Comprehensive utilization system and method of metallurgical solid wastes

A solid waste and metallurgical technology, applied in the field of comprehensive utilization of metallurgical solid waste, can solve the problems of poor dust treatment effect of metallurgical solid waste, unsatisfactory treatment effect, low resource utilization rate, etc., to reduce difficulty, reduce energy consumption, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

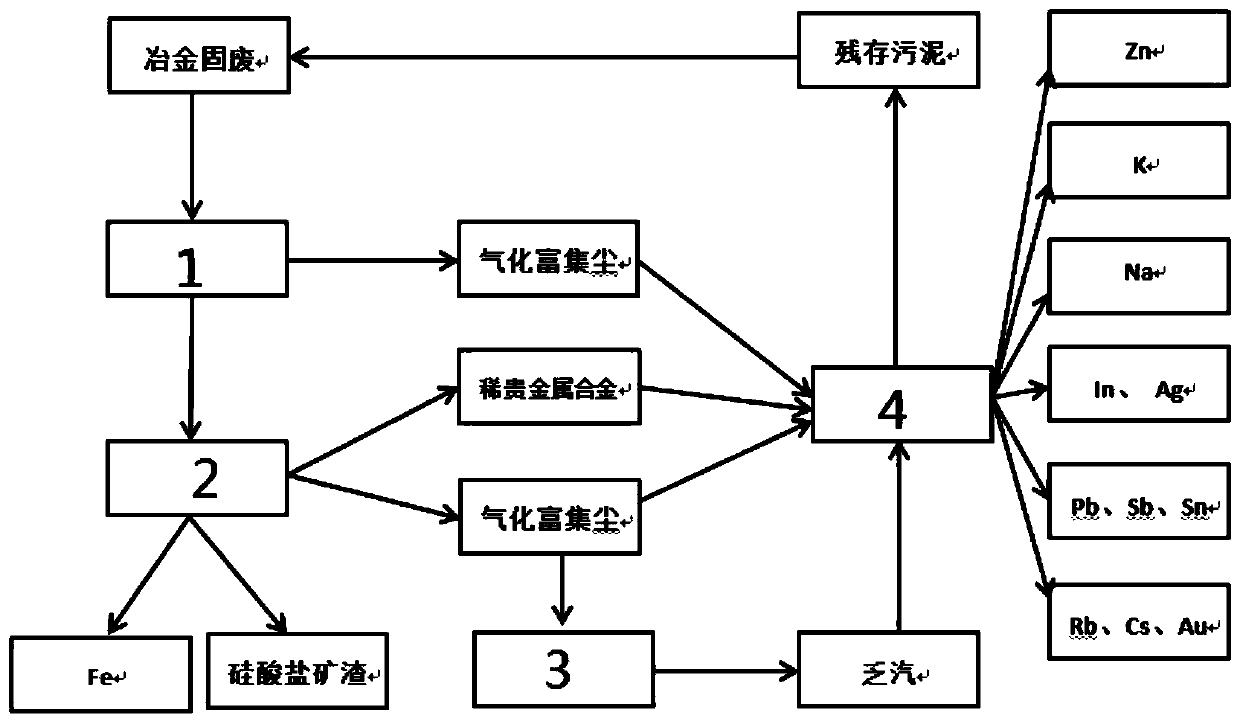

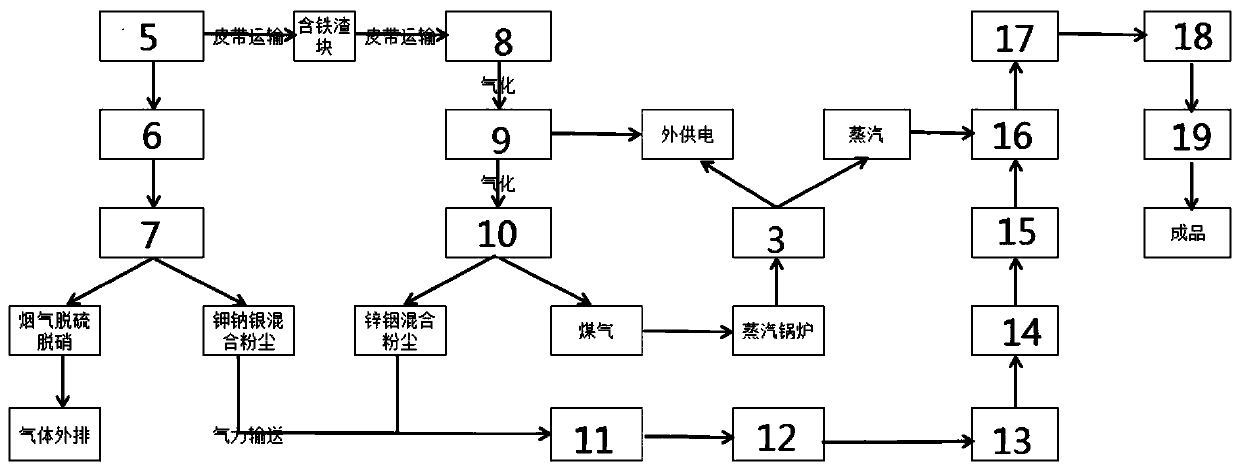

[0050] A comprehensive utilization system for metallurgical solid waste, including an oxidation gasification unit, a reduction gasification unit, a power generation unit and a displacement separation unit;

[0051] The oxidation gasification unit includes an oxidation gasification kiln, a first cyclone flue gas magnetization device and a first high-temperature bag filter, and the flue gas of the oxidation gasification kiln passes through the first cyclone flue gas magnetization device and the first cyclone flue gas magnetization device. A high-temperature bag filter, the outlet of the first high-temperature bag filter communicates with the displacement separation unit, and the outlet of the oxidation gasification kiln communicates with the reduction gasification unit through a belt conveyor;

[0052] The reduction gasification unit includes a reduction gasification furnace, a second cyclone flue gas magnetization device and a second high temperature bag filter; the top of the r...

Embodiment 2

[0063] Embodiment 2 of the present invention discloses a comprehensive utilization method of metallurgical solid waste, which specifically includes the following steps:

