Rapid pyrolysis reactor

A pyrolysis reactor and fast technology, applied in the chemical industry, can solve the problems of thinning of pyrolysis dry distillation gas, complicated process, low oil yield, etc., and achieve the advantages of reducing secondary cracking, uniform temperature distribution and improving oil yield. Effect

Active Publication Date: 2016-04-20

SHENWU TECH GRP CO LTD

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The oil yield of some furnace types is low, and the gas is used as the heating carrier, resulting in a huge condensation recovery system, the pyrolysis and retort gas is diluted, the calorific value of the gas is low, and it is difficult to further comprehensively utilize other problems; the pyrolysis of some solid heat carriers For the furnace type, there are processes such as mixing of raw materials and heat carrier, and reheating and back mixing of heat carrier. The process is more complicated, the equipment is more, and the manufacturing cost and operating cost are high.

In addition, in the existing industrial pyrolysis process, the purpose is to produce a large amount of tar, the output of pyrolysis gas is small, or the pyrolysis gas is burned and utilized by the subsequent cycle process, and what is more harmful to coal pyrolysis gas production and Not enough oil

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment example

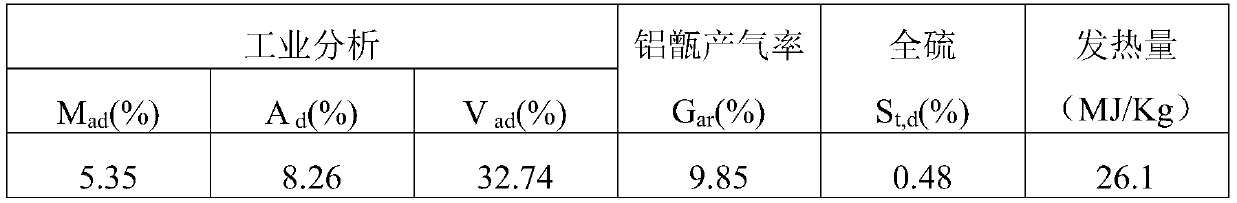

[0048] Implementation case: The typical long-flame coal is processed by the regenerative down-bed catalytic fast pyrolysis system. The basic data of raw materials, process operation parameters and material balance are shown in Table 1-Table 2.

[0049] Table 1: Basic data of typical long-flame coal

[0050]

