Catalytic cracking catalyst capable of improving coke selectivity and preparation method of catalytic cracking catalyst

A catalytic cracking and catalyst technology, which is applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of small-pore coke selectivity and heavy oil conversion, and the inability to improve the acid center coke selectivity and loss in the channel. Heavy oil conversion capacity and other issues to achieve the effect of improving catalytic activity and coke selectivity, reducing contact probability, and reducing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

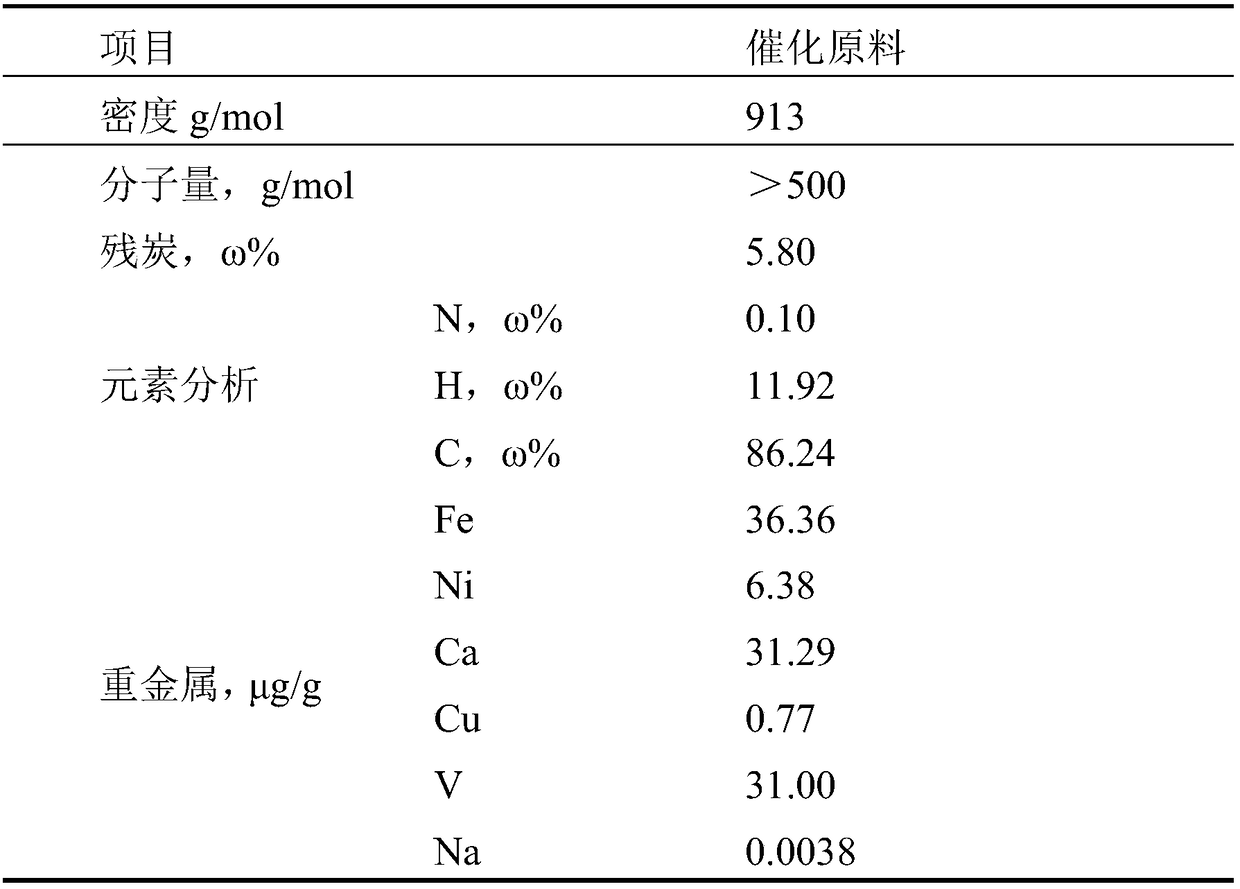

Image

Examples

Embodiment 1

[0048] Preparation of catalyst microspheres: 660g pseudo-boehmite, 991g kaolin, 216g aluminum sol, 990gUSY molecular sieve, 2431g deionized, 2.1g activated carbon, 3g diammonium hydrogen phosphate (calculated as phosphorus), homogenized and spray-molded Catalyst microspheres CB-1.

[0049] Get 307 grams of catalyst microspheres CB-1 and roast at 450°C for 90 minutes. After beating with 1516 grams of deionized water, add 2.1 grams of magnesium chloride (calculated as magnesium) and 10 grams of ammonium chloride for mixing and beating to adjust the pH value to 3.9. Raise the temperature to 85°C and stir for 40 minutes, filter and dry at 120°C for 45 minutes to obtain the patented catalyst C1 of the present invention.

Embodiment 2

[0051] Preparation of catalyst microspheres: 0.3 g of phosphoric acid (calculated as phosphorus), 570 g of pseudoboehmite, 503 g of kaolin, 225 g of aluminum sol, 810 g of REY molecular sieves, 80 g of ZSM-5, 28 g of polystyrene, 5175 g of deionized and 67 mL of hydrochloric acid Mixing, homogenization, and spray molding to prepare catalyst microspheres CB-2.

[0052] Get 307 grams of catalyst microspheres CB-2 and bake at 600° C. for 60 minutes. After beating with 620 grams of deionized water, add 15 grams of magnesium nitrate (calculated as magnesium) and 3 grams of ammonium nitrate for mixing and beating to adjust the pH value to 2.5. Raise the temperature to 55°C and stir for 60 minutes, filter and dry at 80°C for 60 minutes to obtain the patented catalyst C2 of the present invention.

Embodiment 3

[0054] Preparation of catalyst microspheres: 1095g pseudo-boehmite, 728g kaolin, 1.5g ammonium phosphate (calculated as phosphorus), 300g phosphoric acid (calculated as phosphorus), 365g halloysite, 1082g aluminum sol, 26 grams polystyrene, 353g of REY molecular sieve, 358g of REHY molecular sieve, 352g of DASY molecular sieve, 31g of ZSM-5, 5375g of deionized mixture, homogeneous, spray molding to prepare catalyst microspheres CB-3.

[0055] Get 303 grams of catalyst microspheres CB-3 and roast at 300 ° C for 180 minutes, after beating with 1200 grams of deionized water, add 30 grams of ammonium chloride, 0.2 grams of magnesium sulfate (calculated as magnesium) and 0.1 grams of magnesium chloride (calculated as magnesium) Mix and beat, adjust the pH value to 3.4, heat up to 110°C and stir for 15 minutes, filter, and dry at 150°C for 30 minutes to obtain the patented catalyst C3 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com