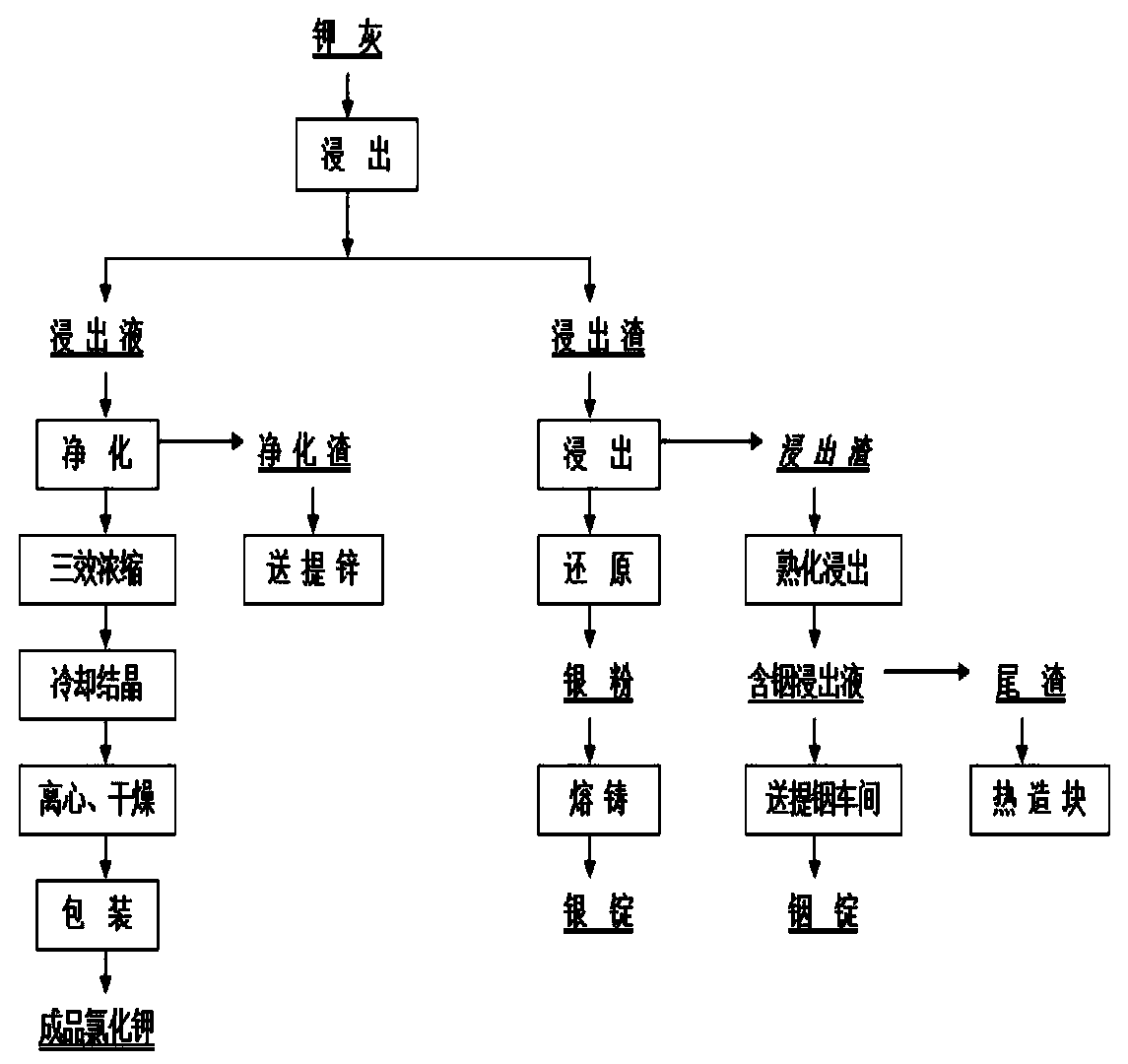

[0064] (1) Metallurgical solid waste is sent to the oxidation gasification kiln, the oxygen content of the atmosphere inside the oxidation gasification kiln is 16%, the oxidation gasification temperature is controlled at 1350 ° C, and the gasification oxidation enrichment is obtained to obtain potassium-sodium-silver mixed dust (potassium-sodium-silver mixed dust) Dust K element content 50%) and iron-containing slag;

[0065] (2) Break the iron-containing slag into 25mm pellets, and send some coke into the reduction gasifier. The mass ratio of slag-containing iron and coke is 2.5:1. The reduction gasification temperature is controlled at 1580°C, and the gasification reduction enrichment Obtain zinc-indium mixed dust (Zn element content of zinc-indium mixed dust is 55%), molten iron, rare metal alloy and silic...

Embodiment 3

[0070] Embodiment 3 of the present invention discloses a comprehensive utilization method of metallurgical solid waste, which specifically includes the following steps:

[0071] (1) Metallurgical solid waste is sent to the oxidation gasification kiln, the oxygen content of the atmosphere inside the oxidation gasification kiln is 17%, the oxidation gasification temperature is controlled at 1550 ° C, and the gasification oxidation enrichment is obtained to obtain potassium-sodium-silver mixed dust (potassium-sodium-silver mixed dust) Dust K element content 52%) and iron-containing slag;

[0072] (2) Break the iron-containing slag into 25mm pellets, and send part of the coke to the reduction gasifier. The mass ratio of slag-containing iron and coke is 2.5:1. Obtain zinc-indium mixed dust (zinc-indium mixed dust Zn element content 45%), molten iron, rare metal alloy and silicate slag;

[0073] (3) The exhaust gas from the reduction gasifier (the calorific value of the exhaust gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com