Method for selectively regulating and controlling products of Fischer-Tropsch synthesis

A Fischer-Tropsch synthesis and selectivity technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of liquid hydrocarbon mixtures, etc., can solve the problem of low selectivity of other products, and achieve the suppression of secondary reactions and heat transfer Good performance and long catalyst life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

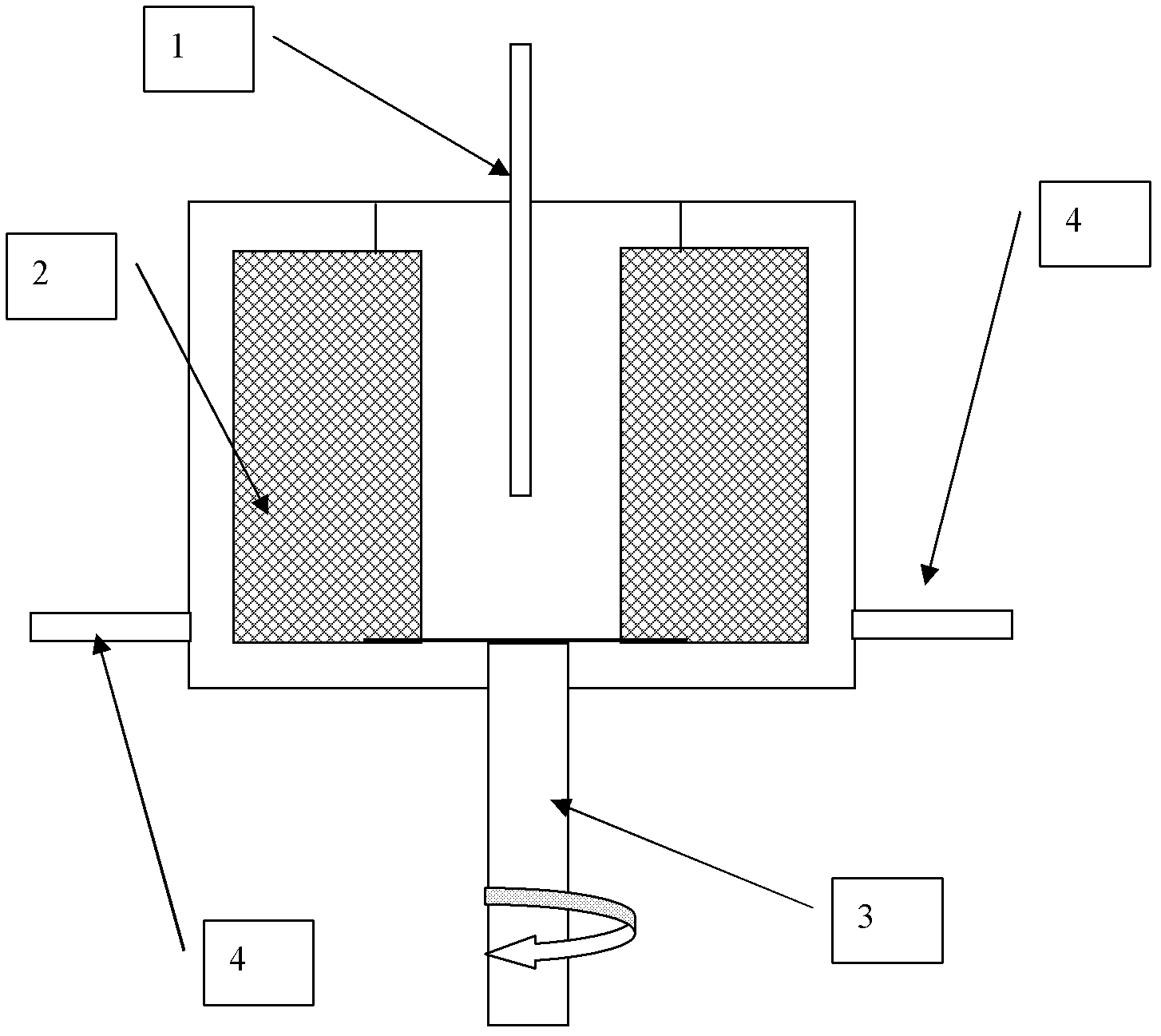

Image

Examples

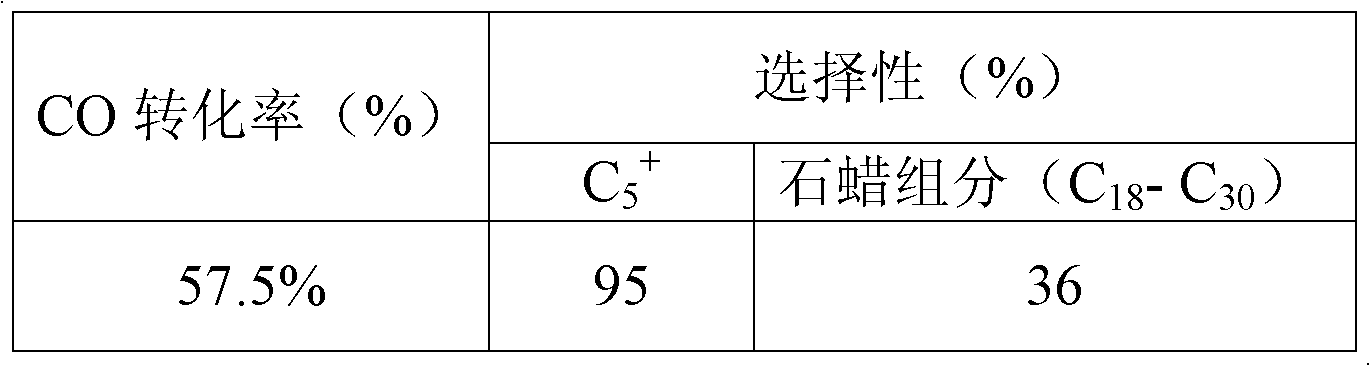

Embodiment 1

[0040] Fischer-Tropsch synthesis of paraffin wax in a high-gravity reactor. Syngas as CO+H 2 Mixed gas, CO / H 2 = 1 / 2. Co / SiO 2 The Fischer-Tropsch catalyst is placed in a mesh support and fixed on the rotor of the supergravity reactor.

[0041] The processing conditions of reaction are as follows:

[0042] Syngas air velocity: 600h -1 , Reaction temperature: 210°C, Reaction pressure: 1.2MPa

[0043] Catalyst bed super gravity level: 10g

[0044] Fischer-Tropsch synthesis to paraffin wax reaction results in high gravity reactor:

[0045]

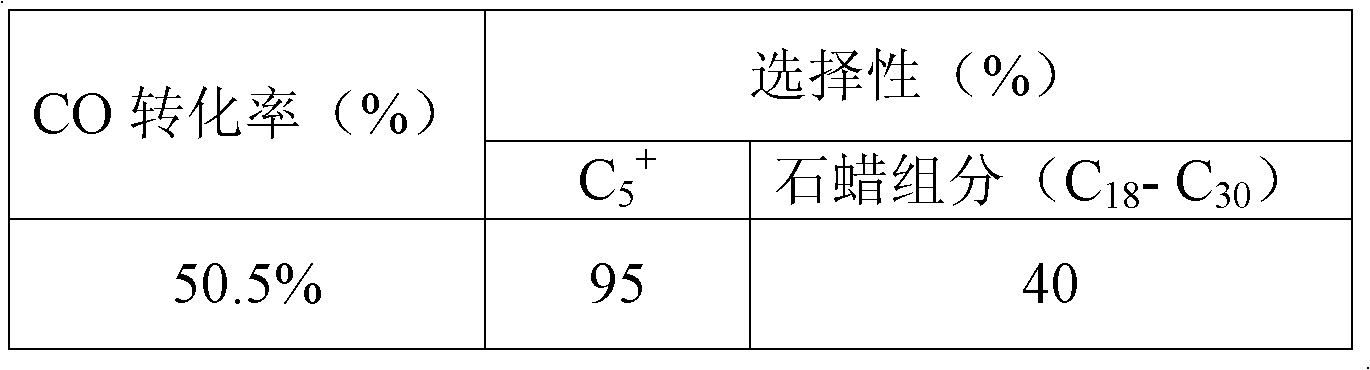

Embodiment 2

