Copper coat slag shell clearing vibration platform and clearing method

A vibrating platform and copper cladding technology, which is applied in mechanical cleaning, casting molten material containers, manufacturing tools, etc., can solve the problems of hidden safety hazards, low work efficiency, time-consuming and labor-consuming, etc., to ensure operation safety, improve work efficiency, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

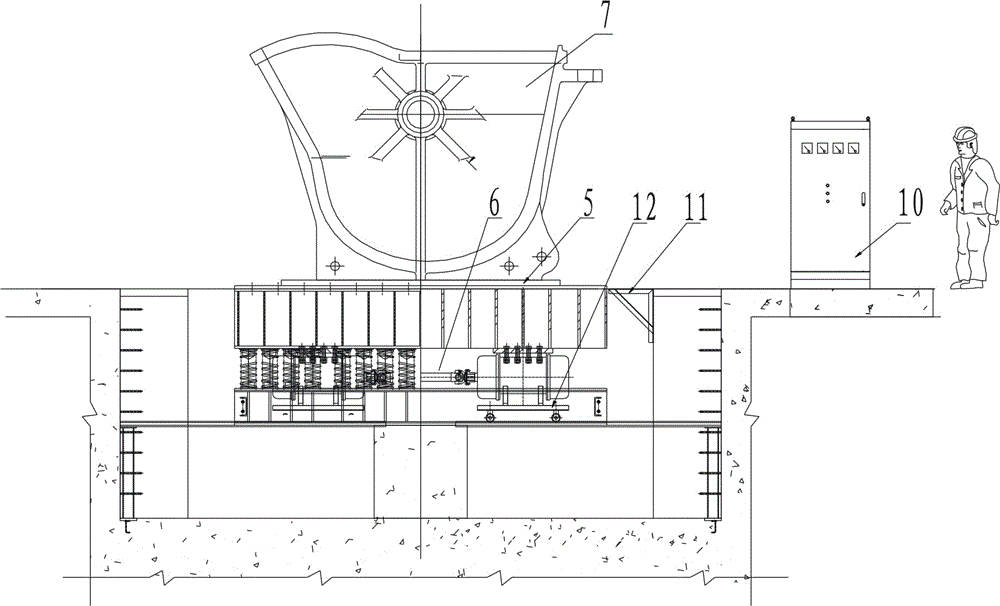

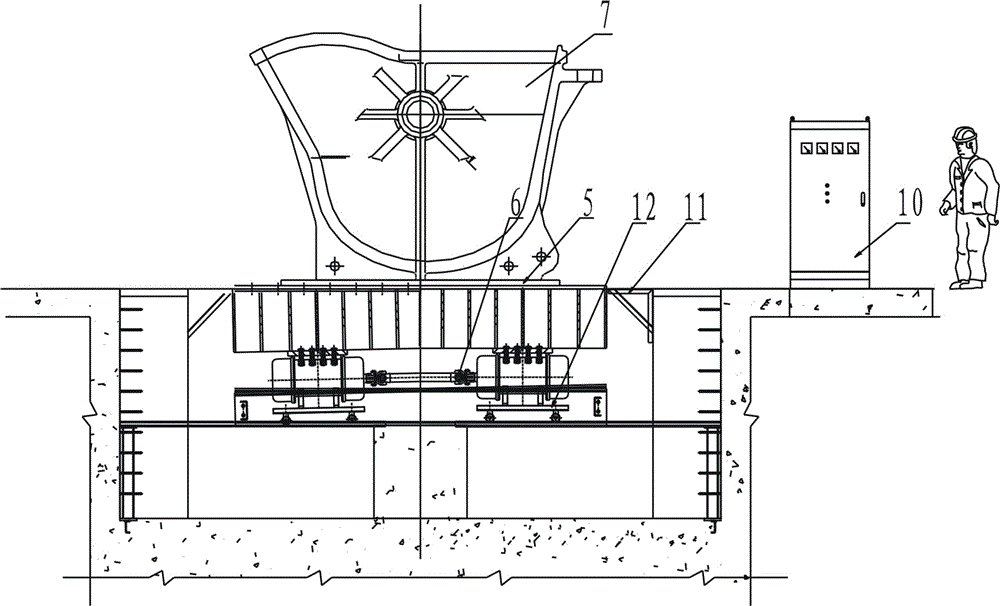

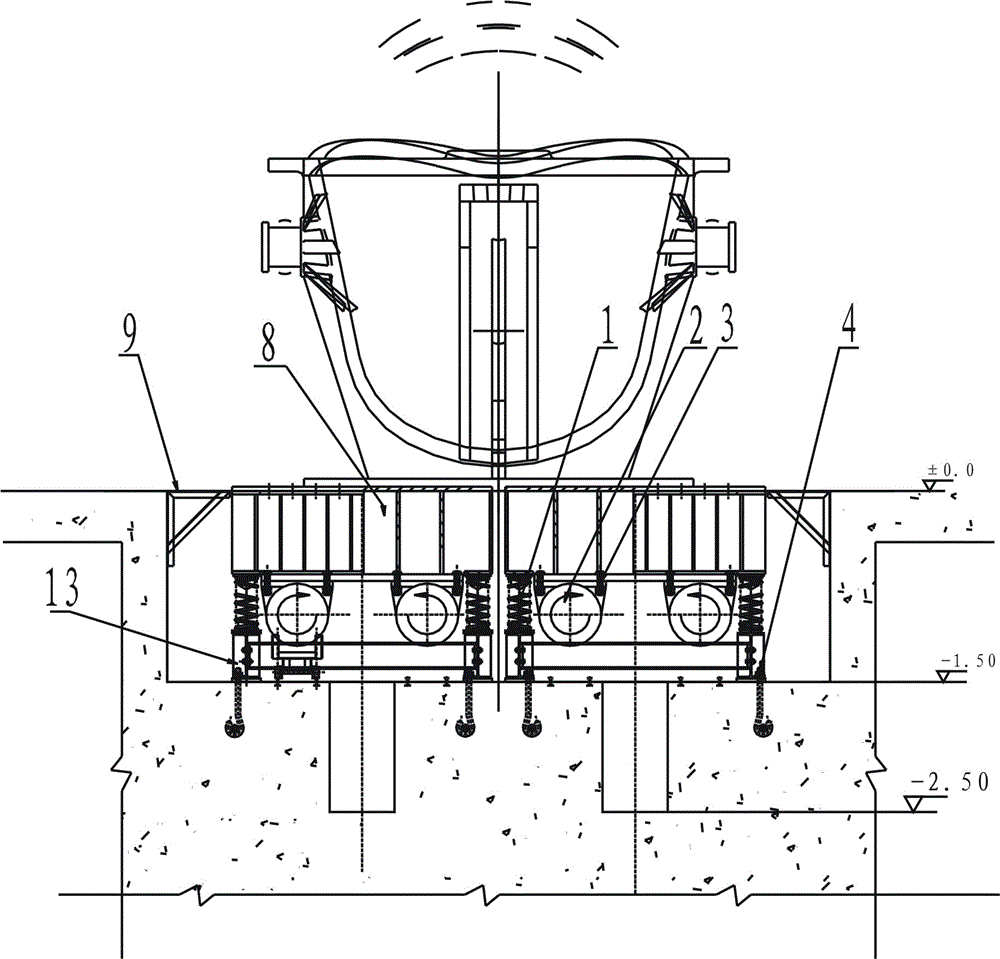

[0024] The present invention will be further described below in conjunction with the drawings.

[0025] Such as Figure 1-4 As shown, this embodiment provides a copper-clad slag shell cleaning vibration platform, which includes a base 13, a cylindrical working spring 1, a vibrating body 8, a vibration motor 2, and an electrical control cabinet 10 for controlling the vibration motor 2. Among them, the lower end of the base 13 is fixed on the pit in the workshop by anchor bolts, the working spring 1 is symmetrically arranged below both sides of the vibrating body 8, and both ends of the working spring 1 are connected to the base 13 and the vibrating body respectively. 8 is connected, the vibrating motor 2 is arranged inside the working spring 1 and below the vibrating body 8, and the upper end of the casing is fixedly connected to the vibrating body 8 by a high-strength bolt 3. Among them, the working surface of the vibrating body 8 is level with the ground of the workshop, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com