[0051] Table 2: Process operating parameters

[0052] serial number

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

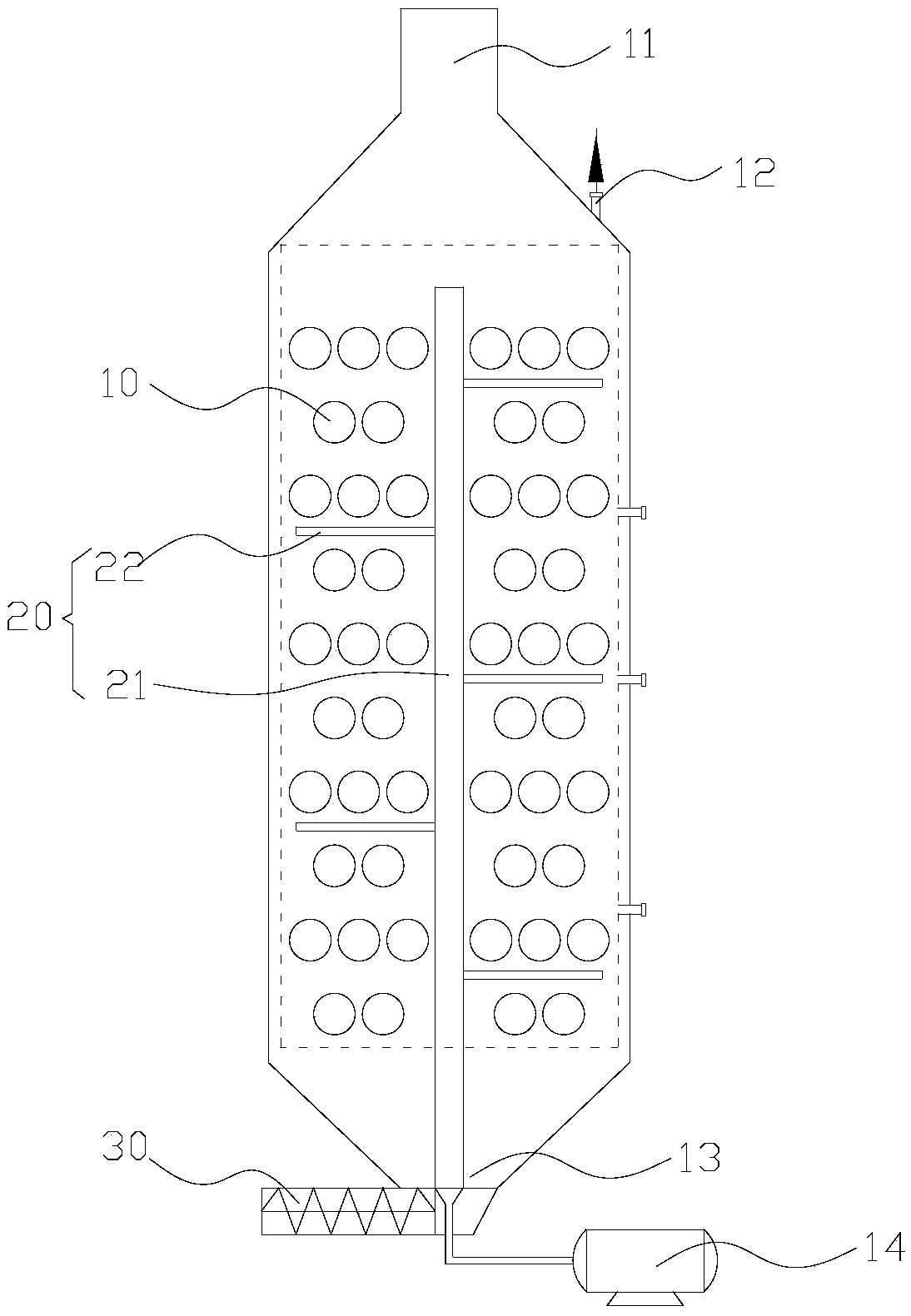

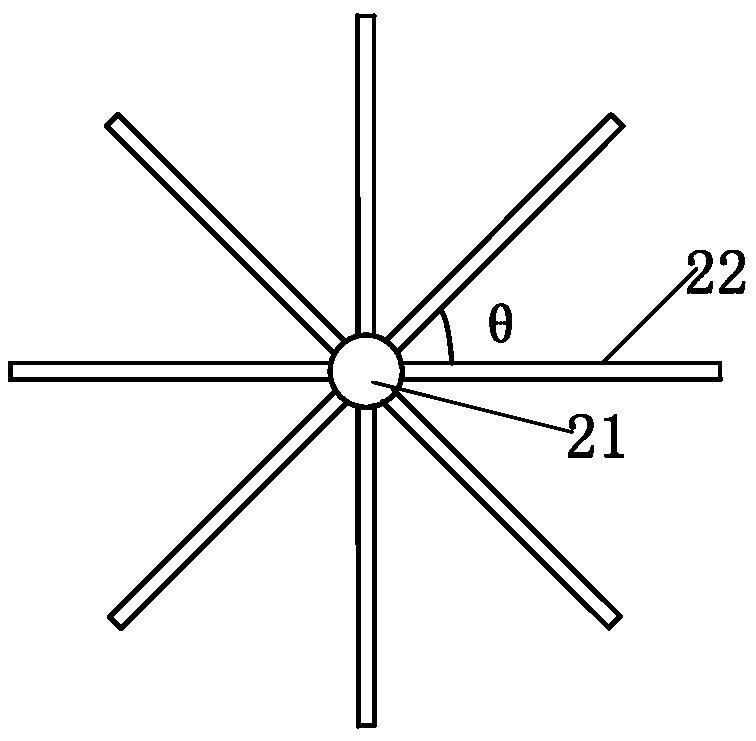

The invention provides a rapid pyrolysis reactor. The rapid pyrolysis reactor comprises heat storage type radiant tubes and a stirring device. The multiple layers of the heat storage type radiant tubes are arranged inside the rapid pyrolysis reactor in the length direction of the pyrolysis reactor, and multiple heat storage type radiant tubes parallel to one another in the horizontal direction are arranged on each layer. The stirring device comprises a stirring shaft and multiple stirring rods connected to the stirring shaft. The stirring shaft rotationally stretches into the reactor from a semi-coke outlet. By means of the rapid pyrolysis reactor, pyrolysis efficiency can be remarkably improved, and the yield of pyrolysis oil can be increased.

Description

technical field [0001] The invention belongs to the field of chemical industry, in particular, the invention relates to a fast pyrolysis reactor. Background technique [0002] Natural gas is a very precious resource due to its clean and environmentally friendly performance. my country's energy structure is characterized by "more coal, less oil, and less gas". Therefore, the production of oil and gas from fossil fuels is the way out to solve my country's energy problems. The process of coal-to-gas is complex, the scale of investment is large, and the consumption of water resources is large, which has become a bottleneck restricting the development of coal-to-gas. Coal low-temperature dry distillation, the products can be comprehensively utilized (oil, gas, semi-coke), which can not only increase the added value, increase economic benefits, but also reduce environmental pollution caused by coal burning. It is considered to be an effective way for efficient and clean utilizatio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10B53/04C10B47/22

CPCC10B47/22C10B53/04

Inventor 陈水渺耿层层姜朝兴任守强马正民孙祖平薛逊吴道洪

Owner SHENWU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com