Patents

Literature

41results about How to "Inhibition of secondary reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

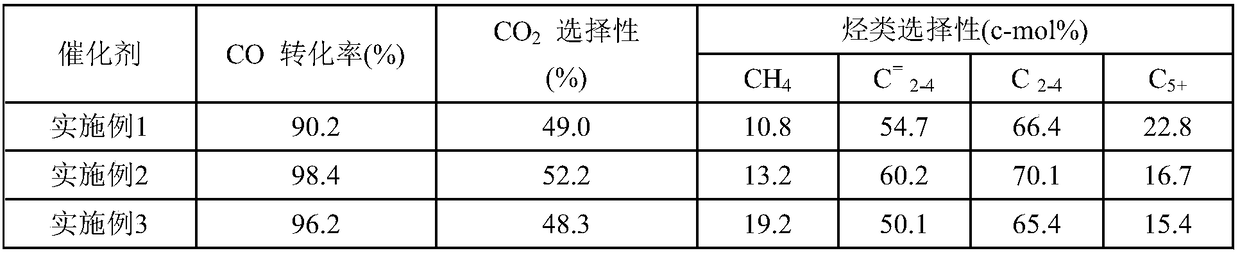

Method for selectively regulating and controlling products of Fischer-Tropsch synthesis

InactiveCN102559234AInhibition of secondary reactionsHigh selectivityHydrocarbon from carbon oxidesOrganic compound preparationBiomassCoal

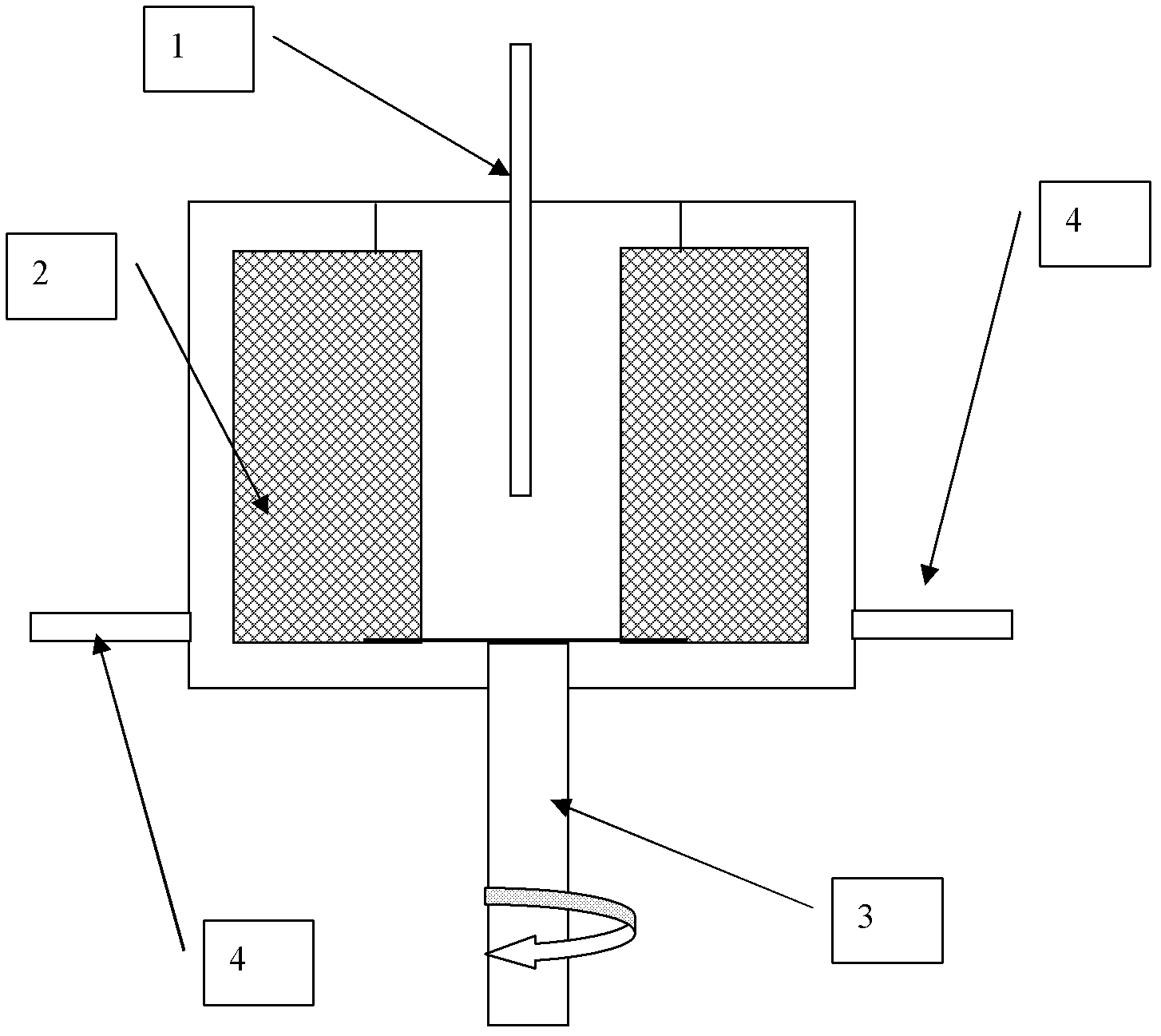

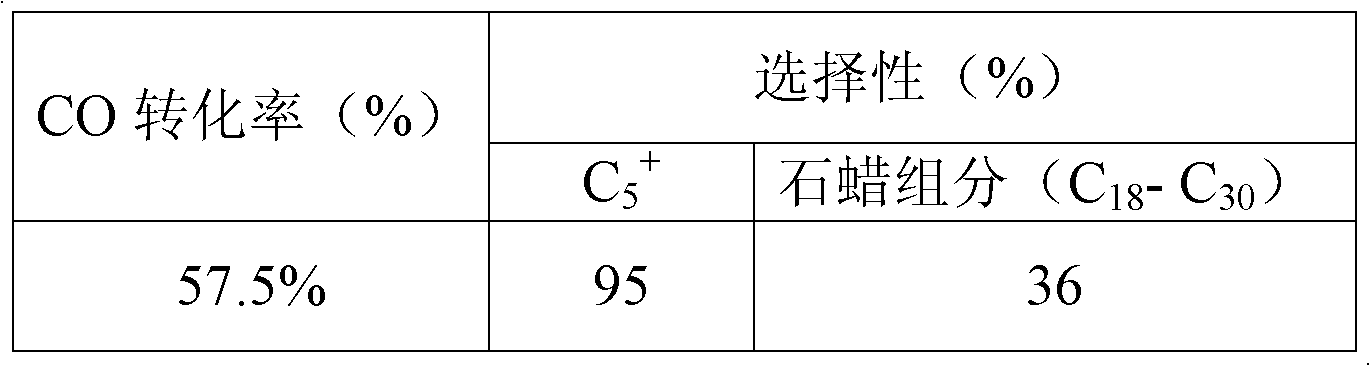

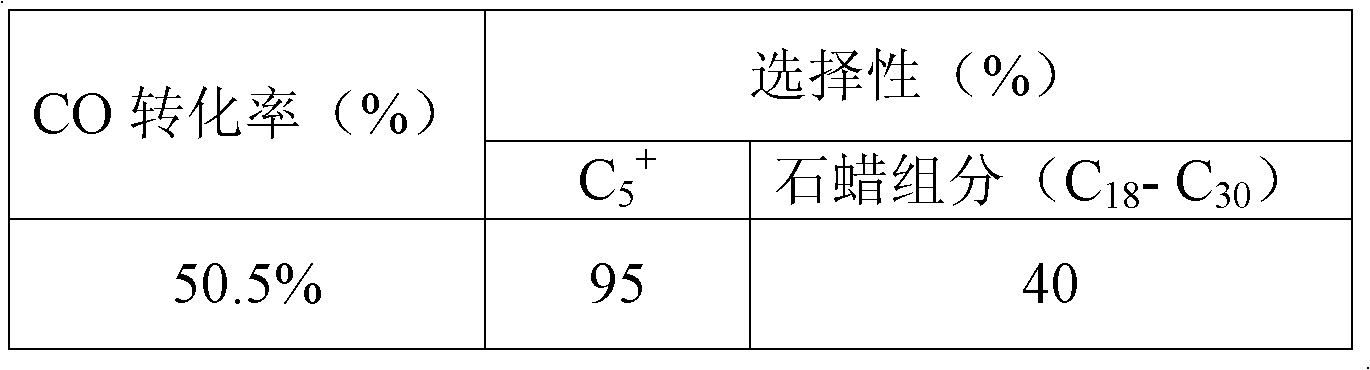

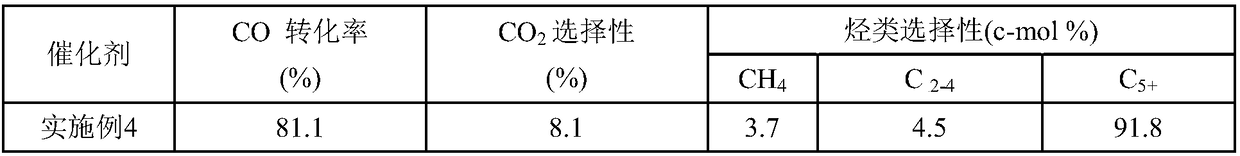

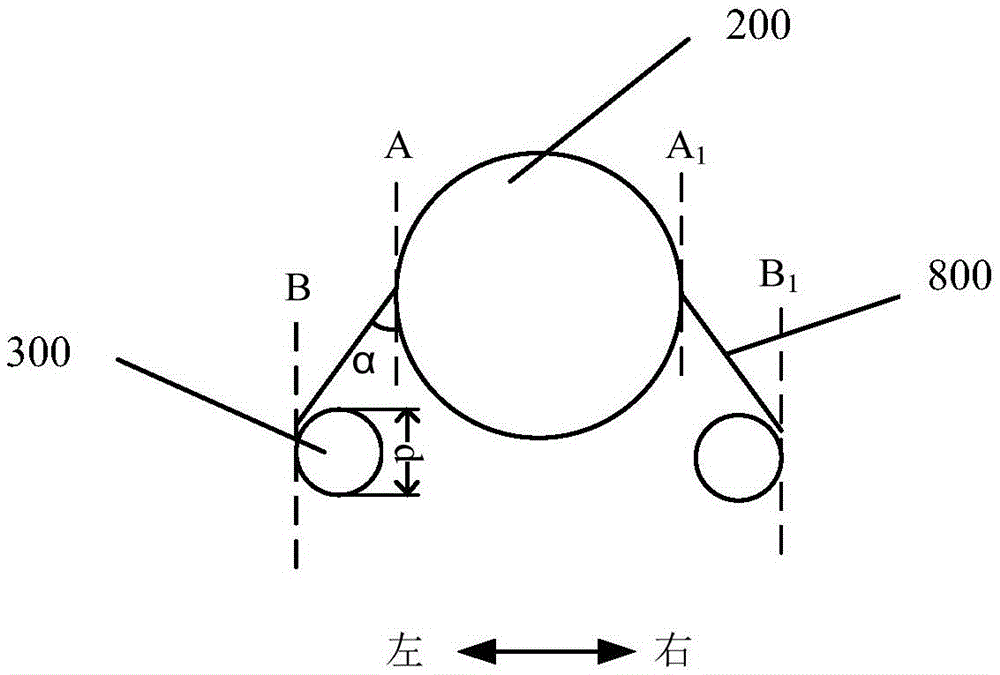

The invention discloses a method for selectively regulating and controlling products of Fischer-Tropsch synthesis, belonging to the technical field of supergravity, which is a novel Fischer-Tropsch synthesis method. The method comprises the following steps of: carrying out a Fischer-Tropsch synthesis reaction in a supergravity reactor to selectively synthesizing specific products, wherein a catalyst bed rotates in a certain rotation speed during reaction, reaction materials comprises coal-based synthetic gas, natural gas based synthetic gas, a coal bed gas synthetic gas or biomass-based synthetic gas, the supergravity level of the supergravity reactor is 2-400g, the reaction temperature is 180-500 DEG C, the reaction pressure is 1-100atm, and the gas airspeed is 100-100,000h<-1>. The method disclosed by the invention has the characteristics of directional production of target products, mass transfer, good heat transfer property and long catalyst service life.

Owner:BEIJING UNIV OF CHEM TECH +1

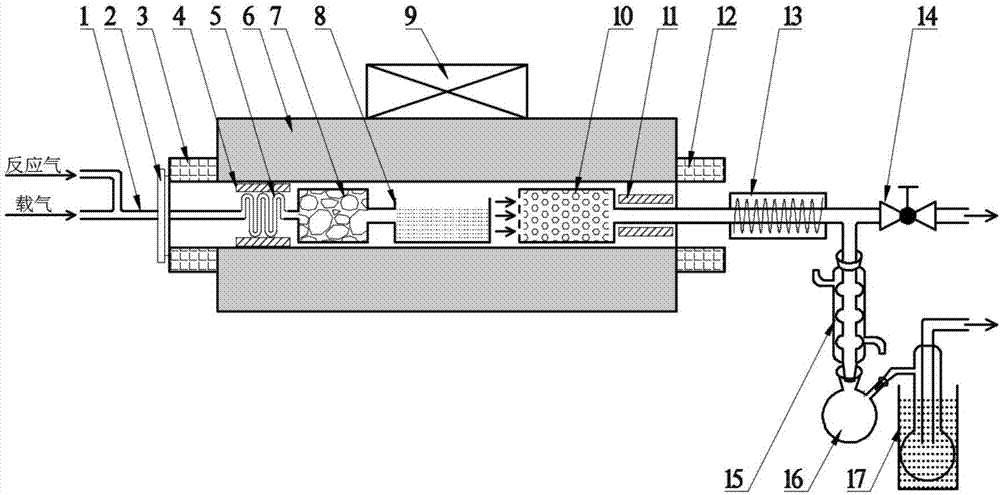

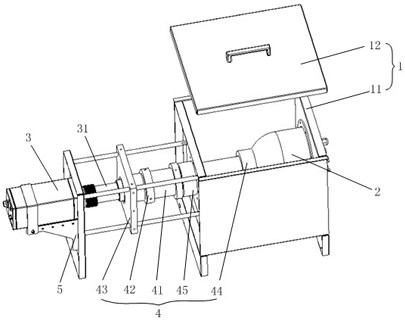

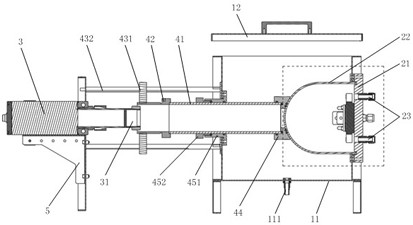

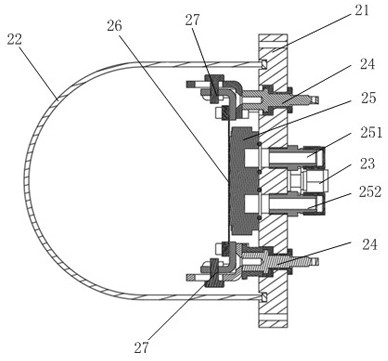

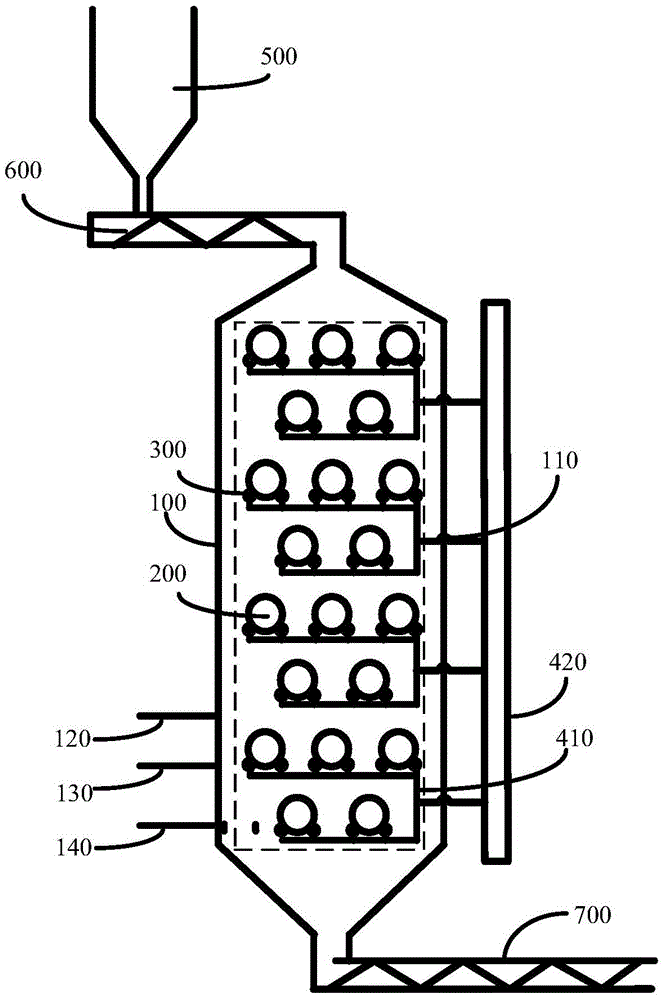

Device and method for coproducing bio-oil and biochar from solid waste through efficient microwave depolymerization

ActiveCN107987866ARealize online catalytic reformingAchieve hierarchical enrichmentLiquid hydrocarbon mixture productionCatalytic pyrolysisLiquid product

The invention discloses a device and a method for coproducing bio-oil and biochar from solid waste through efficient microwave depolymerization. The device comprises a gas inlet system for providing reaction gas and carrier gar, wherein an outlet end of the gas inlet system is connected with a preheating system, an outlet end of the preheating system is connected with a thermal-insulation filtration system, an outlet end of the thermal-insulation filtration system is connected with a reaction system, an outlet end of the reaction system is connected with a product collecting system, a productthermal insulation system is arranged on a pipeline between the reaction system and the product collecting system, and the outer sides of the preheating system, the thermal-insulation filtration system and the reaction system are sleeved with a microwave generation system. Solid waste can be converted into high-value liquid product bio-oil and solid product pyrolytic carbon in an efficient reduction, harmless and recycling manner with a two-stage conversion method of microwave depolymerization and catalytic pyrolysis.

