System and method for comprehensive utilization of metallurgical solid waste

A solid waste, metallurgical technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

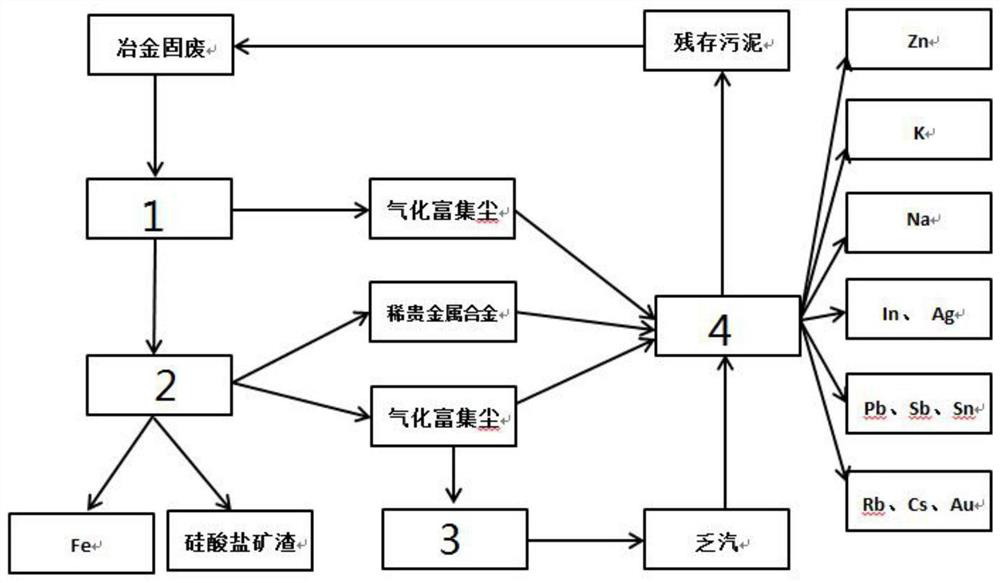

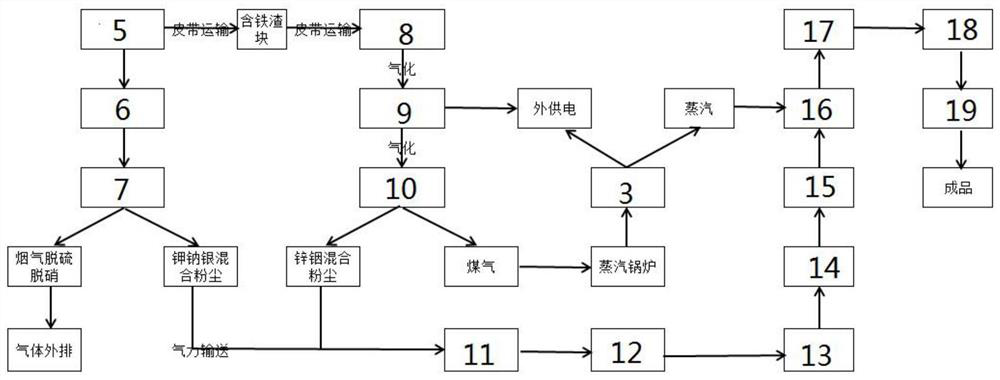

[0050] A comprehensive utilization system for metallurgical solid waste, comprising an oxidation gasification unit, a reduction gasification unit, a power generation unit and a replacement separation unit;

[0051] The oxidation gasification unit includes an oxidation gasification kiln, a first cyclone flue gas magnetization device and a first high temperature bag filter, and the flue gas of the oxidation gasification kiln passes through the first cyclone flue gas magnetization device and the first cyclone flue gas magnetization device. a high temperature bag filter, the discharge port of the first high temperature bag filter is communicated with the displacement separation unit, and the discharge port of the oxidation gasification kiln is communicated with the reduction gasification unit through a belt conveyor;

[0052] The reducing gasification unit includes a reducing gasification furnace, a second cyclone flue gas magnetization device and a second high-temperature bag filt...

