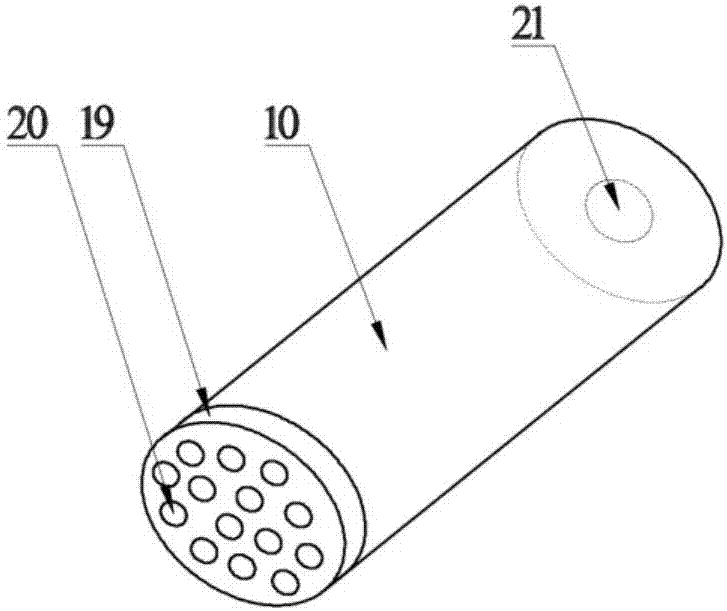

Embodiment 1

[0046] 10g of corn stalks are crushed into a particle size of 0.5-2mm, and placed in a cracking reactor 8 composed of 80% recrystallized silicon carbide and 20% iron oxide material; the HZSM-5 zeolite catalyst with a particle size of 2mm is placed In the catalytic reactor 10 made of recrystallized silicon carbide, a helium gas flow rate of 50 mL / min was introduced to remove the air in the reaction system. Turn on the electric heating and heat preservation device 13, the temperature is 250°C, open the gas valve 14, and then turn on the microwave generation system, the microwave frequency is 2.45GHz, the microwave power is 200W, react for 10 minutes, and then feed methanol reaction gas with a flow rate of 1mL / min , open the condensed water in the condensation pipe 15, control the temperature to be 2°C, add a dry ice acetone bath in the secondary bio-oil collection device 17, close the gas valve 14, adjust the microwave power to 800W, and the cracking reactor 8 is heated up to 550...

Embodiment 2

[0048] Taking the waste plastic raw material as an example to introduce the implementation process of the present invention is as follows:

[0049] 10g of waste plastics is crushed into a particle size of 2-5mm, and placed in a cracking reactor 8 composed of 90% recrystallized silicon carbide and 10% copper oxide material; the SBA-15 zeolite catalyst with a particle size of 5mm is placed In the catalytic reactor 10 made of recrystallized silicon carbide, a helium gas flow rate of 300 mL / min was introduced to remove the air in the reaction system. Turn on the electric heating and heat preservation device 13, the temperature is 350°C, open the gas valve 14, and then turn on the microwave generation system, the microwave frequency is 2.45GHz, the microwave power is 400W, react for 5 minutes, and then feed the methane reaction gas with a flow rate of 20mL / min , open the condensed water in the condensation pipe 15, control the temperature at 5°C, add a dry ice acetone bath in the s...

Embodiment 3

[0051] Taking the papermaking sludge raw material as an example to introduce the implementation process of the present invention is as follows:

[0052] 10g of papermaking sludge is pulverized into a particle size of 0.5-3mm, and placed in a cracking reactor 8 composed of 85% recrystallized silicon carbide and 15% magnesium oxide; the HY zeolite catalyst with a particle size of 10mm is placed in In the catalytic reactor 10 made of recrystallized silicon carbide, a helium gas flow rate of 100 mL / min was introduced to remove the air in the reaction system. Turn on the electric heating and heat preservation device 13, the temperature is 300°C, open the gas valve 14, and then turn on the microwave generation system, the microwave frequency is 2.45GHz, the microwave power is 300W, react for 5 minutes, and then feed the formaldehyde reaction gas with a flow rate of 10mL / min , open the condensed water in the condensation pipe 15, control the temperature to be 3°C, add a dry ice aceto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com