[0047] Fischer-Tropsch synthesis of paraffin wax in a high-gravity reactor. Syngas as CO+H 2 Mixed gas, CO / H 2 = 1 / 2. Ru / SiO 2 The Fischer-Tropsch catalyst is placed in a mesh support and fixed on the rotor of the supergravity reactor.

[0048] The processing conditions of reaction are as follows:

[0049] Synthetic gas air velocity: 5000h -1 , Reaction temperature: 190°C, Reaction pressure: 6.0MPa

[0050] Catalyst bed super gravity level: 80g

[0051] Fischer-Tropsch synthesis to paraffin wax reaction results in high gravity reactor:

[0052]

Embodiment 3

[0054] Fischer-Tropsch synthesis of paraffin wax in a high-gravity reactor. Syngas as CO+H 2 Mixed gas, CO / H 2 = 1 / 1. Put the iron-based Fischer-Tropsch catalyst into the mesh support and fix it on the rotor of the high-gravity reactor.

[0055] The processing conditions of reaction are as follows:

[0056] Syngas air velocity: 2000h -1 , Reaction temperature: 280°C, Reaction pressure: 3.0MPa

[0057] Catalyst bed super gravity level: 50g

[0058] Fischer-Tropsch synthesis to paraffin wax reaction results in high gravity reactor:

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com