Grate with multi-edge convex

A technology of grate pieces and bosses, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as insufficient combustion, uneven stirring, etc., achieve simple structure, shorten drying time, prevent entering the air chamber and air leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

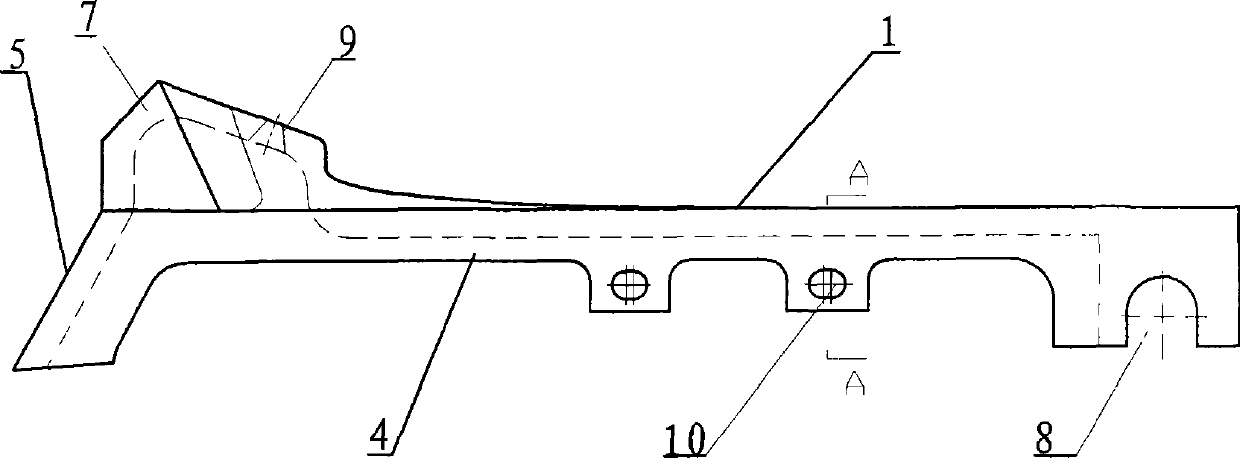

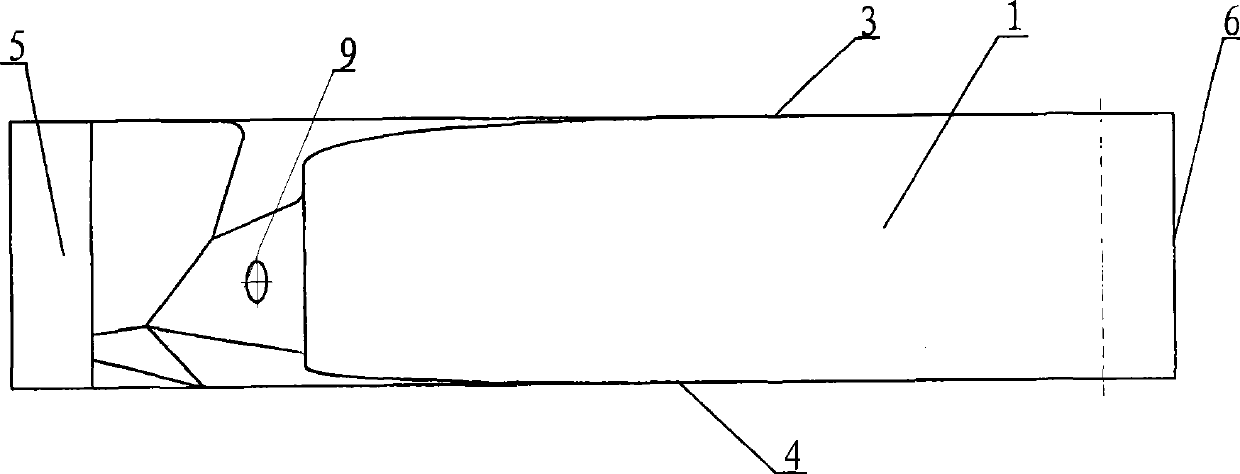

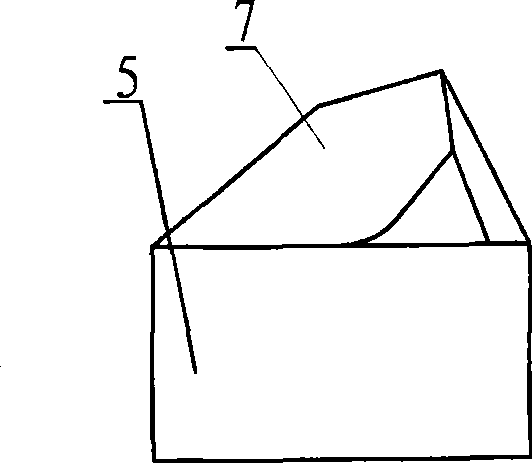

[0021] See figure 1 , figure 2 , image 3 , the fire grate with multi-blade boss in the present invention is composed of an upper surface 1, a bottom 2, a left side 3, a right side 4, a front side 5, and a rear side 6 to form a long strip, and the bottom 2 is provided with a ventilation Groove 11, the tail end of the bottom 2 is provided with a card slot 8 for tail fixing, and a boss 7 is arranged on the front end of the upper surface 1, and the outer surface of the boss 7 is surrounded by 5 to 10 slopes. In this embodiment There are 7 faces in the middle, and the included angles between each inclined plane and the horizontal plane are not equal, and the inclined planes intersect with the inclined planes to form a knife edge. An air outlet 9 is arranged on the rear slope of the boss 7, and the air outlet 9 communicates with the ventilation groove 11 of the bottom 2; the shape of the boss 7 is a polyhedron with a small top, a large bottom, a narrow front end, and a wide rear...

Embodiment 2

[0025] See Figure 4 , Figure 5 , Image 6 , the composition and connection relationship of the grate sheet with multi-blade boss described in this embodiment is basically the same as that of Embodiment 1, the difference is that the outer surface of the boss 7 is surrounded by 6 slopes; the height of the boss 7 200mm, mix and disperse the upper-layer garbage with the surrounding garbage. The agitation effect of the grate piece on the garbage in the height direction is expanded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com