Novel method for high-gravity reinforced conversion of coal-based chemical raw material

A chemical raw material and supergravity technology, which is applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the problems of high catalyst regeneration frequency, increased catalyst cost, high catalyst development cost, etc. problems, to achieve the effects of reducing by-product formation, inhibiting secondary reactions, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

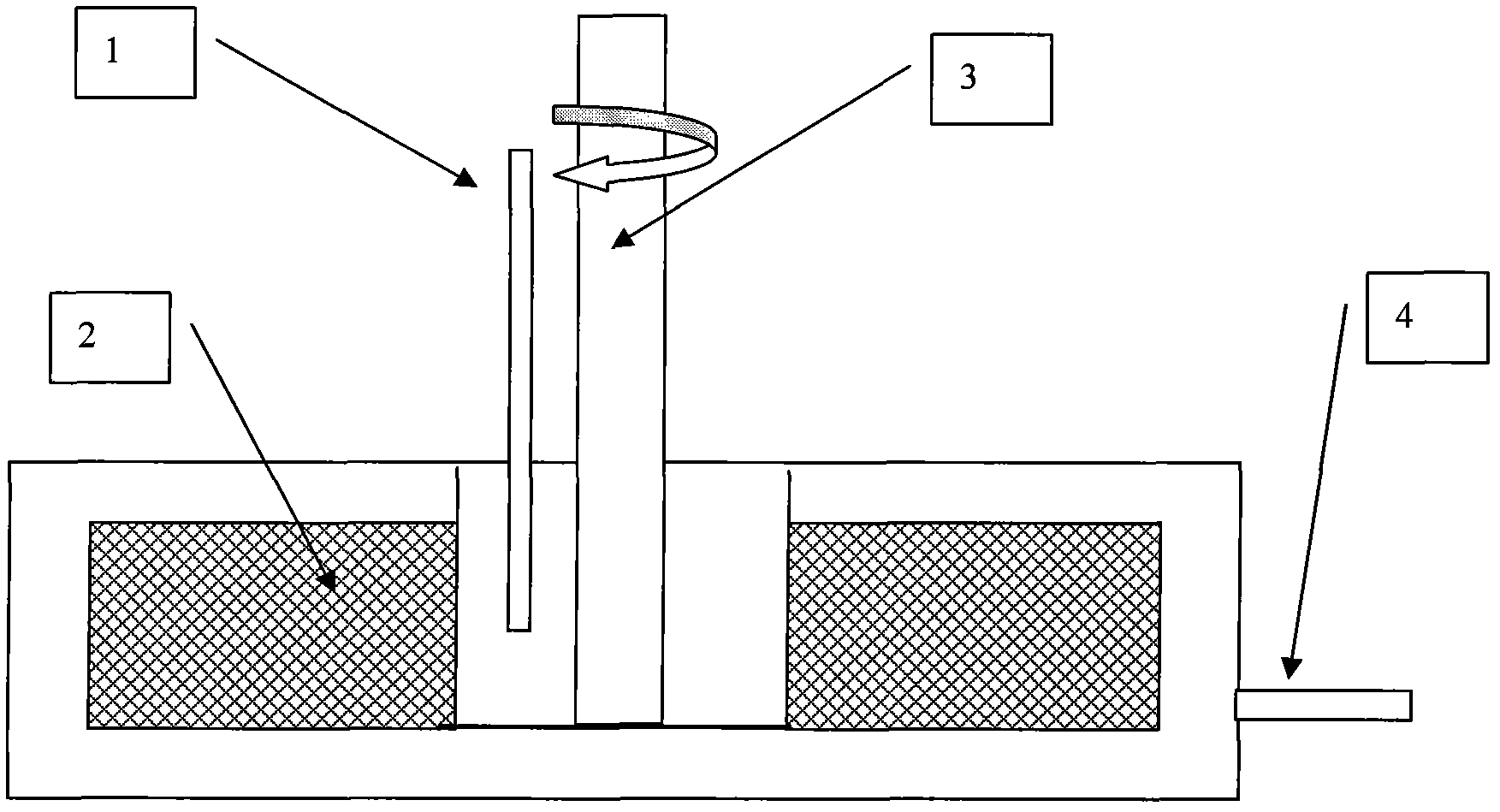

Image

Examples

Embodiment 1

[0028] The methanol-to-olefins reaction is carried out using a high-gravity reactor. Methanol was used with a purity of 99%. The commercially available SAPO-34 molecular sieve without any modification was put into the mesh support as the methanol-to-olefins catalyst, and fixed on the rotor of the high-gravity reactor.

