Method for delaying coking

A delayed coking method and coke technology, which is applied in the field of delayed coking, can solve the problems that the continuous operation of the decoking process cannot be realized, and achieve the effects of shortening the coke production time, avoiding processing, and reducing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

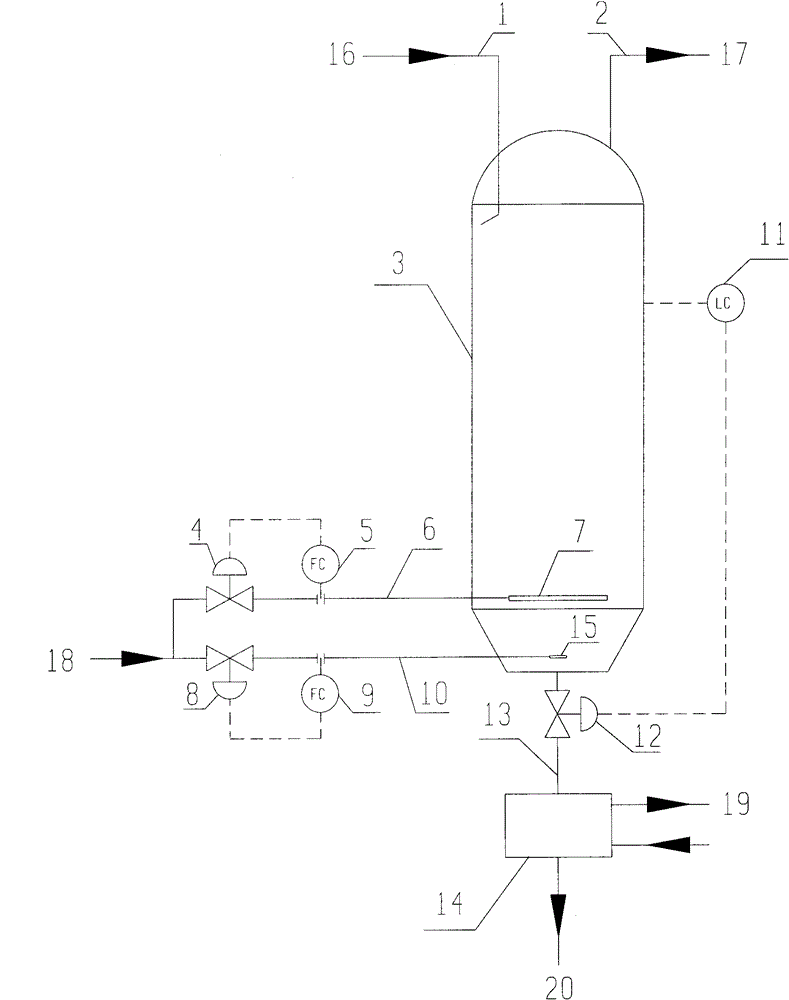

[0034] figure 1 In the process, the high-temperature material 16 from the radiant section of the heating furnace enters the coke tower from the upper side or top of the coke tower 3 through the oil transfer line 1. After entering the tower, it flows downward in a tangential manner along the inner surface of the upper part of the coke tower. The gasified high-temperature The oil gas 17 is quickly discharged from the top of the coke tower and goes to the fractionation tower through the oil gas pipeline 2 for fractionation, and the heavy oil without gasification remains in the tower to continue the coking reaction; the steam flow is adjusted at the bottom of the coke tower and above the bottom conical head Valves 8 and 4, flowmeters 9 and 5, steam pipelines 10 and 6, and steam distributors 15 and 7 are continuously blown in two ways. ℃~550℃ high temperature steam 18 to strip the generated coke. Control the top pressure of the coke tower to be 0.10MPa-0.6MPa, and the coke-forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com