Preparation method for on-thread and continuously growing carbon nanotubes on surface of carbon fiber

A carbon nanotube and surface growth technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of complex growth process, small scale, high cost, etc., and achieve the goal of solving complex growth process, improving surface activity and promoting development Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

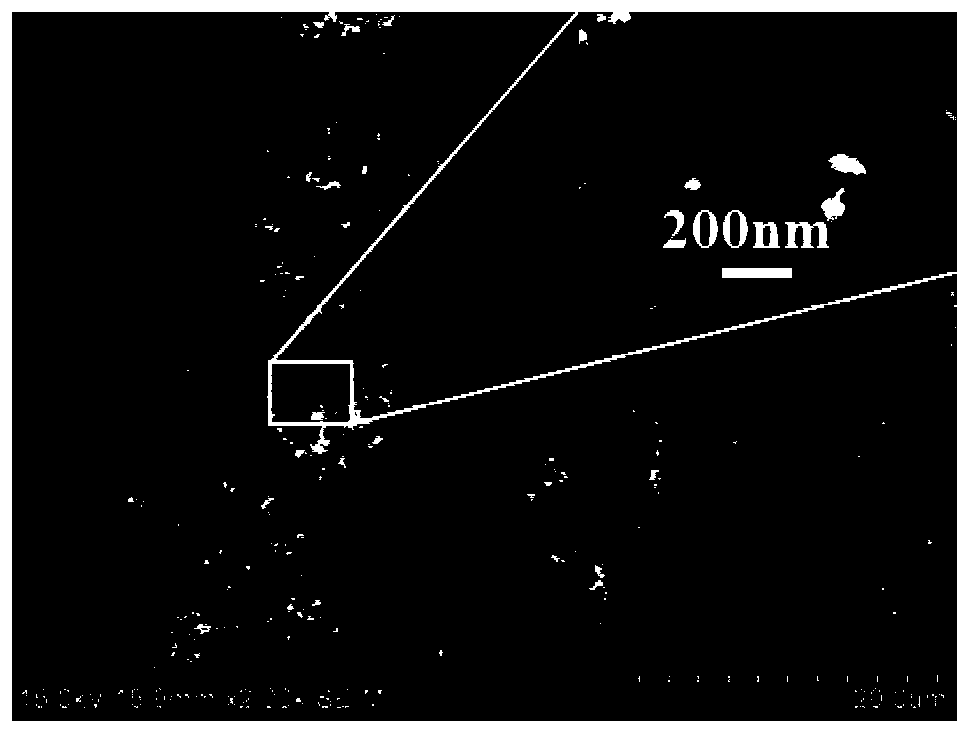

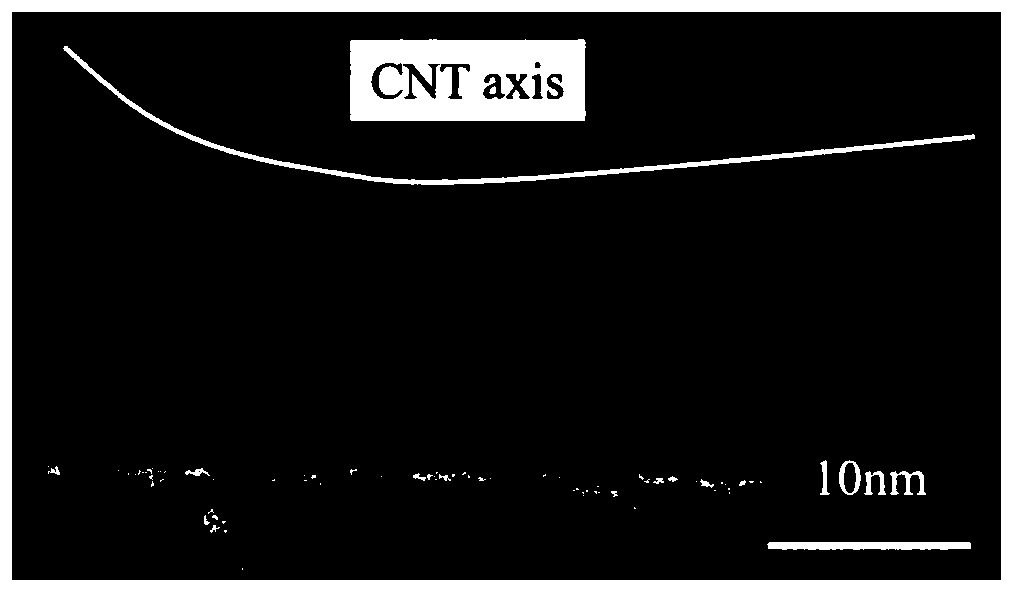

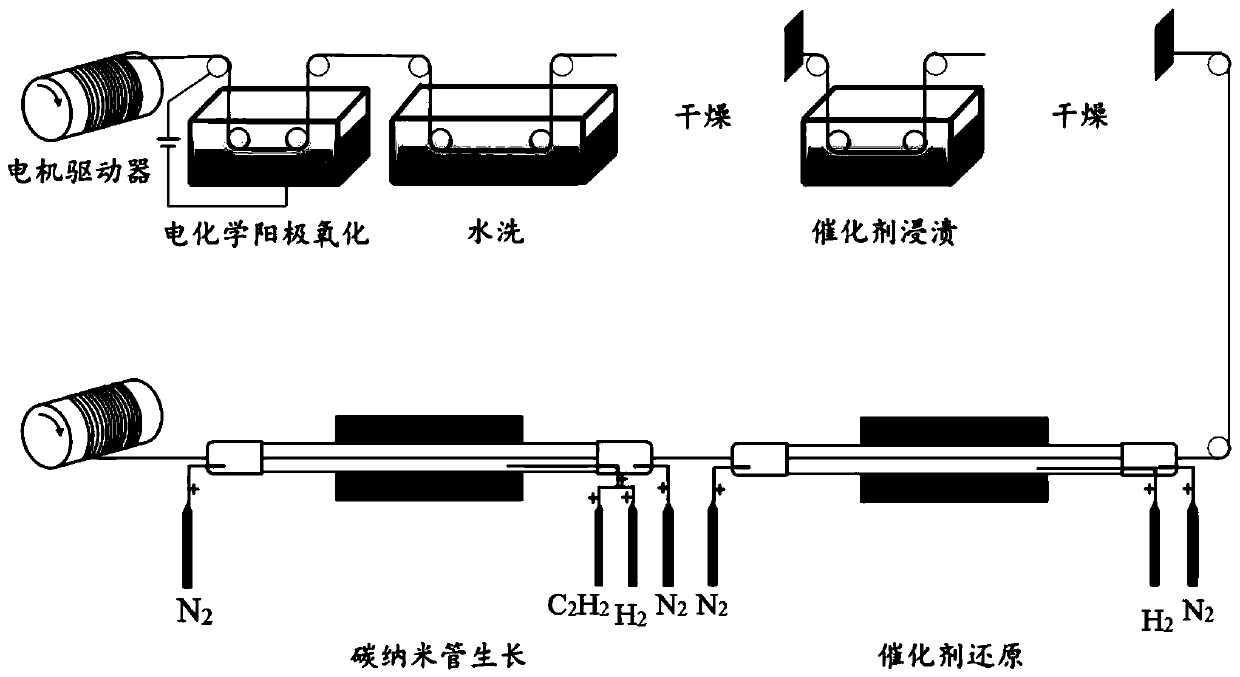

[0054] Step 1: Electrochemically modify the carbon fiber to promote the uniform coating of the catalyst precursor, the electrochemical anodization time is 40s, and the current intensity is 0.2A;

[0055] Step 2: Immerse the carbon fiber in 0.03mol / L catalyst precursor (Co(NO 3 ) 2 ) for 5 minutes;

[0056] Step 3: Pull the carbon fiber obtained in step 2 into the tube furnace, 2 Atmosphere, using H 2 Reducing the catalyst precursor coating to metal nanoparticles, the reduction temperature is 450°C, and the reduction time is 10 minutes;

[0057] Step 4: continue to extend the carbon fiber sample obtained in step 3 into the chemical vapor deposition furnace, and pass H 2 and C 2 h 2 The mixed gas was used to synthesize carbon nanotubes at 650 °C, and finally the samples were collected by an electric winder.

[0058] The samples were tested for fiber tensile strength and interfacial shear strength, and the measured tensile strength of the carbon fiber was 3.80GPa, and the ...

Embodiment 2

[0060] Step 1: Electrochemically modify the carbon fiber to promote the uniform coating of the catalyst precursor, the electrochemical anodization time is 60s, and the current intensity is 0.2A;

[0061] Step 2: Immerse the carbon fiber in 0.03mol / L catalyst precursor (Co(NO 3 ) 2 ) for 10 minutes;