[0029] The process conditions for carrying out methanol to olefins reaction are as follows:

[0030] Methanol gas space velocity: 2500h -1 , Reaction temperature: 370°C, Reaction pressure: 0.1MPa

[0031] Catalyst bed speed: 500-1500rpm

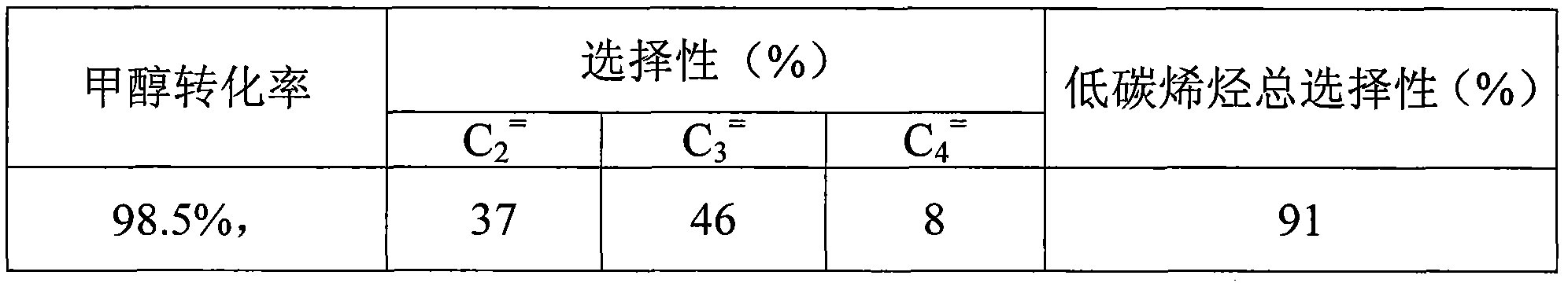

[0032] High gravity enhanced methanol to olefins reaction results:

[0033]

Embodiment 2

[0041] The reaction of dimethyl ether to olefins was carried out in a high gravity reactor. A commercially available ZSM-5 molecular sieve without any modification was put into a mesh support as a dimethyl ether-to-olefins catalyst, and fixed on the rotor of the high-gravity reactor.

[0042] The processing conditions for carrying out the reaction of dimethyl ether to olefins are as follows:

[0043] Dimethyl ether space velocity: 2500h -1 , Reaction temperature: 370°C, Reaction pressure: 0.1MPa

[0044] Catalyst bed speed: 500-1500rpm

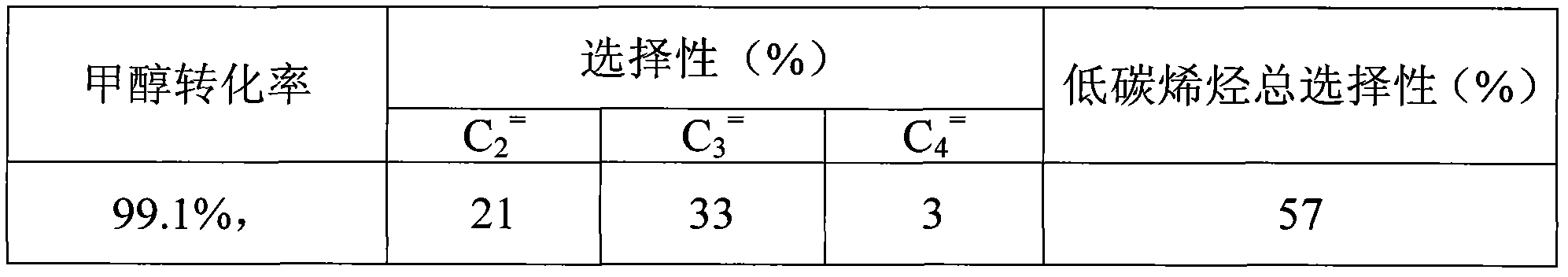

[0045] The results of high gravity enhanced dimethyl ether to olefins reaction:

[0046]

Embodiment 3

[0048] One-step synthesis of dimethyl ether from syngas using a supergravity reactor. The physical mixture of commercially available methanol synthesis catalyst and ZSM-5 molecular sieve is used as a catalyst for the one-step synthesis of dimethyl ether from synthesis gas, which is placed in a mesh support and fixed on the rotor of the high-gravity reactor.

[0049] The process conditions for carrying out the reaction of syngas one-step system of dimethyl ether are as follows:

[0050] Synthetic gas air velocity: 2500h -1 , CO / H 2 =1 / 2 Reaction temperature: 270°C, reaction pressure: 5MPa, catalyst bed rotation speed: 500-1500rpm

[0051] The reaction results of one-step synthesis of dimethyl ether from syngas enhanced by high gravity:

[0052] CO conversion rate

[0053] Coal-based methanol to dimethyl ether (MTD) of the present invention, methanol to aromatics (MTA), coal-based dimethyl ether to aromatics (DTA), and coal-based methanol dimethyl ether mixture to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com