Owner:临沂市新大环保科技有限公司

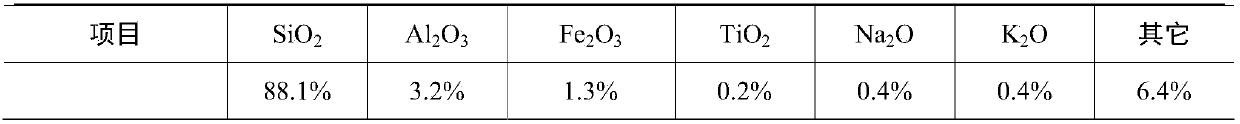

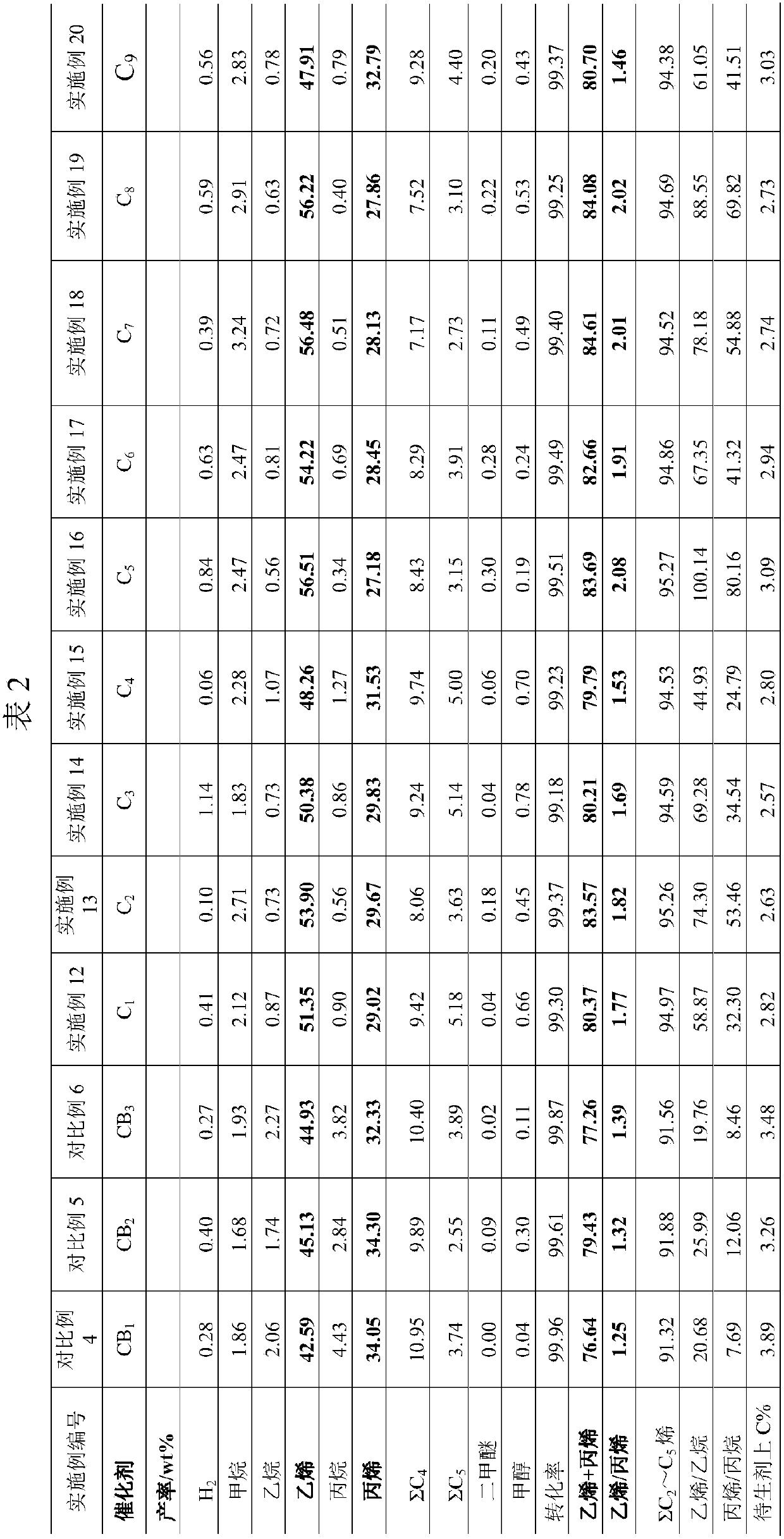

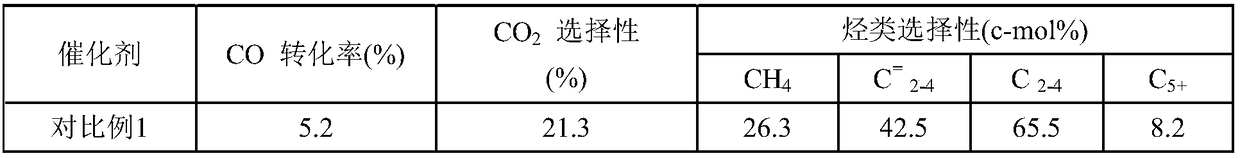

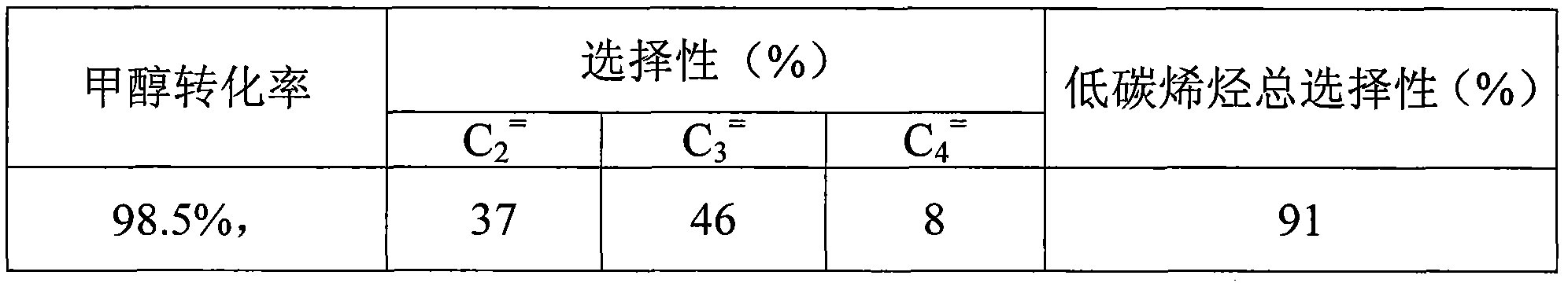

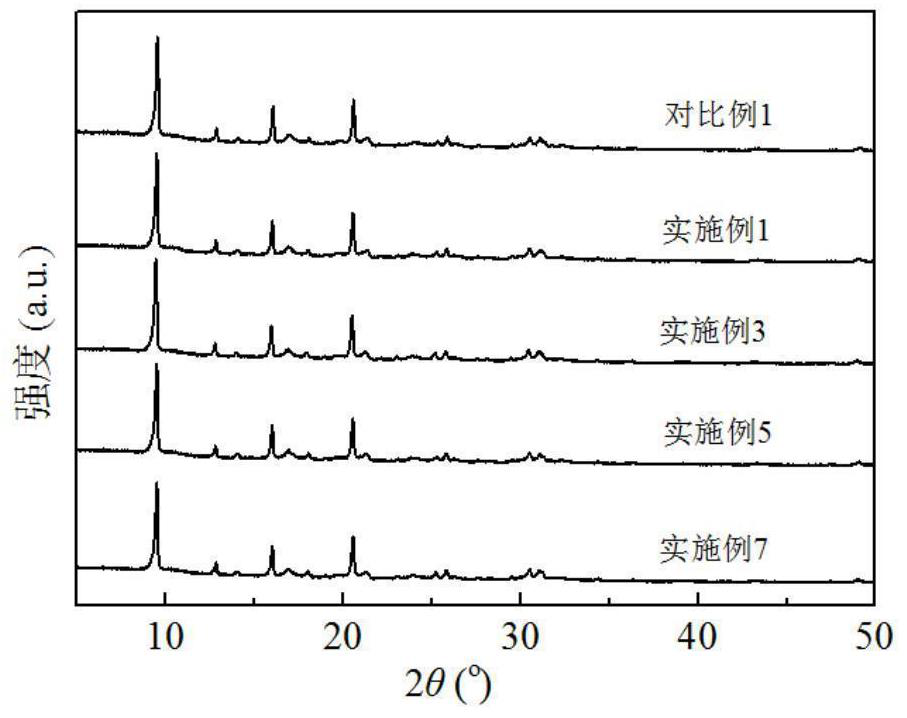

High-ethylene-selectivity catalyst for preparation of low carbon olefins from methanol

InactiveCN107626345AImprove catalytic performanceEnhanced Surface AcidityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveEthylene

The invention discloses a catalyst used for conversion of methanol for preparation of low carbon olefins (C2=-C4=). The catalyst is characterized by comprising, on a dry basis, 5 to 95 parts by weightof a modified silicoaluminophosphate (SAPO) molecular sieve, 4 to 50 parts by weight of an inorganic binder, 0.1 to 25 parts by weight of a Zn additive and 0.1 to 25 parts by weight of a phosphorus additive, and may optionally comprises 4 to 50 parts by weight of adhesion-free inorganic oxide or inorganic hydroxide and 1 to 60 parts by weight of clay, wherein the contents of the adhesion-free inorganic oxide or inorganic hydroxide, the inorganic binder, the Zn additive and the phosphorus additive are all calculated on in terms of oxide; and the Zn additive and the phosphorus additive do not contain Zn and P included in the modified silicoaluminophosphate (SAPO) molecular sieve. When the catalyst is applied to the process for preparation of low carbon olefins (C2=-C4=) through conversion of methanol, the catalyst can efficiently convert methanol into low carbon olefins (C2=-C4=), and in particular, the catalyst can greatly improve ethylene selectivity.

Owner:任丘市华北石油科林环保有限公司

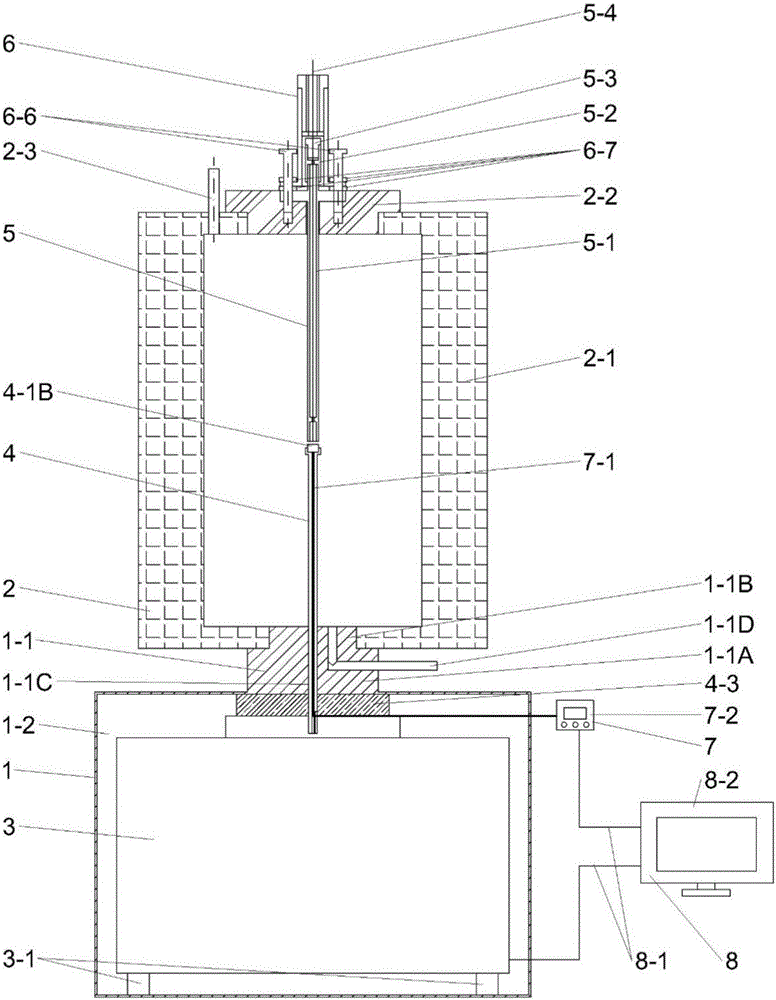

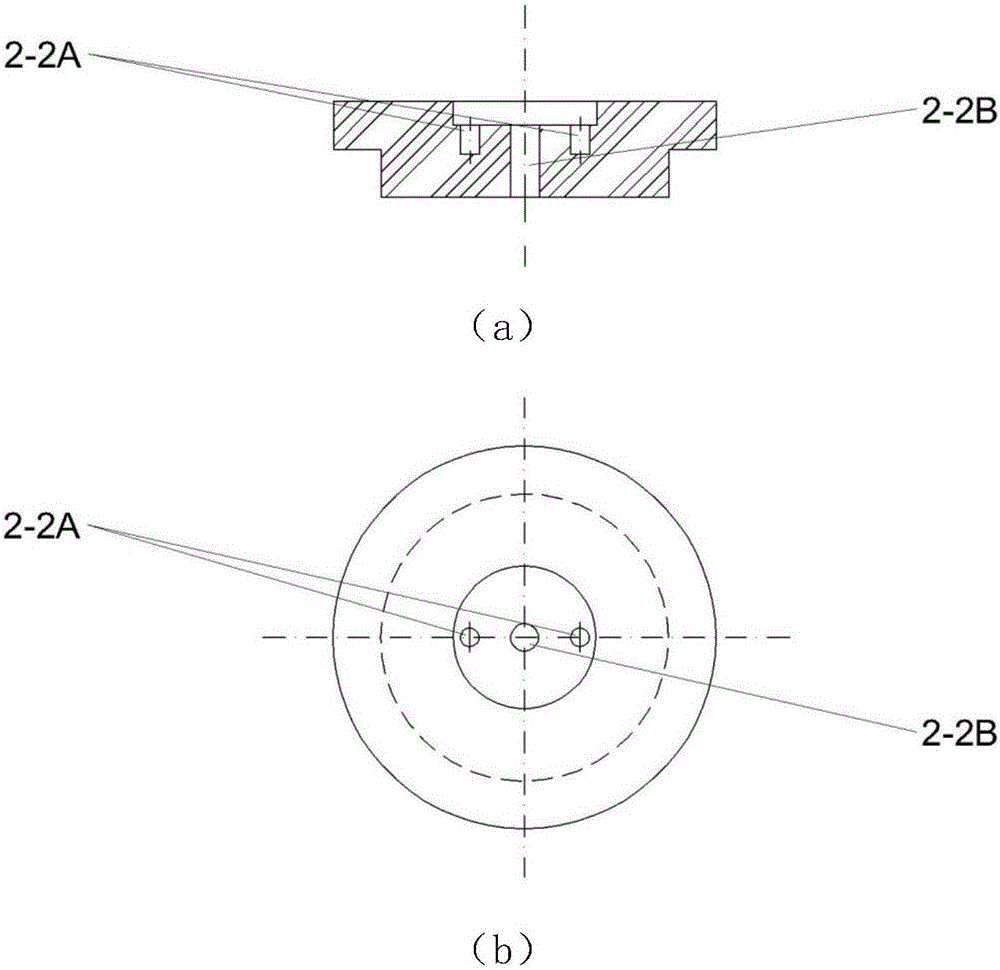

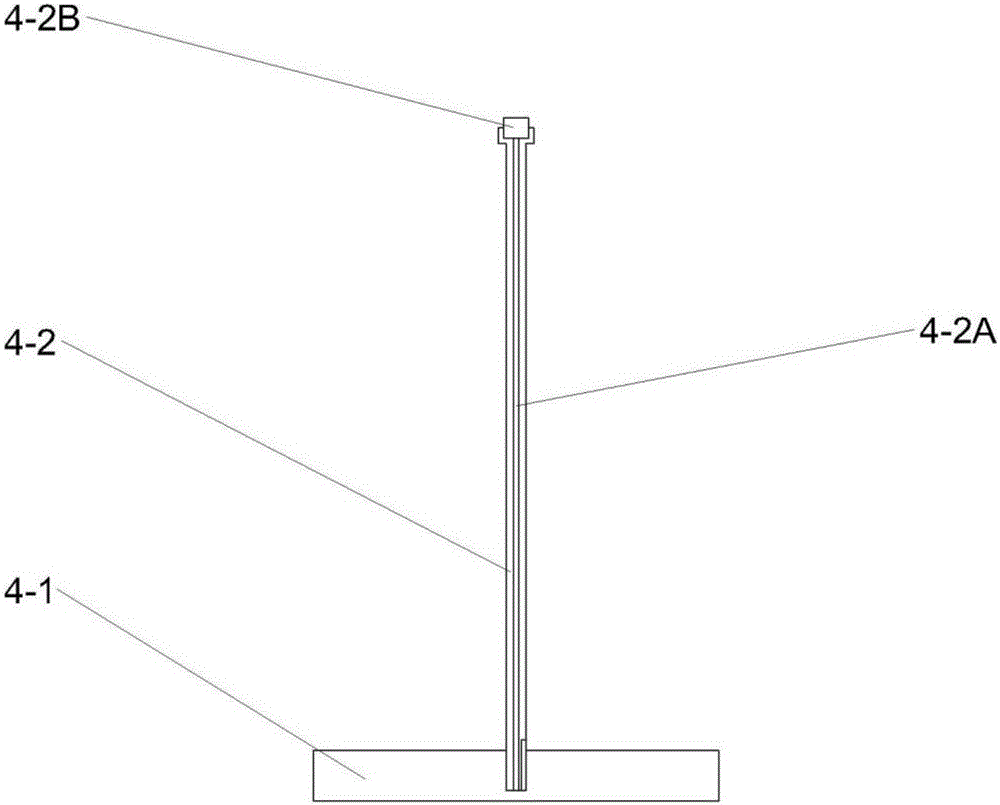

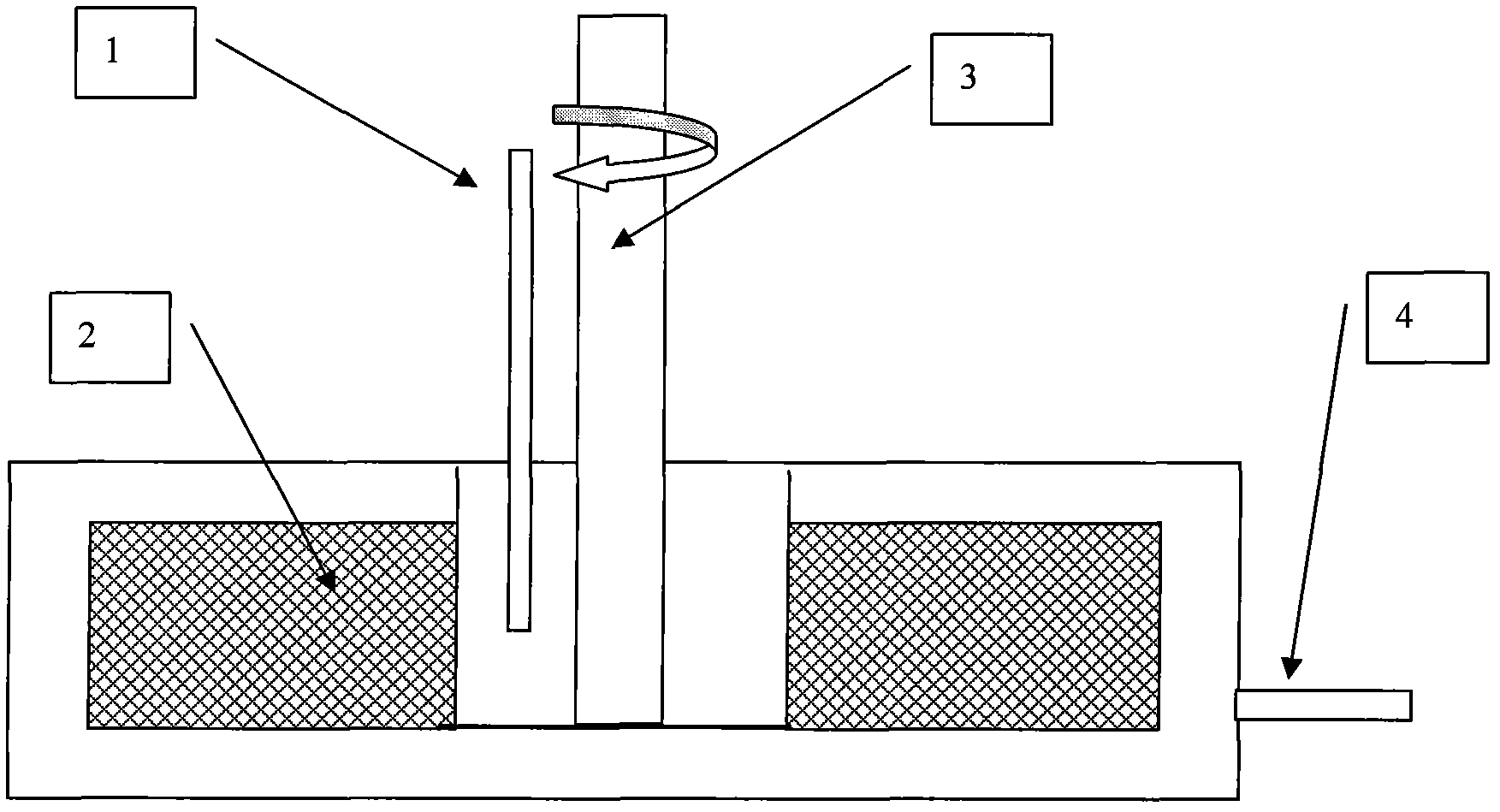

In-situ rapid sampling thermogravimetric analyzer

ActiveCN105954137AReduce the impact of concentration measurementsRealize the collectionWeighing by removing componentFurnace temperatureCrucible

The invention discloses an in-situ rapid sampling thermogravimetric analyzer. The in-situ rapid sampling thermogravimetric analyzer comprises a worktable, a heating furnace, a sample holder, a sampling probe, a heat preservation pipe, a furnace temperature control device and a data analysis device, wherein the heating furnace is arranged on the worktable; the sample holder is mounted on an electronic balance in the worktable and stretches into a hearth, and a crucible is arranged on the sample holder; the sampling probe is mounted on the heating furnace and is located above the crucible; the heat preservation pipe sleeves the outer part of the sampling probe and is internally provided with an ultrafine capillary tube; the ultrafine capillary tube stretches into the heat preservation pipe and the sampling probe in sequence and extends into the crucible; the furnace temperature control device is used for detecting and controlling the temperature of the heating furnace; and the data analysis device is used for acquiring weight and temperature signals. With the adoption of the in-situ rapid sampling thermogravimetric analyzer, the problems that a measurement error is large and a pipeline is easily blocked by a product can be effectively solved; and the in-situ rapid sampling thermogravimetric analyzer has the advantages of high measurement precision, convenient for operation, simple structure and the like.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Foam carbon-based catalyst and preparation method and application thereof

InactiveCN108607570ARegulatory responsivenessImprove diffusion abilityHydrocarbon from carbon oxidesOrganic compound preparationManganesePotassium

The invention discloses a foam carbon-based catalyst and relates to the field of catalysts. The foam carbon-based catalyst is prepared from a carrier which is porous foam carbon with a treated surfaceas well as active metals or active metals and additives combined on the surface of the carrier, wherein the active metals are selected from one or more of the following elements: iron, cobalt, nickel, copper, molybdenum, tungsten, ruthenium, platinum and rhodium, and the active metals exist in the form of a simple substance, an oxide or a carbide; and the additives are selected from one or more of the following elements: manganese, potassium, silver, calcium, magnesium, zirconium, aluminum, zinc, sodium and phosphorus, and the additives exist in the form of a simple substance or an oxide. Thefoamed carbon-based catalyst can adjust and control the selectivity of a reaction product when in use, and the catalytic reaction performance of the catalyst can be improved. The invention also discloses a preparation method and application of the catalyst.

