Method for promoting depolymerization of lignin sulfate through filter tips of abandoned cigarettes

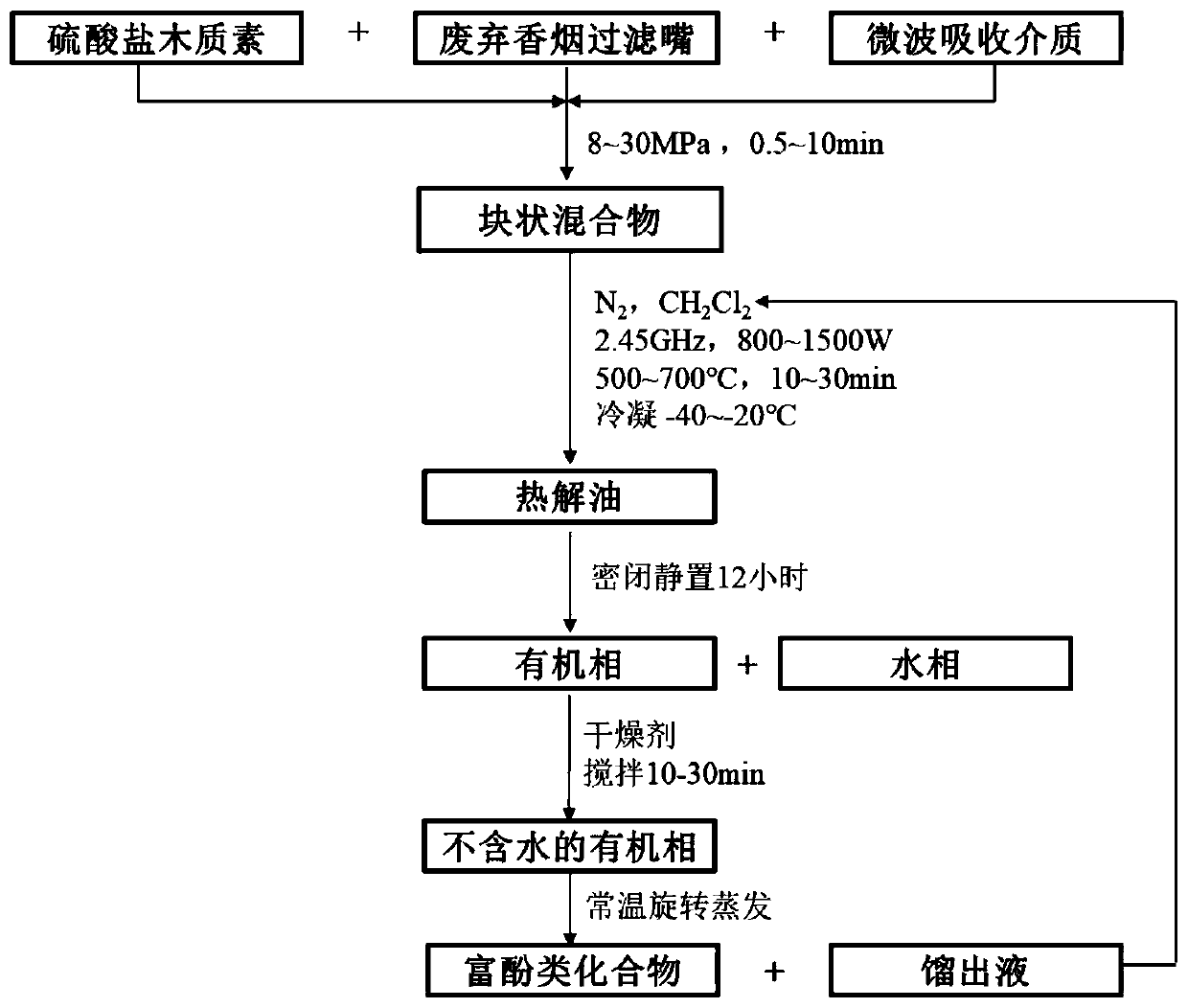

A kraft lignin and filter technology, which is applied in the field of waste resource utilization, can solve problems such as kraft lignin is difficult to effectively depolymerize, and achieve the effect of increasing utilization value, improving depolymerization efficiency, and realizing oil-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Mix 10g of kraft lignin with a particle size of 0.3mm to 0.5mm, 10g of discarded cigarette filters crushed to a particle size of 0.6 to 1mm, and 10g of sodium carbonate with a particle size of 500 to 800nm, and then grind the mixture evenly. Pressurize for 0.5 minutes under the condition of 30MPa, and press it into a cylindrical shape. The cylindrical mixture was placed in a microwave reactor, and nitrogen gas was introduced at 120 mL / min for 5 minutes, and then the nitrogen gas was passed through a Montessori scrubber bottle filled with dichloromethane to carry the dichloromethane with the nitrogen gas, and the carrying amount was 600 mg / min. After 5 minutes, the microwave reactor was turned on, the microwave frequency was 2.45GHz, the microwave power was 1500W, the temperature was raised to 700°C, and the temperature was kept for 10 minutes. The generated depolymerization vapor was condensed at -40°C, and 24.2g of dichloromethane was collected. The liquid product - pyr...

Embodiment 2

[0037] 10g of kraft lignin with a particle size of 0.1mm to 0.3mm was mixed with 5g of discarded cigarette filters with a particle size of 0.4 to 0.6mm and 5g of ferric oxide with a particle size of 800nm to 0.2mm, and then ground. The ground mixture was pressurized for 5 minutes under the condition of 15 MPa, and pressed into a square shape. Place the square mixture in a microwave reactor, feed nitrogen gas at 60mL / min for 7 minutes, then pass the nitrogen gas through a Montessori scrubber bottle filled with dichloromethane to make the nitrogen gas carry dichloromethane, the carrying amount is 240mg / min, 5 Minutes later, the microwave reactor was turned on, the microwave frequency was 2.45GHz, the microwave power was 1200W, the temperature was raised to 600°C, and the temperature was kept for 20 minutes. The generated depolymerization vapor was condensed at -30°C, and 18.4g of dichloromethane was collected Liquid product - pyrolysis oil. Then close the microwave reactor, r...

Embodiment 3

[0039] Mix 10g of kraft lignin with a particle size of 0.01 to 0.1mm, 0.5g of discarded cigarette filters crushed into a particle size of 0.1 to 0.4mm, and 2g of silicon carbide with a particle size of 0.2 to 0.5mm, and then grind them evenly. The mixture was pressurized at 8MPa for 10 minutes and pressed into a rhombus shape. Put the rhombohedral mixture in a microwave reactor, pass nitrogen gas at 12.5mL / min for 10 minutes, then pass the nitrogen gas through a Montessori gas scrubber bottle filled with dichloromethane to carry dichloromethane with the nitrogen gas, and the carrying amount is 37.5mg / min After 5 minutes, turn on the microwave reactor, the microwave frequency is 2.45GHz, the microwave power is 800W, the temperature is raised to 500°C, and the temperature is kept for 30 minutes. The generated depolymerization vapor is condensed at -20°C, and 10g of dichloromethane is collected The liquid product - pyrolysis oil. Then close the microwave reactor, remove the Mont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com