Catalyst for preparing acetaldehyde by dehydrogenation of ethanol, its preparation method and application

A technology of catalysts and supported catalysts, applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve the problem of low acetaldehyde selectivity and achieve high acetaldehyde selectivity and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation process of mesoporous carbon supported Cu catalyst:

[0025] (1) Prepare Cu(NO 3 ) 2 ·3H 2 O aqueous solution;

[0026] (2) At 25°C, take an equal volume of the above solution and impregnate it on mesoporous carbon, and let it stand for 0.5-2 hours;

[0027] (3) drying the mixture after step (2) standing at 50° C. for 10 to 12 hours to obtain a catalyst precursor;

[0028] (4) Dry the precursor obtained in step (3) at 140°C for 0.5h, then hydrogen reduction at 450°C or 350°C for 2h (10vol%H 2 / N 2 ), respectively prepared 5Cu / mesoporous carbon (No. 2 in Table 1) catalyst and 10Cu / mesoporous carbon (No. 4 in Table 1) catalyst.

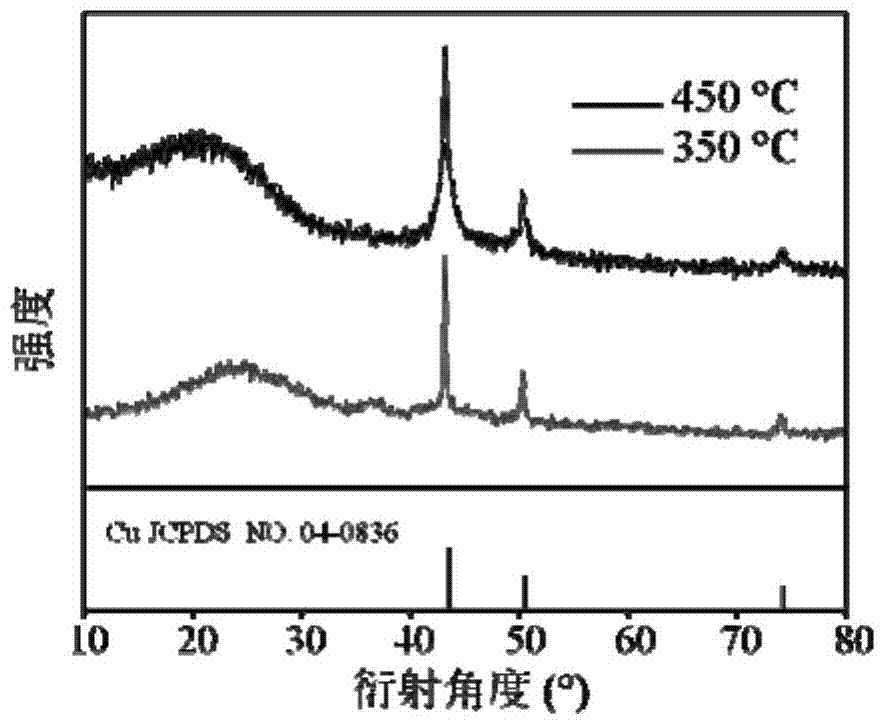

[0029] The XRD pattern of 10Cu / mesoporous carbon catalyst is as follows figure 1 shown.

Embodiment 2

[0031] Preparation process of biochar-supported Cu catalyst:

[0032] (1) Take biomass coconut shells, wash them with water, dry them, and primary crush them, and then carry out pyrolysis treatment in an inert gas atmosphere at 600°C for 2 hours; the pyrolysis products are further ground and pulverized, and then pyrolyzed again at 800°C for 2 hours in an inert atmosphere to obtain biomass coconut shell charcoal;

[0033] (2) At 25°C, take Cu(NO 3 ) 2 ·3H 2 On the biochar prepared by impregnating the equal volume of O aqueous solution in step (1), let stand for 2h;

[0034] (3) drying the mixture after step (2) at 50° C. for 10 h to obtain a catalyst precursor;