Owner:BEIJING UNIV OF CHEM TECH

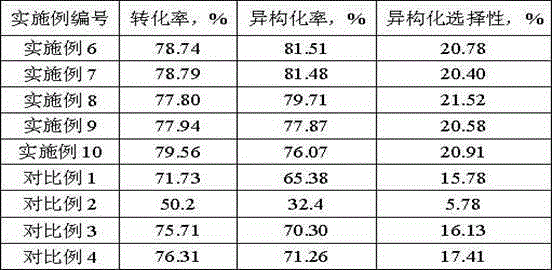

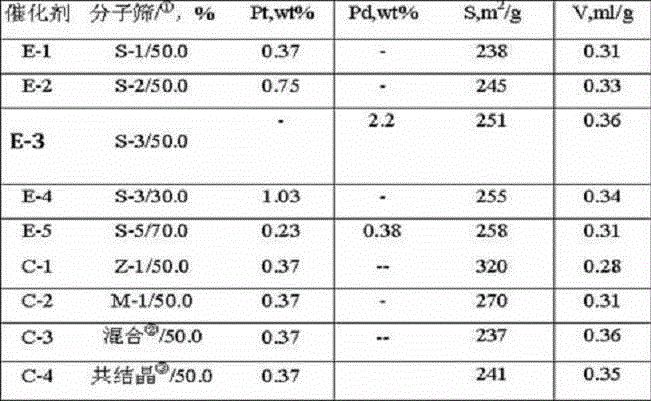

Low-carbon alkane isomerization catalyst and preparation method thereof

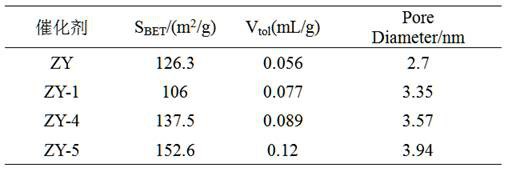

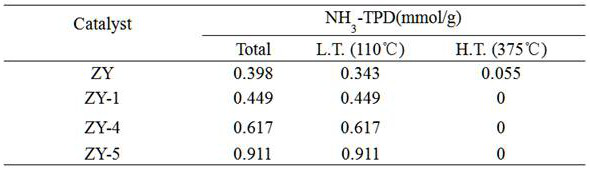

InactiveCN106669805AHigh activityHigh selectivityMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveIsomerization

The invention discloses a low-carbon alkane isomerization catalyst and a preparation method thereof. The catalyst contains an MCM-22 / ZSM-35 composite molecular sieve and group-VIII precious metal active components, wherein counted by the weight content of the catalyst, the content of the MCM-22 / ZSM-35 composite molecular sieve is 1.0 to 90 percent, the content of group-VIII precious metals is 0.1 to 1.5 percent, an MCM-22 molecular sieve of the MCM-22 / ZSM-35 composite molecular sieve wraps a ZSM-35 molecular sieve, and the weight content of the MCM-22 in the MCM-22 / ZSM-35 composite molecular sieve is 1.0 to 50 percent. The catalyst can shorten the dwell time of a carbonium ion intermediate in pores of the catalyst, improves the activity and isomerization selectivity and stability of the catalyst, and also suppresses secondary reaction such as polymerization coking and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

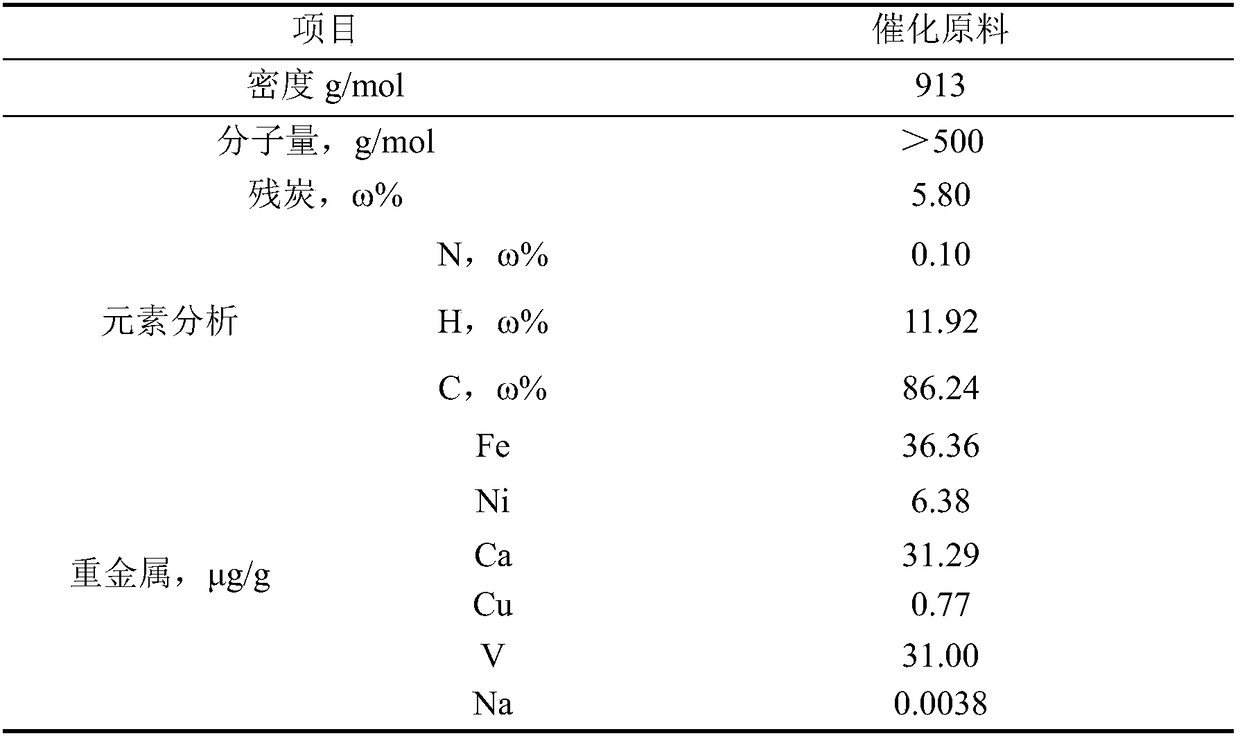

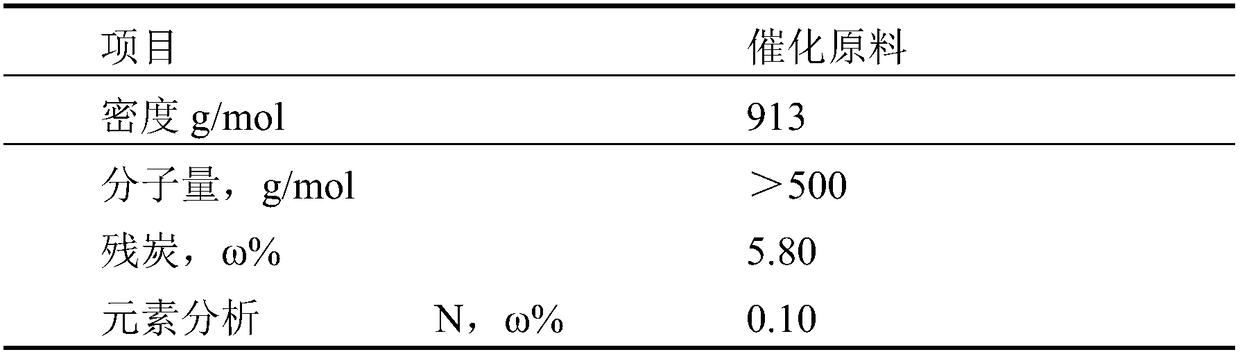

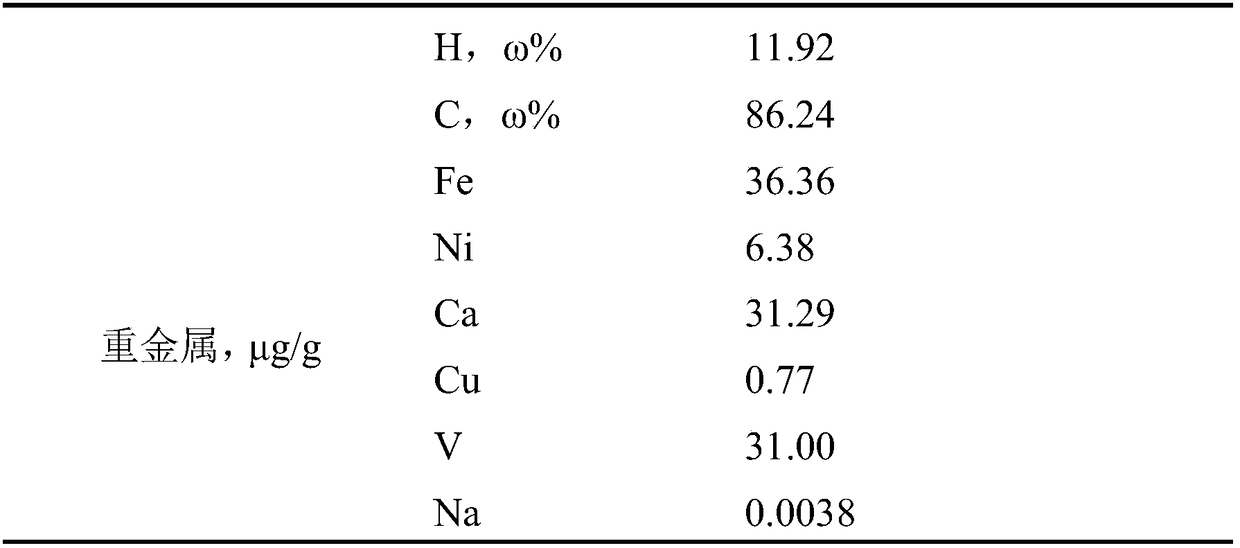

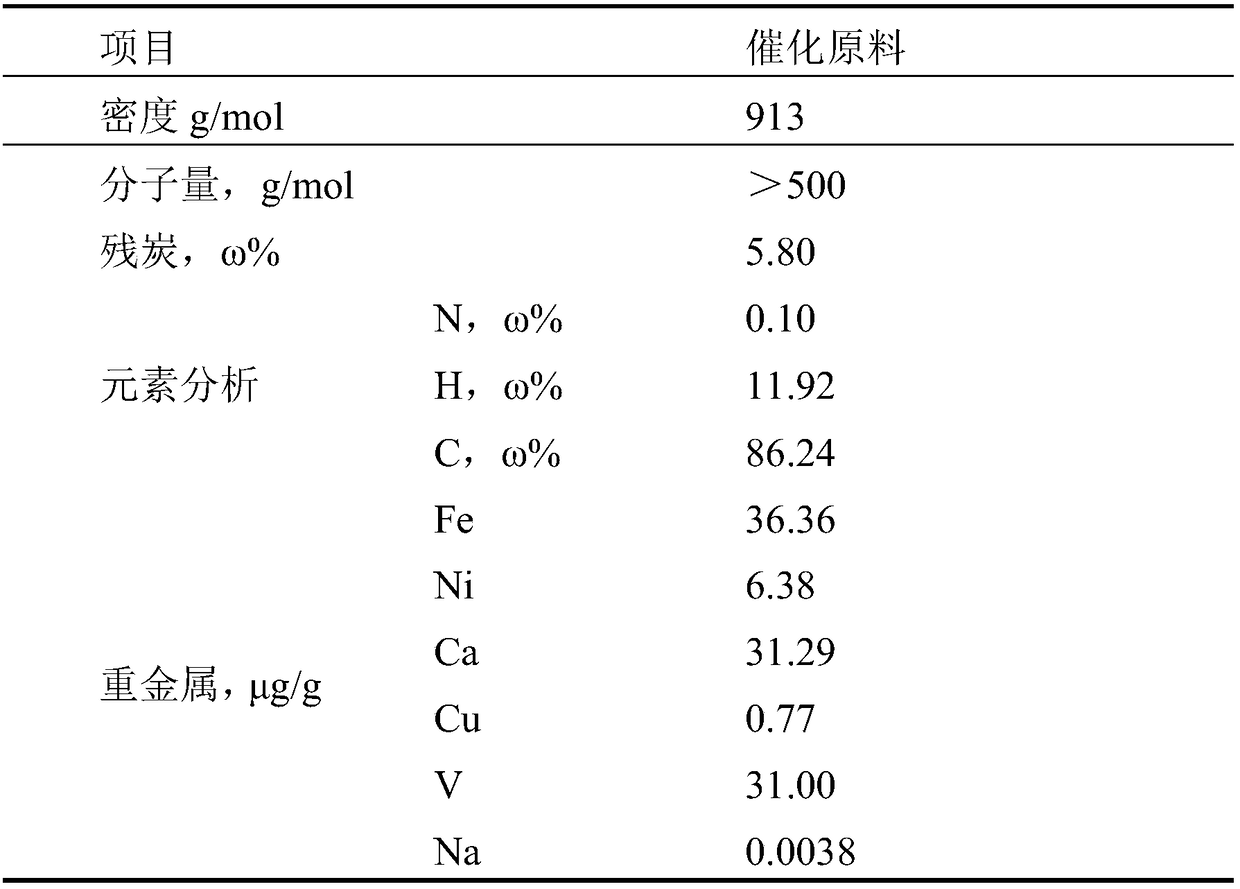

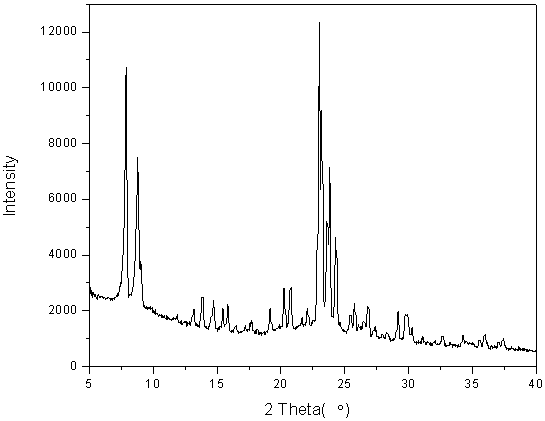

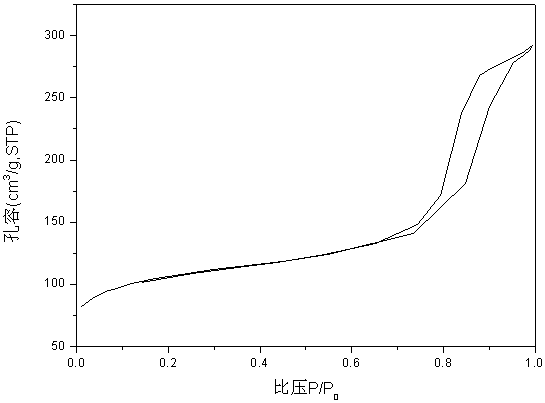

Catalyst for increasing yield of low-carbon olefins by directly catalytically cracking crude oil and preparation method thereof

PendingCN113385223ARegulating Pore DistributionHigh selectivityMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention provides a catalyst for increasing the yield of low-carbon olefins by directly catalytically cracking crude oil and a preparation method thereof. The catalyst comprises, on the basis of dry base weight, 5%-20% of a Y-type molecular sieve, 20%-50% of a phosphorus and zirconium modified ZSM-5 molecular sieve, 10%-40% of a carrier and 5%-25% of a binder; the catalyst is characterized in that the phosphorus and zirconium co-modified ZSM-5 molecular sieve is used for regulating and controlling the acid amount of the catalyst and the pore distribution of the catalyst, and diffusion of reactants in the catalyst and generation of a target product are facilitated. The developed catalyst is used for inhibiting secondary reaction in the direct catalytic cracking process of crude oil, the yield of the low-carbon olefins in the product is increased, and the catalyst has a relatively good application prospect.

Owner:郑州中科新兴产业技术研究院 +1

Novel method for high-gravity reinforced conversion of coal-based chemical raw material

InactiveCN102463075AInhibition of secondary reactionsHigh selectivityChemical/physical/physico-chemical processesSyngasHigh Gravity

The invention discloses a novel method for high-gravity reinforced conversion of a coal-based chemical raw material, which belongs to the technical field of high gravity. According to the method, a conversion reaction for a coal-based chemical raw material is carried out in a high-gravity reactor, and a catalyst bed is fixed on a rotor of a rotating packed bed and is always in a rotation state during the process of the reaction; through adjustment of the rotating speed of the rotor of the rotating packed bed, the mass transfer process of reaction products is reinforced, distribution of the reaction products is controlled, and selectivity of a target product is improved. The method provided in the invention carries out conversion reactions on chemical raw materials like coal-based syngas, methanol and dimethyl ether by using a rotating packed bed reactor and is a brand novel method for conversion of coal-based chemical raw materials.

Owner:BEIJING UNIV OF CHEM TECH

Catalytic cracking catalyst and preparation method thereof

ActiveCN109304212AReduce sodiumHigh activityCatalytic crackingMolecular sieve catalystsPseudoboehmiteMolecular sieve

The invention provides a catalytic cracking catalyst and a preparation method thereof, the catalyst is prepared from 15-60 wt% of molecular sieve, 15-60 wt% of clay, 10-30 wt% of pseudoboehmite, 5-20wt% of adhesive, 0.1-5 wt% of phosphorus-containing compound (calculated by P), 0.1-3 wt% of magnesium-containing compound (calculated by Mg), and may also contain 0-5 wt% of rare earth oxide. The preparation method comprises the following steps: (1) catalyst forming: mixing and pulping molecular sieve, clay, pseudoboehmite, phosphorus-containing compound and adhesive; then adding magnesium-containing compound to mix and pulp, heating and stirring, spraying and forming, and roasting to obtain the formed catalyst; (2) catalyst modification: mixing and pulping the formed catalyst, ammonium salt,phosphorus-containing compound and water, adjusting pH, heating and reacting, and filtering and drying to obtain the catalytic cracking catalyst of the invention. The catalytic cracking catalyst provided by the invention has the characteristics of low coke yield and high total liquid collection (liquefied gas, gasoline and diesel).

Owner:PETROCHINA CO LTD

Catalytic cracking catalyst capable of increasing yield of gasoline and preparation method thereof

ActiveCN109304209AHigh catalytic activityIncrease chance of contactCatalytic crackingMolecular sieve catalystsMolecular sieveGasoline

The invention provides a catalytic cracking catalyst capable of increasing the yield of gasoline and a preparation method thereof. The catalyst is prepared from 15-70 wt% of a molecular sieve, 15-60 wt% of clay, 8-30 wt% of pseudo-boehmite, 3-20 wt% of a binder, 0.01-2 wt% of phosphorus in terms of phosphorus and 0.01-3 wt% of magnesium in terms of magnesium. The preparation method comprises the following steps that (1) a phosphorus and magnesium modified Y type molecular sieve is prepared, specifically, the Y-type molecular sieve and a phosphorus-containing compound are mixed and pulped for reaction, and then a magnesium-containing compound is added for heating reaction; (2) a modified matrix material is prepared, specifically, the clay, the pseudo-boehmite, the binder and water are mixedand pulped, and the phosphorus-containing compound is added for uniform stirring; and (3) the phosphorus and magnesium modified Y type molecular sieve and the modified matrix material are mixed and pulped, and spray drying, washing, filtering and drying are carried out in sequence. The catalyst prepared through the method has strong heavy oil conversion capability and good coke and gasoline selectivity, the preparation process is simple, and industrial production is easy to realize.

Owner:PETROCHINA CO LTD

Catalytic cracking catalyst capable of improving coke selectivity and preparation method of catalytic cracking catalyst

ActiveCN109304205AImprove pore structureWeakening of acid strengthCatalytic crackingMolecular sieve catalystsMolecular sieveHydrogen

The invention provides a catalytic cracking catalyst capable of improving the coke selectivity and a preparation method of the catalytic cracking catalyst. The catalyst is prepared from 15 to 70 weight percent of a molecular sieve, 15 to 60 weight percent of clay, 8 to 30 weight percent of pseudo-boehmite, 3 to 20 weight percent of a binding agent, 0.01 to 10 weight percent of phosphorus (based onP) and 0.01 to 5 weight percent of magnesium (based on Mg). The preparation method of the catalytic cracking catalyst comprises the following steps: mixing the molecular sieve, a pore-expanding agent, the clay, the pseudo-boehmite, a phosphorus-containing compound and the binding agent and pulping; spraying and molding; roasting a molded catalyst microsphere, and mixing with magnesium-containingcompound, ammonium salt and water and pulping; adjusting the pH (Potential of Hydrogen) value and raising the temperature and stirring; filtering and drying to obtain the catalytic cracking catalyst.Under the condition that the conversion ratio is improved and the content of heavy oil is reduced, the catalyst prepared by the method has more excellent coke selectivity.

