Bifunctional catalyst containing hierarchical porous SAPO-34 molecular sieve as well as preparation method and application of bifunctional catalyst

A SAPO-34, bifunctional catalyst technology, applied in the field of molecular sieves, can solve the problems of high cost, complicated process, cumbersome steps, etc., and achieve the effect of low cost, simple and easy steps, and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Weigh 10.10g of pseudo-boehmite and 51.6g of deionized water and stir evenly, then slowly add 16.09g of phosphoric acid, 2.93g of silica sol, and 20.26g of triethylamine in sequence, and continue stirring until a uniform gel is formed. The obtained gel was transferred into a 150 mL stainless steel synthesis kettle with a polytetrafluoroethylene liner, heated to 200°C over 120 min, and crystallized at this temperature for 38 h. After the crystallization was completed, the synthesis kettle was taken out of the rotary oven and cooled to room temperature with flowing water, and then the crystallized product was rotated in a constant temperature 40° C. rotary oven for 20 minutes. The obtained product is subjected to centrifugal washing to neutrality, and placed in an oven at 110° C. to dry overnight to obtain the original powder of multi-order porous SAPO-34 molecular sieve. After the raw powder is calcined at 550°C in air to remove the organic template, a calcined hierarchi...

Embodiment 2

[0050] Same as Example 1, except that the reaction temperature in the reaction conditions is changed from 350°C to 375°C.

