Liquid guide tower plate with horizontal opening hole

A liquid-conducting plate, horizontal technology, applied in distillation separation, chemical/physical/physical-chemical process, dispersed particle separation, etc. The effect of large gas-liquid channel, large passing capacity and simple plate hole structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

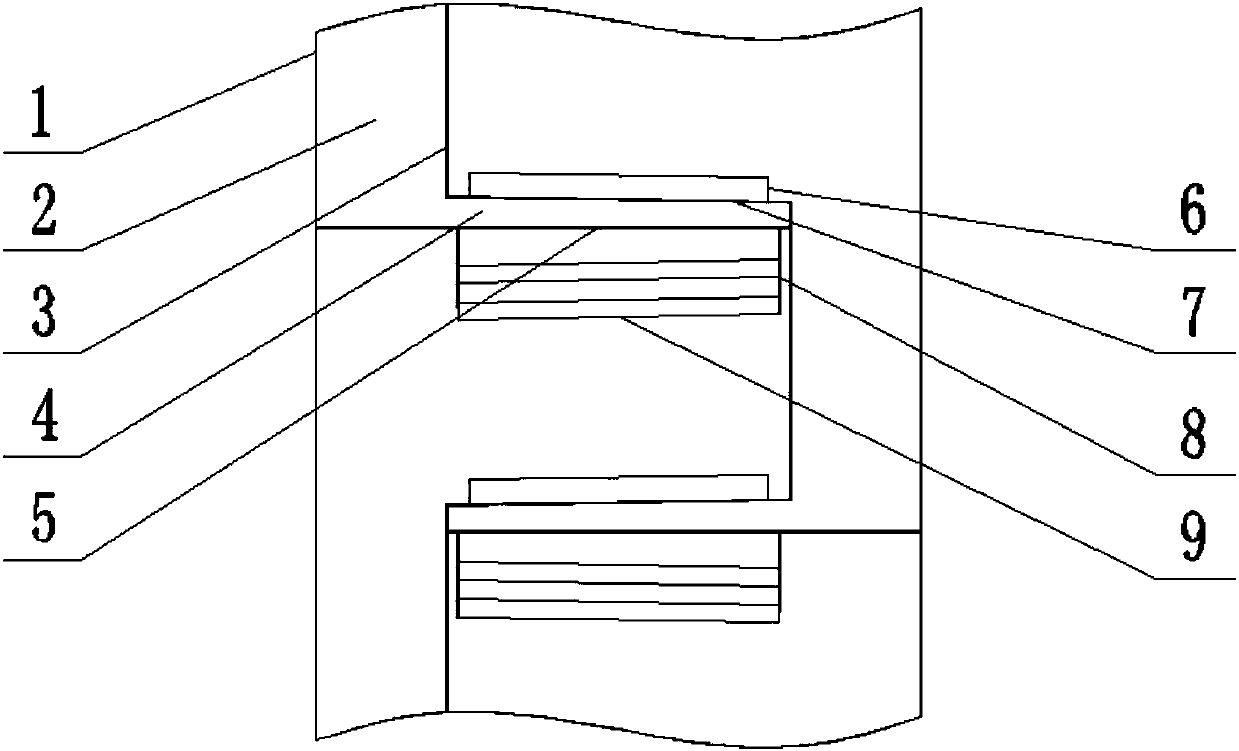

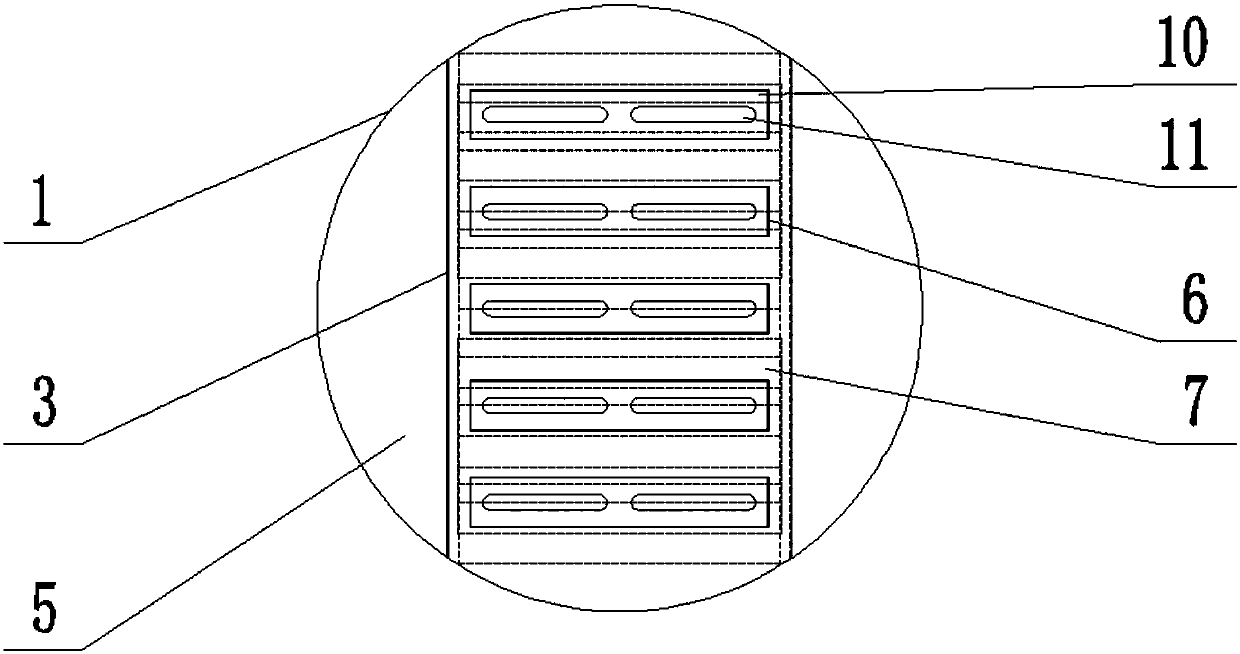

[0010] The invention provides a liquid-conducting horizontal open-hole tray (see Figure 1-3 , referred to as the tray), including a tower shell 1, characterized in that the tray also includes a downcomer 3, a bottom plate 5, a liquid guide weir 6, a liquid guide 7, a liquid retainer connecting plate 8 and a liquid retainer 9; The bottom plate 5 is fixed horizontally on the inner wall of the tower shell 1, and the bottom plate 5 is provided with plate holes 11; the downcomer plate 3 is vertically fixed on the inner wall of the tower shell 1; the downcomer plate 3 and the tower shell 1 form a downcomer 2; the liquid guide plate 7 is seamlessly connected with the downcomer plate 3; there is a bottom gap 4 between the liquid guide plate 7 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com