Preparation method of mesoporous ZSM-5 zeolite

A ZSM-5 and mesoporous technology, applied in the field of zeolite molecular sieve synthesis, can solve the problems of difficult industrial production acceptance, increased synthesis cost, and high synthesis cost, and achieve the effects of prolonging life, reducing diffusion resistance, and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

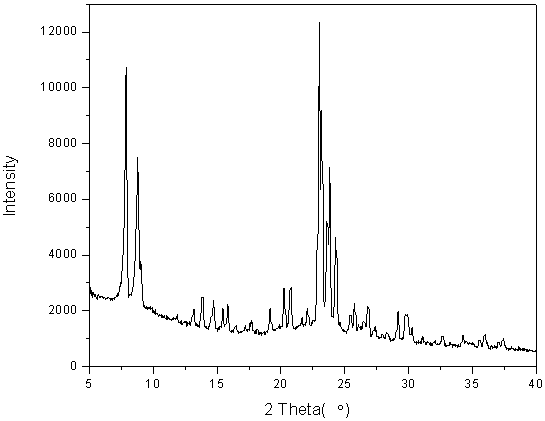

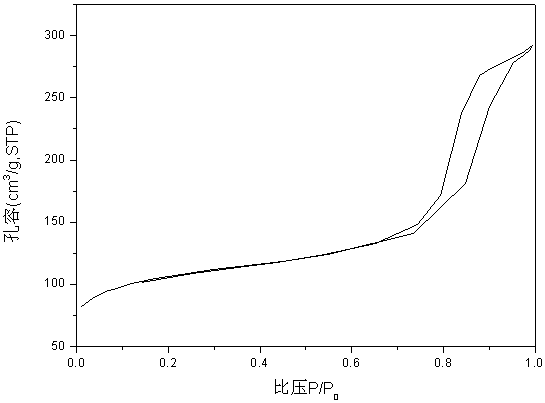

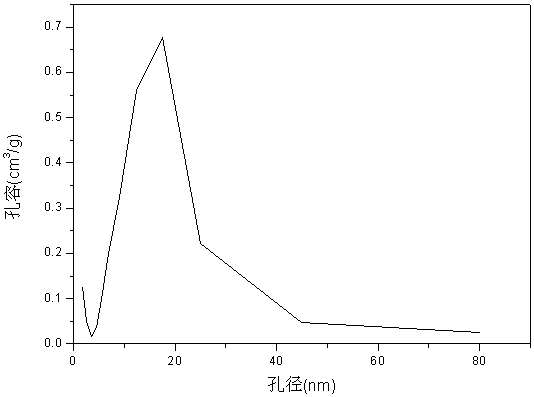

Embodiment 1

[0025] 8.33g Al 2 (SO 4 ) 3 18H 2 O (chemically pure) was dissolved with 80g deionized, and then 8.82g concentrated sulfuric acid (98%) was added dropwise to prepare a uniform solution a; the molar ratio of solution a based on the following substances was: Al 2 o 3 :H 2 SO 4 :H 2 O=1:7:374. 100g water glass (SiO 2 ≥30wt%, modulus 3.5) mixed with 107g deionized water and 3g copolymer, stirred at room temperature for 1 hour, then slowly added solution a to the above solution under rapid stirring, and continued to stir for 6 hours to obtain a uniform gel. The molar ratio of described gel is based on the following substances: Na 2 O: SiO 2 :Al 2 o 3 :H 2 O=10:40:1:1120. The above gel was transferred to a high-pressure reactor and crystallized at 170°C for 110 hours. The crystallized product was filtered and washed until neutral, then dried at 120°C, and then calcined at 500°C for 8 hours to obtain a well-crystallized product. Mesoporous ZSM-5 zeolite. The specific ...

Embodiment 2

[0027] 5.55g Al 2 (SO 4 ) 3 18H 2 O was dissolved with 100g of deionized, and then added dropwise with 10g of concentrated sulfuric acid to prepare a uniform solution a; the molar ratio of solution a based on the following substances was: Al 2 o 3 :H 2 SO 4 :H 2 O=1:12:667. Mix 100g water glass with 105g deionized water and 4.5g copolymer, stir at room temperature for 2 hours, then slowly add solution a to the above solution under rapid stirring, and continue stirring for 5 hours to obtain a uniform gel. The molar ratio of described gel is based on the following substances: Na 2 O: SiO 2 :Al 2 o 3 :H 2 O=17:60:1:1800. The above gel was transferred to an autoclave for crystallization at 180°C for 72 hours, the crystallized product was filtered and washed until neutral, then dried at 110°C, and then calcined at 540°C for 8 hours to obtain a well-crystallized product Mesoporous ZSM-5 zeolite. The specific surface area of the sample is 390.6m 2 / g, the micropore ...

Embodiment 3

[0029] 4.76g Al 2 (SO 4 ) 3 18H 2 O was dissolved with 120g deionized, and then 8.57g concentrated sulfuric acid was added dropwise to prepare a uniform solution a; the molar ratio of solution a based on the following substances was: Al 2 o 3 :H 2 SO 4 :H 2 O=1:12:933. Mix 100g water glass with 130g deionized water, 3.65g n-butylamine and 9g copolymer, stir at room temperature for 2 hours, then slowly add solution a to the above solution under rapid stirring, and continue stirring for 4 hours to obtain a uniform gel glue. The molar ratio of described gel is based on the following substances: Na 2 O: SiO 2 :Al 2 o 3 : NBA: H 2 O=19:70:1:7:2450. Transfer the above gel into an autoclave and crystallize at 175°C for 36 hours. The crystallized product is filtered and washed until neutral, then dried at 110°C, and then calcined at 540°C for 8 hours to obtain a well-crystallized product. Mesoporous ZSM-5 zeolite. The specific surface area of the sample is 419.1m 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com