Owner:PETROCHINA CO LTD

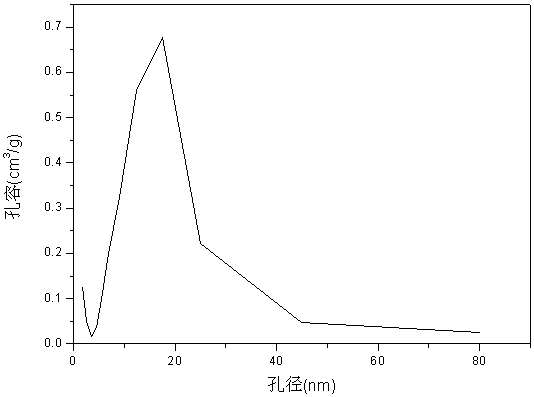

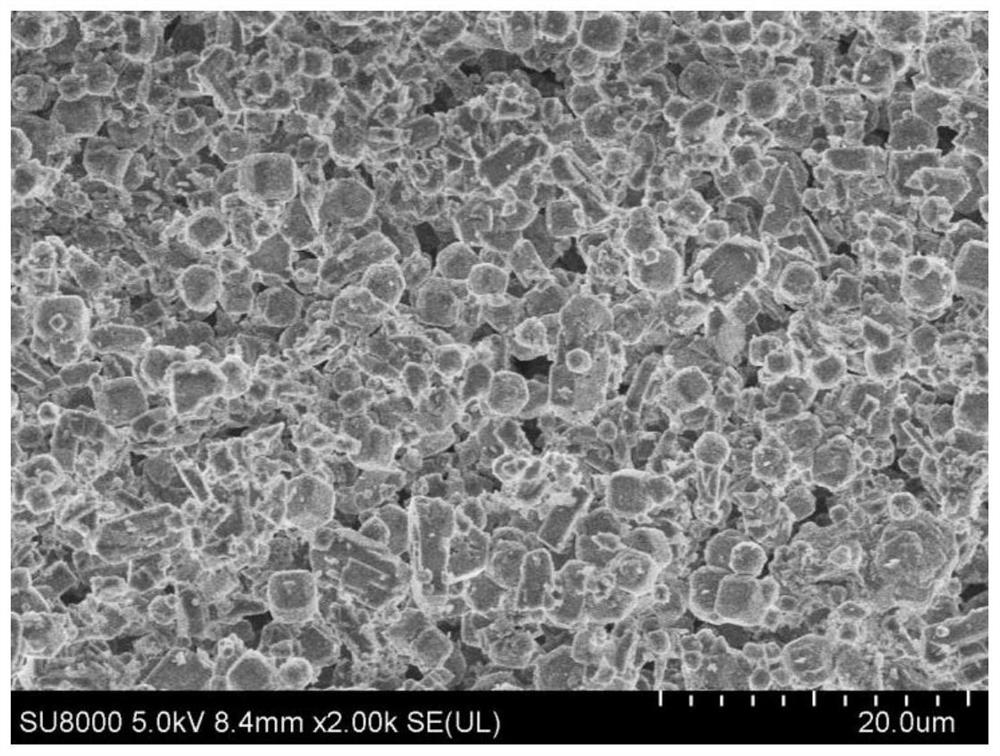

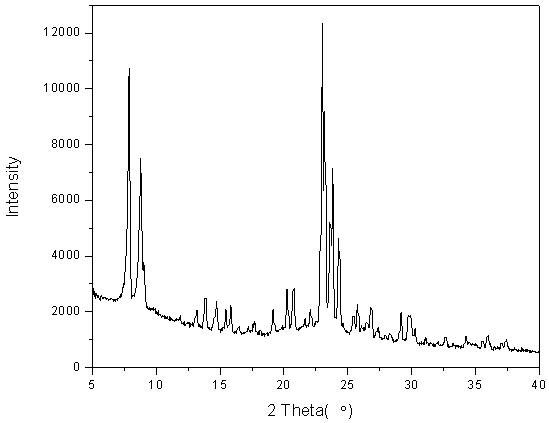

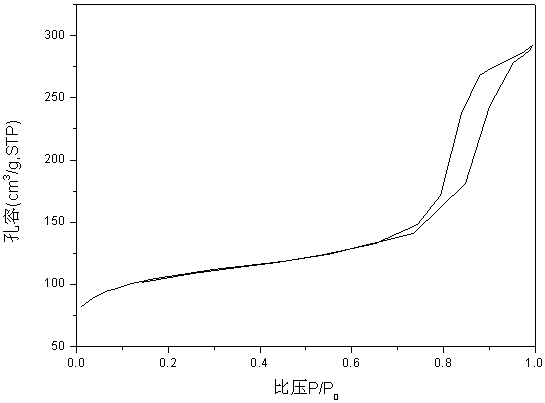

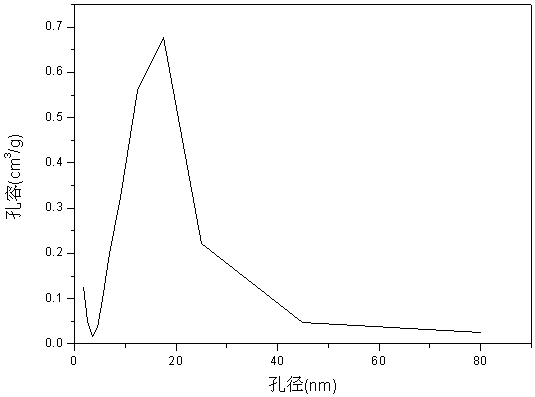

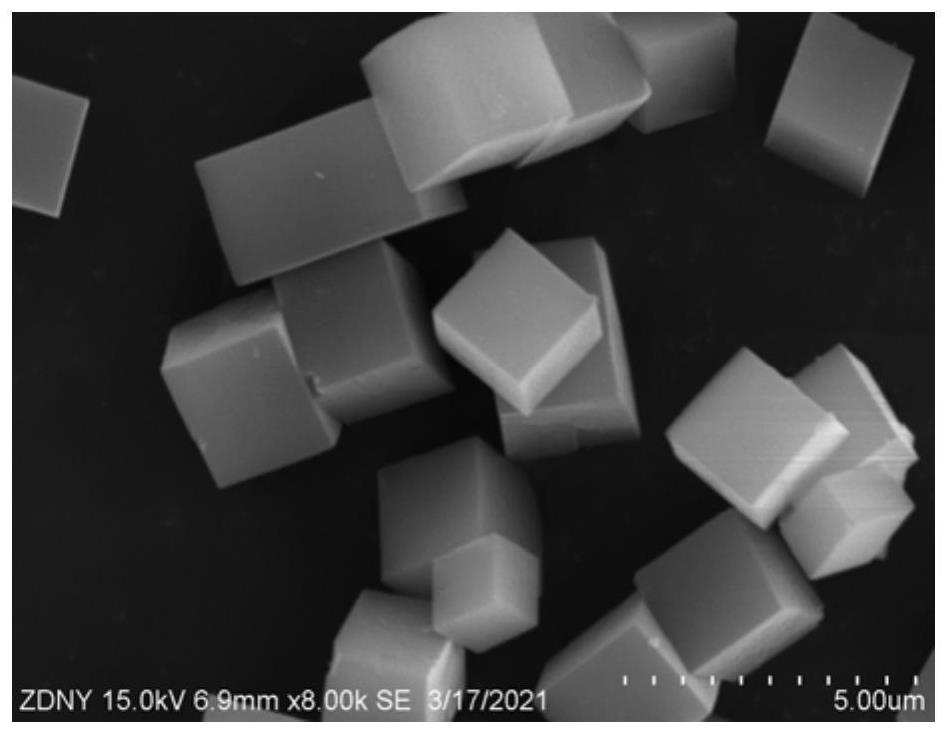

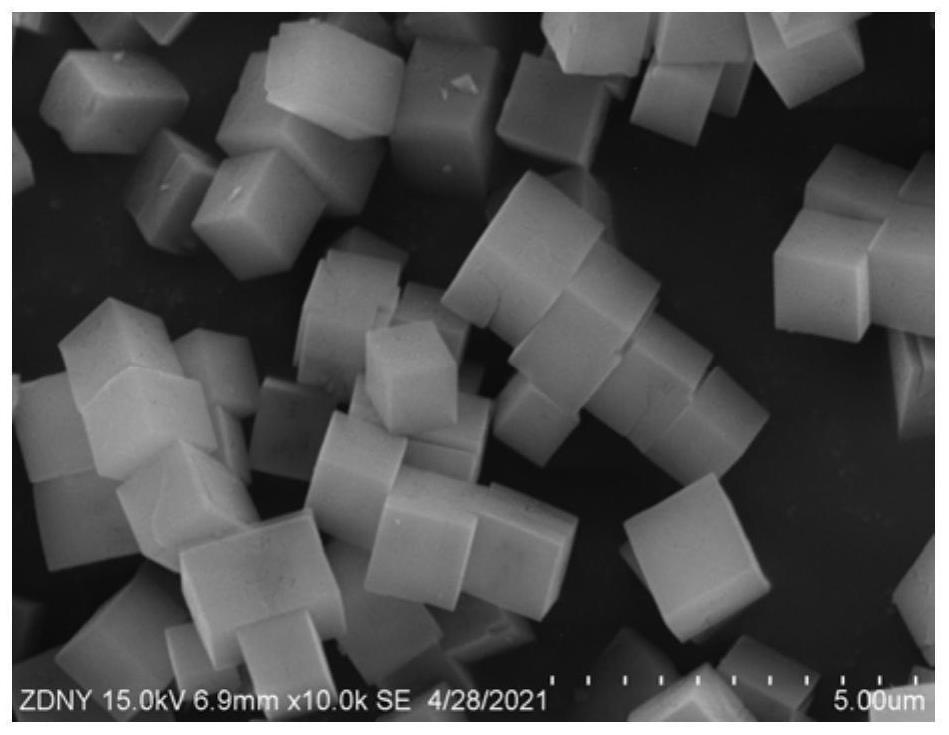

Preparation method of mesoporous ZSM-5 zeolite

ActiveCN107804857AInhibition of secondary reactionsHigh selectivityPentasil aluminosilicate zeoliteIonChemistry

The invention discloses a preparation method of mesoporous ZSM-5 zeolite. The preparation method comprises the following steps: 1) allyl glycidyl ether and dimethyl diallyl ammonium are uniformly mixed, a sodium persulfate aqueous solution with mass concentration being 10-30% is added, the materials are uniformly stirred and heated to the temperature of 60-90 DEG C, and then a polymerization is carried out for 2-8 hours, and cooling is carried out to obtain a copolymer; 2) aluminum sulfate, concentrated sulfuric acid and deionized water are prepared to an uniform solution; 3) water glass, deionized water and the copolymer obtained in the step 1) are mixed, a mixture is continuously stirred for 0.5-3 hours, then the solution prepared in the step 2) is slowly added while rapid stirring, andthe materials are continuously stirred for 1-6 hours to obtain an uniform gel; and 4) the above gel is transferred to a high-pressure reaction vessel for crystallization, the crystallized products aresubjected to pumping filtration and washed to neutrality, and then the crystallized products are dried and roasted to obtain the mesoporous ZSM-5 zeolite. The prepared mesoporous ZSM-5 zeolite contains a lot of meso-structures, cost of raw material is low, operation is simple and easy, no special requirement is generated on equipment, and the method is suitable for industrial production and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

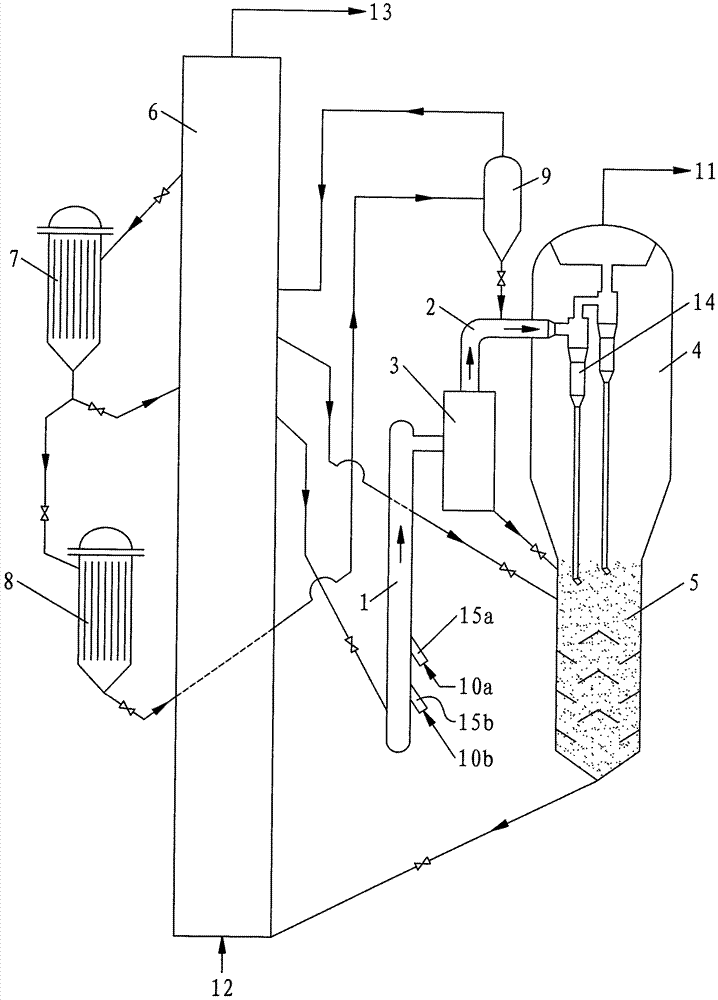

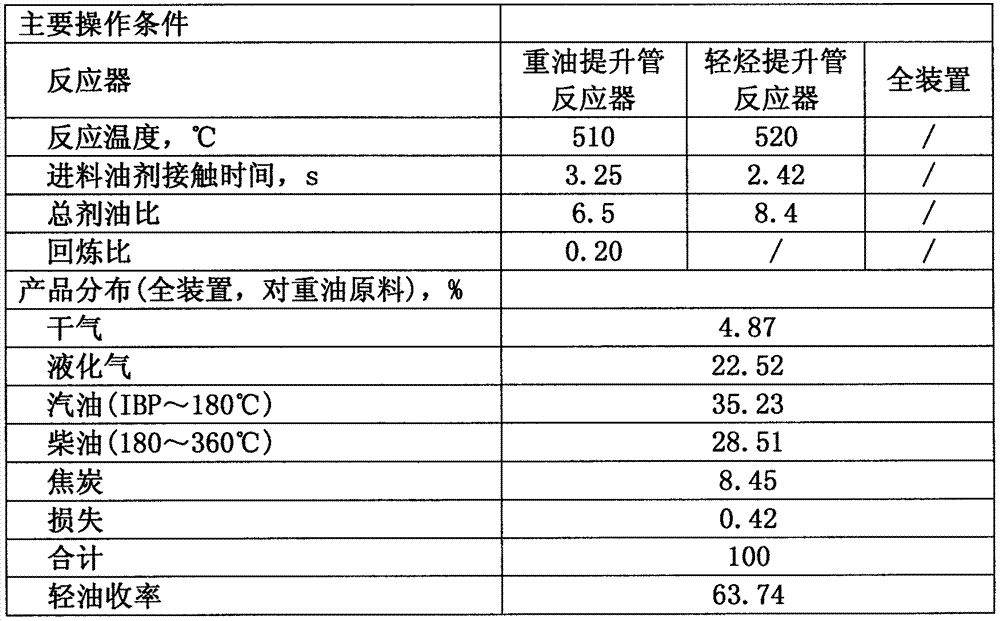

Combined catforming of high-production low carbon alkene

ActiveCN101045667BReduce backmixingHigh selectivityChemical recyclingBulk chemical productionAlkeneCracking reaction

A combined catalytic converting process for preparing low-carbon olefin with high output includes such steps as contacting between heavy oil as raw material, regenerated catalyst and carbon depositedcatalyst in flow-down tube reactor, cracking reaction, separating the cracked product from the catalyst to be regenerated, separating low-carbon olefin from cracked product, contacting between rest ofsaid product and regenerated catalyst in flow-up tube reactor, reaction, separating oil gas from catalyst, separating low-carbon olefin from oil gas, and regenerating the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

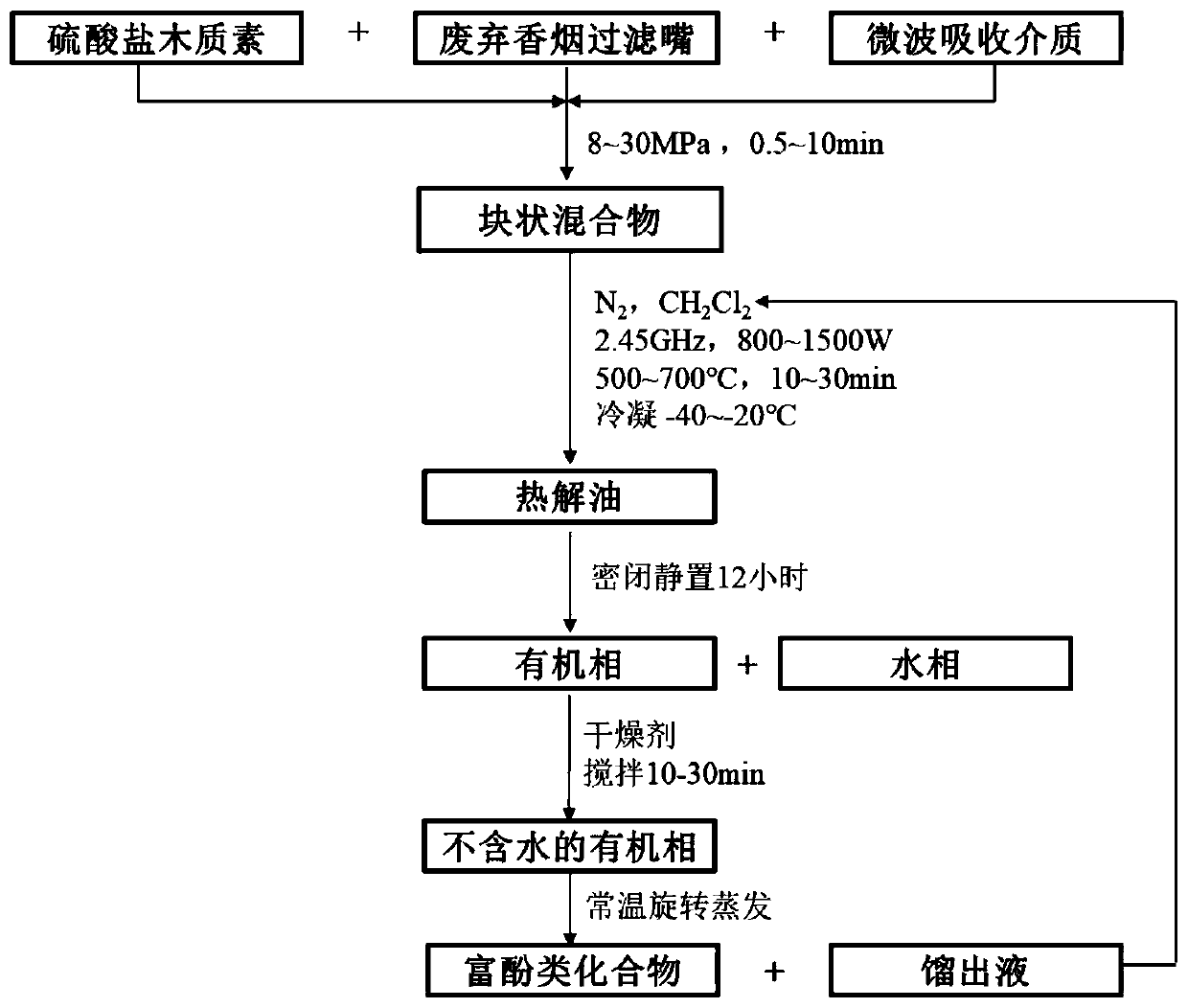

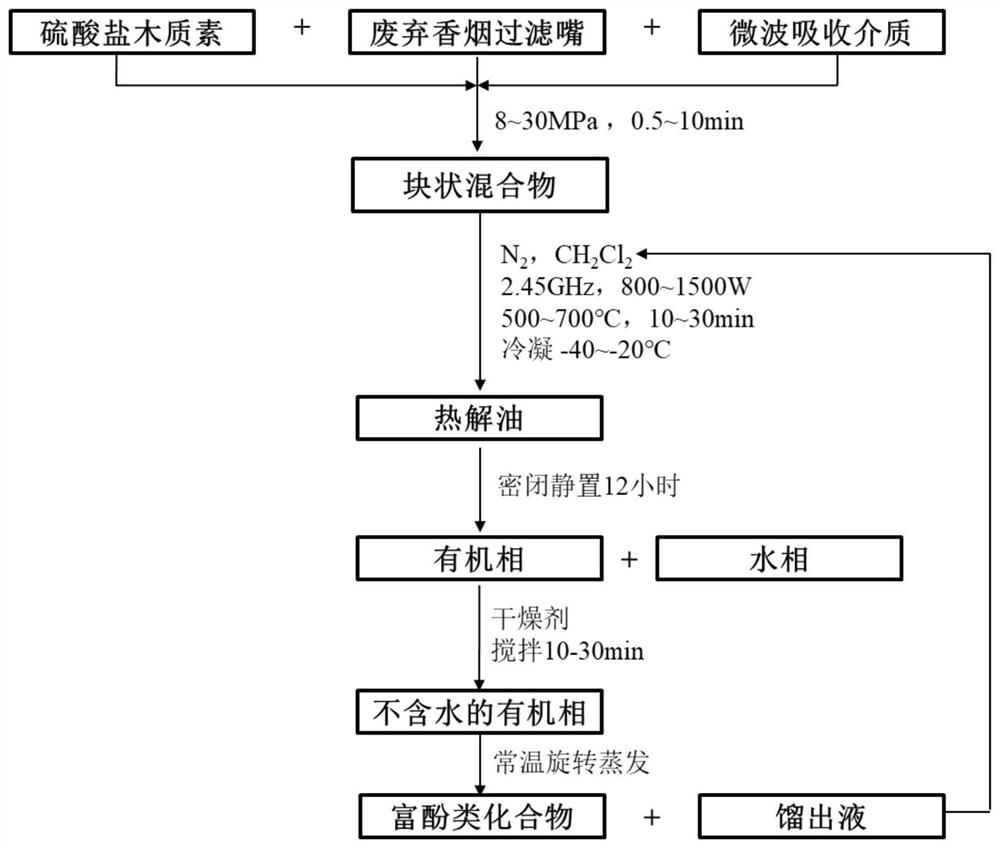

Method for promoting depolymerization of lignin sulfate through filter tips of abandoned cigarettes

ActiveCN110407888AImprove depolymerization efficiencyEasily brokenOrganic compound preparationLignin derivativesDepolymerizationEvaporation

The invention discloses a method for promoting depolymerization of lignin sulfate through filter tips of abandoned cigarettes. According to the method, after the filter tips of the abandoned cigarettes are smashed, the smashed filter tips are mixed uniformly with the lignin sulfate and a microwave absorption medium, then a mixture is ground, and the ground mixture is pressed into massive mixturesin different shapes; the massive mixtures are put in a microwave reactor, nitrogen is introduced in advance to discharge air in a reaction system, then nitrogen carrying dichloromethane is introducedinto the microwave reactor, the microwave reactor is started up, and generated depolymerization steam is condensed to obtain liquid, namely pyrolytic oil; the pyrolytic oil is subjected to airtight standing at normal temperature, a low-layer organic phase is collected, the collected organic phase is dehydrated, an organic phase which does not contain moisture is obtained and subjected to normal-temperature rotary evaporation, when no distillate is distilled off, a substance which is not evaporated out is a phenol-rich compound, a liquid substance which is evaporated out is dichloromethane, andthen recycling is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