Embodiment 3

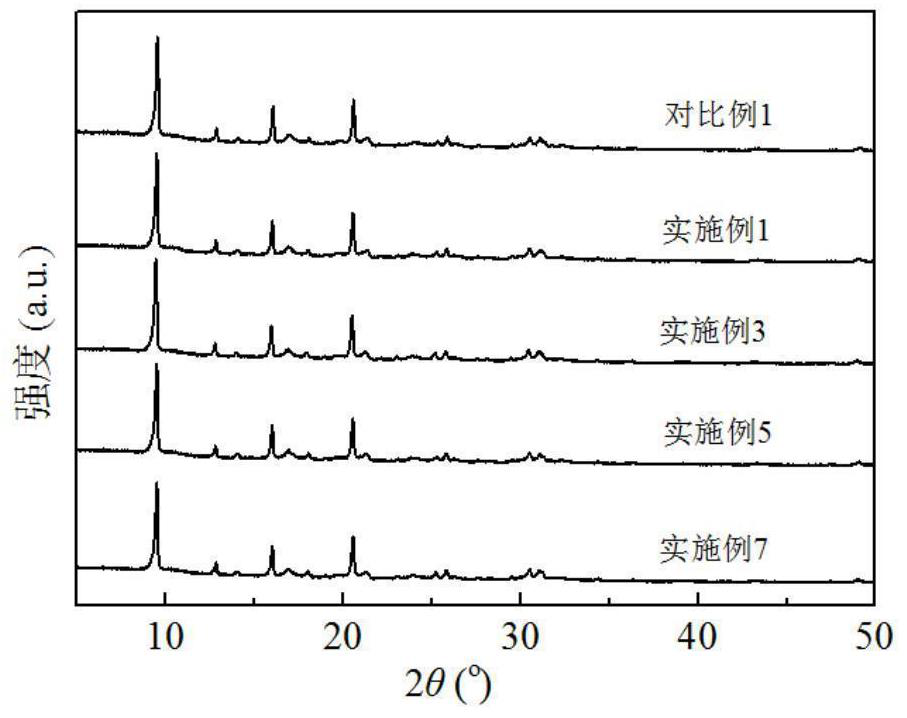

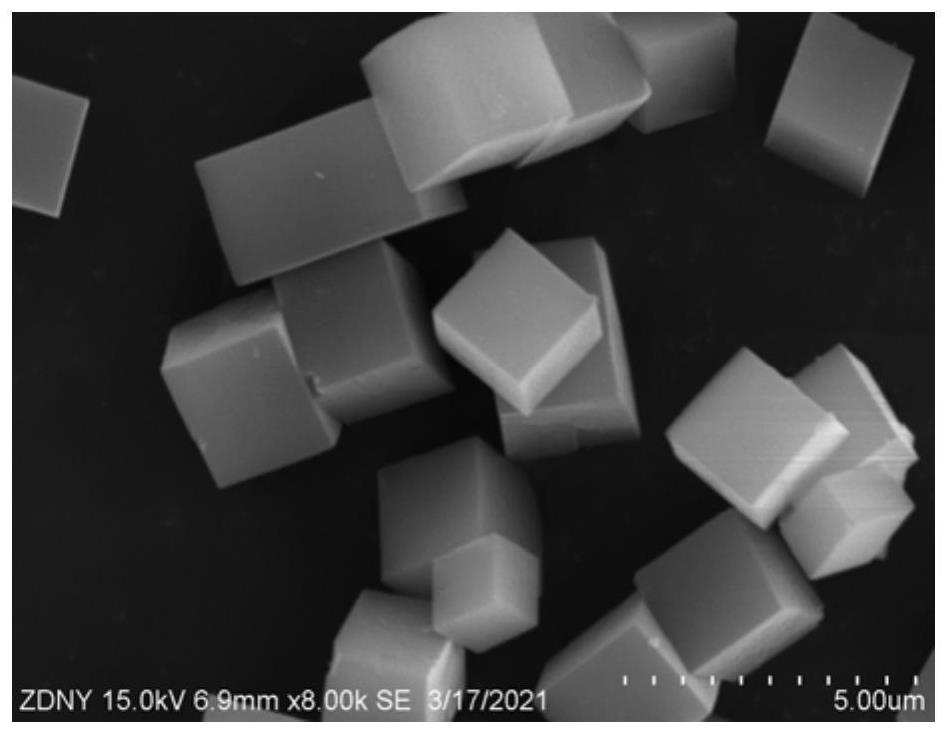

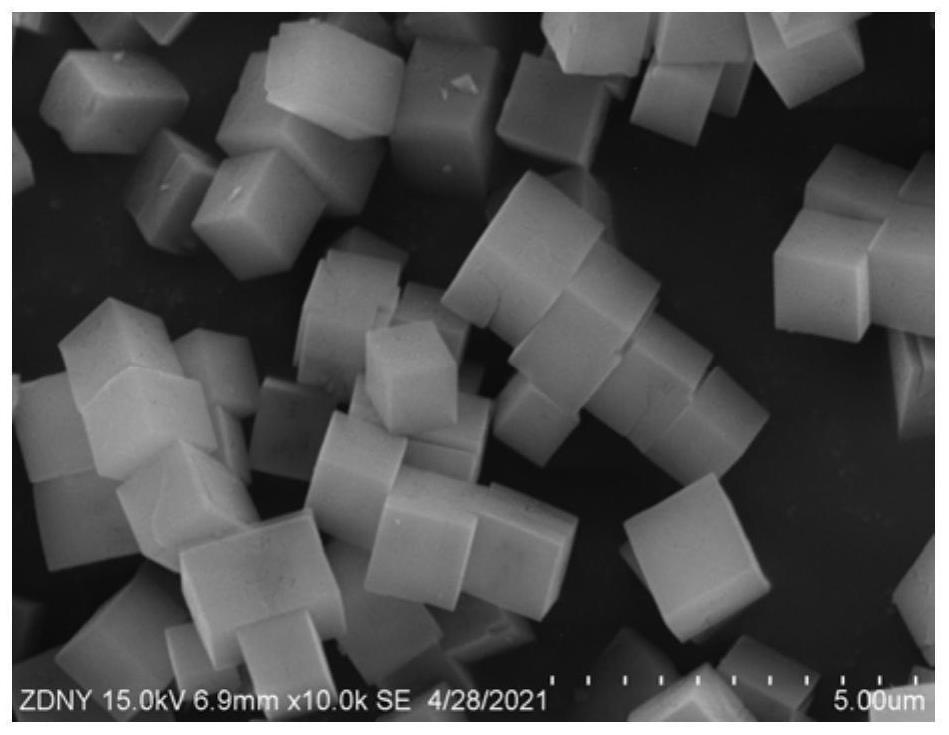

[0052] The preparation process of the catalyst was the same as in Example 1, except that the crystallized product was rotated in a rotary oven at a constant temperature of 40° C. for 40 minutes, and the obtained multi-order porous SAPO-34 molecular sieve was designated as SP34-40. The XRD results show that it is a SAPO-34 molecular sieve structure, and the scanning electron microscope results can clearly observe the formation of a butterfly-like macroporous structure. Scanning electron microscope results show that SAPO-34 molecular sieve has a hierarchical pore structure, which consists of micropores and macropores.

[0053] Preparation of bifunctional catalyst: uniformly mix SP34-40 molecular sieve (40-60 mesh) with metal oxide ZnCrAl (40-60 mesh) prepared by co-precipitation method according to the weight ratio of molecular sieve to metal oxide of 1:2.

[0054] The evaluation conditions and process of the bifunctional catalyst are the same as in Comparative Example 1.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com