A kind of method for preparing oligomeric proanthocyanidins from litchi peel

A technology of oligomeric proanthocyanidins and lychee peel, which is applied in microorganism-based methods, biochemical equipment and methods, organic chemistry and other directions, can solve the problems of increasing purification difficulty, low degradation yield, waste of raw materials, etc. High depolymerization efficiency and time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

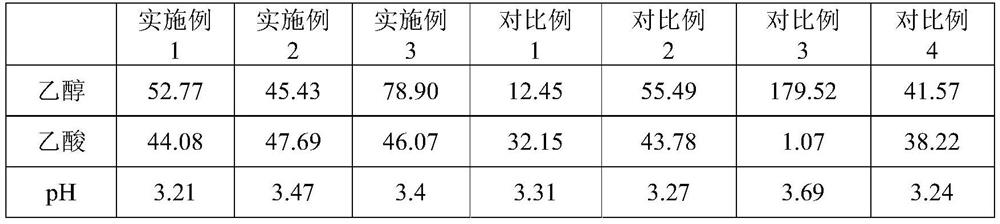

Examples

Embodiment 1

[0045] (1) Fermentation in one step: collect lychee skins, air-dry them and crush them, take 3 kg of litchi skin powder, put them in an iron barrel, add 15 times the mass of water, add 10 kg of sucrose, and mix to obtain fermentation raw materials. Add 50 g of Saccharomyces cerevisiae powder into 5 kg of sterile water containing 2 wt % sucrose, and incubate in a water bath at 37° C. for 30 min to activate. Pour the activated yeast liquid into the fermentation raw material, inoculate 2.8g of Lactobacillus plantarum powder, stir and mix well, leave it to ferment in a closed room at room temperature, take samples every 24 hours to measure the ethanol concentration and pH value, after 24 hours of fermentation, the ethanol concentration reaches 142.71 mg / mL, the pH dropped to 4.17, and the fermentation ended.

[0046] (2) Secondary fermentation: Sprinkle and inoculate 12g of Acetobacter pasteurianum powder on the surface of the fermented raw material after the first fermentation, w...

Embodiment 2

[0049] (1) Fermentation in one step: collect lychee skins, air-dry them and crush them, take 3 kg of litchi skin powders, put them in an iron bucket, add 20 times the quality of water, add 11 kg of sucrose, and mix to obtain fermentation raw materials. Add 50 g of Saccharomyces cerevisiae powder into 5 kg of sterile water containing 2 wt % sucrose, and incubate in a water bath at 37° C. for 30 min to activate. The activated yeast liquid is poured into the fermentation raw material, inoculated with 1.8g of Lactobacillus plantarum powder, stirred and mixed, sealed and left to ferment at room temperature. Samples were taken every 24 hours to measure the ethanol concentration and pH value. After 48 hours of fermentation, the ethanol concentration reached 158.79 mg / mL and the pH dropped to 4.02, and one fermentation was ended.

[0050] (2) Secondary fermentation: Sprinkle and inoculate 30g of Acetobacter pasteurianum powder on the surface of the fermented material after the first f...

Embodiment 3

[0053] (1) Fermentation in one step: collect lychee skins, air-dry them and crush them, take 3 kg of litchi skin powder, put them in an iron bucket, add 25 times the quality of water, add 12 kg of sucrose, and mix to obtain fermentation raw materials. Add 45g of Saccharomyces cerevisiae powder into 4.5kg of sterile water containing 2wt% sucrose, and incubate in a water bath at 37°C for 30 minutes to activate. Pour the activated yeast liquid into the fermentation raw material, inoculate 0.9g of Lactobacillus plantarum powder, stir and mix well, leave it to ferment in a closed room at room temperature, take samples every 24 hours to measure the ethanol concentration and pH value, after 72 hours of fermentation, the ethanol concentration reaches 172.43 mg / mL, the pH dropped to 3.87, and the fermentation ended.

[0054] (2) Secondary fermentation: Sprinkle and inoculate 25g of Acetobacter pasteurianum powder on the surface of the fermented material after the first fermentation, wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com