A method for the preparation of oligomeric proanthocyanidins by high-voltage pulsed electric field combined with ultra-high pressure micro-jet

A high-voltage pulsed electric field, oligomeric proanthocyanidin technology, which is applied in the direction of organic chemistry, etc., can solve the problems of low ultra-high pressure micro-fluid treatment efficiency, severe oxidative degradation conditions, easy damage to phenolic hydroxyl groups, etc., so as to save the resin separation step and the method is simple. , the effect of easy disaggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

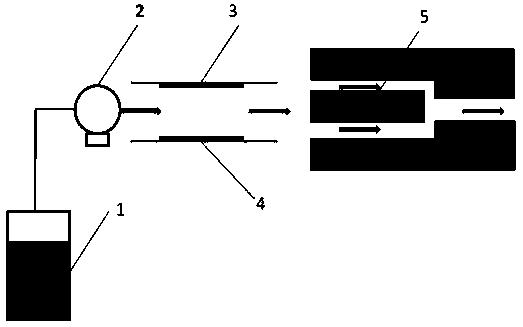

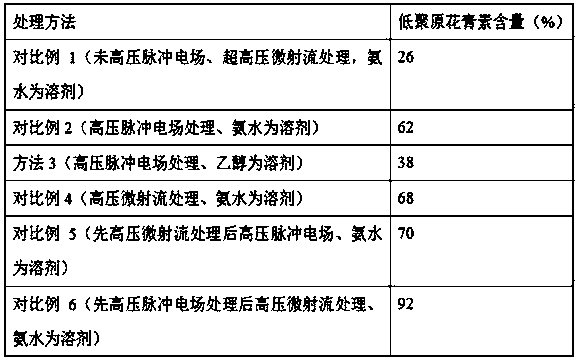

[0022] The method for preparing oligomeric proanthocyanidins by high-voltage pulsed electric field in cooperation with ultra-high pressure micro-jet in this embodiment, the preparation process is as follows figure 1 , including the following steps:

[0023] (1) Use 2% ammonia solution to dissolve the proanthocyanidin solution 1, and the concentration of the proanthocyanidin solution reaches 20%, and then pump it into the pipeline equipped with the high-voltage electrode 3 and the low-voltage electrode 4 through the high-pressure pump 2, connect the high-voltage pulse electric field, and the high-voltage The voltage between the high-voltage electrode and the low-voltage electrode of the pulse electric field is 20KV, the pulse front of the pulse voltage is 50 nanoseconds, and the pulse width is 10 microseconds;

[0024] (2) The proanthocyanidin solution is pumped into the micro-jet head 5 of the ultra-high-pressure micro-fluid after being treated with a high-voltage pulsed elect...

Embodiment 2

[0028] The method for preparing oligomeric proanthocyanidins according to the high-voltage pulsed electric field in cooperation with the ultra-high pressure micro-jet of this embodiment comprises the following steps:

[0029] (1) Use 2% ammonia solution to dissolve the proanthocyanidin solution, and the concentration of the proanthocyanidin solution reaches 20%, and then pump it into the pipeline equipped with high-voltage electrodes and low-voltage electrodes through a high-pressure pump, and connect the high-voltage pulse electric field, and the high-voltage pulse electric field is high-voltage The voltage between the electrode and the low-voltage electrode is 50KV, the leading edge of the pulse voltage pulse is 50 nanoseconds, and the pulse width is 10 microseconds;

[0030] (2) The proanthocyanidin solution is pumped into the micro-jet head of the ultra-high pressure micro-fluid after being treated with high-voltage pulsed electric field, and the treatment pressure is 400MP...

Embodiment 3

[0034] The method for preparing oligomeric proanthocyanidins according to the high-voltage pulsed electric field in cooperation with the ultra-high pressure micro-jet of this embodiment comprises the following steps:

[0035] (1) Use 2% ammonia solution to dissolve the proanthocyanidin solution, and the concentration of the proanthocyanidin solution reaches 10%, and then pump it into the pipeline equipped with high-voltage electrodes and low-voltage electrodes through a high-pressure pump, and connect the high-voltage pulse electric field, and the high-voltage pulse electric field is high-voltage The voltage between the electrode and the low-voltage electrode is 50KV, the leading edge of the pulse voltage pulse is 20 nanoseconds, and the pulse width is 10 microseconds;

[0036] (2) The proanthocyanidin solution is pumped into the micro-jet head of the ultra-high pressure micro-fluid after being treated with high-voltage pulsed electric field, and the treatment pressure is 500MP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com