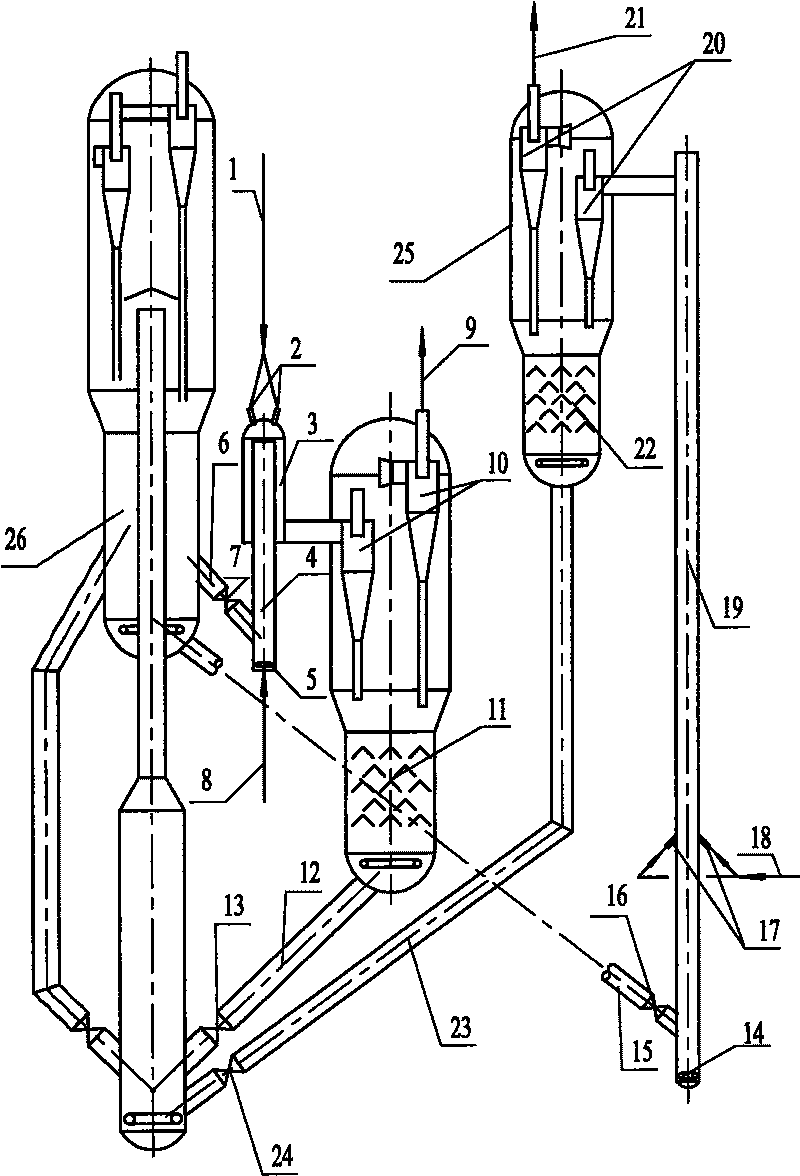

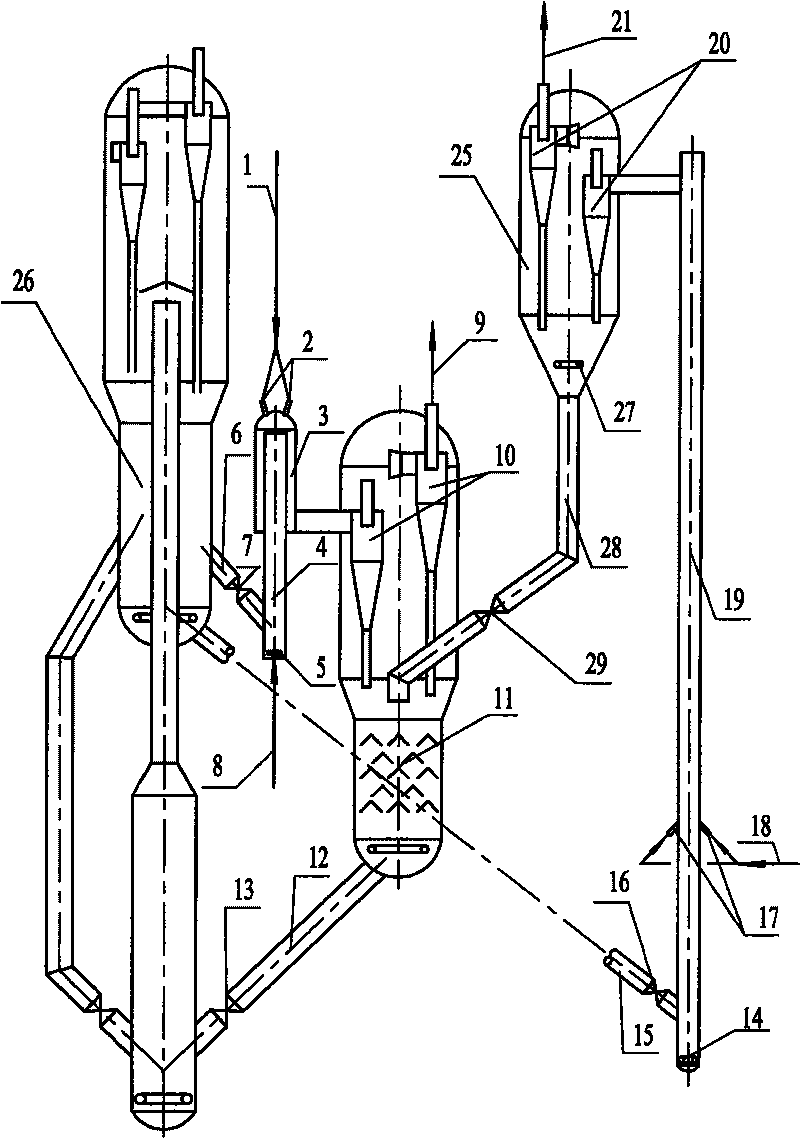

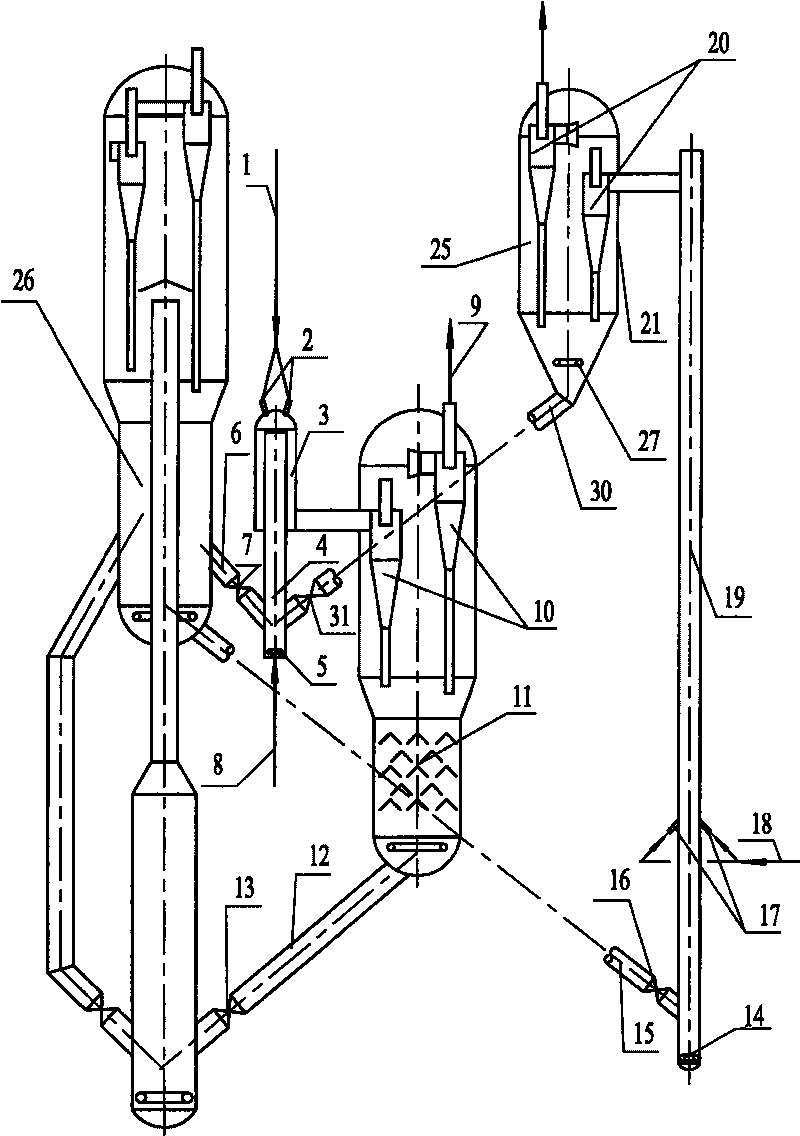

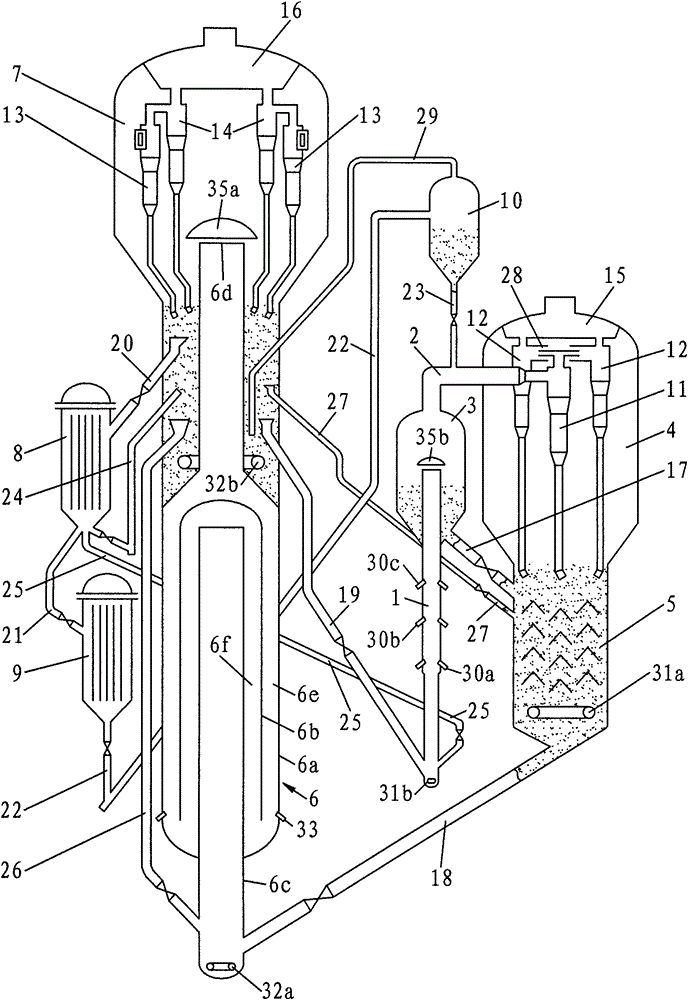

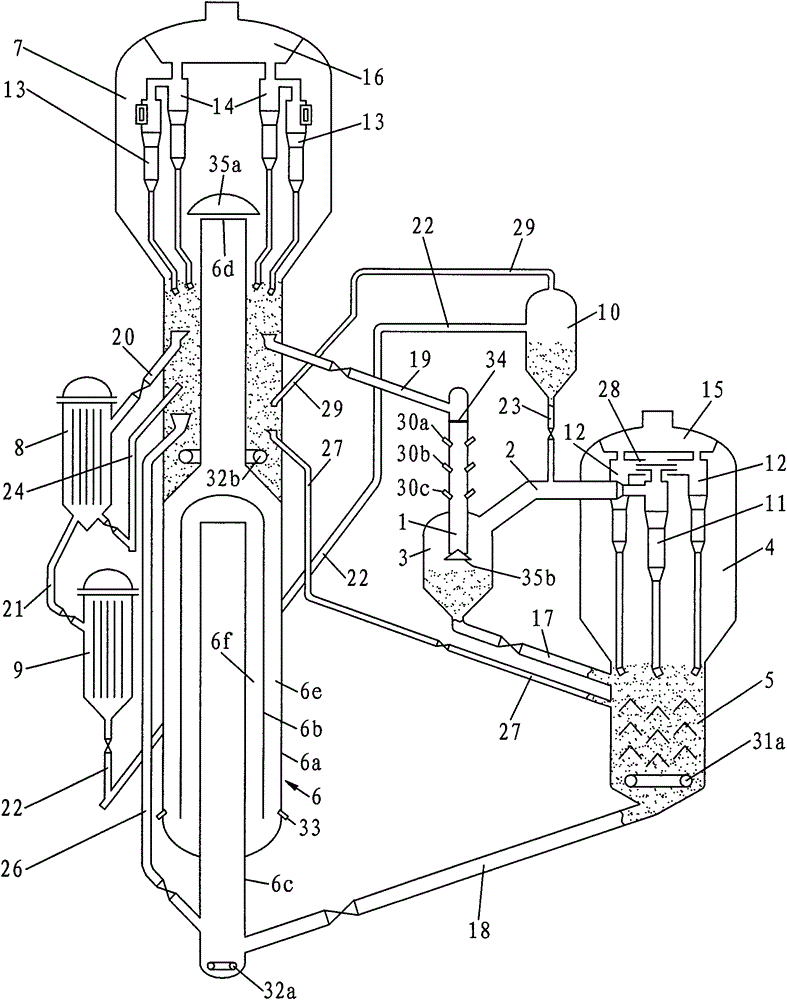

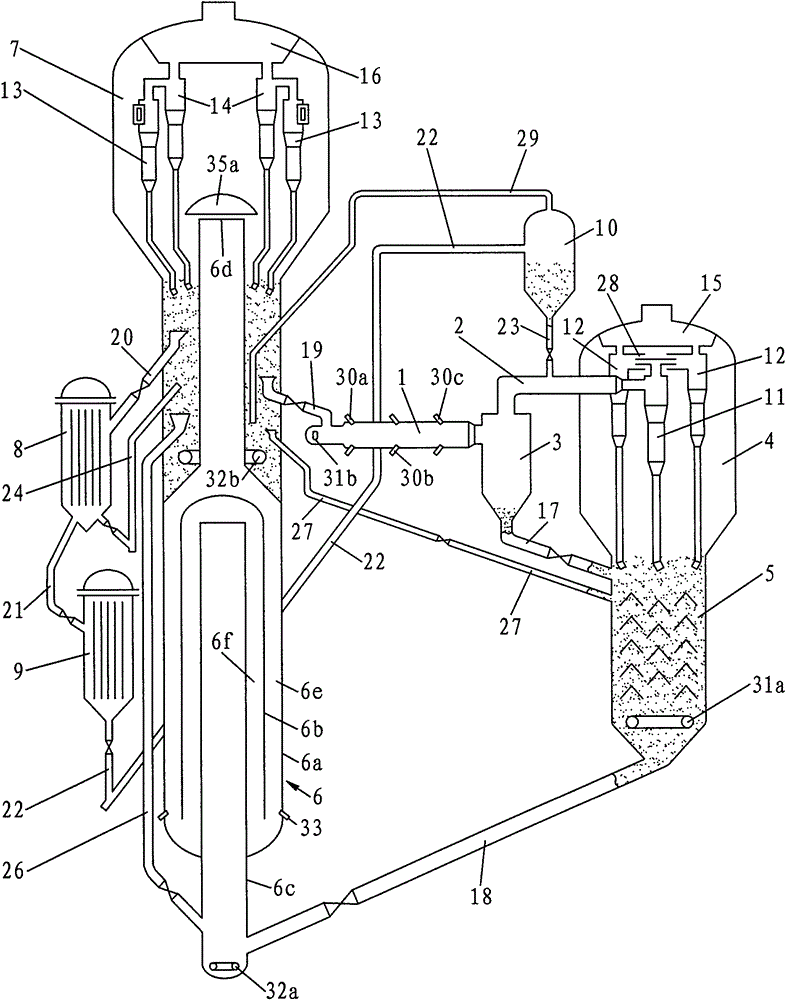

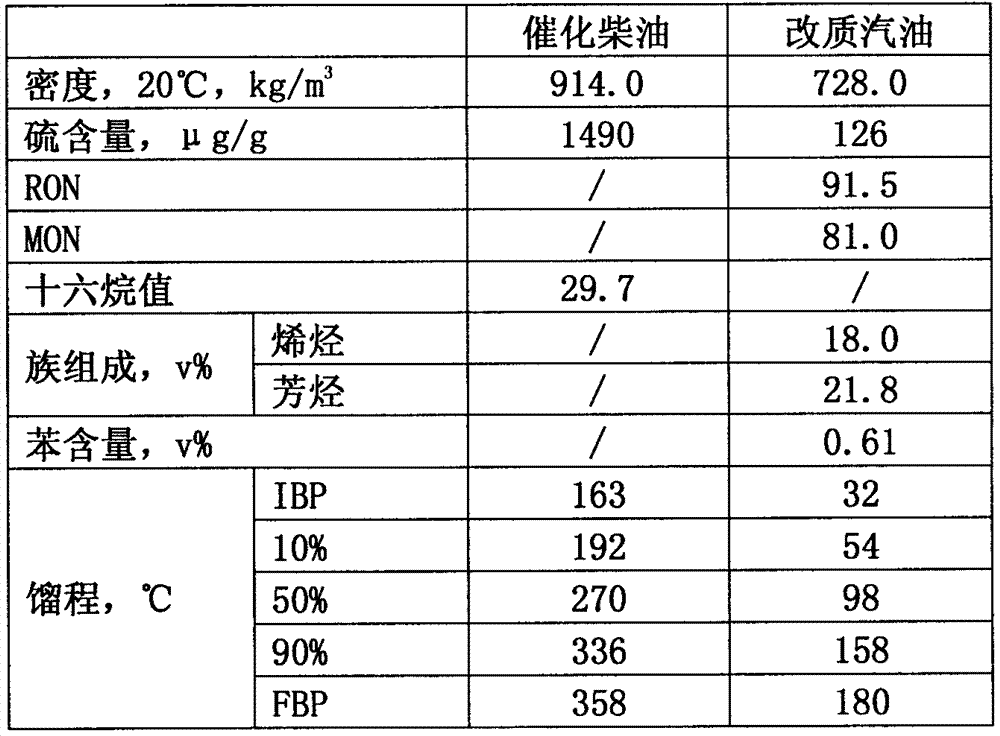

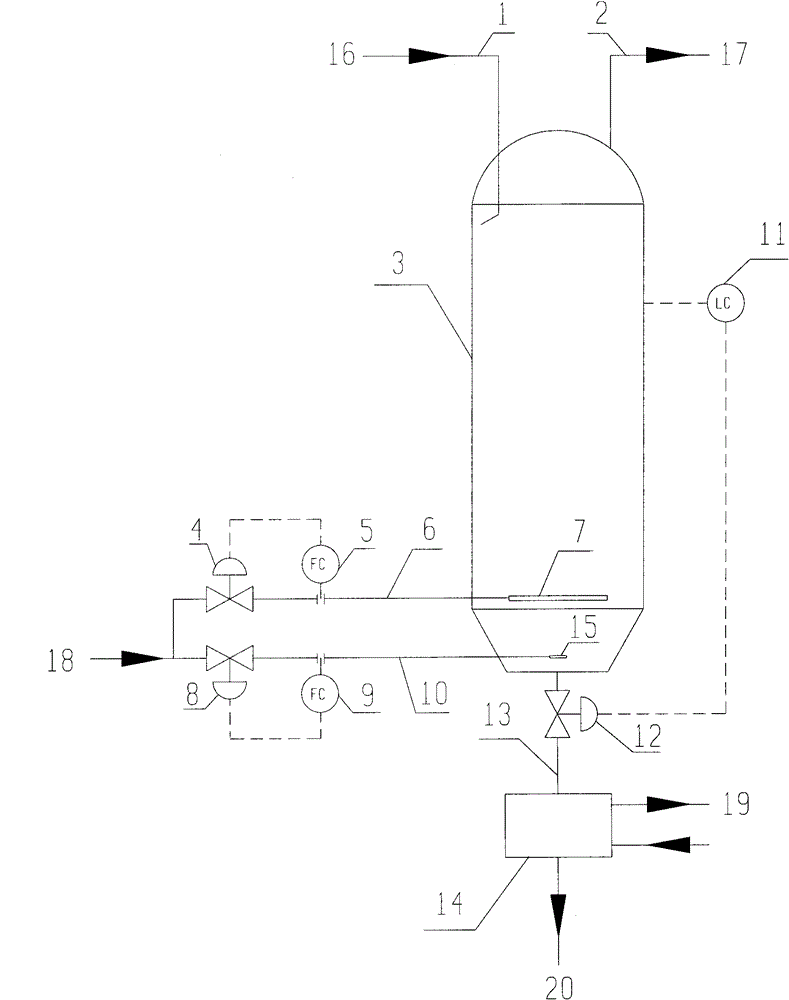

Fluid catalytic cracking device

ActiveCN105885938AHigh char strengthLarge heat capacityTreatment with plural serial stages onlyGasolinePetrochemical

The invention discloses a fluid catalytic cracking device in a petrochemical industry. The device mainly comprises a first tubular reactor with reaction section length of 5-15m, a second tubular reactor with reaction section length of 5-10m, a sedimentation device, a gas-solid separator, a regenerator composed of a baffle pipe-type separator and a turbulent bed separator, a first-grade regenerated catalyst cooler, a second-grade regenerated catalyst cooler, a low-temperature regenerated catalyst tank and pipes connected to corresponding devices. The baffle pipe-type separator mainly comprises a housing, an outer pipe and an inner pipe. The housing comprises a housing pipe, a transition section and an outlet pipe connected in series from top to bottom. Circular passages are formed between the housing pipe and the outer pipe and between the outer pipe and the inner pipe. The separator wall at the bottom of the inner pipe is provided with a regenerated catalyst inlet and an inlet of a catalyst to be regenerated. The separator wall at the bottom of the housing pipe is provided with a main air inlet pipe. The device can be used for heavy oil catalytic cracking and gasoline catalytic modification.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

