High-ethylene-selectivity catalyst for preparation of low carbon olefins from methanol

A low-carbon olefin and catalyst technology, applied in the field of special catalysts, can solve problems such as difficult operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

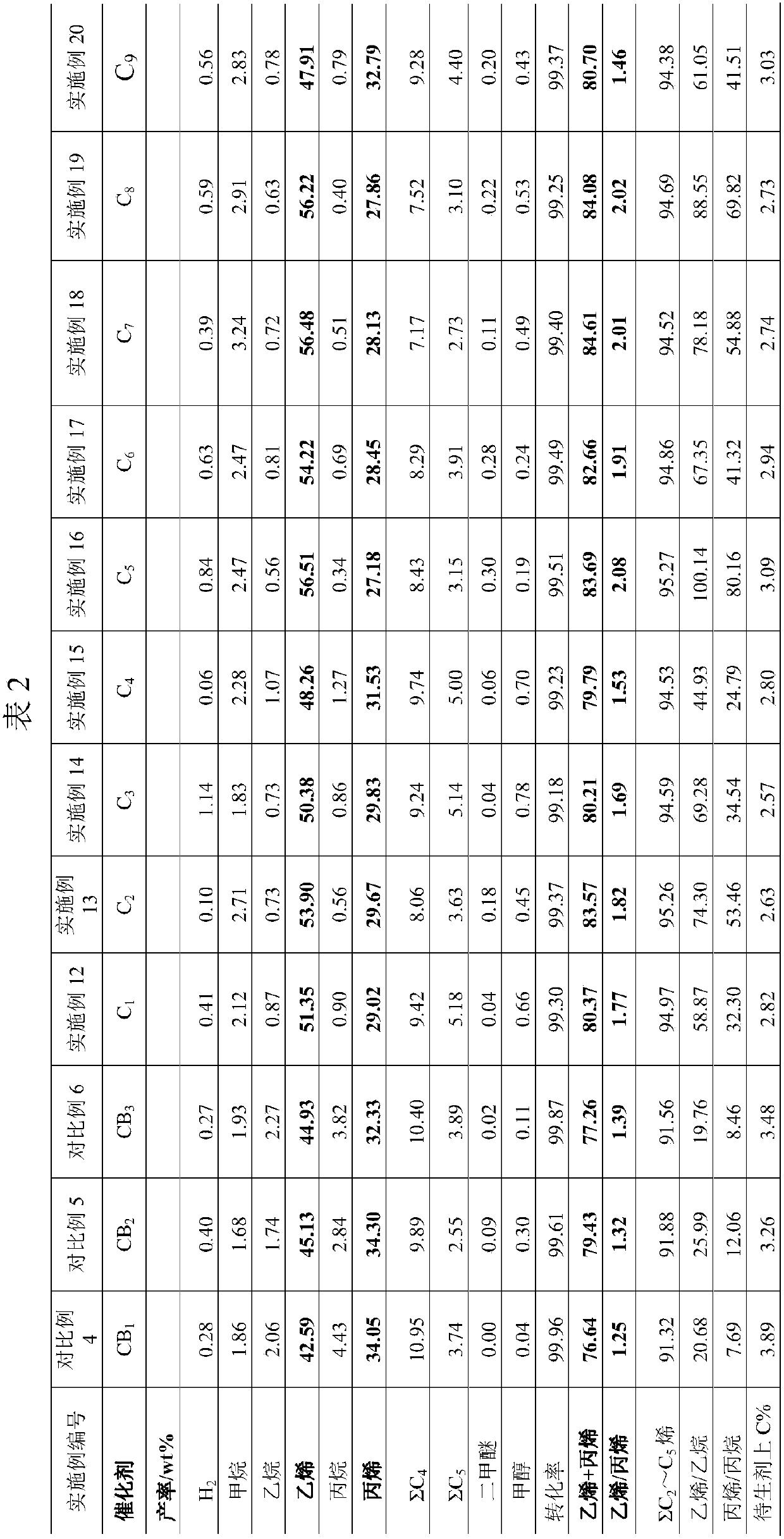

Examples

Embodiment 1

[0063] Put de-cationic water and 10 kg of conventional SAPO molecular sieve (dry basis) into the stirred tank, beating and dispersing into a slurry with a solid content of 25% by weight. Sequentially add a zinc acetate aqueous solution containing 0.273 kg of ZnO and 0.54 kg of P to the slurry 2 O 5 Concentrated phosphoric acid, stir and disperse uniformly, heat up to 55°C and keep the temperature constant for 45 minutes, and then flash dry the mixed slurry. The dried product was calcined at 550°C for 60 minutes to obtain 2.5 wt% Zn modifier (calculated as ZnO) and 5.0 wt% P modifier (calculated as P 2 O 5 Calculated) modified silicon aluminum phosphate (SAPO) molecular sieve KSAPO-01.

Embodiment 2

[0065] Put de-cationic water and 10 kg of conventional SAPO molecular sieve (dry basis) into the stirred tank, beating and dispersing into a slurry with a solid content of 25% by weight. Sequentially add a zinc nitrate aqueous solution containing 0.43 kg ZnO and 0.268 kg P to the slurry 2 O 5 Stir and disperse the ammonium dihydrogen phosphate uniformly, raise the temperature to 55°C and keep the temperature constant for 45 minutes, and then flash dry the mixed slurry. The dried product was calcined at 550°C for 60 minutes to obtain 4.0 wt% Zn modifier (calculated as ZnO) and 2.5 wt% P modifier (calculated as P 2 O 5 Calculated) modified silicon aluminum phosphate (SAPO) molecular sieve KSAPO-02.

Embodiment 3

[0068] Take 5 kg (dry basis) of diatomaceous earth (as non-cohesive inorganic oxide or inorganic hydroxide (E)), be beaten with deionized water and dispersed into a slurry with a solid content of 30% by weight, and pumped into a ball mill for grinding , Until the particle size of more than 90% of the solid matter in the slurry <5.5μm.

[0069] Put 1.8 kg of decationized water, 0.05 kg (dry basis) acidic silica sol (as an inorganic binder), 0.4 kg (dry basis) modified silicon aluminum phosphate (SAPO) molecular sieve KSAPO-01, 0.1 kg in the stirred tank. (Dry basis) diatomaceous earth, 0.25 kg (dry basis) kaolin, 0.02 kg (dry basis) Zn(NO 3 ) 2 .6H 2 O and 0.1 kg (dry basis) pseudo-boehmite (as a binder), beating and dispersing for 120 minutes. Add 0.13 kg of concentrated phosphoric acid and continue beating for 60 minutes. Then, the obtained slurry was spray-dried at an inlet temperature of 500°C and an exhaust gas temperature of 180°C to prepare a molecular sieve KSAPO-01 conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com