Dielectric barrier discharge pollutant treatment device based on micro-gap channel

A technology for dielectric barrier discharge and pollutant treatment, applied in the field of pollutant treatment, can solve the problems of high cost of micro-bubble generators, poor technical combination effect, and difficult maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

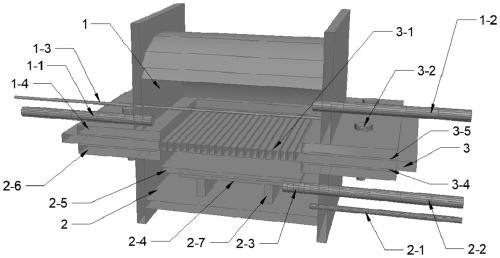

[0035] Example: see figure 2 : A pollutant treatment device based on micro-slit channel dielectric barrier discharge, which includes a water tank (1), a static pressure gas box (2) and a micro-slit assembly (3).

[0036] The water inlet of the water tank (1) is connected to the water inlet pipe (1-1), and the water outlet of the water tank (1) is connected to the water outlet pipe (1-2);

[0037] A grounding electrode (1-3) is arranged in the water tank (1);

[0038] One end of the water tank (1) is provided with a water tank flange (1-4) for connection with other parts of the device;

[0039] The air inlet of the static pressure gas box (2) is connected to the air inlet pipe (2-1);

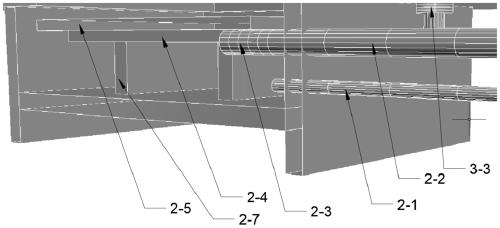

[0040] The static pressure gas box (2) includes a high voltage electrode (2-4), an insulating medium (2-5) and an electrode support (2-7);

[0041] One end of the static pressure air box (2) is provided with an air box flange (2-6) for connection with other parts of the device;

[0042] One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com