Catalyst for increasing yield of low-carbon olefins by directly catalytically cracking crude oil and preparation method thereof

A technology for catalytic cracking and low-carbon olefins, which is applied in the direction of carbon compound catalysts, physical/chemical process catalysts, catalysts, etc., and can solve the problem of low yield of low-carbon olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

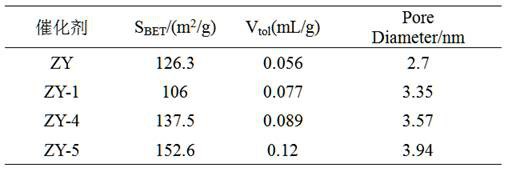

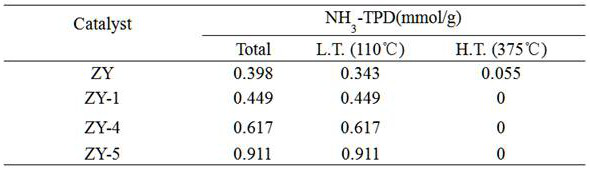

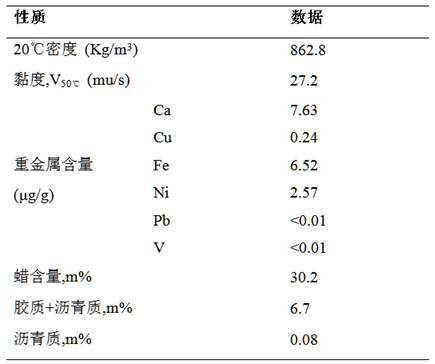

[0029] Weigh 1.43 Kg of diammonium hydrogen phosphate, dissolve in an appropriate amount of deionized water, slowly add 26 Kg ZSM-5 molecular sieve (SiO 2 / Al 2 o 3 =38), let stand overnight, dry at 100°C for 10 h, place in a muffle furnace and bake at 650°C for 4 h to obtain modified P / ZSM-5; weigh 0.26 Kg of zirconium nitrate and dissolve it in an appropriate amount of deionized water, Slowly add the above-mentioned modified P / ZSM-5 molecular sieve under low temperature, let stand overnight, dry at 100°C for 10 h, and place in a muffle furnace for calcination at 650°C for 2 h to obtain modified P-Zr / ZSM-5;

[0030] Weigh 3.36 Kg USY molecular sieve and 13.86 Kg pseudo-boehmite, mix them evenly, and acidify them with hydrochloric acid, mix the aluminum phosphate, the acidified pseudo-boehmite sol and water for beating, stir well, and then add the modified P- Zr / ZSM-5 molecular sieve and 15.2Kg kaolin were mixed and beaten for 6 hours, dried at 100°C for 12 hours, calcined a...

Embodiment 2

[0032] Weigh 1.43 Kg of diammonium hydrogen phosphate, dissolve in an appropriate amount of deionized water, slowly add 26 Kg ZSM-5 molecular sieve (SiO 2 / Al 2 o 3=38), let stand overnight, dry at 100°C for 10 h, place in a muffle furnace and bake at 650°C for 4 h to obtain modified P / ZSM-5; weigh 0.4 Kg of zirconium nitrate, dissolve in appropriate amount of deionized water, and stir Slowly add the above-mentioned modified P / ZSM-5 molecular sieve under the conditions, let it stand overnight, dry at 100°C for 10 h, and place it in a muffle furnace for calcination at 650°C for 2 h to obtain the modified P-Zr / ZSM-5 molecular sieve;

[0033] Weigh 3.36 Kg USY molecular sieve and 13.86 Kg pseudo-boehmite, mix them evenly, and acidify them with hydrochloric acid, mix the aluminum phosphate, the acidified pseudo-boehmite sol and water for beating, stir well, and then add the modified P- Zr / ZSM-5 molecular sieve and 15.2 Kg kaolin were mixed and beaten for 6 hours, dried at 100°C ...

Embodiment 3

[0035] Weigh 1.43 Kg of diammonium hydrogen phosphate, dissolve in an appropriate amount of deionized water, slowly add 26 Kg ZSM-5 molecular sieve (SiO 2 / Al 2 o 3 =38), let it stand overnight, dried at 100°C for 10 h, and roasted at 650°C in a muffle furnace for 4 h to obtain modified P / ZSM-5; weighed 0.82 Kg of zirconium nitrate and dissolved it in an appropriate amount of deionized water, and put it under stirring conditions Slowly add the above-mentioned modified P / ZSM-5 molecular sieve under low temperature, let stand overnight, dry at 100°C for 10 h, and place in a muffle furnace for calcination at 650°C for 2 h to obtain modified P-Zr / ZSM-5;

[0036] Weigh 3.36 Kg USY molecular sieve and 13.86 Kg pseudo-boehmite, mix them evenly, and acidify them with hydrochloric acid, mix the aluminum phosphate, the acidified pseudo-boehmite sol and water for beating, stir well, and then add the modified P- Zr / ZSM-5 molecular sieve and 15.2Kg kaolin were mixed and beaten for 6 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com