Clean process for preparing activated aluminum oxide by using pulverized fuel ash

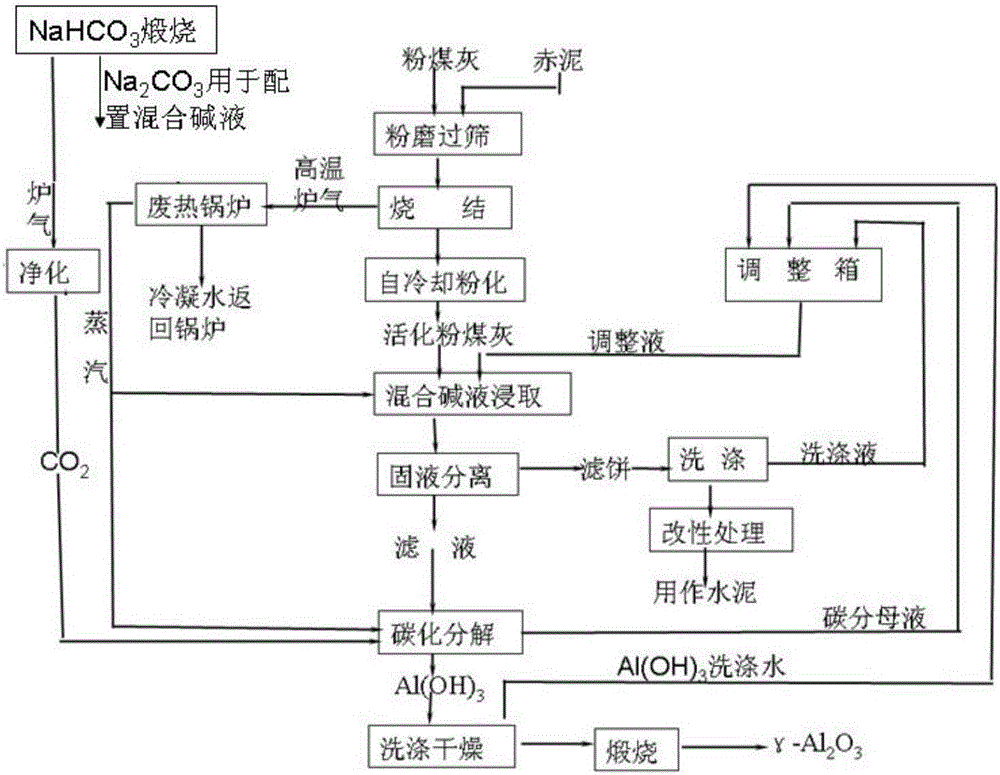

A technology of activated alumina and fly ash, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, inorganic chemistry, aluminum compounds, etc., can solve the problem of high cost, high water treatment cost, secondary accumulation, etc. problems, to achieve the effect of reducing the difficulty of operation and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with embodiment the present invention is further described in detail.

[0033] Prepare raw materials and instruments:

[0034] Raw materials: a. Fly ash is taken from the drained ash under the electrostatic precipitator of a thermal power station boiler in a chemical company in Yibin. The main chemical composition (mass fraction) is: SiO 2 : 49.61%; Al 2 o 3 : 36.46%; Fe 2 o 3 : 4.58%; CaO: 2.79%; MgO: 1.25%; K 2 O: 0.79%; loss on ignition: 4.52%.

[0035] b. The red mud is obtained from an alumina company in Yibin with limestone sintering red mud. The main chemical components (mass fraction) are: CaO: 48.79%; SiO 2 : 24.61%; Fe 2 o 3 : 9.58%; Al 2 o 3 : 2.46%; C.NaHCO 3 (AR) or Na 2 CO 3(AR): 14.56%.

[0036] Instruments: SX2-5-12 muffle furnace, Shanghai Experimental Electric Furnace Factory; KYM-DA grinder, Xianyang Jinhong Machinery Factory; 501 constant temperature water bath, Shanghai Experimental Instrument Factory; Z93-1B elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com