Low porosity grouting technology for pouring concrete

A concrete and low-altitude technology, applied in the field of concrete pouring, can solve problems such as the influence of the strength of concrete blocks, and achieve the effects of facilitating timely maintenance, improving safety, and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

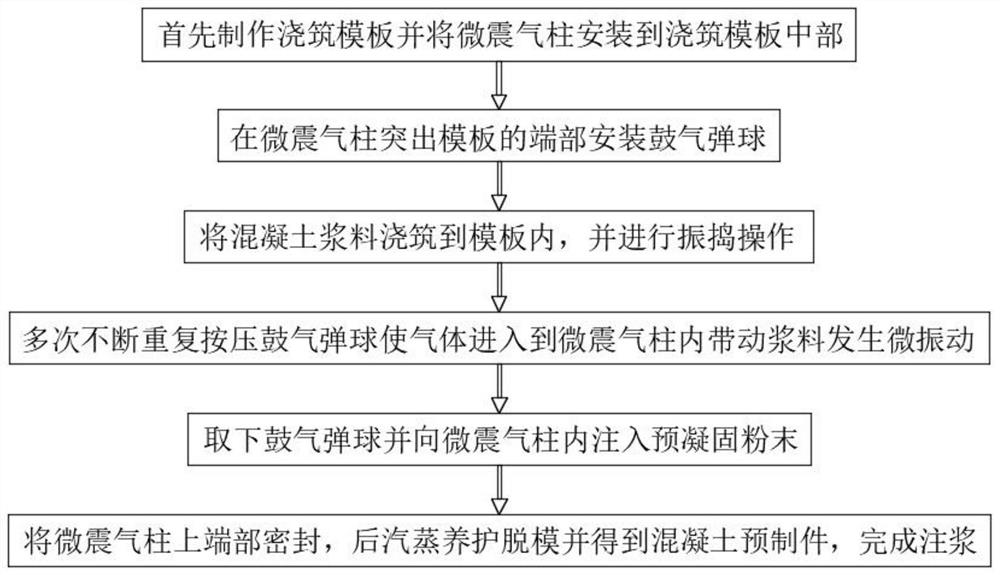

[0054] see figure 1 , the low porosity grouting process of concrete pouring, comprising the following steps:

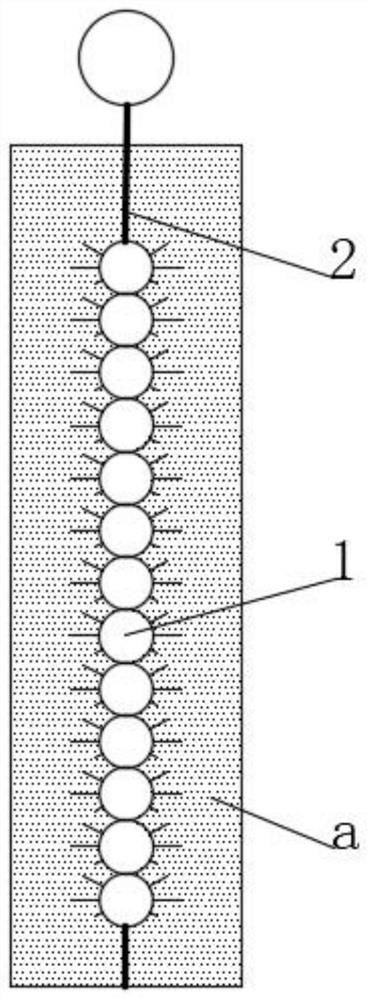

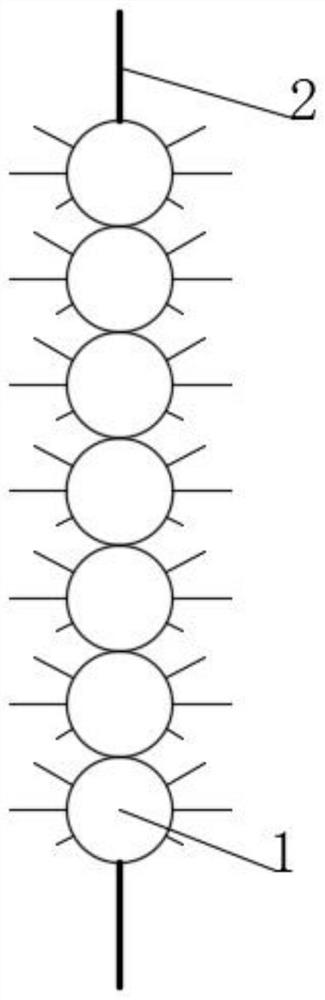

[0055] S1, see figure 2 , first make the pouring formwork, and then install the micro-seismic air column longitudinally in the middle of the pouring formwork;

[0056] S2. Install inflatable pinballs at the end of the micro-vibration air column protruding from the formwork;

[0057] S3. Pouring concrete slurry into the formwork from above the formwork, and vibrating;

[0058] S4. Afterwards, the inflatable pinball is repeatedly pressed repeatedly, and the gas inside the inflatable pinball enters into the micro-vibration air column, thereby driving the concrete slurry to vibrate slightly from the inside;

[0059] S5. After a period of time, remove the inflated pinball, and inject pre-solidified powder into the micro-vibration air column along the upper port of the micro-vibration air column;

[0060] S6. Seal the upper end of the micro-seismic gas column, perform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com