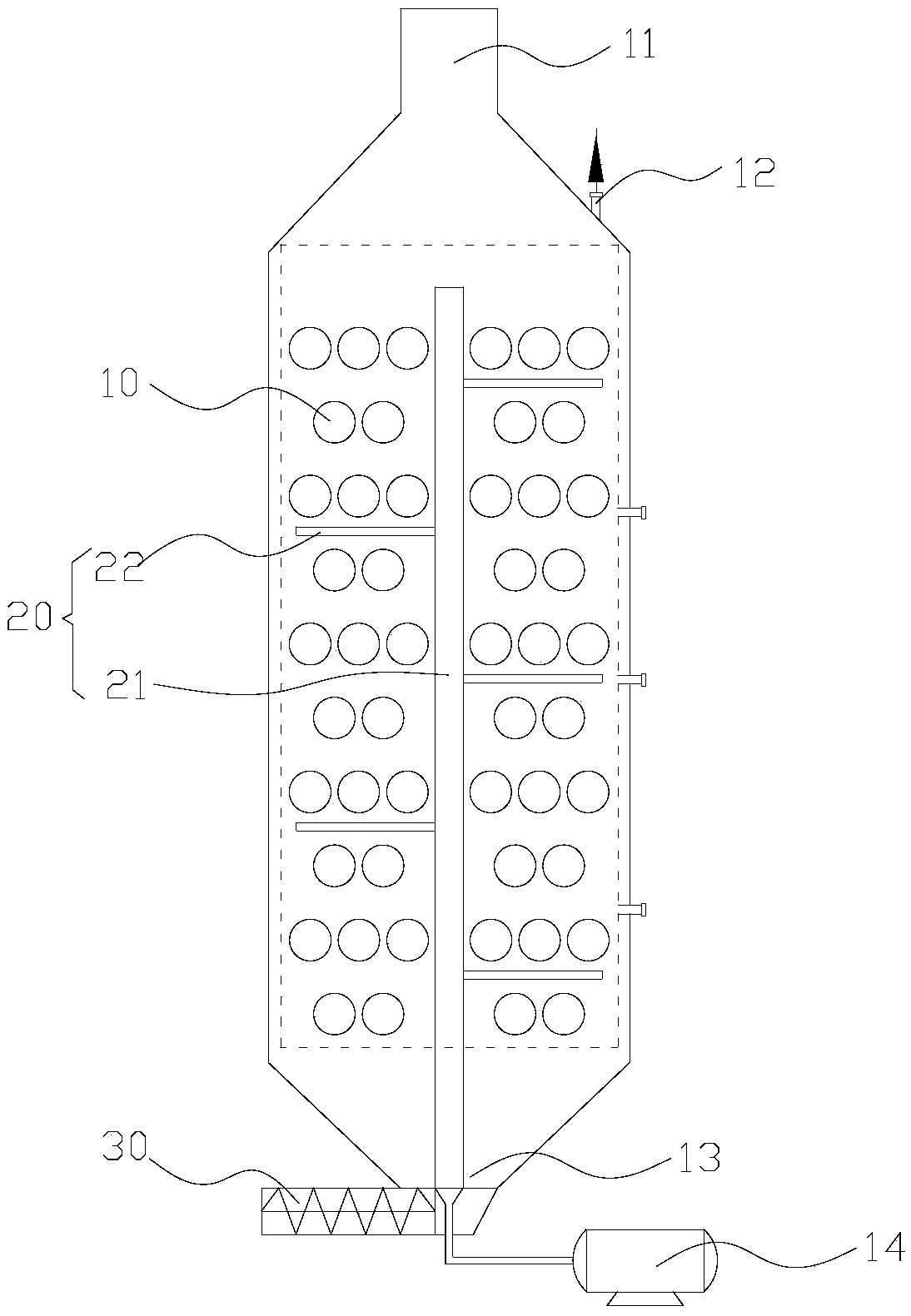

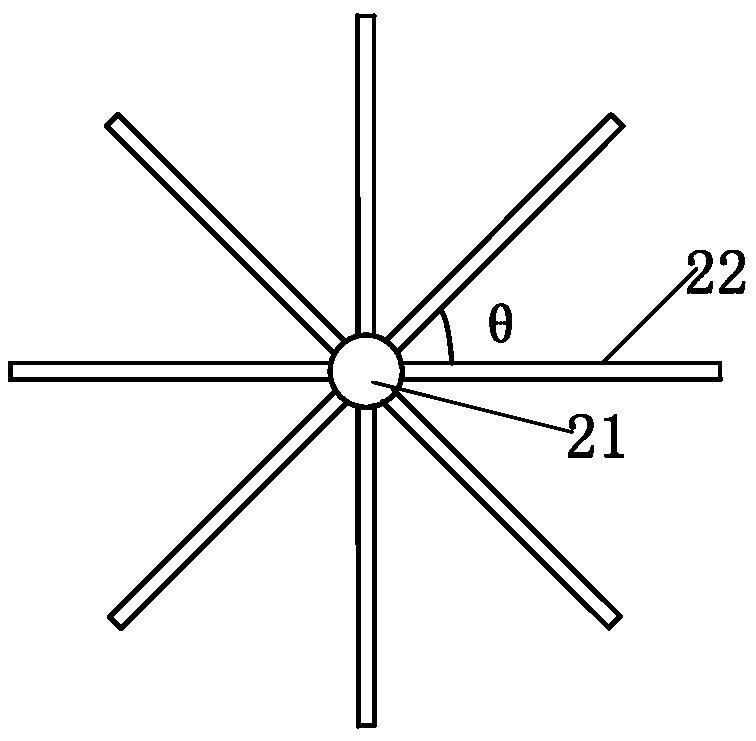

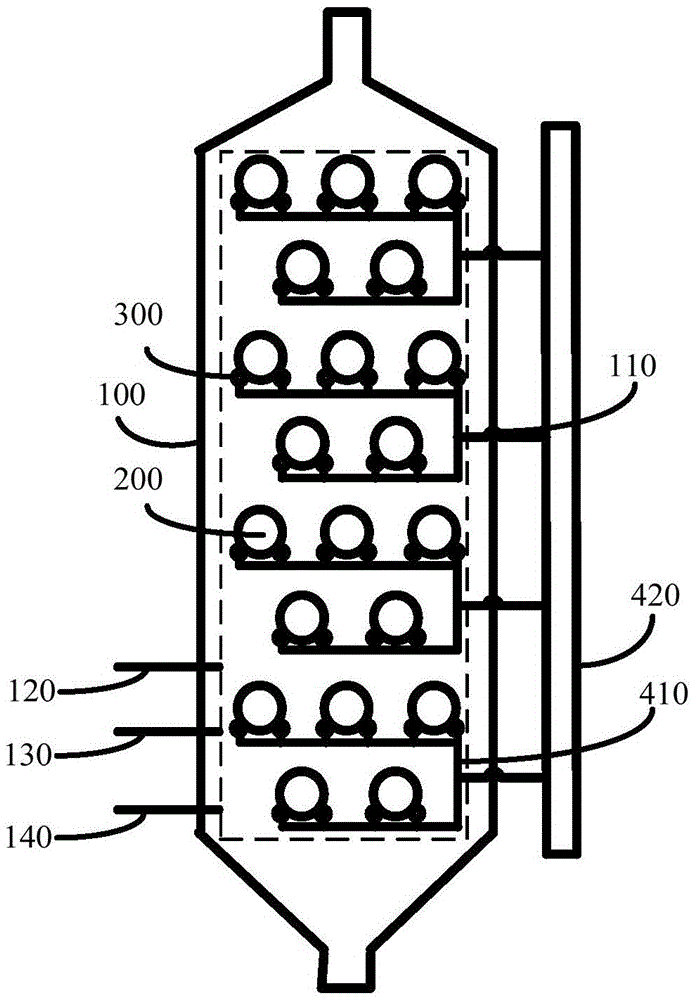

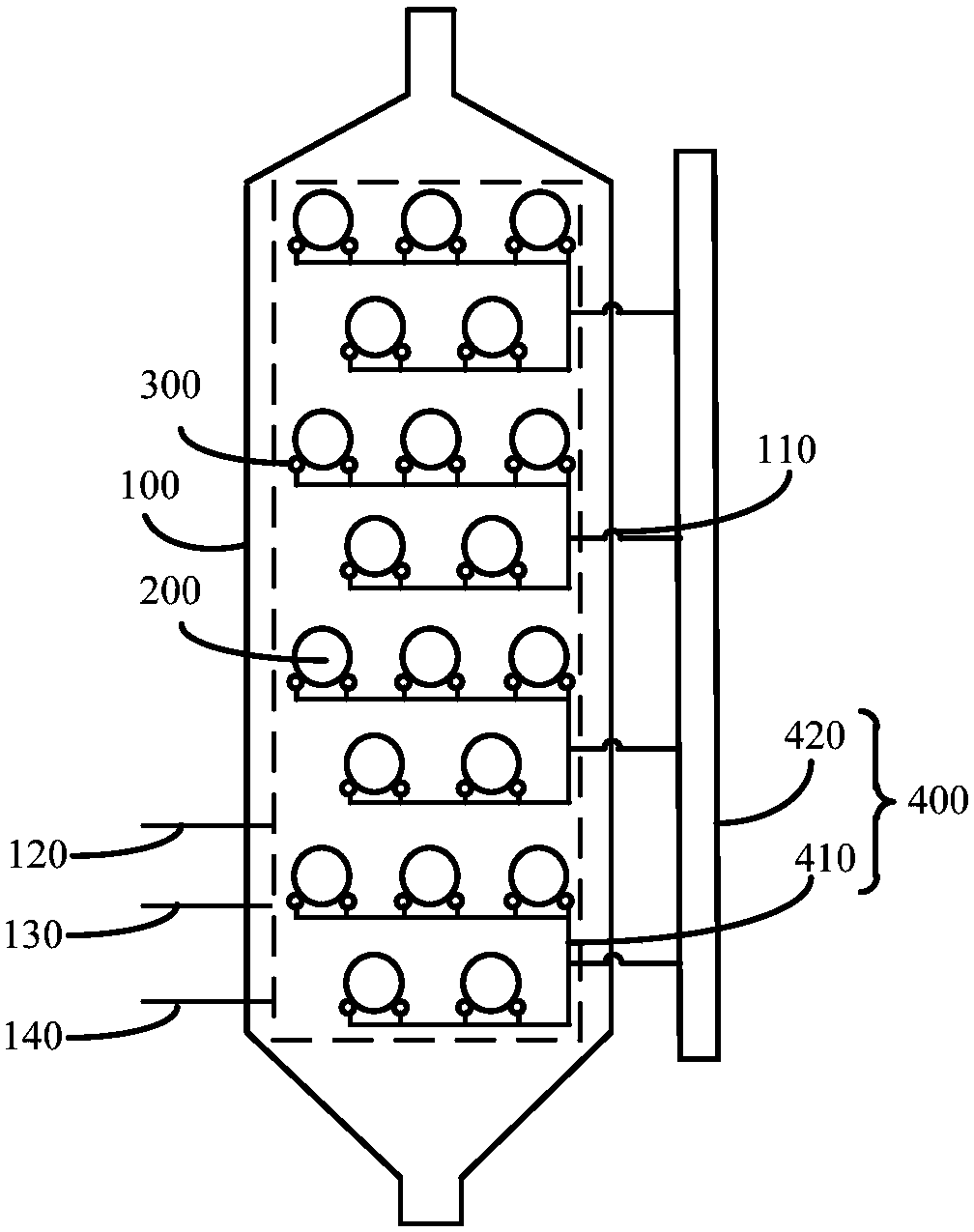

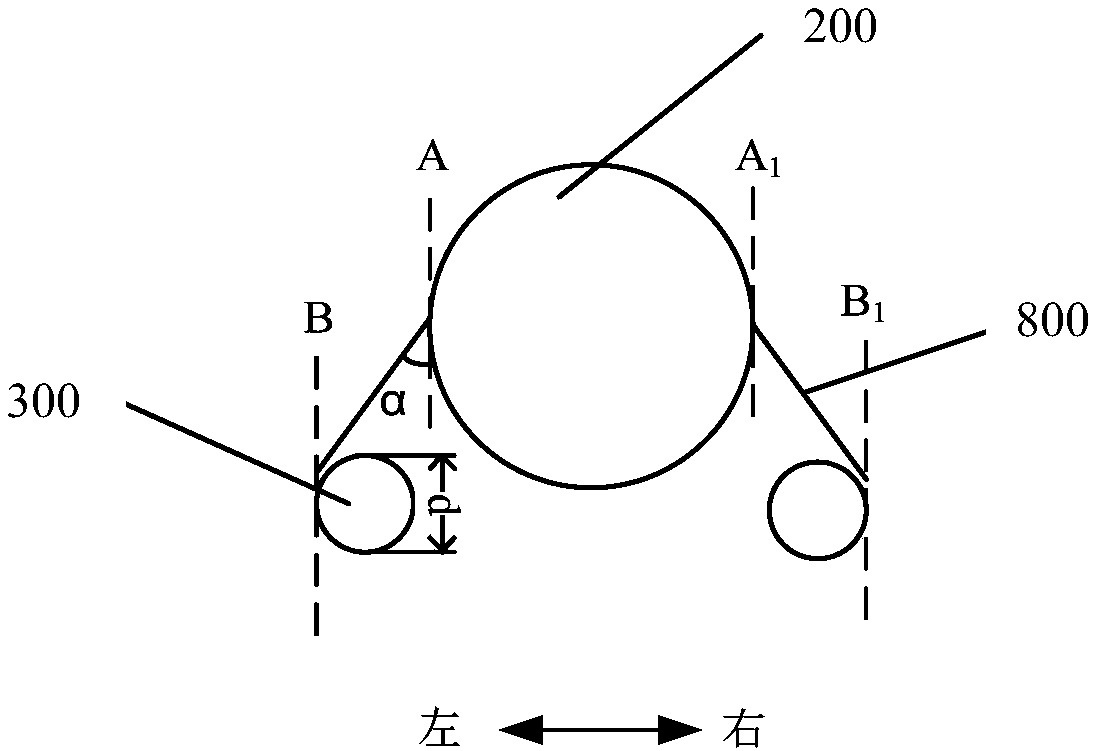

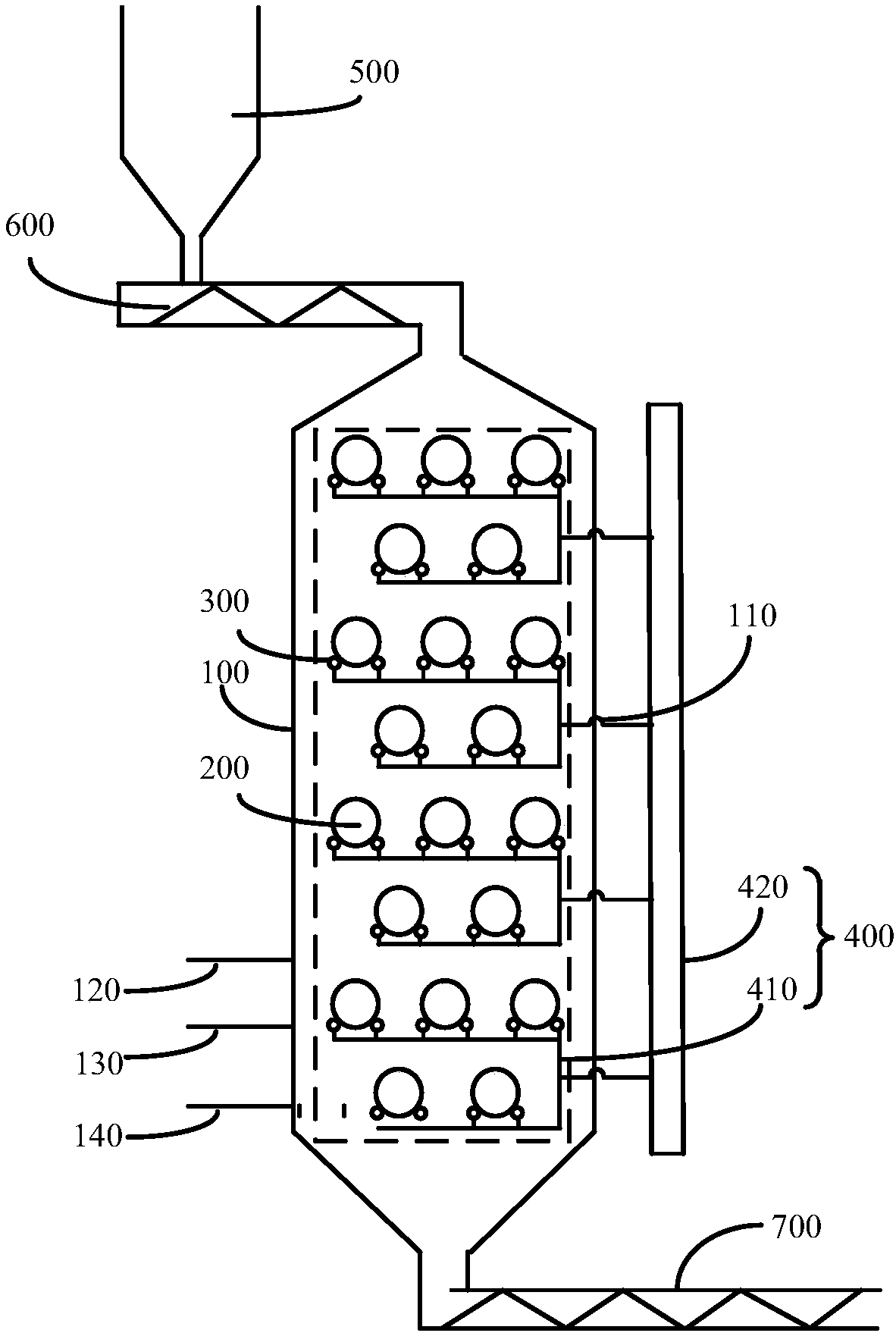

Rapid pyrolysis reactor

ActiveCN105505420AEffective looseningSimple structureIndirect heating destructive distillationSpecial form destructive distillationBiochemical engineeringStorage type

The invention provides a rapid pyrolysis reactor. The rapid pyrolysis reactor comprises heat storage type radiant tubes and a stirring device. The multiple layers of the heat storage type radiant tubes are arranged inside the rapid pyrolysis reactor in the length direction of the pyrolysis reactor, and multiple heat storage type radiant tubes parallel to one another in the horizontal direction are arranged on each layer. The stirring device comprises a stirring shaft and multiple stirring rods connected to the stirring shaft. The stirring shaft rotationally stretches into the reactor from a semi-coke outlet. By means of the rapid pyrolysis reactor, pyrolysis efficiency can be remarkably improved, and the yield of pyrolysis oil can be increased.

