Method for continuous production of polyoxymethylene dimethyl ether

A technology of polyoxymethylene dimethyl ether and paraformaldehyde, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as low mass transfer efficiency and low solubility, and achieve improved reaction efficiency, Improve depolymerization efficiency and strengthen the effect of speed-determining steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

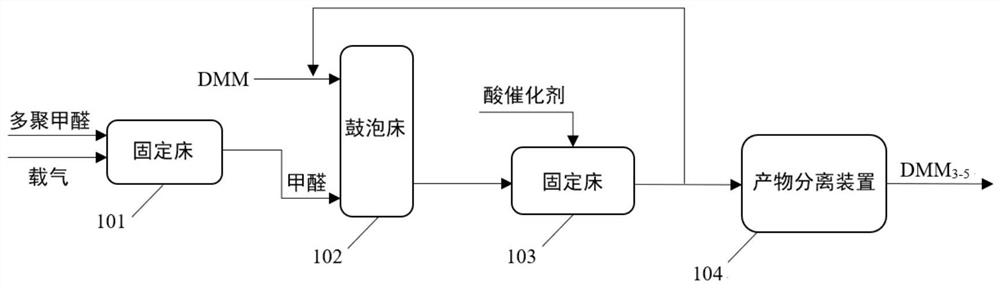

Examples

Embodiment 2

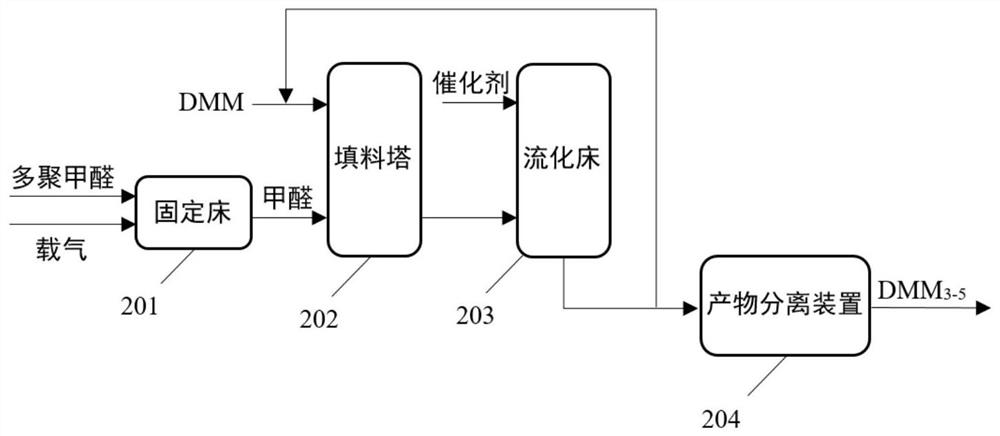

[0048] The processing device of embodiment 2 is as figure 2 As shown, paraformaldehyde decomposes in the fixed-bed pyrolysis reactor 201 with a pyrolysis temperature of 180° C. to produce formaldehyde gas, which is carried out of the pyrolysis reactor by nitrogen as a carrier gas.

[0049] The formaldehyde gas is passed into the packed tower absorption device 202, and is absorbed by the methylal liquid to obtain a methylal solution containing formaldehyde.

[0050] The methylal solution of formaldehyde and the acidic resin catalyst were respectively added into the fluidized bed reactor 203, the reaction temperature was 100° C., the operating pressure was 0.5 MPa, and the reaction time was 12 minutes.

[0051] The mixed liquid flowing out from the fluidized bed reactor 204 is divided into two streams, one stream refluxes into the packed tower 202, and the other stream enters the product separation device 204 for separation and purification to obtain DMM 3-5 .

Embodiment 3

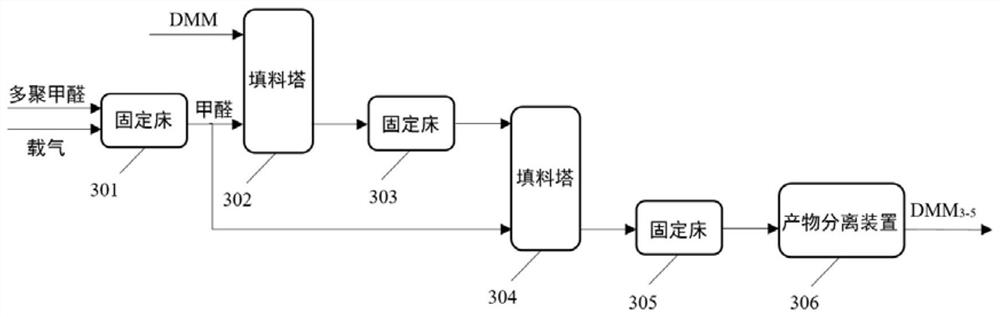

[0053] The processing device of embodiment 3 is image 3 As shown, in the fixed bed pyrolysis reactor 301, the formaldehyde gas produced by the decomposition of paraformaldehyde is taken out of the pyrolysis reactor by nitrogen, and passed into the packed tower absorption devices 302 and 304 respectively.

[0054] In the packed tower absorption device 302, the formaldehyde gas is dissolved in the methylal liquid to obtain the methylal solution of formaldehyde, and then enters the fixed bed reactor 303, and reacts under the catalysis of an acidic resin catalyst, the reaction temperature is 80°C, and the operating pressure is 0.3MPa, reaction time 15min.

[0055] The mixed solution flowing out from the fixed bed reactor 302 has a low concentration of formaldehyde. After the formaldehyde gas is dissolved in the packed tower absorption device 304, it enters the fixed bed reactor 305 to continue the reaction. The reaction temperature is 80°C and the operating pressure is 0.3MPa.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com