Catalyst for preparing acetaldehyde by direct dehydrogenation of ethanol, preparation method and application thereof

A catalyst and catalyst carrier technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of low acetaldehyde selectivity and achieve high acetaldehyde Selectivity, simple preparation method, and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] SiO 2 Preparation process of coated carbon carrier:

[0048] (1) take trimethylbenzene as solvent, prepare 10 and 40vol% furfuryl alcohol / trimethylbenzene solution, add trace oxalic acid simultaneously as catalyst;

[0049] (2) Impregnate the carrier once with an equal volume of the furfuryl alcohol solution prepared in step (1); after the impregnation, let stand at room temperature for 0.5-2 hours;

[0050] (3) Place the mixture after step (2) standing in an oven at 60°C and 80°C for 12 hours to dry;

[0051] (4) Dry the dried product in step (3) at 150°C for 3h in an Ar atmosphere, and then stay at 850°C for 2h to obtain the C-coated SiO 2 Surface C / SiO 2 Complex.

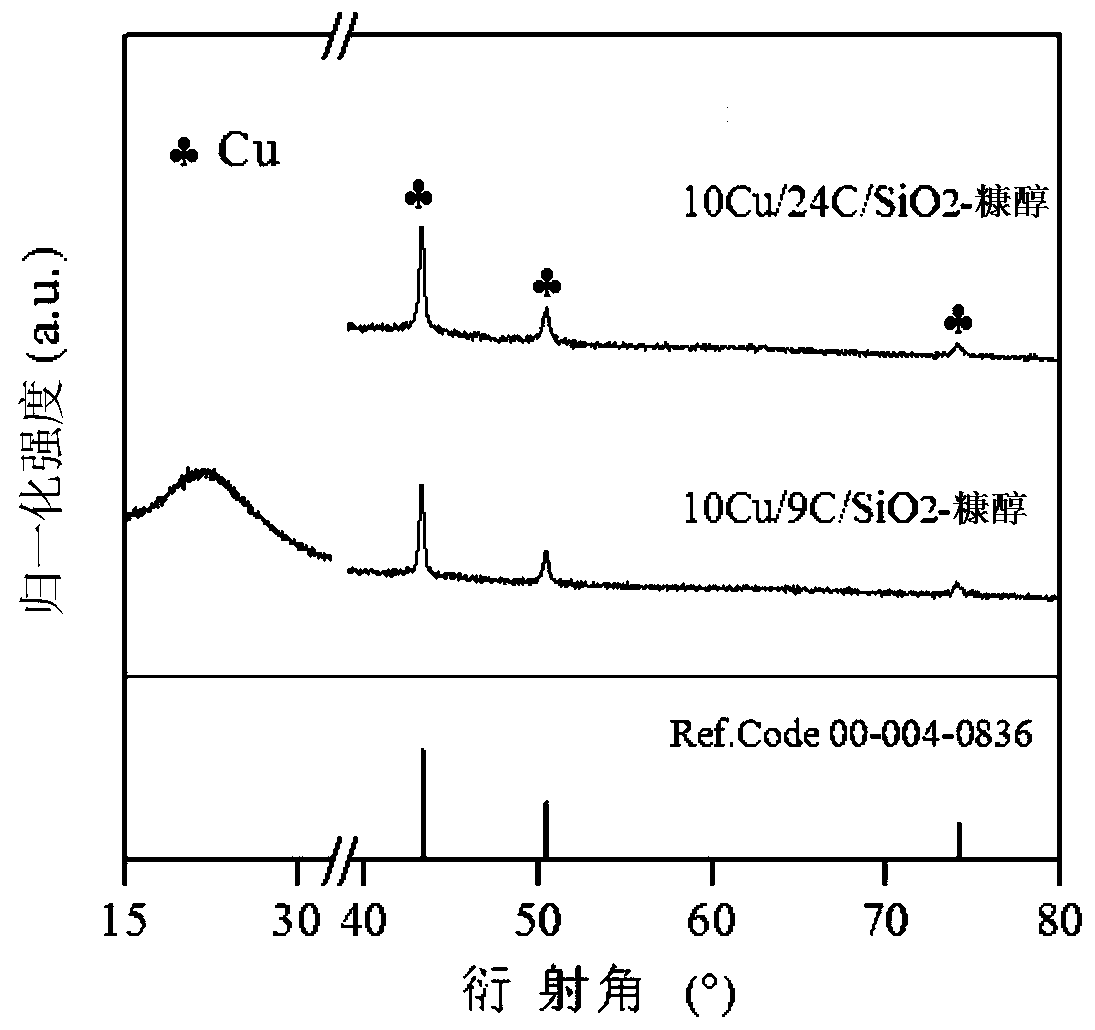

[0052] (5) Using 10 and 40vol% furfuryl alcohol / trimethylbenzene solution, SiO 2 The thickness of the surface carbon layer is 0.5 and 1.5nm, respectively, and the carbon content is 9 and 24wt%, respectively, and the obtained supports are respectively recorded as 9C / SiO 2 -Furfuryl alcohol and 24C / SiO...

Embodiment 2

[0054] Al 2 o 3 Preparation process of coated carbon carrier:

[0055] (1) Using acetylene as the carbon source, the C / Al on the surface of the carbon layer was prepared by chemical vapor deposition. 2 o 3 Composite carrier;

[0056] ②Place the chemical vapor deposition furnace horizontally, place the porcelain boat carrying 1.0g sample in the constant temperature zone of the furnace, and purge with Ar for 30 minutes;

[0057] ③ Place the Al placed in step ② 2 o 3 Dry at 150°C for 2 hours under an Ar inert atmosphere to remove surface-adsorbed water and other impurities;

[0058] ④ Heat the dried product in step ③ to 600°C for 1 hour under an Ar inert atmosphere; then pass 100 mL / min of 10vol% C 2 h 2 / Ar gas, and then stay at 600°C for 0.1h to obtain the C coated on Al 2 o 3 Surface C / Al 2 o 3 Complex. Then close the C 2 h 2 / Ar gas, replace it with Ar gas, continue purging for 1h, and then cool down to room temperature. The tested carbon content is 8.6wt%, an...