Owner:SHENWU TECH GRP CO LTD

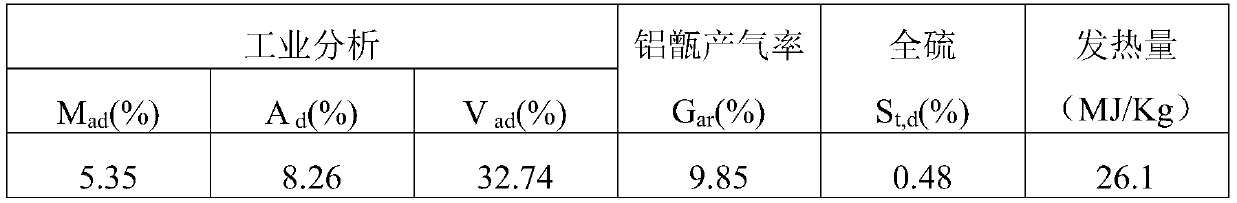

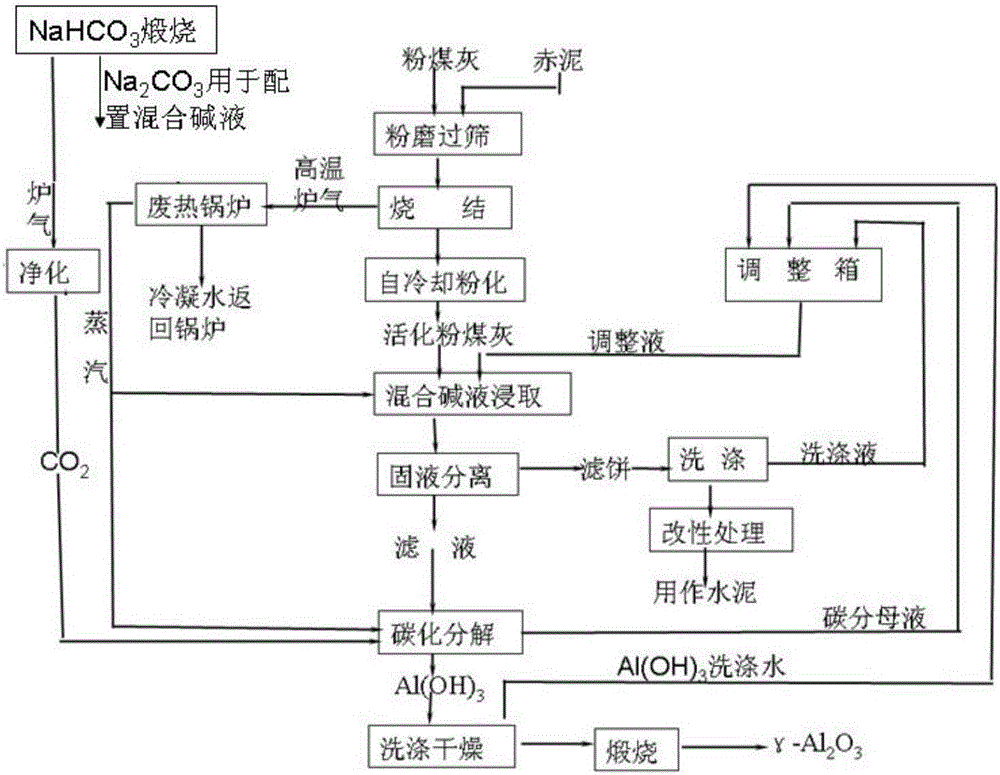

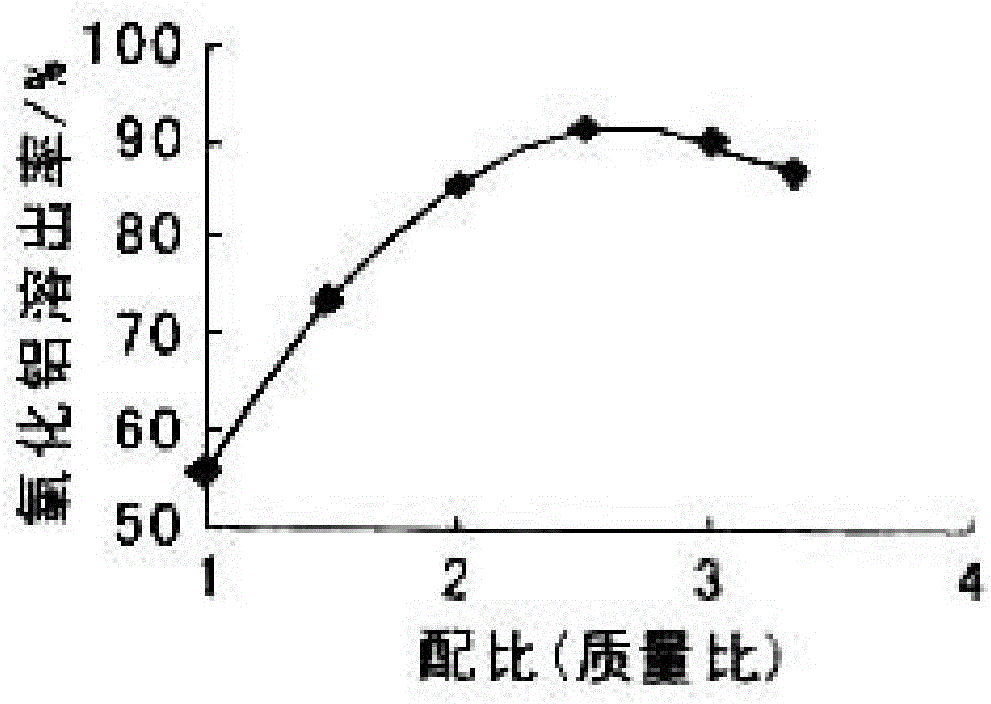

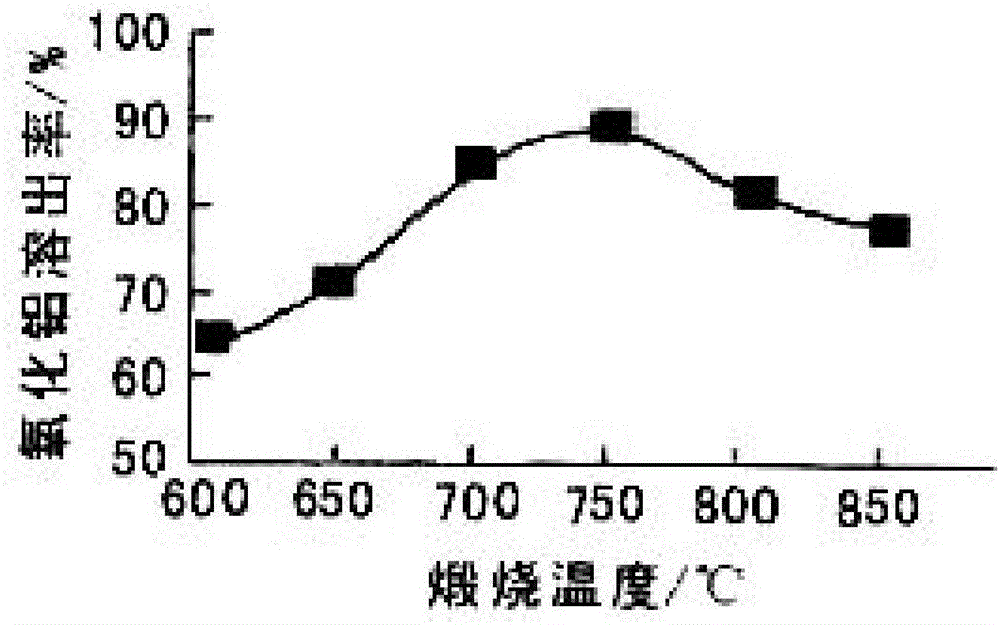

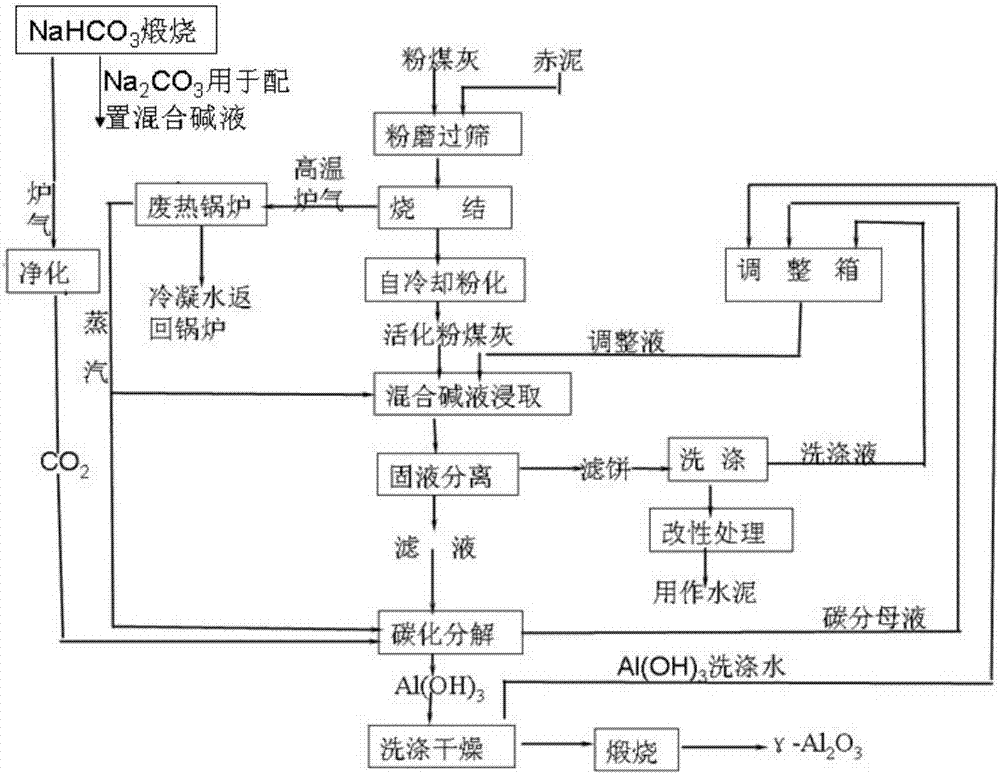

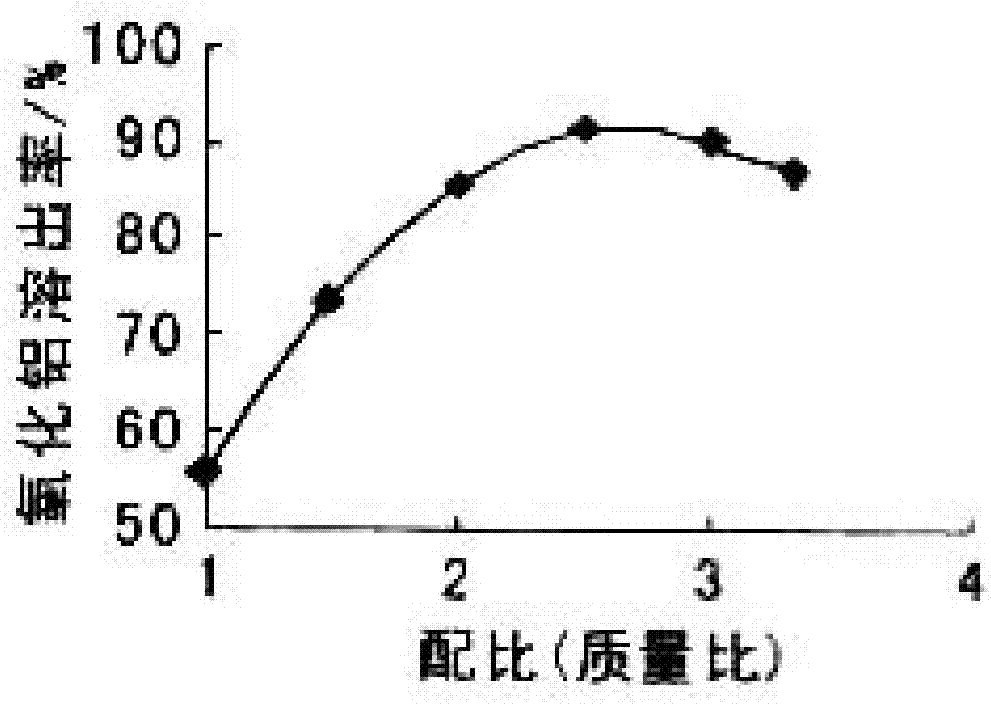

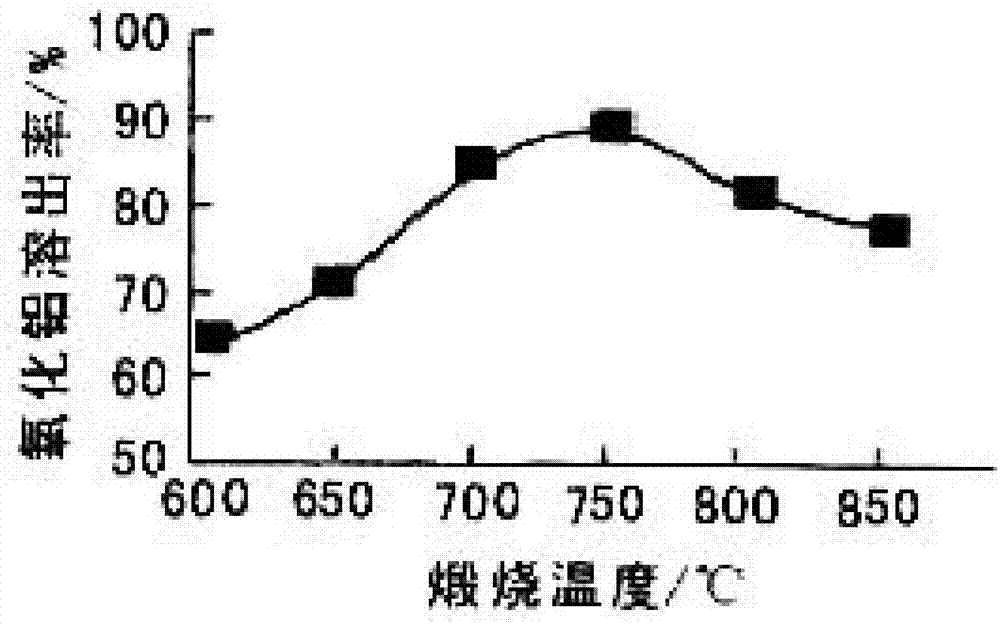

Clean process for preparing activated aluminum oxide by using pulverized fuel ash

InactiveCN106044813ALow activation temperatureReduce the difficulty of operationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationThree levelSludge

The invention discloses a clean process for preparing activated aluminum oxide by using pulverized fuel ash. The clean process comprises the following steps that 1, pulverized fuel ash is activated; 2, leaching with a mixed alkaline liquor and solid-liquid separation are performed; 3, carbonating disintergration and wash-drying are performed; 4, calcination is performed. The red sludge from an aluminum oxide enterprise is used for replacing limestone, the pulverized fuel ash is activated by adopting a low-temperature sintering process, and then Al2O3 is dissolved out of the mixed alkaline liquor. Waste residues are modified, waste water is treated, energy is recovered, the resource utilization rate and waste recovery rate are high, and the cleaning degree of the process meets the requirement for three-level clean production in the domestic aluminum oxide industry.

Owner:YIBIN UNIV

Composite molecular sieve catalyst for increasing yield of low-carbon olefins through light hydrocarbon cracking and preparation method thereof

PendingCN114505097AHigh selectivityExtended service lifeMolecular sieve catalystsBulk chemical productionMolecular sievePtru catalyst

The preparation method comprises the following main steps: pre-hydrogenating an LTA molecular sieve, mixing the pre-hydrogenated LTA molecular sieve with a commercial hydrogen type ZSM-5 molecular sieve, and uniformly compounding the molecular sieves by virtue of the synergistic effect of mechanical stirring and ultrasonic mixing, so as to obtain the composite molecular sieve catalyst for increasing the yield of low-carbon olefins through catalytic cracking of light hydrocarbons. Therefore, the advantages of specific pore structures of the two molecular sieves are fully exerted. The catalyst prepared by the method is used for the catalytic cracking reaction of light hydrocarbon, efficient cracking of light hydrocarbon is realized by virtue of the catalytic action of the acidic ZSM-5 molecular sieve with a ten-membered ring pore channel structure, and secondary reaction of a cracking product is inhibited by virtue of an eight-membered ring pore channel structure of the LTA molecular sieve, so that the selectivity of low-carbon olefin is improved; the deactivation rate of the coke generation catalyst is effectively reduced, and the service life of the catalyst is prolonged. The method is simple, efficient and excellent in performance, and has good application value in the process of producing ethylene propylene through catalytic cracking of petroleum.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

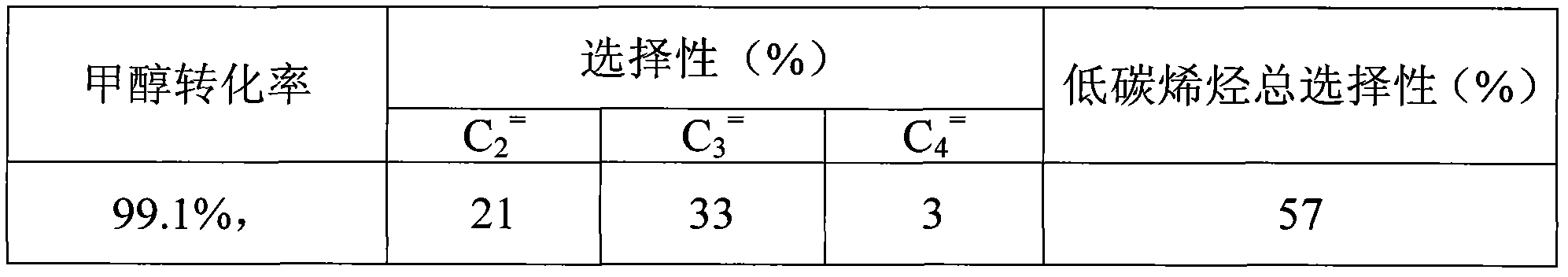

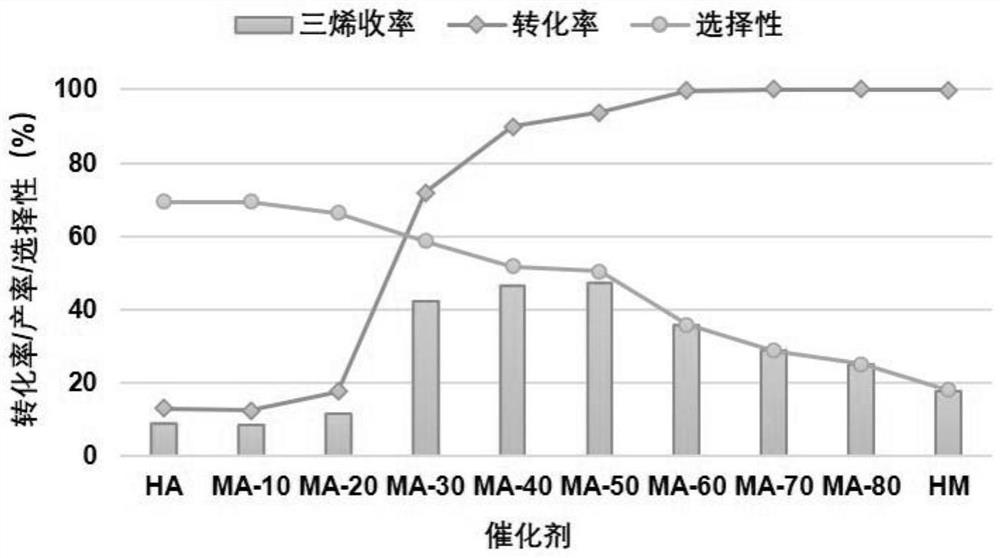

Catalyst for preparing low-carbon olefin from methanol

PendingCN110801862AImprove catalytic performanceEnhanced Surface AcidityMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention discloses a catalyst for preparing low-carbon olefin from methanol. The catalyst consists of the following raw material components in percentage by mass: 25-65% of a cobalt modified silicon-aluminum phosphate molecular sieve, 15-25% of pseudo-boehmite, 10-20% of a phosphorus-containing additive and 10-30% of an alkali oxide, wherein the sum of the percentages of the raw materials is100%. The catalyst has the beneficial effects that (1) the cobalt modified silicon-aluminum phosphate molecular sieve is adopted as an active component, meanwhile, a proper amount of a P additive is further introduced, and thus the catalyst with excellent catalysis performance is prepared; and (2) the pseudo-boehmite is adopted to replace or partially replace clay, so that the surface acidity of the active component and a matrix can be optimized, a reaction that ethylene is generated through dimolecular conversion of methanol molecules is intensified, reactions that propylene and hydrocarbonsof C4 or greater are generated through trimolecular and polymolecular conversion of the methanol are inhibited, and ethylene selectivity of an MTO (methanol to olefin) device can be greatly improved.

