Prussian blue sodium ion battery positive electrode material and preparation method thereof

A technology for sodium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve problems such as low initial Na+ content, achieve high Na+ content, and improve cycle stability , the effect of improving the crystal morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

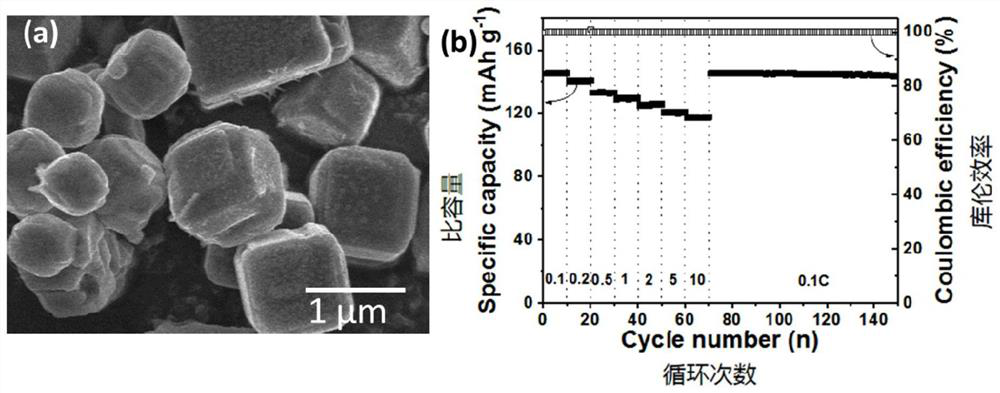

Embodiment 1

[0043] This embodiment provides a method for preparing the positive electrode material of Prussian blue sodium-ion battery, comprising the following steps:

[0044] Dissolve 2mmol sodium ferrocyanide decahydrate and 8mmol sodium citrate in 100mL deionized water to obtain precursor solution A;

[0045] Dissolve 2mmol ferrous chloride tetrahydrate and 8mmol sodium citrate in 100mL deionized water to obtain precursor solution B;

