Preparation method of modified alumina carrier, catalytic ozone oxidation catalyst, and application of catalyst

A technology of alumina carrier and modifier, which is applied in the field of water treatment, can solve the problems that the performance cannot fully meet the industrial application, and achieve the effects of improving catalytic activity and service life, increasing removal rate, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

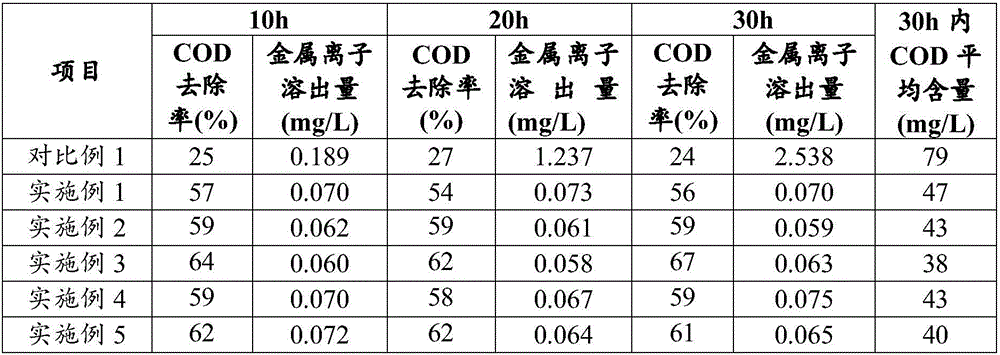

Examples

preparation example Construction

[0036] Described in the present invention, a kind of preparation method of modified alumina support comprises the following steps:

[0037] An alumina substrate is provided; the alumina substrate is sprayed with a modifier once, dried once, baked once, and cooled naturally to room temperature.

[0038] As described in the present invention, the primary modifier is an aqueous compound solution of one or more elements of nitrogen group elements, carbon group elements, and halogen group elements;

[0039] As described in the present invention, the mass content of the primary modifier is 0-10mmol / g; preferably, the mass content of the primary modifier is 0-6mmol / g; the balance is the carrier;

[0040] As described in the present invention, the primary drying temperature is 120-150°C, and the time is 3-4h;

[0041] As described in the present invention, the primary firing temperature is 300-800°C, and the time is 2-4h;

[0042] The alumina base material is subjected to the second...

Embodiment 1

[0063] As described in this embodiment, a method for preparing a modified alumina support comprises the following steps:

[0064] Provide an alumina substrate, spray 0.1mmol / g ammonium fluoride aqueous solution on the 3-5mm alumina substrate, then dry at 120°C for 4h, bake at 300°C for 4h, and naturally cool to room temperature;

[0065] A 2 mmol / g sodium hydroxide aqueous solution was sprayed and dipped on the alumina substrate for the second time, then dried at 100°C for 4 hours, then calcined at 400°C for 4 hours, and naturally cooled to room temperature to obtain a surface-modified alumina carrier.

[0066] Described in the present embodiment, the preparation method of catalytic ozone oxidation catalyst comprises the following steps:

[0067] Prepare the metal ion concentration in weight percentage, both are 10% manganese acetate and ferric nitrate solution, then measure the above two solutions respectively according to the volume ratio of 20:10 to prepare a mixed impregna...

Embodiment 2

[0069] This embodiment is improved on the basis of Embodiment 1, and the content described in Embodiment 1 is also included in this embodiment, and will not be described in detail here.

[0070] As described in this embodiment, a method for preparing a modified alumina support comprises the following steps:

[0071] Provide an alumina substrate, spray 4mmol / g polyacrylamide aqueous solution on a 3-5mm alumina substrate, then dry at 120°C for 3h, bake at 500°C for 2h, and cool naturally to room temperature;

[0072] A 10 mmol / g potassium nitrate aqueous solution was sprayed and dipped on the alumina substrate for the second time, then dried at 100°C for 4 hours, then calcined at 300°C for 4 hours, and naturally cooled to room temperature to obtain a surface-modified alumina carrier.

[0073] A performance test was performed on the catalytic ozonation catalyst obtained in this example, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com