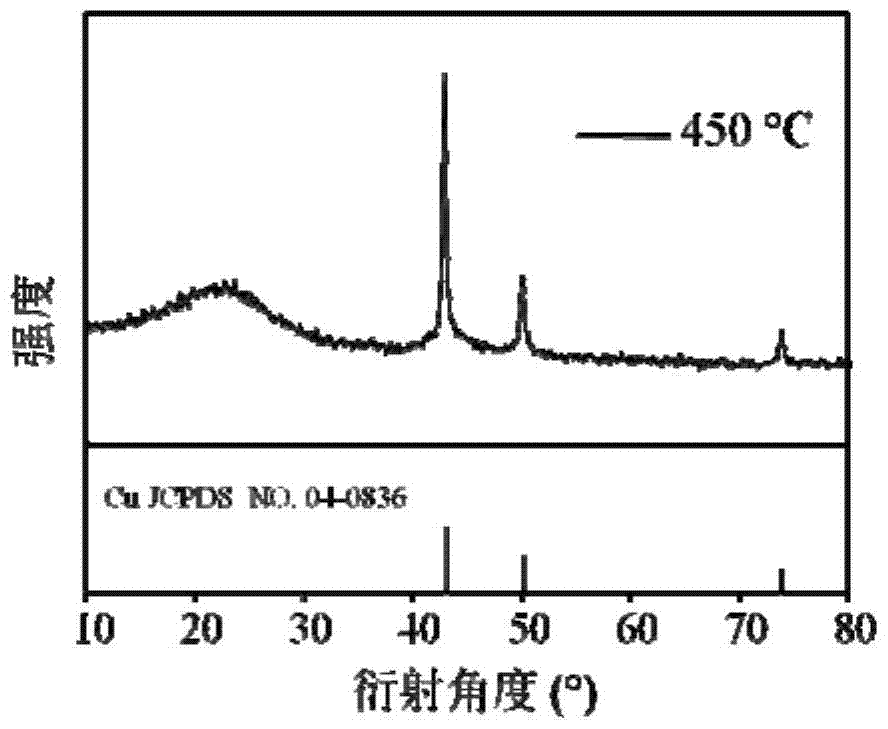

[0035] (4) Dry the catalyst precursor obtained in step (3) at 140°C for 0.5h, followed by hydrogen reduction at 450°C for 2h (10vol%H 2 / N 2 ), prepared 10Cu / biomass charcoal (No. 15 in Table 1) catalyst. The XRD pattern of gained catalyst is as figure 2 shown.

[0036] The preparation condition process of ot...

Embodiment 3

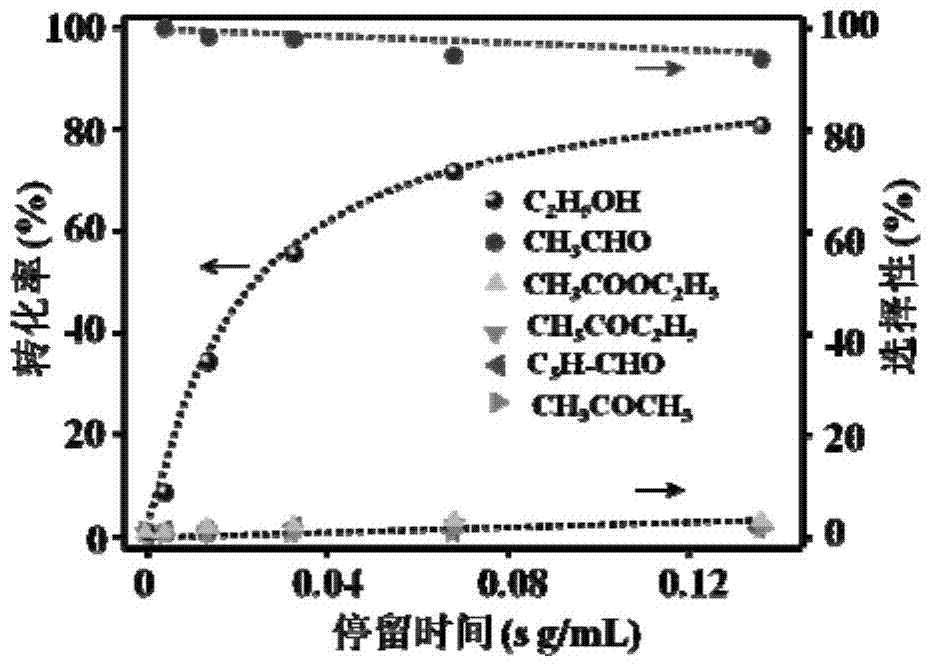

[0040] Experiments on ethanol dehydrogenation catalyzed by Cu catalysts supported on different carbon supports.

[0041] Using ethanol as raw material, the ethanol dehydrogenation reaction is carried out in a fixed bed reactor. The reaction conditions are as follows: a fixed-bed reactor with an inner diameter of 8 mm is filled with catalyst, under normal pressure, the reaction temperature is 260° C., and the ethanol liquid phase flow rate is 0.3 mL / h. After the reaction was stable, the reaction raw materials and products were analyzed by online chromatography. Table 2 shows the correspondence between sample numbers and ethanol dehydrogenation activity.

[0042] Table 2 The corresponding relationship between the sample numbers of Example 3 and the ethanol dehydrogenation activity

[0043] serial number

[0044] 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com