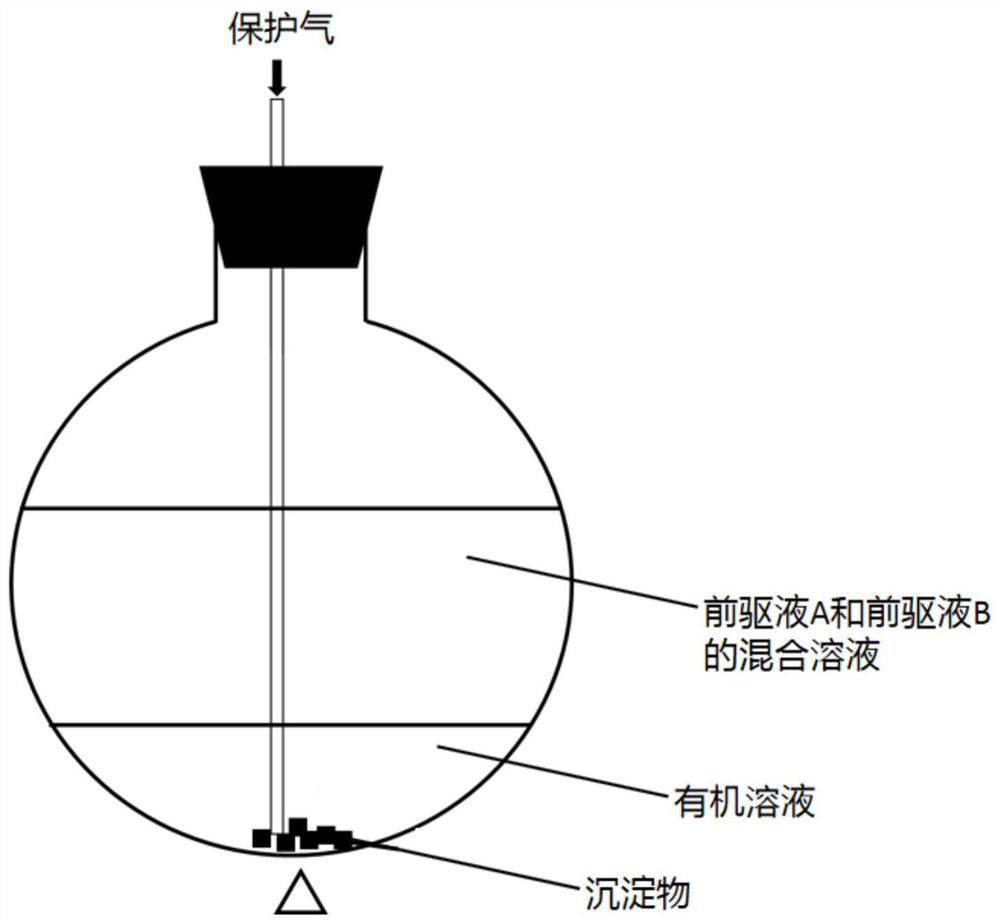

[0046] Such as figure 1 As shown, quickly pour precursor solution A and precursor solution B into the reaction container and mix evenly, then add 100mL methyl benzoate, heat and keep the temperature constant at 90°C, pass N into the methyl benzoate 2 As protective atmosphere, N 2 The flow rate is 20ml / min, standing and aging for 2h;

[0047] The suspension in the reaction vessel was centrifuged at 8000 rpm for 5 min to obtain a precipitate. The precipitate was washed with deionized water, absolute ethanol and acetone three times each. The washed pr...

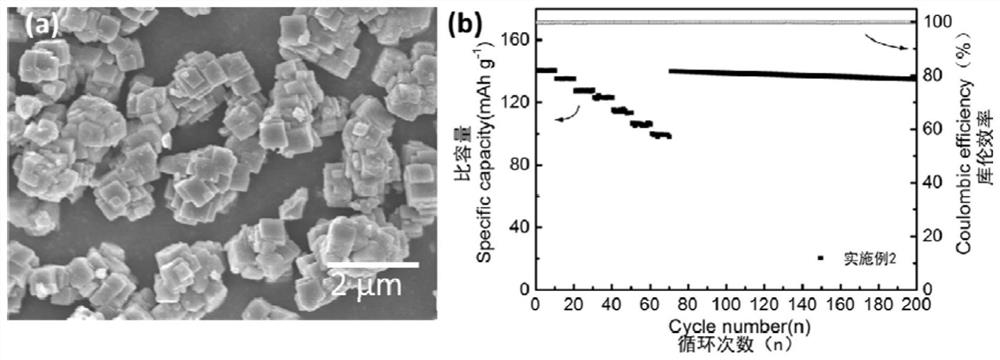

Embodiment 2

[0052] This embodiment provides a method for preparing the positive electrode material of Prussian blue sodium-ion battery, comprising the following steps:

[0053] Dissolve 0.5mmol sodium ferrocyanide decahydrate and 5mmol sodium citrate in 100mL deionized water to obtain precursor solution A;

[0054] Dissolve 0.5 mmol of manganous sulfate tetrahydrate and 5 mmol of sodium citrate in 100 mL of deionized water to obtain Precursor B;

[0055] Such as figure 1 As shown, quickly pour precursor solution A and precursor solution B into the reaction vessel and mix well, then add 100mL carbon tetrachloride, keep the temperature constant at 25°C, pass Ar into carbon tetrachloride as a protective atmosphere, Ar The flow rate is 50ml / min, and it is left to age for 48h;

[0056] The suspension in the reaction vessel was centrifuged at 3000 rpm for 15 min to obtain a precipitate. The precipitate was washed with deionized water, absolute ethanol and acetone three times each. The washe...

Embodiment 3

[0061] This embodiment provides a method for preparing the positive electrode material of Prussian blue sodium-ion battery, comprising the following steps:

[0062] Dissolve 10mmol sodium ferrocyanide decahydrate and 30mmol disodium edetate in 100mL deionized water to obtain precursor solution A;

[0063] Dissolve 10mmol nickel nitrate hexahydrate and 30mmol edetate disodium in 100mL deionized water to obtain precursor solution B;

[0064] Such as figure 1 As shown, quickly pour precursor solution A and precursor solution B into the reaction vessel and mix well, then add 100mL carbon tetrachloride, keep the temperature constant at 50°C, and pass N into the carbon tetrachloride 2 As protective atmosphere, N 2 The flow rate is 100ml / min, standing and aging for 24h;

[0065] The suspension in the reaction vessel was centrifuged at 15000 rpm for 3 min to obtain a precipitate. The precipitate was washed with deionized water, absolute ethanol and acetone three times each. The w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com