Embodiment 2

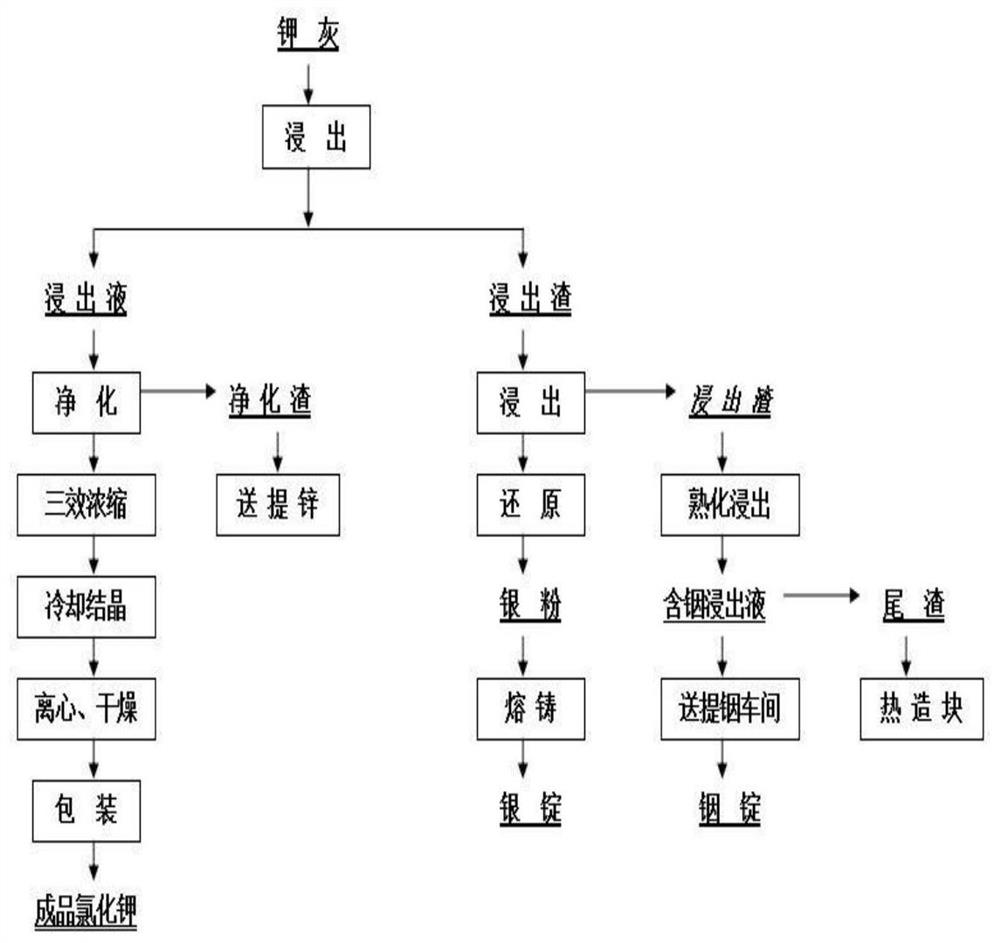

[0063] Embodiment 2 of the present invention discloses a comprehensive utilization method for metallurgical solid waste, which specifically includes the following steps:

[0064] (1) The metallurgical solid waste is sent to the oxidation gasification kiln, the oxygen content of the atmosphere in the oxidation gasification kiln is 16%, the oxidation gasification temperature is controlled at 1350 ° C, and the gasification oxidation enrichment obtains potassium-sodium-silver mixed dust (potassium-sodium-silver mixed dust) Dust K element content 50%) and iron-containing slag;

[0065] (2) The iron-containing slag blocks are broken into 25mm pellets, and part of the coke is sent to the reduction gasification furnace. The mass ratio of the slag-containing iron blocks to the coke is 2.5:1, the reduction and gasification temperature is controlled at 1580 ° C, and the gasification reduction and enrichment are carried out. The zinc-indium mixed dust (the zinc-indium mixed dust has a Zn ...

Embodiment 3

[0070] Embodiment 3 of the present invention discloses a comprehensive utilization method for metallurgical solid waste, which specifically includes the following steps:

[0071] (1) The metallurgical solid waste is sent to the oxidation gasification kiln, the oxygen content of the atmosphere in the oxidation gasification kiln is 17%, the oxidation gasification temperature is controlled at 1550 ° C, and the gasification oxidation enrichment obtains potassium-sodium-silver mixed dust (potassium-sodium-silver mixed dust) Dust K element content 52%) and iron-containing slag;

[0072] (2) The iron-containing slag blocks are broken into 25mm pellets, and part of the coke is sent to the reduction gasifier. The mass ratio of the slag-containing iron blocks to the coke is 2.5:1, the reduction and gasification temperature is controlled at 1550 ° C, and the gasification reduction enrichment Obtained zinc-indium mixed dust (zinc-indium mixed dust with Zn element content of 45%), molten i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com