Pyrolysis reactor

A pyrolysis reactor, pyrolysis oil and gas technology, applied in indirect heating dry distillation, special form dry distillation, petroleum industry and other directions, can solve the problem that the comprehensive utilization technology of waste pyrolysis waste is difficult to achieve major breakthroughs, the comprehensive utilization is difficult, and the tar composition is difficult to achieve. Complicated and other problems, to achieve the effect of easy operation, small size and high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

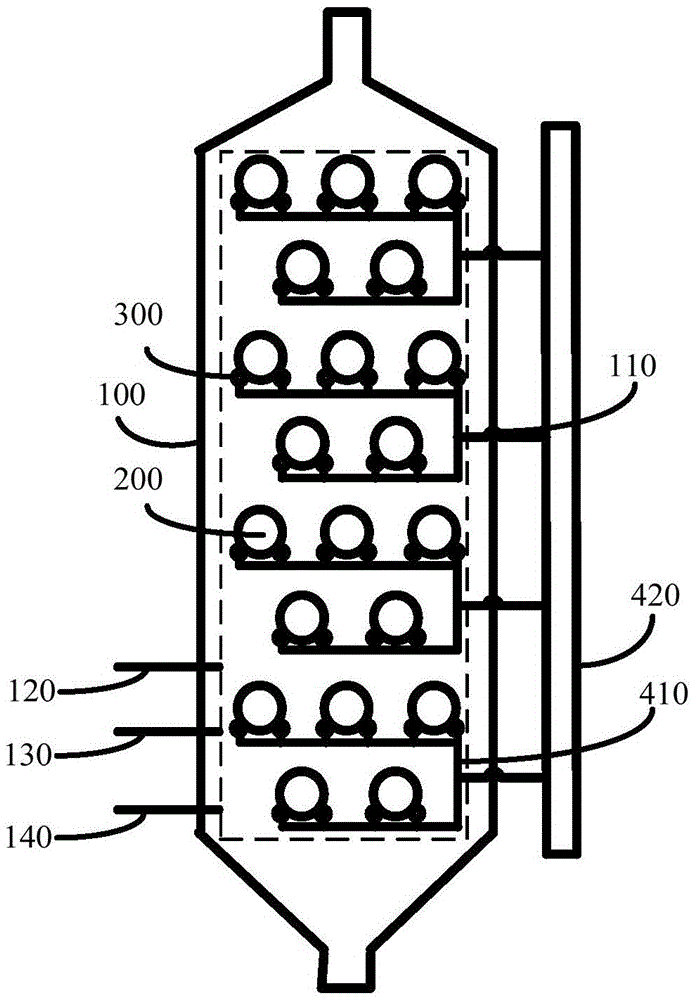

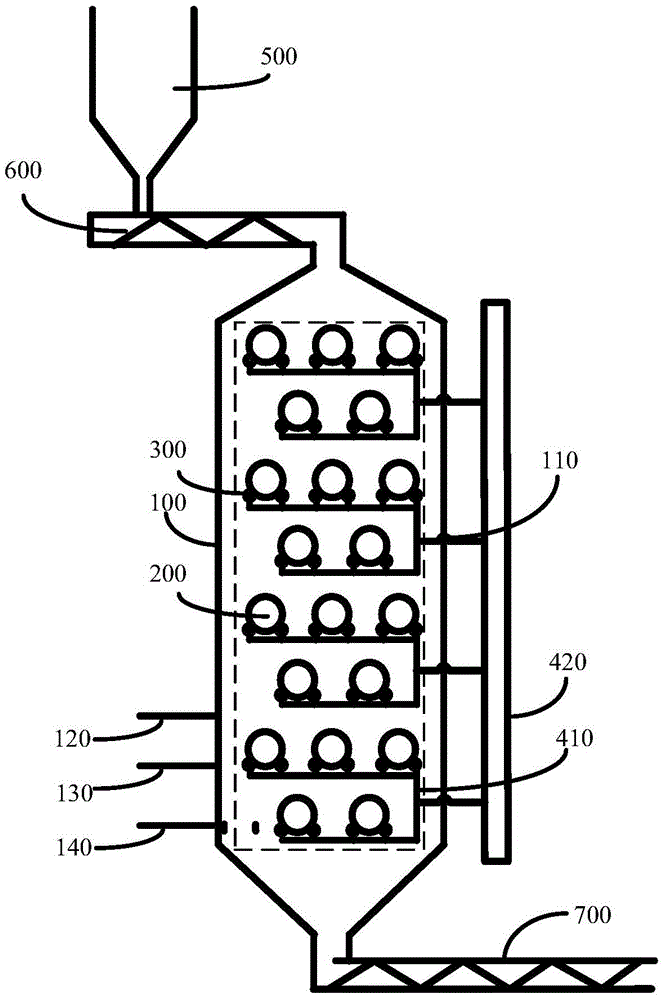

[0052] The analysis of the composition of domestic waste in a city is shown in Table 1. The water content of the waste is 43%. The pyrolysis reactor is used to treat the domestic waste. The structural diagram of the pyrolysis reactor is shown in image 3 As shown, the specific process is as follows:

[0053] Table 1

[0054]

[0055] Table 2

[0056]

[0057] 1. Garbage pretreatment for entering the site. After entering the site, large-size dregs, glass and metals and other substances that are not easy to pyrolyze or cannot be pyrolyzed are removed first;

[0058] 2. The garbage after removing the difficult-to-pyrolyze materials is directly sent to the garbage dump for compression and dehydration, and then sent to the pyrolysis reactor;

[0059] 3. Control the ratio and amount of gas and air entering the radiant tube, control the temperature of the pyrolysis furnace, and ensure that the temperature in the pyrolysis chamber is about 680°C;

[0060] 4. Control the rotat...

Embodiment 2

[0067] The analysis of the composition of domestic waste in a city is shown in Table 3. The water content of the waste is 51%. The pyrolysis reactor is used to treat the domestic waste. The structural diagram of the pyrolysis reactor is shown in image 3 As shown, the specific process is as follows:

[0068] table 3

[0069]

[0070] Table 4

[0071]

[0072] 1. Pretreatment of incoming garbage. After entering the garbage, the large-size dregs, glass and metals contained in the incoming garbage are removed first;

[0073] 2. The garbage after removing the difficult-to-pyrolyze materials is directly sent to the garbage dump for compression and dehydration, and then sent to the pyrolysis reactor;

[0074] 3. Control the ratio and amount of gas and air entering the radiant tube, control the temperature of the pyrolysis furnace, and ensure that the temperature in the pyrolysis chamber of the pyrolysis reactor is about 700°C;

[0075] 4. Control the rotation speed of the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com