Embodiment 3

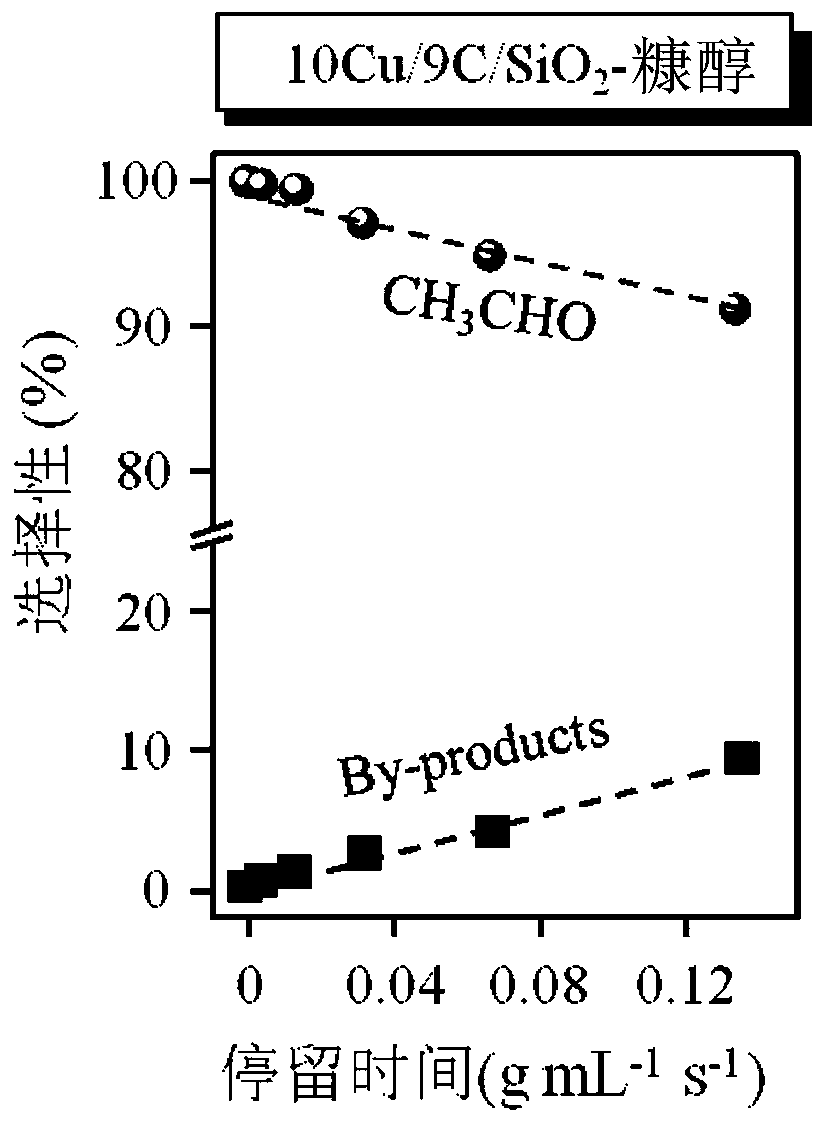

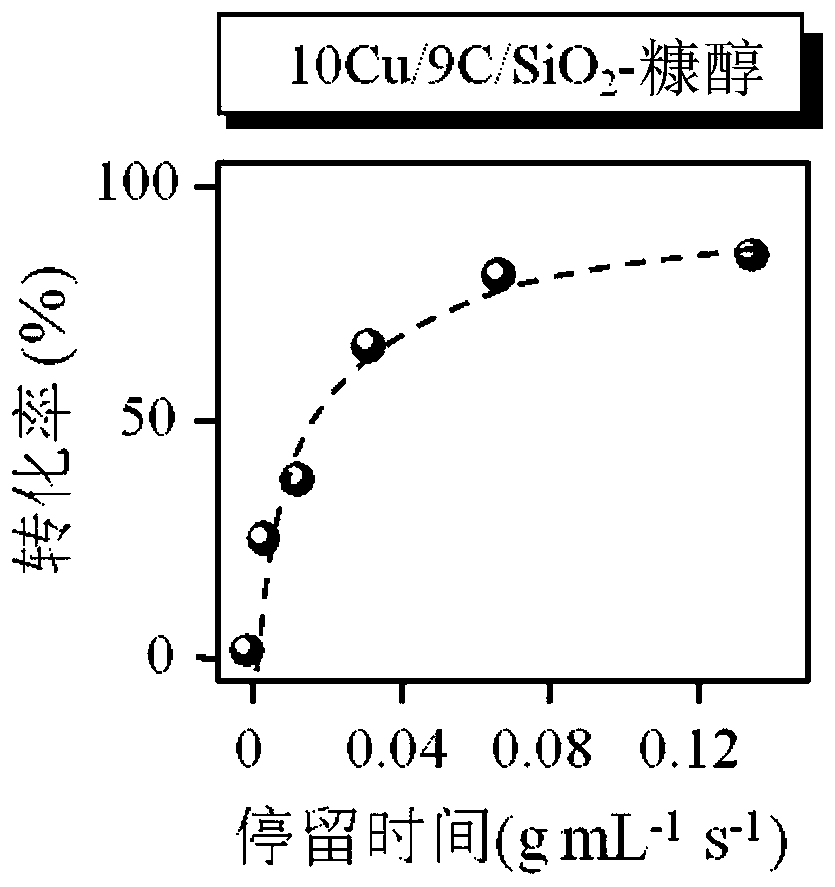

[0060] 9C / SiO 2 -Furfuryl alcohol and 24C / SiO 2 -The preparation process of furfuryl alcohol supported Cu catalyst:

[0061] (1) Take 9C / SiO 2 - Furfuryl alcohol, dried in an airflow oven at 120°C for 2 hours to remove physically adsorbed water on the surface;

[0062] (2) At 25°C, take Cu(NO 3 ) 2 ·3H 2 9C / SiO obtained by drying the obtained 9C / SiO 2 - on furfuryl alcohol charcoal, stand for 2h;

[0063] (3) drying the mixture after step (2) at 50° C. for 10 h to obtain a catalyst precursor;

[0064] (4) Dry the catalyst precursor obtained in step (3) at 140°C for 0.5h, followed by hydrogen reduction at 450°C for 2h (10vol%H 2 / N 2 ), making 10Cu / 9C / SiO 2 - Furfuryl alcohol (No. 3 in Table 1) catalyst.

[0065] (5) 24C / SiO2 2 -The furfuryl alcohol-supported copper catalyst process is the same as the above steps, corresponding to No. 7 in Table 1.

[0066] The XRD pattern of gained catalyst is as figure 1 shown.

[0067] The preparation condition process of oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com