[0062] Step 3: Pull the carbon fiber obtained in step 2 into the tube furnace, 2 Atmosphere, using H 2 Reducing the catalyst precursor coating to metal nanoparticles, the reduction temperature is 450°C, and the reduction time is 10 minutes;

[0063] Step 4: continue to extend the carbon fiber sample obtained in step 3 into the chemical vapor deposition furnace, and pass H 2 and C 2 h 2 The mixed gas was used to synthesize carbon nanotubes at 650 °C, and finally the samples were collected by an electric winder.

[0064] The samples were tested for fiber tensile strength and interfacial shear strength, and the measured tensile strength of the carbon fiber was 3.82GPa, and the...

Embodiment 3

[0066] Step 1: Electrochemically modify the carbon fiber to promote the uniform coating of the catalyst precursor, the electrochemical anodization time is 60s, and the current intensity is 0.2A;

[0067] Step 2: Immerse the carbon fiber in 0.04mol / L catalyst precursor (Co(NO 3 ) 2 ) for 15 minutes;

[0068] Step 3: Pull the carbon fiber obtained in step 2 into the tube furnace, 2 Atmosphere, using H 2 Reducing the catalyst precursor coating to metal nanoparticles, the reduction temperature is 450°C, and the reduction time is 10 minutes;

[0069] Step 4: continue to extend the carbon fiber sample obtained in step 3 into the chemical vapor deposition furnace, and pass H 2 and C 2 h 2 The mixed gas was used to synthesize carbon nanotubes at 650 °C, and finally the samples were collected by an electric winder.

[0070] The samples were tested for fiber tensile strength and interfacial shear strength, and the measured tensile strength of the carbon fiber was 3.88GPa, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Interfacial shear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com