A rotating concentric circle dielectric barrier micro-slit discharge pollutant treatment device

A pollutant treatment and medium blocking technology, applied in the field of pollutant treatment, can solve the problems of high maintenance cost and high degree of device responsibility, and achieve the effects of strong adaptability, short pulse delay, and improved decomposition efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

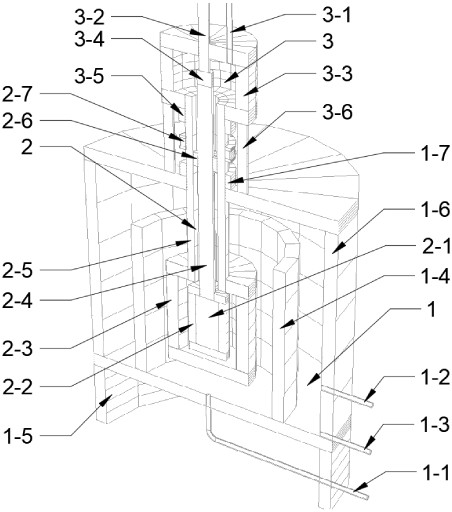

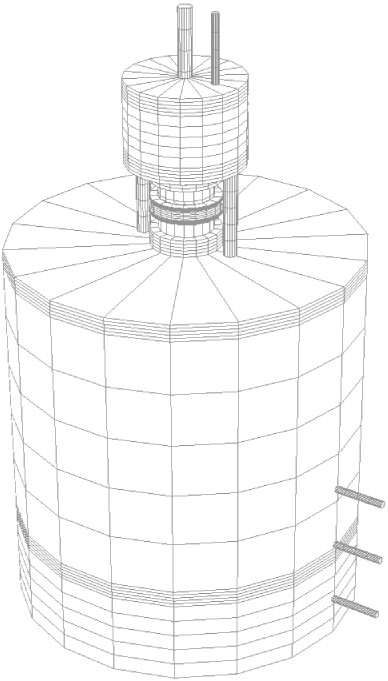

[0029] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described: embodiment: refer to figure 1 : a device for treating pollutants based on a micro-slit channel dielectric barrier discharge, comprising a water tank (1), a gas static pressure tank (3) and a rotating tank (2).

[0030]The water inlet (1-1) of the water tank (1) is connected with the water inlet pipe, the water outlet (1-2) of the water tank (1) is connected with the water outlet pipe, and the emptying port (1-3) of the water tank (1) Connected to the emptying pipe; the water tank (1) is grounded or provided with a ground electrode, and the emptying port (1-3) can also be made of conductive material and grounded; in this embodiment, the emptying pipe is made of conductive material and Grounding, the emptying pipeline is closed when the equipment is in normal operation; an additional grounding electrode can also be installed, which only needs to be installed und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com