Owner:杜成荣

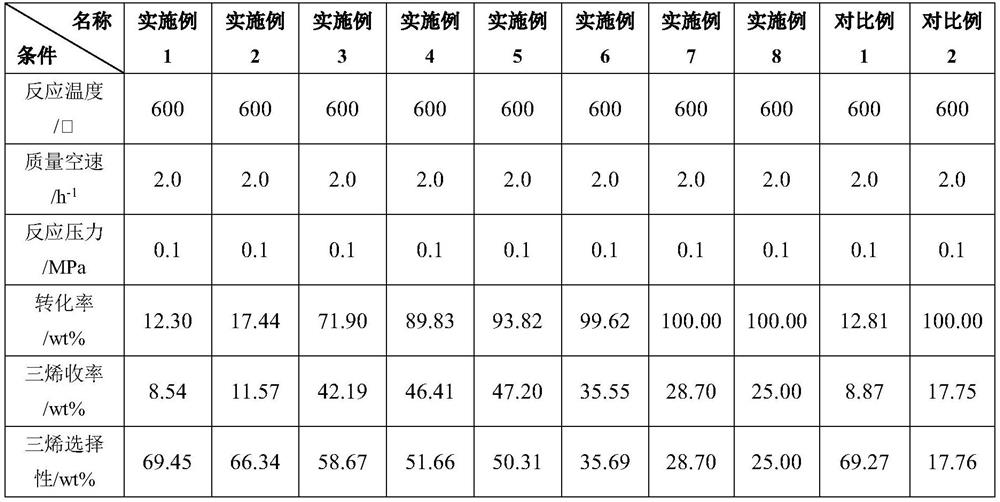

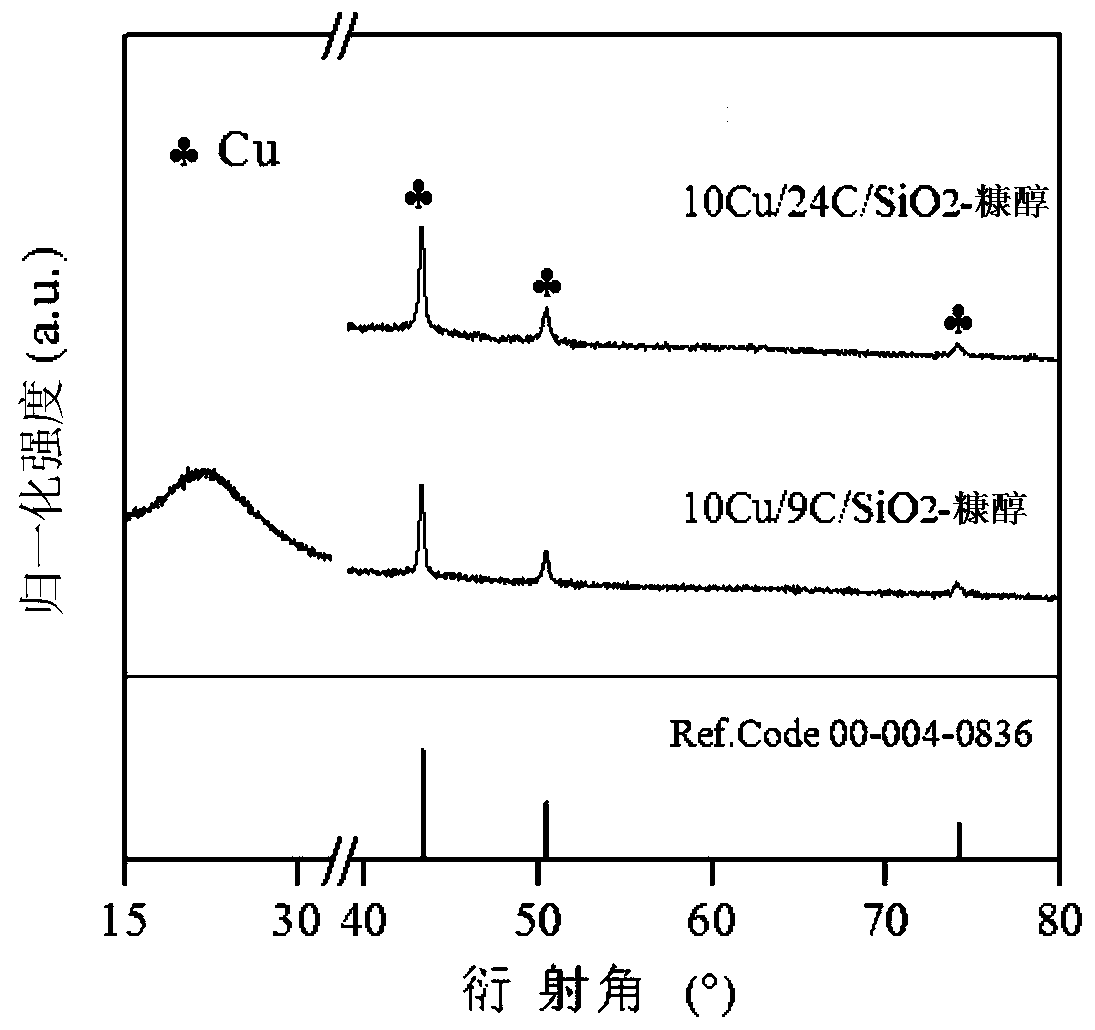

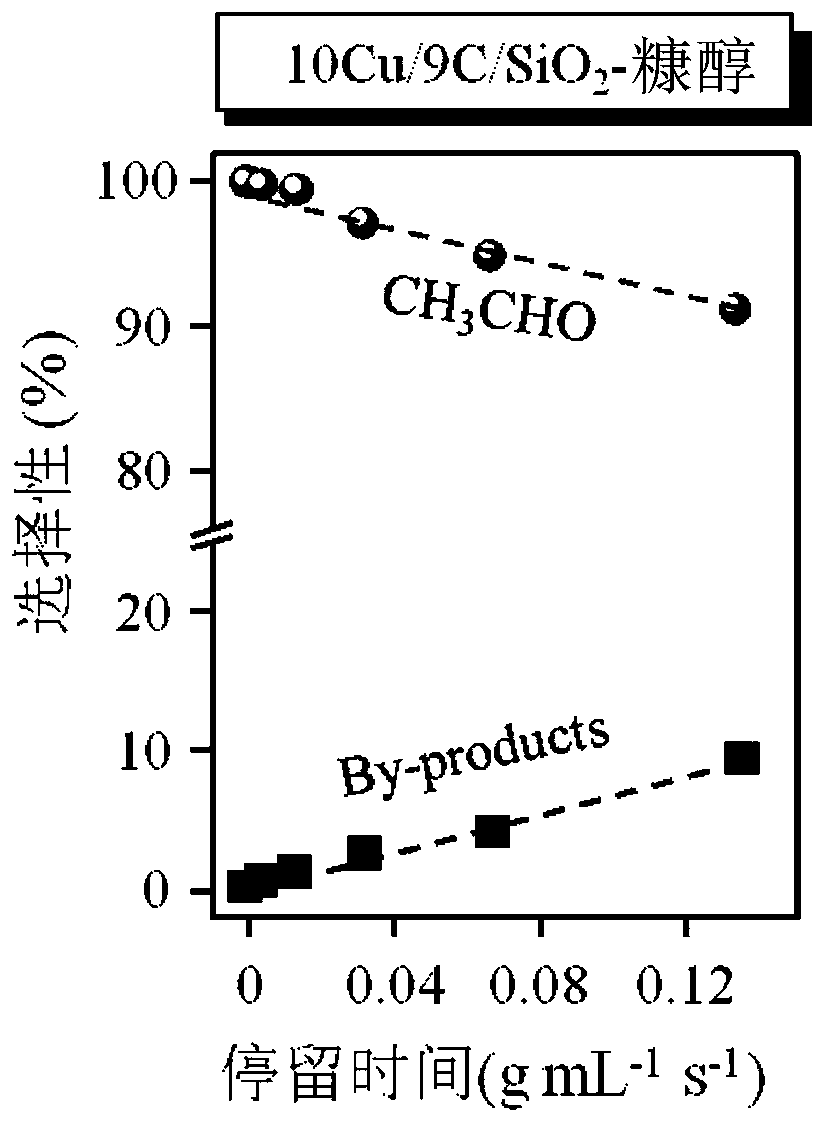

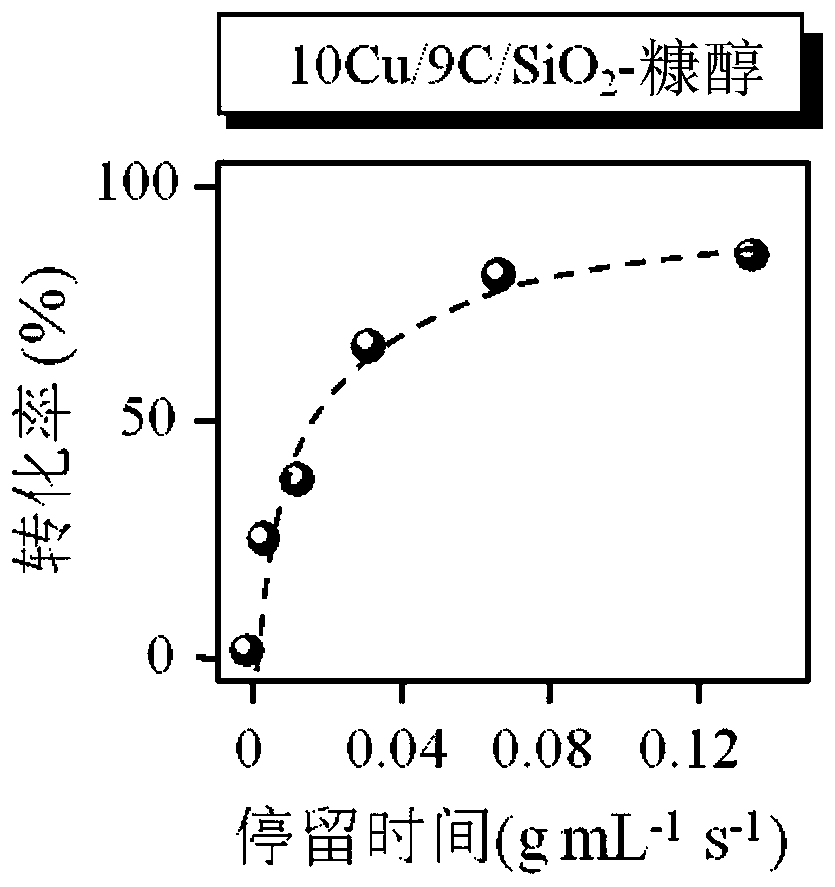

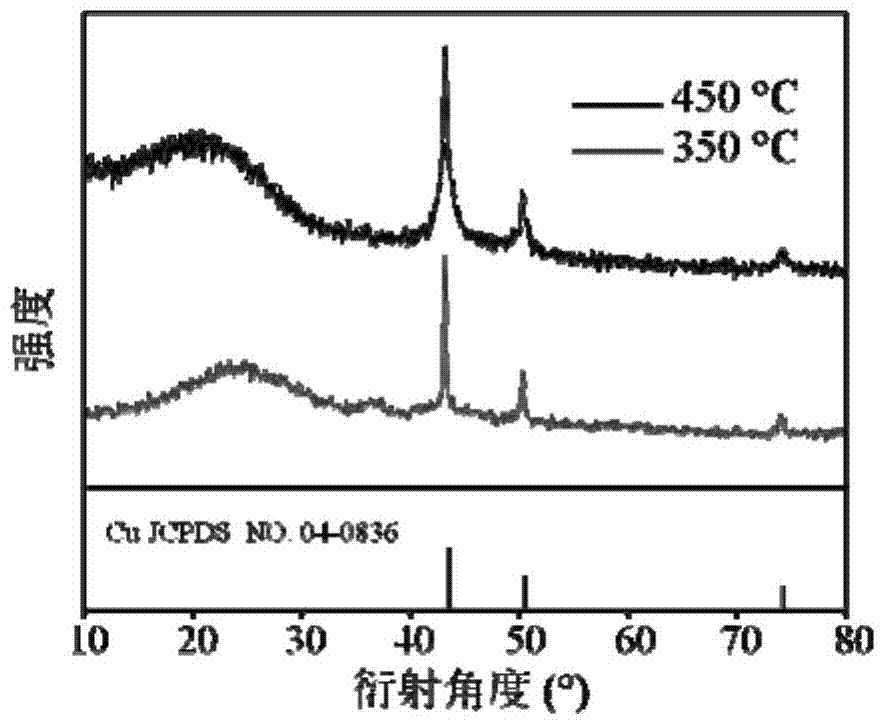

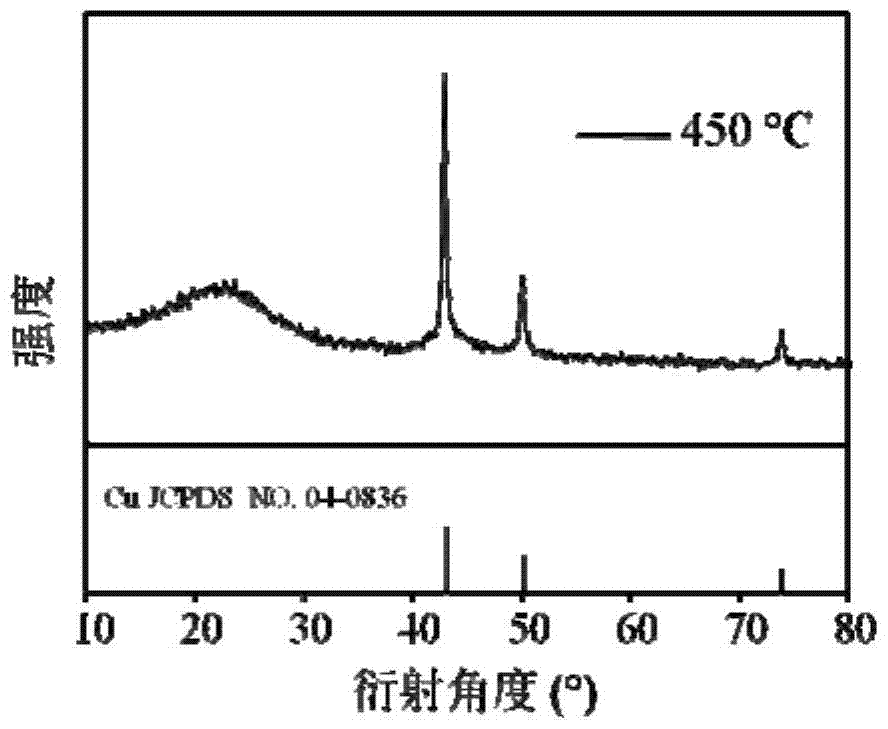

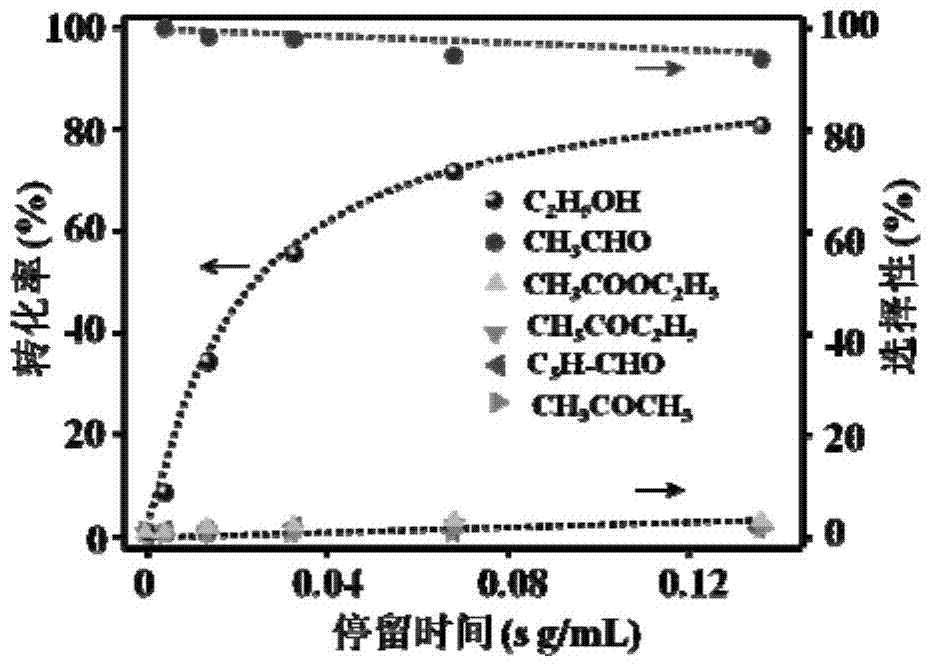

Catalyst for preparing acetaldehyde by direct dehydrogenation of ethanol, preparation method and application thereof

ActiveCN106673977BHigh selectivityImprove stabilityOrganic compound preparationCarbonyl compound preparationAlcoholActive component

The invention provides a catalyst for preparing acetaldehyde through direct dehydrogenation of ethyl alcohol as well as a preparation method and an application thereof and belongs to the technical field of chemical catalysis. The catalyst comprises the following components in percentage by mass: 0.1-30wt% of an active component which is Cu and 70-99.9wt% of a carrier which is a carbon-coated oxide compound, wherein the carrier comprises the following components in percentage by mass: 0.5-50wt% of C and the balance of oxide. The catalyst has extremely high selectivity which is higher than 92.1%; moreover, the catalyst is excellent in stability and almost has no inactivation in 40 hours during test.

Owner:DALIAN UNIV OF TECH

A method for promoting the depolymerization of kraft lignin by using discarded cigarette filters

ActiveCN110407888BImprove depolymerization efficiencyEasily brokenOrganic compound preparationLignin derivativesLignin sulfateDepolymerization

The invention discloses a method for promoting depolymerization of lignin sulfate through filter tips of abandoned cigarettes. According to the method, after the filter tips of the abandoned cigarettes are smashed, the smashed filter tips are mixed uniformly with the lignin sulfate and a microwave absorption medium, then a mixture is ground, and the ground mixture is pressed into massive mixturesin different shapes; the massive mixtures are put in a microwave reactor, nitrogen is introduced in advance to discharge air in a reaction system, then nitrogen carrying dichloromethane is introducedinto the microwave reactor, the microwave reactor is started up, and generated depolymerization steam is condensed to obtain liquid, namely pyrolytic oil; the pyrolytic oil is subjected to airtight standing at normal temperature, a low-layer organic phase is collected, the collected organic phase is dehydrated, an organic phase which does not contain moisture is obtained and subjected to normal-temperature rotary evaporation, when no distillate is distilled off, a substance which is not evaporated out is a phenol-rich compound, a liquid substance which is evaporated out is dichloromethane, andthen recycling is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

Pyrolysis condensed phase reaction device

PendingCN114082371AInhibition of secondary reactionsShort stayVapor condensationPyrolysis reactionsGas phaseCooling fluid

The invention provides a pyrolysis condensed phase reaction device. The device comprises a cooling box and a reactor arranged in the cooling box, and the cooling box can be filled with cooling liquid; and the reactor comprises a vertically arranged seat body and a cover body covering the seat body in the horizontal direction, a silk screen reaction assembly is installed on the side, facing the cover body, of the seat body, and air holes are formed in the seat body. According to the pyrolysis condensed phase reaction device, a sample is pyrolyzed through the silk screen reaction assembly located in the cover body, volatile components can be rapidly cooled through the cooling liquid filled in the cooling box, then the gas phase retention time can be greatly shortened, and the gas phase secondary reaction is effectively inhibited; and meanwhile, the air holes can be externally connected with an air pressure adjusting device to adjust the pressure in the cover body, so that the evaporation rate of a liquid intermediate product is changed, the secondary reaction of the condensed phase is controlled, a gaseous product can be guided out by utilizing the air holes after the reaction is completed, and subsequent analysis and research are facilitated.

Owner:HUNAN UNIV

A kind of preparation method of mesoporous ZSM-5 zeolite

ActiveCN107804857BInhibition of secondary reactionsHigh selectivityPentasil aluminosilicate zeoliteSodium sulfateMaterials science

The invention discloses a preparation method of mesoporous ZSM-5 zeolite. The preparation method comprises the following steps: 1) allyl glycidyl ether and dimethyl diallyl ammonium are uniformly mixed, a sodium persulfate aqueous solution with mass concentration being 10-30% is added, the materials are uniformly stirred and heated to the temperature of 60-90 DEG C, and then a polymerization is carried out for 2-8 hours, and cooling is carried out to obtain a copolymer; 2) aluminum sulfate, concentrated sulfuric acid and deionized water are prepared to an uniform solution; 3) water glass, deionized water and the copolymer obtained in the step 1) are mixed, a mixture is continuously stirred for 0.5-3 hours, then the solution prepared in the step 2) is slowly added while rapid stirring, andthe materials are continuously stirred for 1-6 hours to obtain an uniform gel; and 4) the above gel is transferred to a high-pressure reaction vessel for crystallization, the crystallized products aresubjected to pumping filtration and washed to neutrality, and then the crystallized products are dried and roasted to obtain the mesoporous ZSM-5 zeolite. The prepared mesoporous ZSM-5 zeolite contains a lot of meso-structures, cost of raw material is low, operation is simple and easy, no special requirement is generated on equipment, and the method is suitable for industrial production and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pyrolysis reactor

ActiveCN105623684AShort stayInhibition of secondary reactionsIndirect heating destructive distillationSpecial form destructive distillationGas collecting tubeHeat carrier

The invention discloses a pyrolysis reactor and a method for treating rubbish with the pyrolysis reactor. The pyrolysis reactor comprises a pyrolysis oil gas outlet, heat accumulating type radiant tubes, oil gas guiding-out pipelines and a gas collecting tube. The heat accumulating type radiant tubes are arranged in multiple layers in the height direction of the pyrolysis reactor, and each layer includes multiple heat accumulating type radiant tubes which are parallel to one another in the horizontal direction. The oil gas guiding-out pipelines are arranged in multiple layers in the height direction of the pyrolysis reactor, each layer includes multiple oil gas guiding-out pipelines which are parallel to one another in the horizontal direction, and the surfaces of the oil gas guiding-out pipelines are provided with through holes. The gas collecting tube is communicated with the oil gas guiding-out pipelines and the pyrolysis oil gas outlet. The pyrolysis reactor can effectively restrain a secondary reaction of oil gas and increase the tar yield; in addition, the heat accumulating type heat-carrier-free radiant tube heating technology is adopted, no gas or solid heat carrier is needed, and the heat value of pyrolysis gas is increased; meanwhile, the pyrolysis reactor has the advantages that few devices are used, operation is easy, and the fault rate is low.

Owner:SHENWU TECH GRP CO LTD

Catalyst for preparing acetaldehyde by dehydrogenation of ethanol, its preparation method and application

ActiveCN105148911BInhibition of secondary reactionsHigh acetaldehyde selectivityOrganic compound preparationCarbonyl compound preparationActive componentDehydrogenation

The invention provides a catalyst for preparing acetaldehyde by ethanol dehydrogenation and its preparation method and application. The catalyst in the invention is a supported catalyst, the active component is Cu, and the carrier of the catalyst is a carbon material; the active component The content of Cu is 0.1-30wt%. The catalyst provided by the invention has very high acetaldehyde selectivity, and the acetaldehyde selectivity is higher than 92.1%; and the preparation method provided by the invention is simple and does not need to add any auxiliary agent.

Owner:DALIAN UNIV OF TECH

A kind of catalytic cracking method

ActiveCN105400546BInhibition of secondary reactionsImprove propertiesTreatment with plural serial stages onlyCatalytic reformingPtru catalyst

The invention discloses a catalytic cracking method in the petrochemical industry. The method includes: the reaction is carried out in two stages, the first stage reaction is heavy oil catalytic cracking reaction carried out in the first tubular reactor, the first stage reaction is carried out after gas-solid separation, and the first stage reaction oil gas directly undergoes the second stage reaction, that is, enters the second tube Catalytic reforming reaction of gasoline with a reaction temperature of 430-460°C in a type reactor. The first-stage spent catalyst and the second-stage spent catalyst are stripped and then enter the regenerator for coke regeneration. Part of the regenerated catalyst in the regenerator is directly returned to the first tubular reactor to participate in the first-stage reaction; part of the regenerated catalyst enters the primary regenerated catalyst cooler for primary cooling, and then enters the secondary regenerated catalyst cooler for secondary cooling. After reaching 400-450°C, return to the second tubular reactor to participate in the second-stage reaction. The invention can be used for catalytic cracking of heavy oil and catalytic upgrading of gasoline.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

pyrolysis reactor

ActiveCN105623684BShort stayInhibition of secondary reactionsIndirect heating destructive distillationSpecial form destructive distillationGas collecting tubeHeat carrier

The invention discloses a pyrolysis reactor and a method for treating rubbish with the pyrolysis reactor. The pyrolysis reactor comprises a pyrolysis oil gas outlet, heat accumulating type radiant tubes, oil gas guiding-out pipelines and a gas collecting tube. The heat accumulating type radiant tubes are arranged in multiple layers in the height direction of the pyrolysis reactor, and each layer includes multiple heat accumulating type radiant tubes which are parallel to one another in the horizontal direction. The oil gas guiding-out pipelines are arranged in multiple layers in the height direction of the pyrolysis reactor, each layer includes multiple oil gas guiding-out pipelines which are parallel to one another in the horizontal direction, and the surfaces of the oil gas guiding-out pipelines are provided with through holes. The gas collecting tube is communicated with the oil gas guiding-out pipelines and the pyrolysis oil gas outlet. The pyrolysis reactor can effectively restrain a secondary reaction of oil gas and increase the tar yield; in addition, the heat accumulating type heat-carrier-free radiant tube heating technology is adopted, no gas or solid heat carrier is needed, and the heat value of pyrolysis gas is increased; meanwhile, the pyrolysis reactor has the advantages that few devices are used, operation is easy, and the fault rate is low.

Owner:SHENWU TECH GRP CO LTD

Bifunctional catalyst containing hierarchical porous SAPO-34 molecular sieve as well as preparation method and application of bifunctional catalyst

PendingCN114433223AShort stayInhibition of secondary reactionsHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a bifunctional catalyst containing a hierarchical pore SAPO-34 molecular sieve, the bifunctional catalyst comprises a component I and a component II, the component I is the hierarchical pore SAPO-34 molecular sieve obtained by performing post-treatment on the SAPO-34 molecular sieve with a microporous structure in an original mother solution, and the component II is a ZnCrAl metal oxide. The invention also discloses a preparation method of the bifunctional catalyst containing the hierarchical porous SAPO-34 molecular sieve. The bifunctional catalyst containing the hierarchical porous SAPO-34 molecular sieve prepared by the invention can shorten the residence time of an olefin product in a crystal in a reaction of preparing low-carbon olefin from synthesis gas and inhibit a secondary reaction of hydrogen transfer of the olefin product, so that the selectivity of the low-carbon olefin can be improved. The method provided by the invention has the advantages of simple and feasible steps, rapidness, environmental friendliness and low cost.

Owner:CHIA TAI ENERGY MATERIALS DALIAN

Method for delaying coking

ActiveCN102732297BSimple processShorten coke generation timeTreatment with plural serial stages onlyWater vaporProcess engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

A clean process for preparing activated alumina from fly ash

InactiveCN106044813BLow activation temperatureReduce the difficulty of operationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationThree levelSludge

The invention discloses a clean process for preparing activated aluminum oxide by using pulverized fuel ash. The clean process comprises the following steps that 1, pulverized fuel ash is activated; 2, leaching with a mixed alkaline liquor and solid-liquid separation are performed; 3, carbonating disintergration and wash-drying are performed; 4, calcination is performed. The red sludge from an aluminum oxide enterprise is used for replacing limestone, the pulverized fuel ash is activated by adopting a low-temperature sintering process, and then Al2O3 is dissolved out of the mixed alkaline liquor. Waste residues are modified, waste water is treated, energy is recovered, the resource utilization rate and waste recovery rate are high, and the cleaning degree of the process meets the requirement for three-level clean production in the domestic aluminum oxide industry.

Owner:YIBIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com